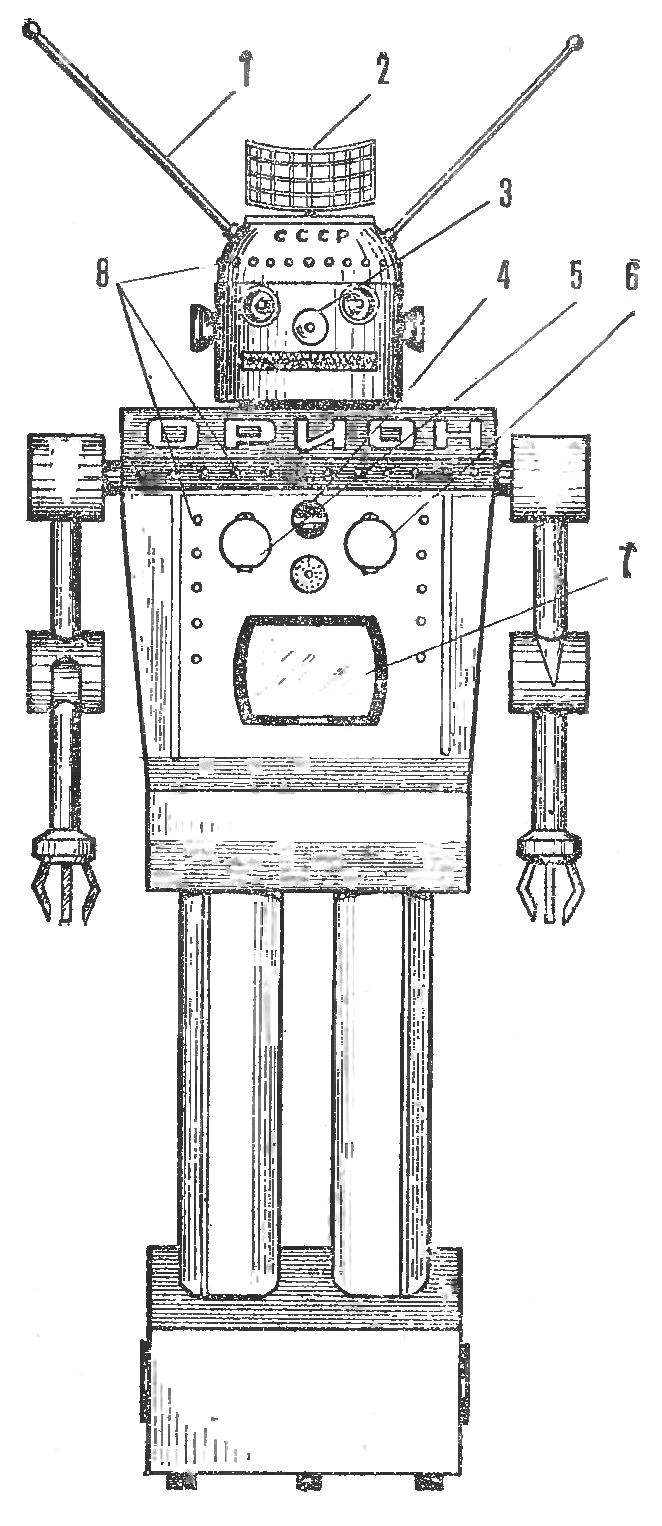

“Head” is mounted directly on the motor shaft DSDR having 2 rpm. To limit the stroke of the engines are mounted the microswitches MP-1.

The radar antenna rotates in one direction only. It is also mounted on the motor shaft DSDR.

The preamplifier normal resistive stage transistor V1. Adjustable frequency-dependent feedback (R8С5) allows to set the selected gain of the entire amplifier with the parameters spread of the circuit elements.

For temperature stabilization of mode of the output stage thermistor R7 MMT-1 to the inverter cascade.

The scheme provided additional measures to improve the regime of stabilization of cascades using diodes V5 and V6.

BLOCK “RADIATION” consists of two parts — electronic and Executive. His function is to detect dangerous radiation for astronauts and to notify on it.

The sensitive element of the device is a discharge sensor (counter), CTC-5. Its action is based on gas ionization under the action of nuclear radiation. At sufficiently high field strength to counter the avalanche discharge, enhancing many times the ionization effect. High voltage for the power meter produces a blocking oscillator, assembled ka transistor V1 (Fig. 9). Transformer T1 is wound on the core of the plates Ш12, the thickness of the package is 12 mm; the primary winding has 146 turns with the withdrawal of 26 turns of wire PEL of 0.2, the secondary winding of 3,000 turns of PEL of 0.08.

The pulses of the blocking oscillator, rectified by the diodes V2—V4, capacitor C3 charged to a voltage of 300-500 V.

As soon as the counter enters the radiation area, occurs level. The voltage pulses from the resistor R2 through the capacitor C4 comes in a two-stage amplifier assembled on the transistor V5, V6. With the collector load of the second cascade of positive voltage pulses received through the capacitor C6 of the rectifier, made according to the voltage doubling circuit diode V7, V8. This rectifier charges the capacitor C8. The voltage produced at the resistor R10 in the discharge of C8, one gets with the reference voltage on the capacitor C7, whose value is set by potentiometer R10. The total voltage applied to the base of transistor V9 is included with the trigger device V9, V10. Here’s how it works.

When there’s no radiation, the potential on the basis only depends on the position of the engine R10. It is set so that using the V9 was the current size of 4-5 mA. Thus the transistor V10 is closed and the current in the relay coil K1 is not.

Radiation causes the appearance of voltage on the capacitor C8, which, flowing into the reference voltage, causing a decrease in current through the transistor V9. At some maximum allowable level of radiation semiconductor triode V10 is opened, triggering turnips K1, the contact plate which include a red lamp and audible tone.

The UNIT “focus ON LIGHT” causes the robot to move exactly to the light. The perceiving elements are two photoresistor B1 and B2 (Fig. 11). When they are not lighted, the transistors V1 and V2 are closed and relay K1 and K2 (RES-15, passport PC4.591.004) is de-energized. Under illumination of the photoresistors current through a semiconductor triode increases, triggering turnips K1 and K2. Their contacts include every motor “legs”, and the robot starts moving forward. If the beam hits only one photoresistor, the robot will povorachivaetsya — to look for the light source.

Fig. 10. The scheme of the power supply.

Fig. 11. “Focus on light”.

Fig. 12. The scheme of connection of electric motors and blocks:

M1, M2 — motors “feet”, M3 — the engine of the locator M4 — turn “head”, M5-the engine of the “brush”, M6 — engine “elbow”, M7 engine, computer, M8, M9 — the engines of recovery “owner”: 1 — unit “focus on light”, 2 — power supply 3 — alarm radiation.

Resistors R1 and R4 are used to set the initial current of the transistors, with the help of variable resistors R2 and RZ is governed by the sensitivity of the automatic device.

The matching and output transformers ULF communication applied from tape recorder “Vesna-3”. The power transformer TS-160 from TVs UNT-47/59 used in the power supply, the secondary winding is converted to voltage 220, 18, 12, 9, and 6 contain respectively the coil 824 of PEV 0,4; 62, 41, 31 round sew 1,3 and 21 round PEV of 1.7 (Fig. 10}.

Both remotes are linked with the robot by wire MGTF 0,12 via connectors SHR-24.

The scheme of connection of electric motors and blocks of the robot is shown in figure 12.

After the structure is assembled, the surface of the robot is covered with napolcom in which a mixed aluminum powder in the ratio 20:1 used for color in silver. The case of Kibera gets soft steel color with a greenish tinge,

V. SPARROW, Sumy

Perhaps in the near future when the new spacecraft will go to the moon, Venus or Mars in the Arsenal of the astronauts will be robots who will come first to the planet’s surface to conduct scientific researches, to perform simple welding and Assembly work. So I decided the guys from the mug space simulation Sumy city station of young technicians and build a similar robot with their hands.

Perhaps in the near future when the new spacecraft will go to the moon, Venus or Mars in the Arsenal of the astronauts will be robots who will come first to the planet’s surface to conduct scientific researches, to perform simple welding and Assembly work. So I decided the guys from the mug space simulation Sumy city station of young technicians and build a similar robot with their hands.