The stone knife, and a bone needle — the ancestors of all the tools ever worked with people — it took in order to divide, reduce and, conversely, to sew, to connect the ancient simple materials provided by nature: meat, fur, skin. And as people turned to new, more advanced materials, taught myself to create them. changed and became more perfect tool. And if Dereza was enough of an axe, Pipa and hammer, the metal took a drill, a cutter in the subsequent welding, glass, diamond glass cutter, and such modern materials as concrete, superhard alloys and materials or, for example, setupy, showed a completely new tool requirements.

The stone knife, and a bone needle — the ancestors of all the tools ever worked with people — it took in order to divide, reduce and, conversely, to sew, to connect the ancient simple materials provided by nature: meat, fur, skin. And as people turned to new, more advanced materials, taught myself to create them. changed and became more perfect tool. And if Dereza was enough of an axe, Pipa and hammer, the metal took a drill, a cutter in the subsequent welding, glass, diamond glass cutter, and such modern materials as concrete, superhard alloys and materials or, for example, setupy, showed a completely new tool requirements.

Not coincidentally, in our days, appeared until recently seemed fantastic, and today found a very different use of a fundamentally new tools: laser and

plasma. Only yesterday the former known only to the laboratories of scientists, they are now embedded in the national economy, finding the wide application in various industries.

Amazing features of this “instrument of the century”, as the plasma is clearly demonstrated in the recent Exhibition of achievements of national economy of the USSR. Here in one of the halls of the pavilion “Atomic energy” were gathered together installation, open up new possibilities in improving productivity, most time-consuming operations, a significant increase in product quality.

All presented in the pavilion of the installation, despite external dissimilarity, have in common one thing — their work on the plasmatron. And although it is in each of the units has its own peculiarities, nevertheless the principle of operation and the purpose of this site is the same everywhere: each of them is pathoanatomical, that is, it is here that created the unusually searing tongue of fire, to which none can resist material. As for the birth it is only necessary electricity, gas or ordinary air.

The plasma head is a small chamber formed by the hollow electrode within which is placed a second, rod. Between them using high-frequency discharge excited by an electric arc, familiar to all school experiences. However, the arc is buried between the electrodes, not the tool: the eye like a dagger in her legs. To retrieve it is called incoming pressurized air. His jet is not just hollow out arc out to and interacts with it: the air is ionized, born saragossie flame plasma, the temperature of which may reach from one thousand to 20 thousand degrees. Before this fire the cutter will not stand any one material.

The plasma head, or plasmatron. has great advantages over all existing burners: gas, thermosetting, and other. And the list of materials that can be processed by the plasma, are virtually limitless.

First and foremost is, of course, metal. Plasma is much superior to the best gas-cutting apparatus, first and foremost because it allows you to “cut out” not just any grade of steel and alloys, and cast iron, aluminum, copper and other nonferrous metals. The cutting process is carried out so easily and cleanly that it almost does not require further processing of the edges, what would the thickness of a metal. And the burning of the molten metal inevitably formed at the incision solidifying spikes and bumpers, the so — called Gart, the removal of which is quite time-consuming work, which reduces productivity.

The plasma torch was even possible to cut non-ferrous metals and stainless steel.

About the indisputable superiority of plasma cutting is clearly evidenced by the interest shown to her by experts in many companies, not only in porridge country but also abroad. The new technology is already implemented and successfully applied ka Dnepropetrovsk plant of metal structures imeni Babushkina and ka crane of the Moscow factory “the Northerner”, in Kommunarsk metallurgical in Voroshilovgrad region, in Kiev, Leningrad, Sverdlovsk, Vladimir. A keen interest to the representatives of the enterprises of the socialist countries, firms in Japan, France and other foreign countries.

