The gas pedal also suspended, the drive of the throttle valve of the carburetor is the standard cable budenovskoy shell.

Arm transmission mounted on the right side of the driver’s seat, on the upper beam of the frame. With the lever on the shaft of the shift motor it connects two rigid rods via an intermediate shaft with a pair of levers.

Engine “Mustang” is triggered by a handle located under the right hand of the driver, under the instrument panel. The drive shaft of the starting mechanism of the motor with nylon rope, two or three turns which are wound on a drum supported in place of the regular lever of a releaser.

The instrument panel is an instrument cluster from the base of the motorcycle. Staff and electrical system; the only difference is that instead of one of the headlights on the ‘ Stang has two.

And now about the main thing, without which “Mustang 350” would not be two-wheeled car— the body. Matusadona, as mentioned above, he closed with a hinged cap-lamp. Such a body can be done in almost any material: plywood and hardboard, roofing steel and duralumin, as well as of fiberglass with the use of polyester or epoxy resin. The most interesting method. Moreover, if the car is made in a single copy, it makes sense to use technology vikaki on the boob.

First of all, this requires a master model or, as it is not too respectfully referred to as specialists, is an asshole. It is a sheathed by a hardboard frame and stringer construction, the surface of which is low in relation to the future surface of the body 10…15 mm. the Final finishing of the body — with the help of clay, netgateway putty or plaster. As a rule, first working on the right (or left) half of the body, and then removing it several plywood templates, go to the symmetrical other half. When you create a fool it is necessary to provide recesses forming at Vileika stiffeners. After final processing of the dummy surface is covered with wax mastic parquet and polished.

The body shell wikiepedia in a dry, well-ventilated room or in warm dry weather on the street. For the first layers it is recommended to use stekloprokata for fine thin fiberglass satin weave. Deepening to increase the stiffness of the paste over the first couple of layers of fiberglass and filled with foam. Last processed flush with the surface of the shell, after which Vileika body continues.

For reasons purely technological body is divided in its lower part, a lamp, rear and front fairings. Accordingly, these elements are formed on the same dummy in several stages: first the lower part — at the same time through the docking housing, and the lantern fixed slats, and then, after removing the slats, front and rear fairings, and last but not least — lantern.

After the formation of the shell thickness 3…4 mm Vileika ends, and the next day the blank body can be removed from the boob. Keep in mind that often this can be done, only breaking the fool, therefore, in its manufacture, consider the areas that will be easy to remove without any risk to damage the fiberglass shell.

The final development of the case — after installing it on the frame. By the way, the docking device needs to be quick — it will greatly facilitate maintenance and repair of aggregates of autoroller.

In conclusion, the shell is carefully puttied and vyshkurivaetsya, it cut the necessary holes and Windows are fitted and installed folding lantern, installed Windows. This is followed by painting in several layers with intermediate Vykurovanie and grinding.

The side Windows are cut from Plexiglas thickness 3…4 mm. Windshield (tempered or laminated) fixed with epoxy and strips of fiberglass.

The inner surface of the cabin are covered with foam, fiberglass and in the last stage is decorated with artificial leather (suitable and suitable for the texture of the fabric).

Cabin floor is made of plywood with a thickness of 6-8 mm, treated with hot linseed oil. Plywood wikiepedia and Nisha under the front wheel. Seats driver and passenger — made of plywood, foam rubber and artificial leather. Please note that the back of the front seat is mounted on a single rack, which can be tipped forward, thereby facilitating embarkation and disembarkation of passenger.

Manage the “Mustang” is as easy as a normal bike. The use of the produced chassis of difficulty, as a rule, is not already in an hour or two when you slow down below acceptable level you will transfer the chassis to the position “released” as relaxed as the driver lowers his foot, holding the stopped bike.

Igor MNEVNIKI, design engineer

Recommend to read

CUSHIONS ON THE BATH

CUSHIONS ON THE BATH

it is Known that the Laundry is passed through the squeegee rollers of the washing machine, less tears and dries faster. For small hand-washings - and they are enough, if the house is a... BEE DINING ROOM

BEE DINING ROOM

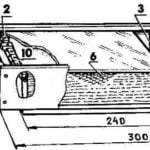

Designed and manufactured by me bee feeder resembles a school pencil case. The side and rear walls made of planks with cross section mm 60x10 each of them with the 4-mm deviation from the...