Before proceeding to describe the snowmobile “Turtle-2”, I’ll tell you about the history of its creation. This happened thanks to an all-terrain vehicle — a predecessor with the same name, only with the index “1”.

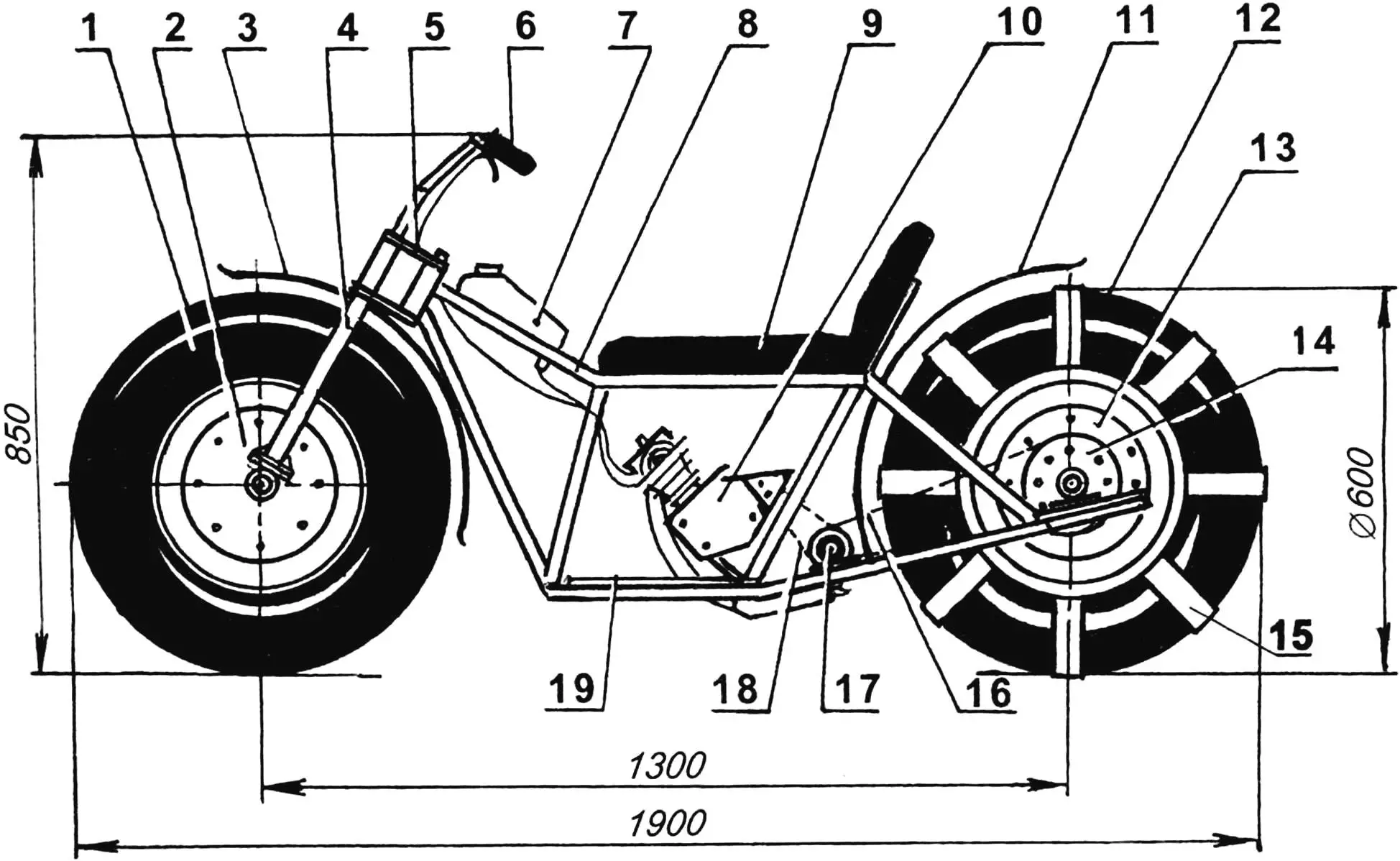

That one was a two-wheeled machine on low-pressure pneumatic tires with a D-8 engine with a power of 1.2 hp.

The pneumatic tires were made from UAZ-452 car inner tubes with a fabric casing. The rear (driving) pneumatic tire had eight transverse banding rings made of rubberized tape 3 mm thick. The wheels of the pneumatic tires (or more commonly — rims) were assembled from two aluminum bathtub basins, fastened to each other at the bottoms using eight M6 bolts.