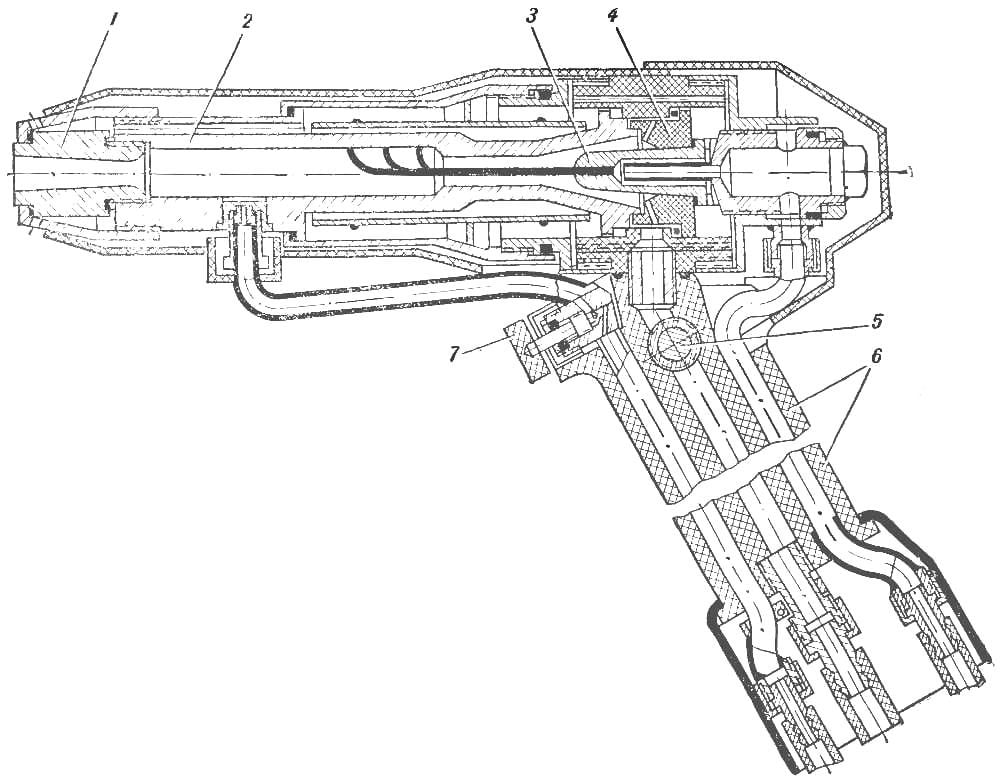

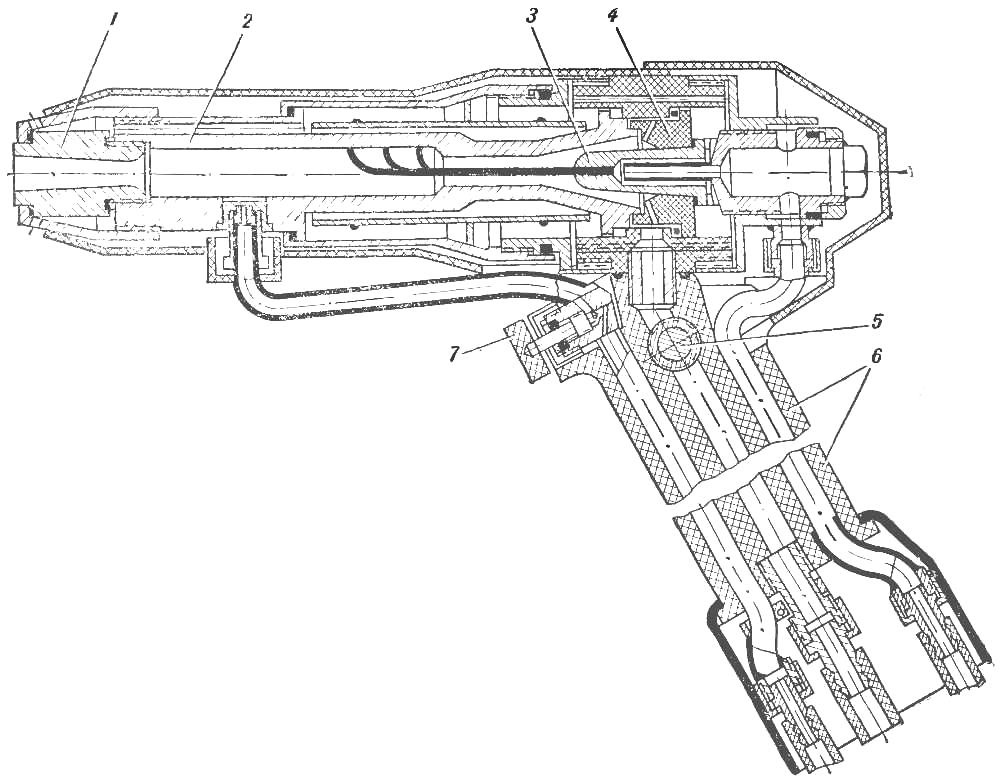

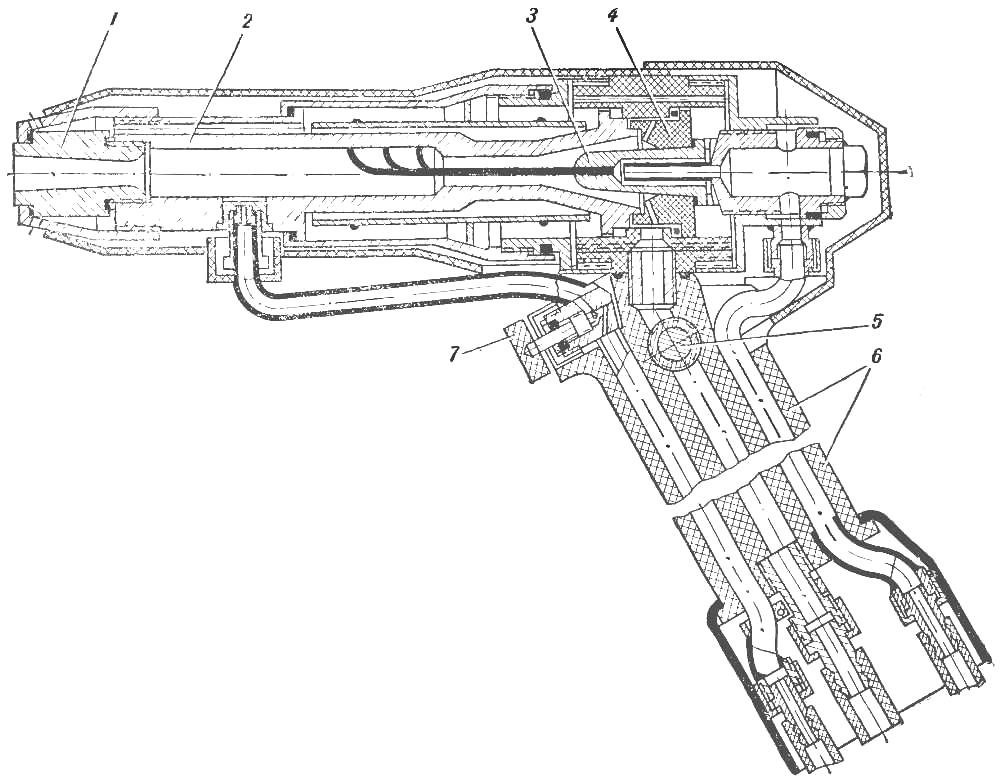

Plasma gun PG-30 for the processing of building stone:

1 — nozzle, 2 — off hollow electrode, 3 — rod electrode, 4 — insulator-swirler, 5, 7 — valves, 6 — insulating handle.

Working principle: the electric arc is ignited by high frequency breakdown between the electrodes 2 and 3 and air swirl in the sky, stabilizing in the discharge channel of the outlet electrode. Working components (compressed air, water and fuel) and electricity supplied to the fittings of the insulating handle 6. Regulating the flow of air and fuel is effected by the valves 5 and 7. The resource most wear parts 3 is over 30 hours. continuous operation.

