To work with a hacksaw to gently, without much pressure, keeping the cloth perpendicular to the plate, as close to her pen, then the cut will be smooth and without chips on the reverse side.

After cutting all the blanks must be carefully cleaned well sharpened plane or sandpaper.

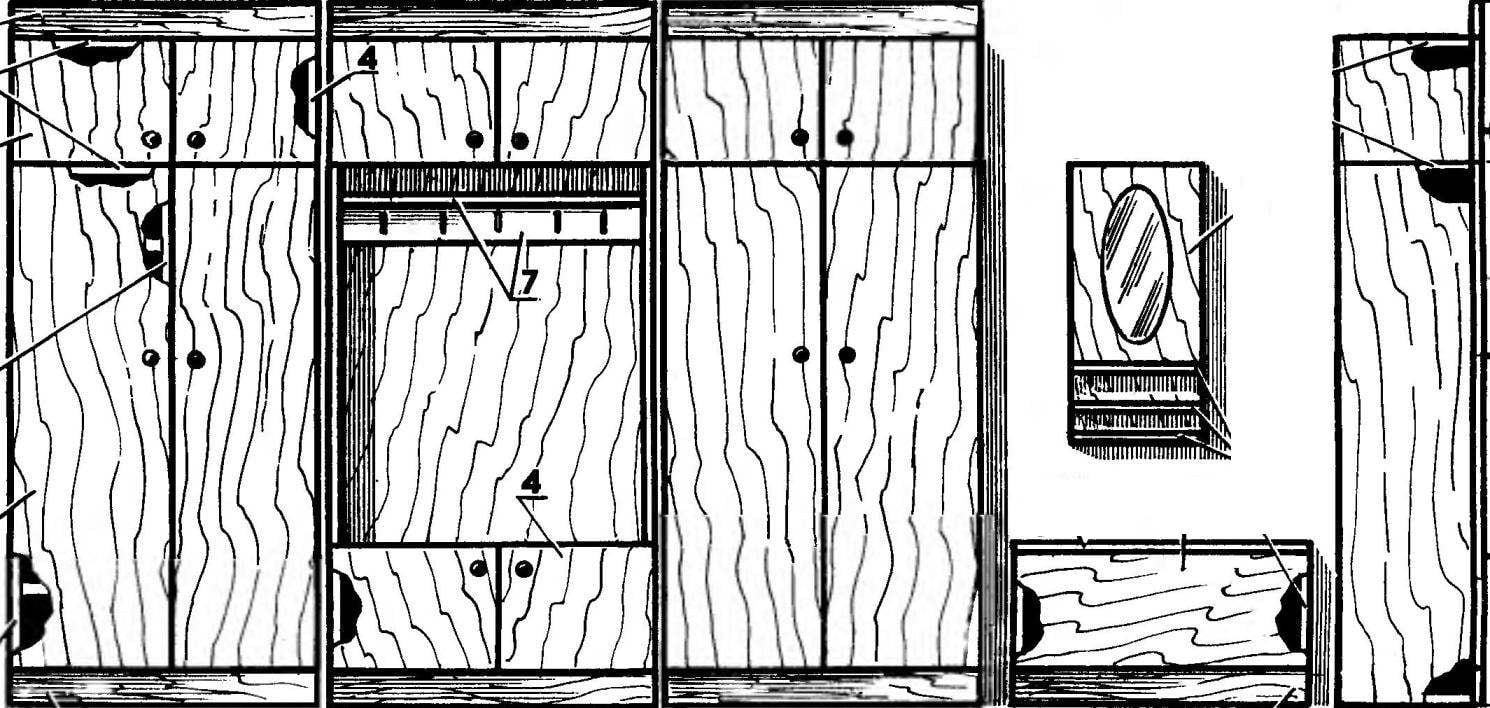

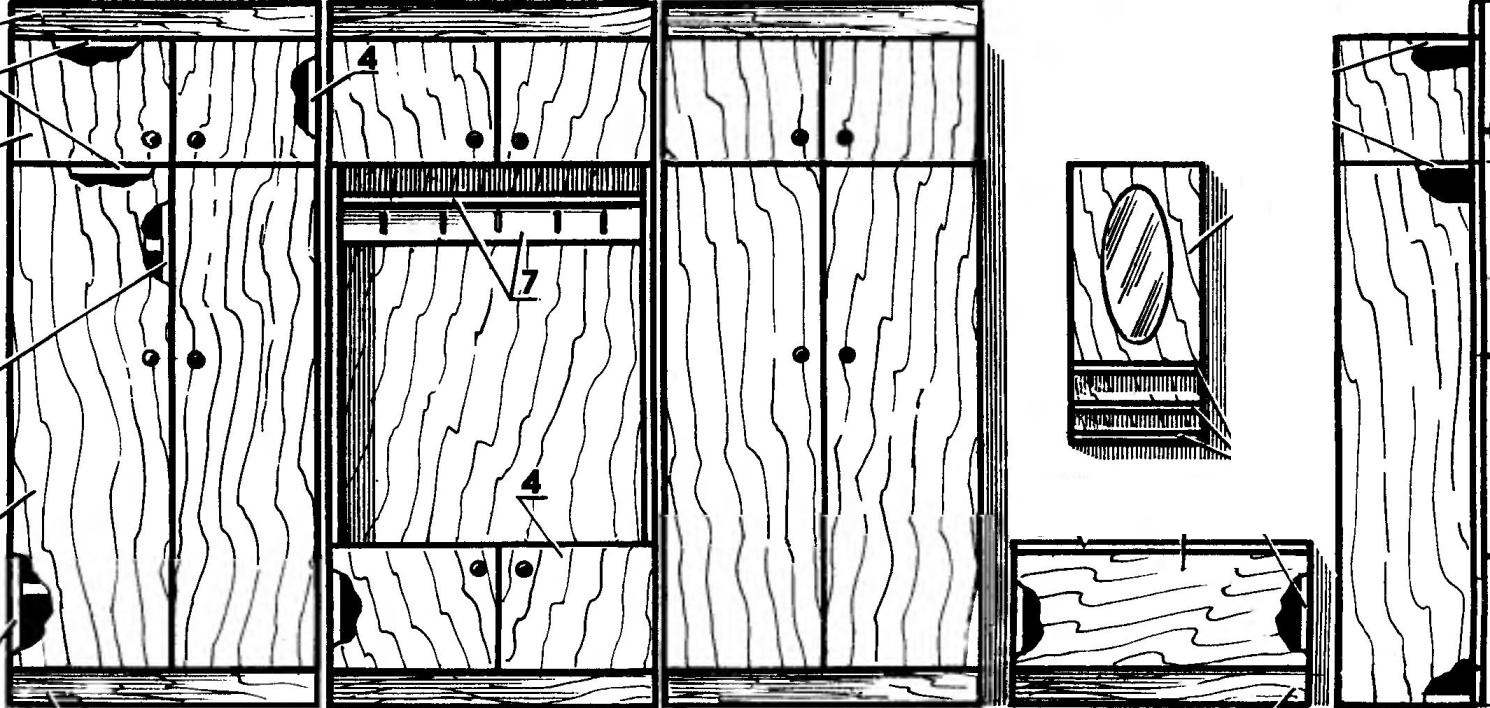

In the considered set single underwear wardrobe, other with wardrobe and between them — closet with hanger. The mezzanine above them are run as separate sections that are installed after Assembly of the main cabinets.

Set of furniture for the hallway:

A Cabinet with shelves; — racking; — a wardrobe; — a mirror with shelves; the D — box of the Shoe;

1 —side panel of the Cabinet (1710×415, 6 PCs); 2— door Cabinet (1650×415, 4pcs.); 3 — partition of the Cabinet (1680×415); 4 — doors and sides (415×415, 14 pieces); 5 — panel horizontal (800×415,11 items); 6 — strap front (830×60, 7 pieces); 7 — panel and shelf hangers (800×260, 2); 8 — bar mirror (820×370); 9 — shelf mirrored (370×195, 3 pieces); 10 — lid of a Shoe box (830×430); 11 — side panel of box (480×415, 2); 12 — panel drawer front (830×420).

The connection of the panels:

In — line template for marking holes (side a — on the end face of the horizontal panel, B — on end face of the sidewall);

1— panel horizontal; 2 — cover; 3 — nut bent; 4 — screws furniture.

Options decorative front panels:

1 — rail profile with a single comb (15×5), 2 — the plastic parts of furniture; 3 — rail profile with two crests (25×8).

Connection of horizontal and vertical panels of a set can be performed by any available mounting hardware items: furniture parts, special eccentric ties or screws to furniture with curved nuts. For the last two options in the panels are blind holes.