1 — front (steering) pneumatic tire (inner tube from UAZ-452 car wheel); 2 — front pneumatic tire rim (aluminum bathtub basin, 2 pcs.); 3 — front fender (aluminum sheet s1); 4 — front wheel fork; 5 — bridge; 6 — handlebar with controls; 7 — fuel tank (from moped); 8 — frame; 9 — seat; 10 — D-8 engine with power of 1, 2 hp.; 11 — rear fender; 12 — rear pneumatic tire; 13 — rear pneumatic tire rim; 14 — driven sprocket; 15 — transverse band; 16 — second stage of chain drive; 17 — intermediate shaft; 18 — first stage of chain drive; 19 — floor (plywood s4, 2 pcs.)

The all-terrain vehicle’s frame is duplex. But such a design is caused not so much by ensuring strength, but by the width of the pneumatic tires and their forks, as well as the simplicity of manufacture.

The all-terrain vehicle “Turtle-1” was created in the bicycle-motorcycle club of the local youth technical station (YTS) in one of the winter-spring seasons in the mid-1990s. And already in the summer, the machine went with the guys on a trip along the Tobol River, carrying two boys. At the final point of the trip, all the guys rode on “Turtle-1”, and not just once. And soon all the grass in the valley and on the surrounding hills was flattened by the pneumatic tires — so the guys rested, and the machine worked.

