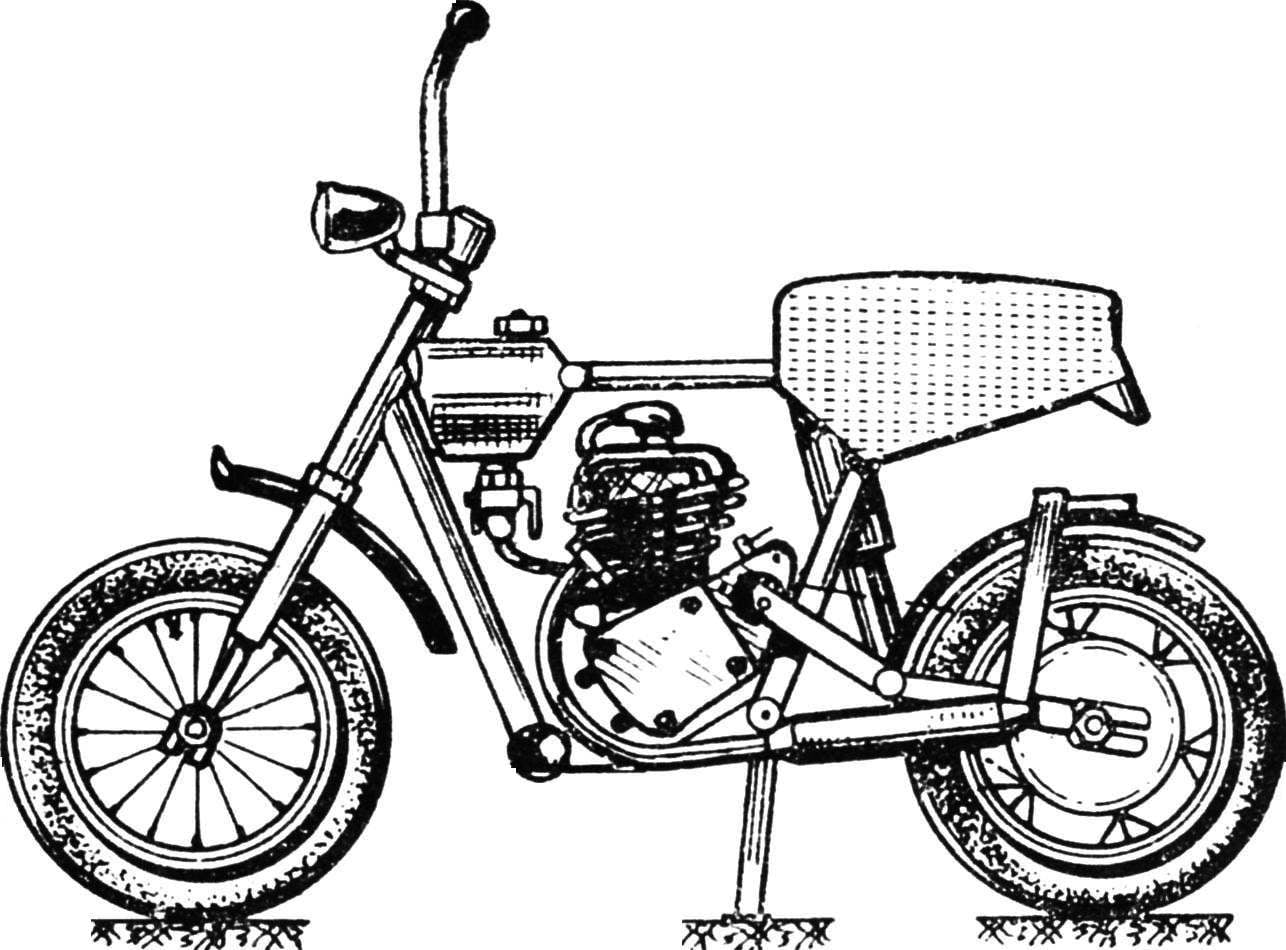

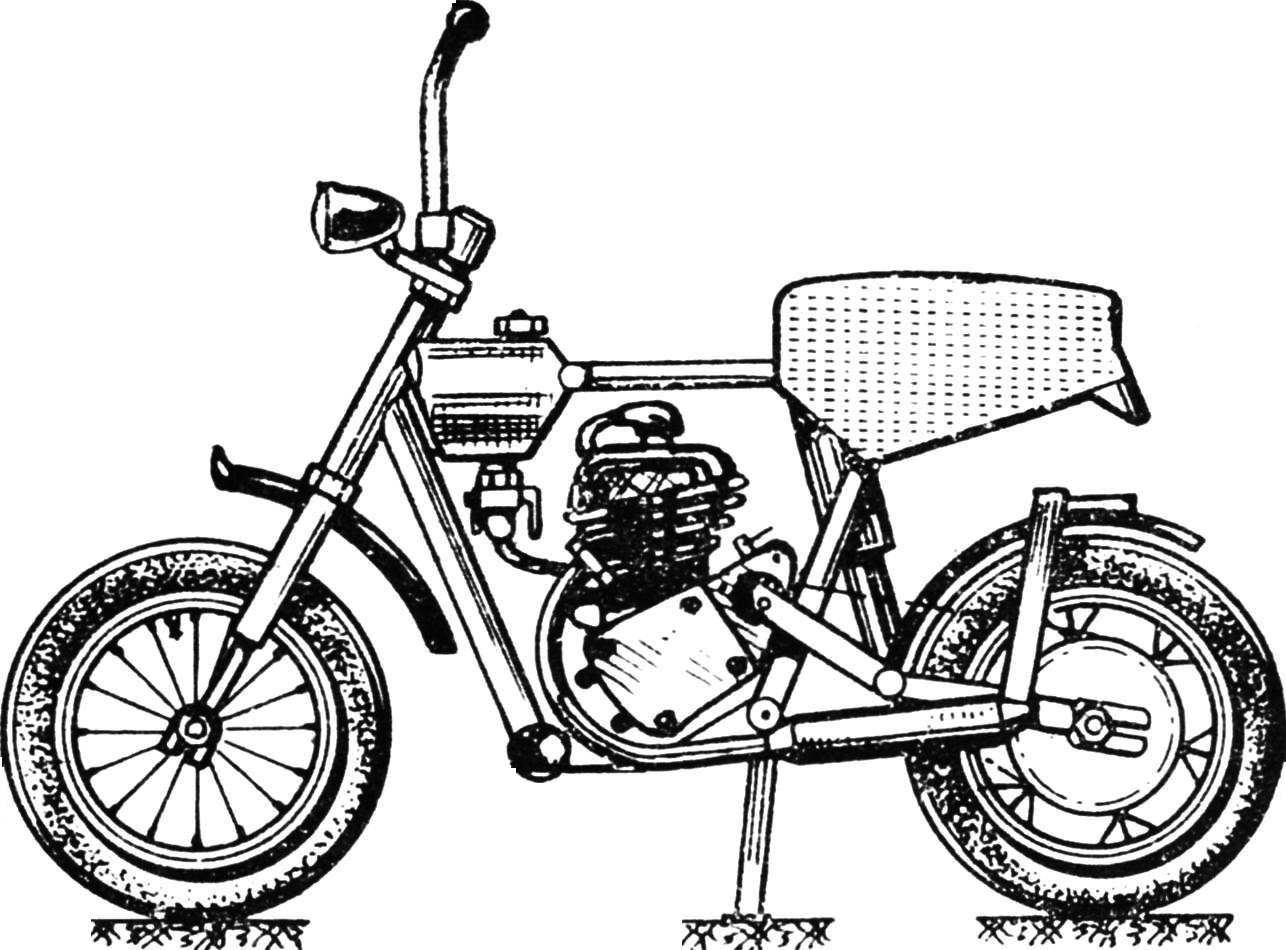

increasingly, in an editorial post meet the voluminous packages of drawings and descriptions of improvised microvesicles. Their fundamental difference from development of previous years – a successful combination in the construction standard and improvised units. The second important detail – the sharp improvement in appearance, a bold design decision. On these pages we present to the readers micromatics, which fully apply the characteristics set forth above.

increasingly, in an editorial post meet the voluminous packages of drawings and descriptions of improvised microvesicles. Their fundamental difference from development of previous years – a successful combination in the construction standard and improvised units. The second important detail – the sharp improvement in appearance, a bold design decision. On these pages we present to the readers micromatics, which fully apply the characteristics set forth above.

Designing the layout of microvesicle, I came to the conclusion that the fuel tank can be made an integral part of the power frame. This would reduce the weight of the car and give it a more dynamic shape. Application for oval frame tubes allowed to perform “the Grasshopper” strong enough, easy and, most importantly, small size. When folded the wheel of his dimensions fit into a box the size 195x750x1050 mm, which allows the “grasshopper” easily accommodate in the trunk of a car, in the Elevator during transport to room and even under the bed.