The proposed structures of the compounds made with the use of furniture screws with curved nuts. For marking the hole for this fastener is advisable to fabricate a line pattern, the holes which make it easy to find the centers of the slots for the nuts (if you combine with the edge of the top and bottom panels And the side line) or holes for screws (if you combine the side B to the edge of the sidewall). A template made from thin plywood or plastic sheet, with holes for sewing, which defines the centers of the future holes. Shiloh performs the role of the core, but to pin them to the ends of the panels be careful not to split.

Sides of wardrobes, Shoe boxes and attics are a reference, they are mounted the other elements. All the holes for Assembly are drilled in the panels in advance, always using the marking template.

If the surface of the plates did not have any cladding, the easiest and most effective way of finishing — taping paper or plastic “wood”.

Pasting paper is as follows. The panel is placed on a horizontal surface (table or floor). Paper roll after rolling is cut into the size of each panel with a small allowance on the edges. Panel using a paint brush cover pre-cooked casein (or PVA) glue. Paper cloth, dipped in water, carefully applied to the panel and rolled down with a roller, painting or photographic — to squeeze out the excess glue. Removing them (especially the ends), allow the panel to dry for days. After drying, cut the allowances of paper on the edge of the panels bonded to the prepared narrow strips of paper (thickness of panel), also rolled down and dried (you can paste only the visible part). The use of self-adhesive paper or film, of course, greatly simplifies the finishing process. After its completion, it is necessary to release the taped holes for Assembly.

If desired, the front or face panel of the furniture can be decorated with decorative plates found in selling furniture plastic corners and embossed slats, lends elegant “factory” look and also accentuates the stylistic unity of the headset.

Assembly design perform traditional furniture technologies. Installing the sides of the Cabinet front edges on the floor, attach the horizontal bar. Blind holes after that close decorative washers or just stick with. Adjusted the Assembly for Squareness, place a sheet of hardboard (MDF), the size of which is 2-3 mm smaller than the width and the height of the Cabinet and nailed with small nails or fastened with special washers and screws. Under this scheme, collect all three frames of the cabinets and Shoe box with the features of their internal solutions. The same applies to the mezzanine. The upper and lower trim strips and the panel hangers and a shelf for her headgear is attached through the corresponding holes of the furniture with screws.

Cabinet doors and mezzanine set by standard furniture fittings; the easiest and most affordable option of them — the so-called piano hinges. At the end of the Assembly of the mezzanine put in place and connected to the racks by inserting the spikes (nails).

Build Shoe box differs only in that instead of doors, he fastened the front panel and top — cover with piano hinge. Because the cover serves as a seat, it is upholstered with leatherette with a foam layer for softness.

Panel mirror with its shelves also combine with the furniture using screws and bent the screws, which drill the appropriate holes as the panels of the cabinets. The mirror can be any shape, but oval looks interesting; all of them attach to the panel with petals of thin metal which have the edges of the glass and bent over him. Panel, mirror, shelves and vertical panels of the Shoe box like hang cabinets.

We do not dwell on the internal structure of the side cabinets as it is dependent on functional needs. It is clear that in the wardrobe will be installed by horizontal rod-hanger by hanger with clothes on it can be a shelf for hats and so on. In another Cabinet is easy to install partition and a number of shelves for household needs, and on the other side of the partition to leave free space for long things.

Yu. KARIMOV, p. Khurba, Khabarovsk Krai

Recommend to read PILOTAGE EIGHTIES Devices leading only pilots, in General, very similar in scheme and design are very different in administration. The reason is simple: everyone builds a microplane "under his hand",... CORNER TABLE A small table offered by the British magazine "Housholder", attracted by the compactness and simplicity of design. It can be recommended for the equipment, for example, the area of the...  The proposed set of furniture for the hall although made at home, but meets the requirements of modern furniture design, creating comfort and coziness at home. This consists of three cabinets with mezzanines, a Shoe box with a flip up lid that is used as a bench if you want to put on shoes and take off my shoes, and as a wall mirror dresser with three shelves for different things. Everything is decorated in the same style.

The proposed set of furniture for the hall although made at home, but meets the requirements of modern furniture design, creating comfort and coziness at home. This consists of three cabinets with mezzanines, a Shoe box with a flip up lid that is used as a bench if you want to put on shoes and take off my shoes, and as a wall mirror dresser with three shelves for different things. Everything is decorated in the same style.