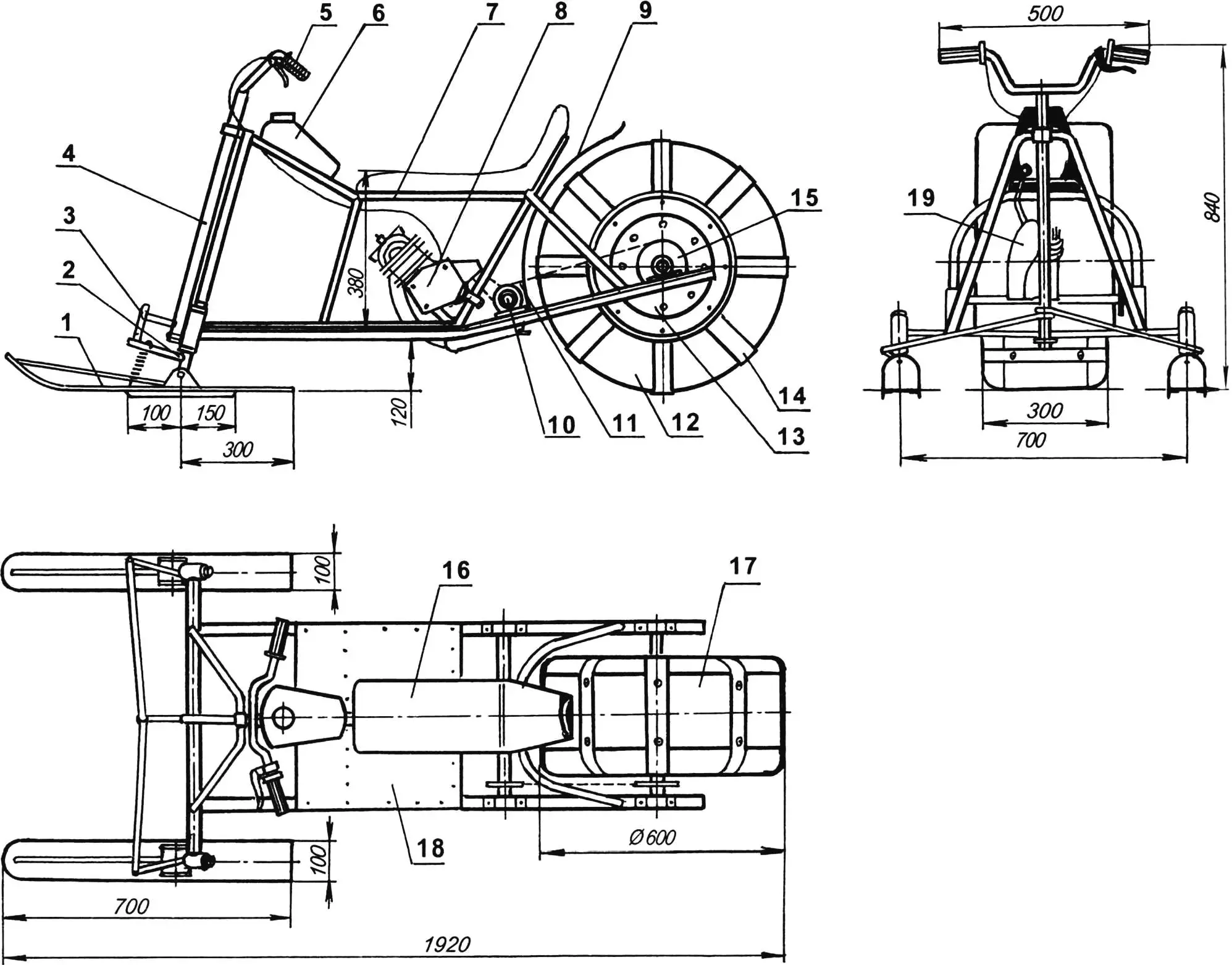

1 — ski (2 pcs.); 2 — steering knuckle (2 pcs.); 3 — steering rod (2 pcs.); 4 — steering shaft; 5 — handlebar; 6 — fuel tank; 7 — frame; 8 — D-8 engine; 9 — pneumatic tire fender (not shown on top view); 10 — intermediate shaft; 11 — chain drive; 12 — pneumatic tire; 13 — wheel rim; 14 — transverse band (conveyor belt s5, 8 pcs.); 15 — drive sprocket; 16 — seat; 17 — longitudinal band (conveyor belt s5); 18 — floor (plywood s6); 19 — forced air cooling system housing for engine

At the beginning of the new school year, in anticipation of winter, the “YTS members” proposed to convert the all-terrain vehicle into a snowmobile and developed reconstruction drawings.

In the autumn period, during the club’s classes, “Turtle-1” changed its appearance, purpose, and index in the name.

The snowmobile is so simple that you just want to call it a snow scooter.

