To date, the most popular are metal fabrication services custom service companies, whose activity is directly connected with the processing of metals.

To date, the most popular are metal fabrication services custom service companies, whose activity is directly connected with the processing of metals.

The process of making parts of almost all businesses is one scenario and it starts always the same: the customer provides the contractor with a sketch of the product. This happens either in person or via the Internet. If the first option everything is clear, the second may raise questions that should be clarified. Drawing of a detail in electronic form sent by e-mail of the company for Metalworking, which experts define manufacturability and check its compliance with normative-technical documents.

The contractor can produce the item exactly according to the provided sketch, despite its deviation from certain standards and norms. In this case, we only check the manufacturability of the product, or rather, the potential production capacity of the contractor.

Metal fabrication services custom require constant communication between the provider and the customer, as all matters connected with the manufacture of parts, must be agreed. Therefore, all the smallest changes in the design documentation, should be notified to the customer.

After discussing all the organizational aspects of the job, process engineer, which shall develop the technological route of manufacture.

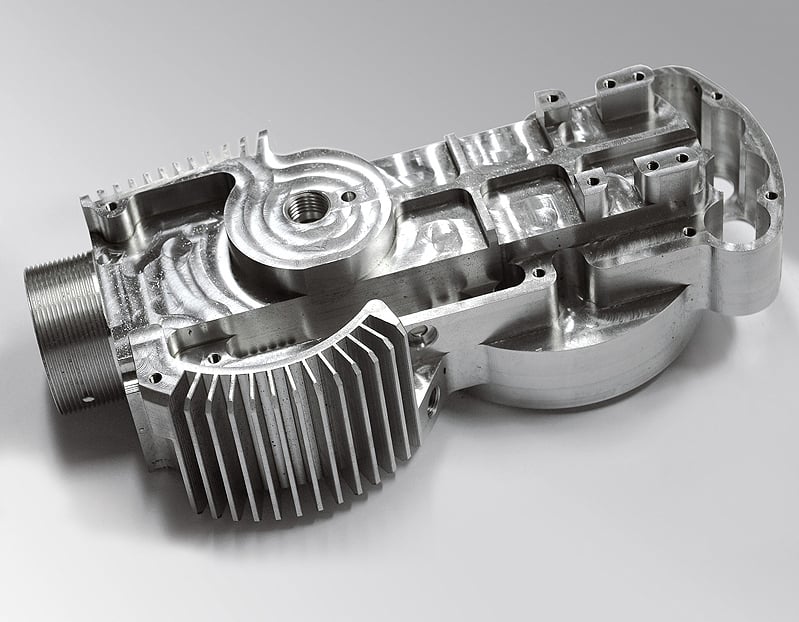

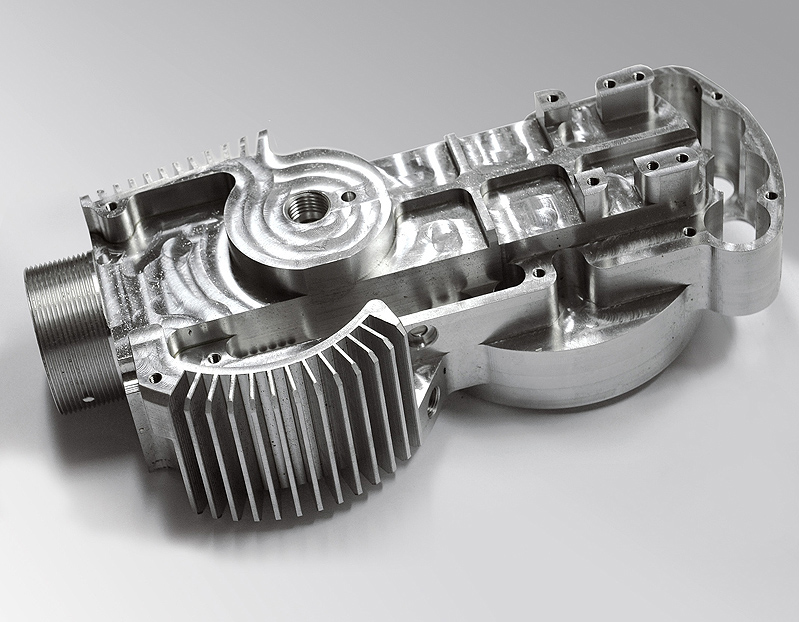

The main stages in the manufacture of bespoke parts

- The choice of blanks and the calculation of its geometrical parameters at this stage are determined with the desired types of machining and allowances are calculated;

- Development of programs for the equipment characterized by the presence of numerical control – from the correctness of its compilation depends directly on the result;

- Selection of cutting tools has a direct impact on the speed of machining and surface quality;

- Introduction to the process of all devices and tools that may be required when performing any particular operation. This item needs to be agreed with the customer, since it entails additional costs;

- After elaboration of design documentation and preparation of strip map, these documents are transferred to the production area, where, in fact, the workers begin to manufacture the parts.

Often, customers come to the enterprise, specializing in the Metalworking, already prepared drawings. But sometimes, due to certain circumstances, the thumbnail is missing. In this situation it can provide an exact copy of the detail required, which specialists will perform a working drawing on the basis of which will be performed all the works listed above.

Company-provided metal fabrication services to the order must be accompanied by a guarantee of quality. In most cases, controlled every stage of production parts, although there are unpleasant surprises, so better safe than sorry.

When selecting a contractor, it is recommended to pay attention to the technology used in the processing of ferrous and nonferrous metals. Today there are many advanced methods, allowing to obtain the desired item is much faster and cheaper than more traditional ways.

S. ROMANOV