Do you know what’s the most annoying thing about a summer shower at the cottage or in a private house? Constantly running to check if there’s water in the tank. It feels like you just filled it — and after a couple of washes, the level is already at zero. And every time it’s the same story: you go, turn on the tap, wait for it to fill, then forget to turn it off… Basically, an endless hassle. I decided to put an end to this and came up with an automation system that monitors the water level and fills the tank when needed. It works based on a simple float valve, like in old toilet tanks. It’s simple: water is present — the valve is closed, water decreases — the valve opens and starts the flow. And no extra effort on my part. Now I don’t even think about whether there’s water — it’s always there. Plus, this method saves time, nerves, and resources. Since I live in a house with a septic system, excess water in the sewer is only harmful to me. That’s why in summer and until late autumn I shower here, and the system takes care of everything by itself.

How my automation works and what I built it from

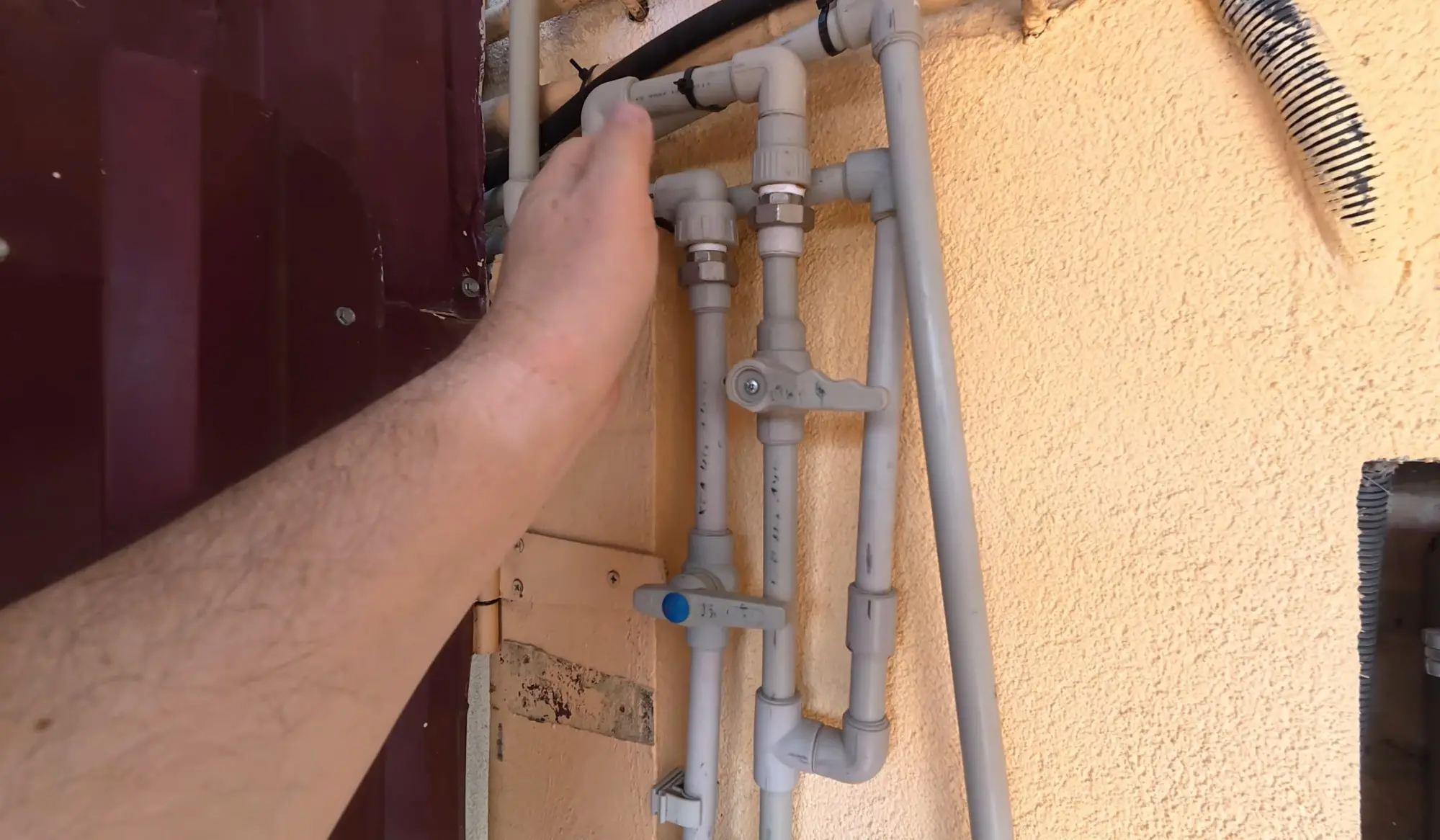

Honestly, there’s no rocket science here. It’s just “made from what I had on hand.” The base is a regular summer shower tank and a side-mounted float valve. Why side-mounted? Because it’s easier to connect hoses and service the system this way. For the pipeline, I used gas hoses left over after reinstalling the stove. They’re flexible, durable, and, most importantly, free — why buy new ones if you already have suitable ones at home? For drilling the hole for the valve, a step drill bit worked perfectly — it makes a neat hole of the right diameter without extra fuss. I also used plastic pipes, but only where it made sense, for example, for temporary water heating in the sun. Why temporary? Because the sun destroys plastic, and after a few years, it starts to crumble. Mine has lasted for more than five years, but for the main parts, I still use hoses, which are easier to remove and store for the winter.

Why the system is detachable and how I use it by season

I designed the shower so that it wouldn’t stay assembled in winter. The water in the pipes would freeze, everything would burst, and in spring I’d have to redo it all. That’s why the design is fully detachable. The connections are made with “union fittings” — these are quick-release couplings that let you disconnect a hose or remove a part in two moves. In winter, I simply shut off the water, disconnect the hoses, and store them in the shed. In spring, everything is reassembled in about an hour, and it’s ready to use. From the heat of April–May until late autumn, I only shower here. And you know what? It’s not only convenient but also good for the septic system. All the water drains directly into the ground near the shower, not into the sewer, where it would unnecessarily load the system. Plus, there’s a nice bonus — the water in the pipe lying in the sun heats up naturally, so you can enjoy a comfortable shower temperature without extra heating costs.

