The fuselage is of rectangular cross section, rolling into a triangular in the rear. Structurally, it is a truss I-beam — this type of fuselage has a minimal weight with exceptional stiffness.

He does so. Prepared Reiki the spars and braces of the workpiece, the drawing of the fuselage with diluted resin is collected by two opposing farm in the sidewall. Cut from the remnants of several square foam frames. They come in handy when building, after its completion, these frames are removed. Cementing the sidewall thread, check to see if the resulting fuselage curvatures and twists. You can now glue the remaining struts.

Fig. 4. