The hydraulic device of the tractor is also unsophisticated. It does not differ from the technical decision, which was published in the above journal. The hydraulic cylinder lowers-raises and holds at the desired height of the suspension frame, welded from steel unequal angle so that the cross section of each power element was a square.

Front axle is a beam — a thick-walled pipe welded to its ends pivot bushings from segments of the same pipe. In the middle of the beam is welded to the bearing housing axis of oscillation of the bridge, reinforced with steel gussets.

The rotary axle of the wheels cut from channel number 20. To the shelves of the holes and tapped M8.

The thickness of the ring flange are not the same. It is made for camber of the front wheels.

Frame bag FR-tractor hitopadesha:

1 — base (steel channel No. 18); 2 — cross bar (angle steel 50×50, 4 pieces); 3 — bracket front axle (steel plate 200x170x10, 2); 4 — rear axle bracket (steel plate section 180×10, 2); 5 — bracket (steel strip section 150×10,2); 6 — bracket strengthening (steel channel No. 12, L70); 7 — (steel channel No. 12,L450); 8 — suspension frame (angle steel 40×40); 9 — bushing (steel pipe 60×10, L80, 2); 10 — cylinder; 11 — turnbuckle (steel plate 120х80х 10 with hole Ø 40); 12 ’ scarf (steel plate 70x70x10,2); 13 — absorber-limits-tel of rotation of the front axle (2 PCs.)

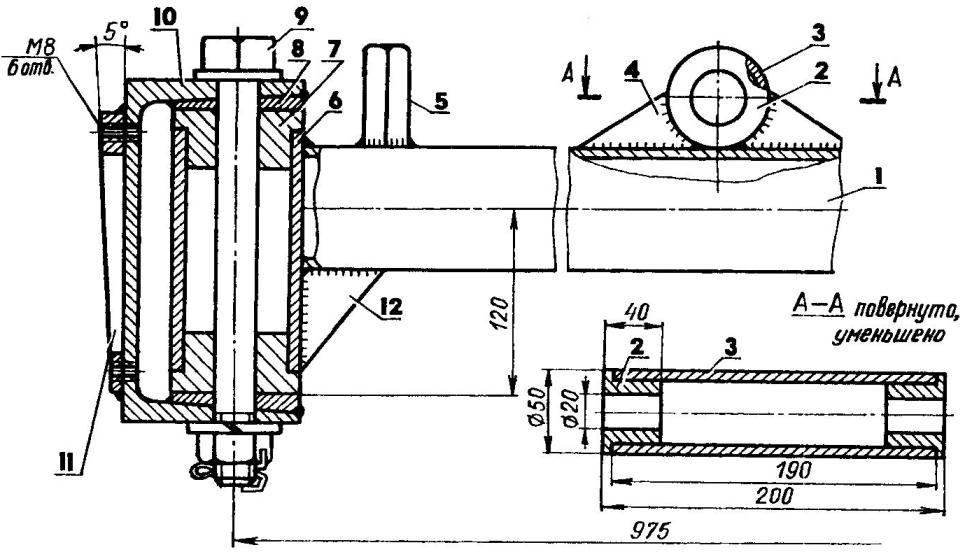

Front axle:

1 — axle beam (steel pipe 57×8, L975); 2 — insert axial bearing (bronze, 2pcs); 3 — housing of the axial bearing (steel pipe 50×5, L190); 4 — gusset plate (a steel plate 100x20x5, 4 pieces); 5 — rotation limiter (steel hexagon bar, h50, 2); 6 — bushing, pivot (steel pipe 57×8, L110,2); 7 — liner (bronze, 4 items); 8 — washer oblique (ST5, 4 PCs.); 9 — pin (bolt M20-2 PCs); 10 — axle swivel (steel channel No. 20, L145, 2); 11 —flange ring (from the UAZ-452Д, upgraded, 2); 12 — cosina (45x45x10 steel plate, 2 PCs.).

Flew upgraded steering gear UAZ-452:

and connection steering bipod with the left axle;

1 — fry steering (2); 2 — thrust of the cross; 3 — pull longitudinal.

Steering model. Swivel bipod homemade. Welded to the axles, they have the sleeve with a conical hole for a finger pull. Lever for rod — factory. Axle with axle beam connected by pins.

Rods — UAZ-452: control, cropped (by bending) to the length of 950 mm, and longitudinal — up to 600 mm. From the UAZ-452 is taken and the power steering gear. But as its body is a steel mount, borrowed node had to be installed vertically, welded to it cut a steel angle 70×70 mm and through it to attach to the frame of MT bolts M8.

Steering shaft (UAZ-452) I redid it, extending through warney bushings were 20 almost 150 mm and setting it on the lower end of the propeller plug steering from GAZ-66. For this sawed hollow steering shaft in two, drove in each half of a segment of steel rod with a diameter of 8 mm, leaving a free end length less than 10 mm, and insert them on both sides in the hub clamped in the vise, welded together.

With the steering column I did differently: instead of too short “Wazowski” installed on my mini-tractor homemade, cut from gazotoplivnoy pipe of suitable size, which is bored through on a lathe socket under the steering shaft bearings. The results were satisfied.

A. KLIMENKO, Primorsky Krai

While still a student of the 3rd class of high school (20 years ago) persuaded the parents to issue an annual subscription to “modelist-Konstruktor”. Since then, and are a regular reader, cherish all the sent mail rooms favorite edition. The desire to build their own mini-tractor (MT) caught fire when in No. 12 of the journal in 1978 read the article about “Lukovichki”.

While still a student of the 3rd class of high school (20 years ago) persuaded the parents to issue an annual subscription to “modelist-Konstruktor”. Since then, and are a regular reader, cherish all the sent mail rooms favorite edition. The desire to build their own mini-tractor (MT) caught fire when in No. 12 of the journal in 1978 read the article about “Lukovichki”.