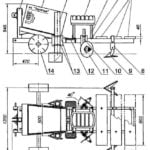

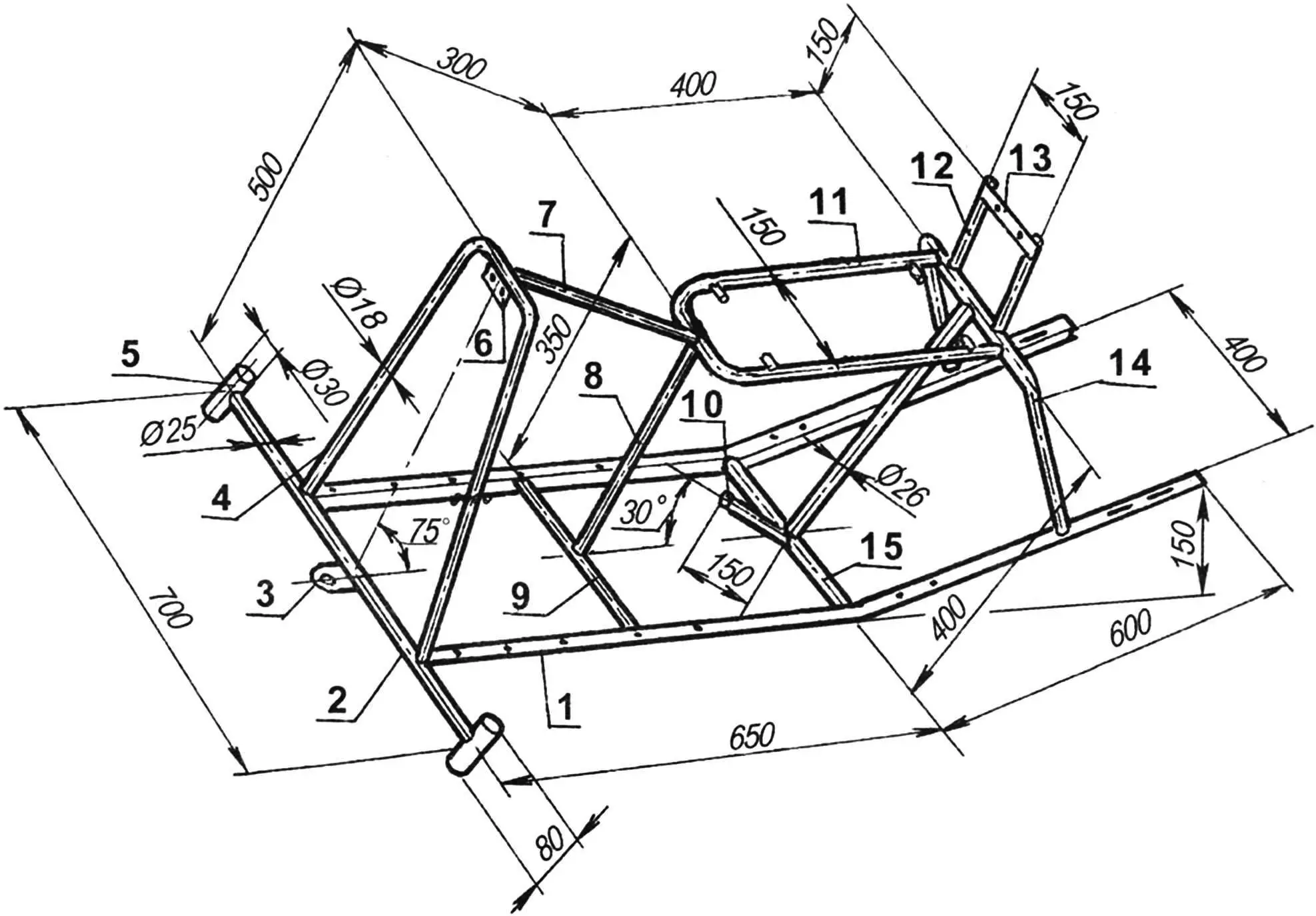

1 — longitudinal member (angle 35×35, 2 pcs.); 2 — crossmember (tube Ø25); 3 — steering shaft support bracket (steel sheet s4); 4 — arched steering post (tube Ø18); 5 — ski steering knuckle bushing (tube Ø30, 2 pcs.); 6 — steering shaft mounting plate (steel sheet s3); 7 — spacer (tube Ø18); 8 — front seat post (tube Ø18); 9 — front sub-post crossmember (tube Ø18); 10 — engine sub-frame bracket (tube Ø18); 11 — seat arc (tube Ø18); 12 — seat back post (tube Ø18, 2 pcs.); 13 — seat back crossmember (steel sheet s2); 14 — pneumatic tire fork (tube Ø18); 15 — rear sub-post crossmember (tube Ø26)