Small tricks and tweaks

Of course, during the process, I noticed a couple of details. For example, the purchased valve had too short a thread, which made it impossible to add an extra gasket. I had to skip it, but in the end, everything is sealed just fine. Another point was with the shower’s support: the factory design makes the stop rest against the wall in the wrong place. I would have made it longer so that it aligned with the tank’s body. But it still works fine. Another neat feature is the ability to plug the hole in the tank if the automation is no longer needed. This can be easily done with a regular plug, and the tank becomes a regular one again, without extra functions. However, I don’t think I’ll ever want to give it up — it’s just too convenient when the system does everything itself, and all you have to do is enjoy a warm summer shower.

Benefits and impressions of use

When I first turned on this system and saw the valve open by itself to refill the water, I realized: this is true convenience. No more carrying buckets or waiting for the tank to fill. You can just come, turn on the shower — and that’s it. The automation made my country life a little easier, which means I can spend time on something more enjoyable — like sitting in the shade with a cup of tea or working in the garden. Saving time, effort, and even money (since I used materials I already had) — these are the main benefits. And this system is a great example of how you can apply the “do it yourself” principle and get a result no worse than expensive factory solutions. Sometimes the simplest ideas turn out to be the most effective.

If you have a summer shower and are tired of checking the water level manually, try building such automation. You only need one float valve, some hoses, a suitable drill bit, and a couple of hours of time. The result will pleasantly surprise you: the shower is always ready to use, the water is at the right level, and you are free of unnecessary worries. The main thing is not to be afraid to experiment and use what you have on hand. My experience shows that even old gas hoses and a tank can be turned into a convenient and reliable system. And believe me, the satisfaction of seeing everything work on its own is worth the effort.

R. ROMANOV, Kropyvnytskyi, Ukraine