It is clear therefore, special attention used ka ENEA presented here a new plasma system for cutting metal, and, in particular, the Assembly for plasma-arc cutting ITEP-20M. developed by the Institute of theoretical and experimental physics. It is used p workshop conditions and on industrial sites for the cutting of ferrous and nonferrous metals with thickness from 6 to 22 cm He is versatile, high performance, excellent cutting quality and increased service life. And the installation of the “Kiev”, created at the Institute Vniiavtogenmash intended for a figure of air-plasma cutting of metals and alloys with contour details for steel templates. How enhances the productivity of the new technology, it can be seen from this comparison. Earlier cutting machines to ensure the implementation of the plan, had to work in two shifts. Now a smaller number of machines employed only in one shift and provides program.

However, the plasma torch is today, not only metallurgists and machine builders. Unprecedented opportunities it provides chemists, builders, researchers, professionals from various branches of industry and science. At the Institute of metallurgy Baikov behalf of the Academy of Sciences of the USSR created the installation for growing single crystals of refractory metals — tungsten, molybdenum, their alloys, which are promising materials of modern technology. In such a setting, called “Monocrystal-PD-2”, plasma-arc melting cabapino record was grown monocrystalline ingots of tungsten thick with good stick and weighing more than 19 kg. the Production of such very pure and homogeneous metals with plasma already developed at the Uzbek plant tugoplavkih and heat-resistant metals.

Plazmatron equips scientists a powerful and subtle tool to study the behavior of gases and different substances and materials at temperatures reaching several thousand degrees, which is of great interest for the development of modern technology. Such installations were presented on a exhibition by the Institute for high temperatures of the USSR Academy of Sciences, Tomsk, and Kazakh Polytechnic institutions.

Kazakh scientists have created a number of plasmatrons for production purposes. Of great interest is developed here plasma drill model PB-40, allowing much more productive and better to drill holes in the hardest rocks, to penetrate cracks and surface processing in the refractory, concrete, granite blocks and concrete.

Higher temperature and velocity of plasma jets (in comparison with existing partiesreceive burners on chemical fuel) provide high performance of the Kazakh plasmopara. Use it on strong ore rocks of Krivoi Rog for drilling turned out to be one and a half times more effective than the use of thermosetting burners, and allowed to achieve a high drilling speed of 25 m per hour.

Equally effective and the other two of the plasma torch from Kazakhstan — plasma expander blast hole model RPS-150, allowing the internal cavity in the bore to lay explosives, and plasma torch PG-30 for the processing of building stone.

With the latter you can do all kinds of holes in such modern construction materials as reinforced concrete, granite, metals. The plasma pistol allows you to and decorative surface treatment of buildings for architectural chains. This burner has passed industrial tests at the Alma-ATA plant in stone processing, showing high productivity and economic efficiency — about 3 thousand roubles a year on each instrument. All of these plasmatrons developed in the Department of plasma processes laboratory of new methods of destruction of rocks and concrete of the Kazakh Polytechnic Institute, headed by Professor A. V. Bolotov.

There is a Department in the Institute of electric Paton of the Academy of Kaun Ukrainian SSR, which also created a series of plasmatrons, are interested in many enterprises in our country and abroad. Are orders from Siberia, the Urals, the Far East, Belarus.

Here working on improvement of apparatus for the airily-plasma cutting and widening the scope of its application in various industries — shipbuilding, metallurgy, mechanical engineering. Creates new sources of power — on of the silicon controlled valves-thyristors. Development of new designs of plasmatrons. One of the main tasks of the laboratory is to expand the technological capabilities of the equipment to cut metals of greater thickness and with greater speed.

As you can see, there is a broad search for new solutions to the plasma-arc processing of advanced materials. The best developments will be presented at the exhibition. Scientific and technical conference held in the USSR national economy on the basis of the exposure plasma technology, outlined the date for the new exhibition “Plasmatron-75”. It will take place in 1975 — the final year of the five-year plan and will reflect new advances in the creation and application of plasma technology — tool of the twentieth century.