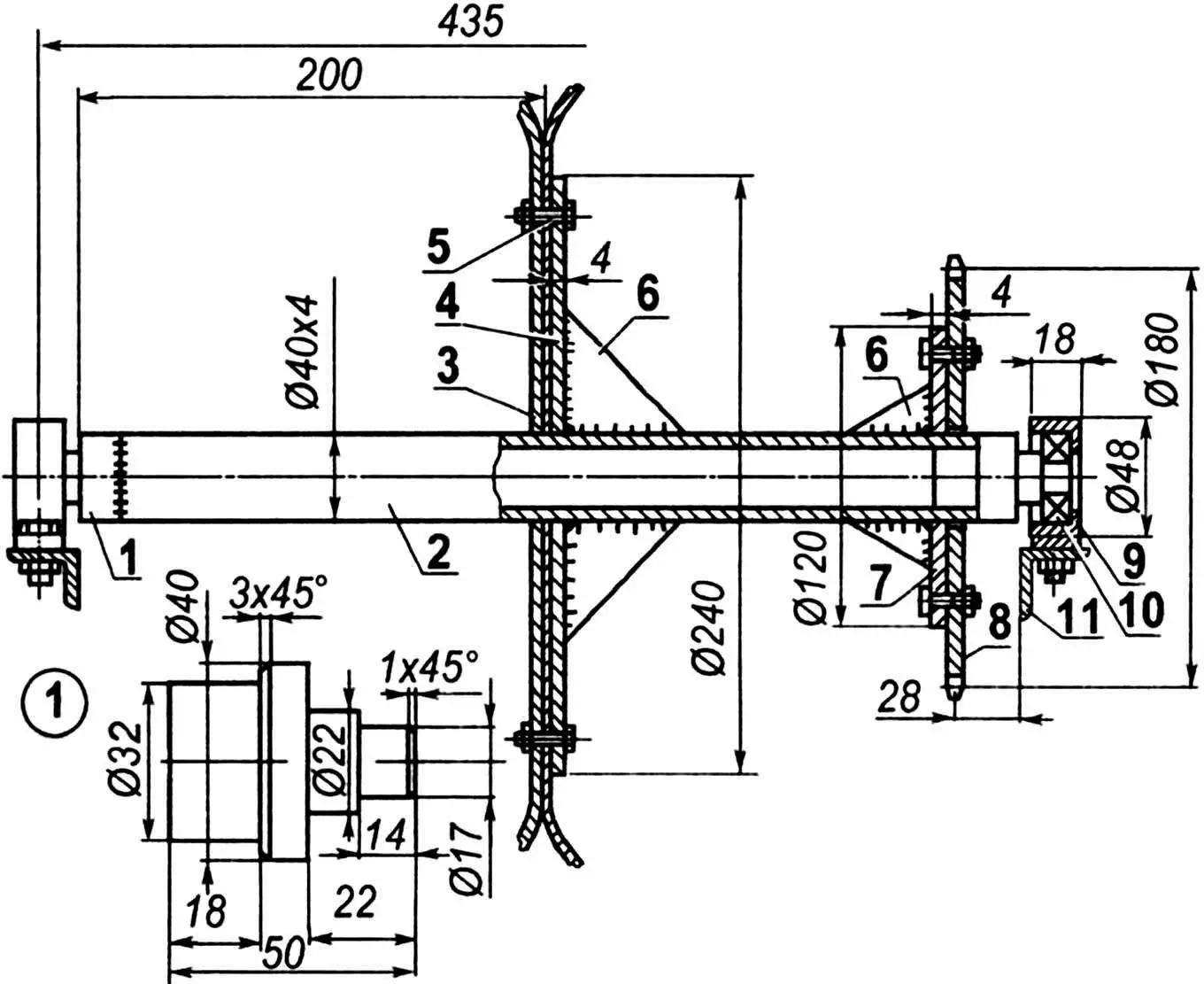

The driving pneumatic tire for the snowmobile was used from the all-terrain vehicle almost without change. Only a longitudinal banding strip was added to it, and the transverse ones were replaced with thicker ones, like the longitudinal one — also from 5-mm conveyor belt with protruding mounting bolts.

1 — steering rods (steel strip 20×3); 2 — steering knuckle lever (tube Ø18); 3 — steering arm (tube Ø18); 4 — steering shaft (tube Ø22); 5 — bushing (capron, 2 pcs.); 6 — steering knuckle axis; 7 — steering shaft mounting bracket to frame plate (steel strip 20×3); 8 — steering shaft mounting plate to frame; 9 — frame arched steering post; 10 — floor-footrest (plywood s6); 11 — steering shaft support platform (steel sheet s3); 12 — spring; 13 — ski nose tie (tube Ø14); 14 — ski-to-steering knuckle connection bracket (steel sheet s3); 15 — ski base (plywood s8); 16 — edge (duralumin angle 20×10, 2 pcs.); 17 — frame longitudinal member; 18 — steering knuckle axis (steel, round 12); 19 — ski sole (duralumin sheet s1); 20 — steering knuckle bushing (tube 16×4)

Only the front part of the frame was modified — here the fork of the steering pneumatic tire gave way to a crossmember with bushings for the steering ski steering knuckles.

To improve operating conditions, the engine was equipped with forced air cooling, driven from the clutch drive gear shaft.

1 — drive shaft; 2 — wheel rim and disc (aluminum basin, 2 pcs.); 3 — tire (inner tube from UAZ-452 car wheel); 4 — tire casing (Tesa fabric); 5 — longitudinal band (conveyor belt b = 300, s5); 6 — transverse band (conveyor belt b = 40, s5, 8 pcs.); 7 — band fastening (bolt M6x20, 24 pcs.); 8 — frame longitudinal member (2 pcs.)

Part of the frame in front of the engine is covered with plywood, forming a foot platform. The seat with backrest is quite long, and a passenger can also fit on it.

By the way, the frame and transmission allow installing a Sh-50 motor and even one from a “Minsk” motorcycle instead of the D-8 engine on the snowmobile.

1 — shaft journal (steel 45, round 40, 2 pcs.); 2 — shaft (tube Ø40×4); 3 — wheel rim; 4 — wheel rim mounting flange; 5 — rim-to-flange fastening (bolt M6, 6 pcs.); 6 — gussets (8 pcs.); 7 — drive sprocket mounting flange; 8 — drive sprocket (from “Minsk” motorcycle); 9 — bearing housing (2 pcs.); 10 — bearing No. 203 (2 pcs.); 11 — frame longitudinal member

The snowmobile’s transmission is chain-driven, two-stage with an intermediate shaft. Chains and sprockets are from different mopeds, but with the same pitch t = 15.875 mm.

For three winters in a row, the snowmobile “Turtle-2” “ate” gasoline and in gratitude gave rides to kids, both “YTS” and others.

1 — large sprocket; 2 — shaft (tube Ø30); 3 — small sprocket; 4 — shaft journal tip (steel, round 30, 2 pcs.); 5 — bearing housing (2 pcs.); 6 — bearing No. 202 (2 pcs.); 7 — frame longitudinal member (2 pcs.)

Unfortunately, the machine itself and its drawings have not been preserved, so the description gives its approximate dimensions. But for craftsmen who want to create a similar snowmobile themselves, I think they are not particularly needed. For them, the layout of the units and the structural diagram of the machine itself are much more important, which are quite clear from the given drawings.

«Modelist-Konstruktor» No. 2’2007, A. MATVEYCHUK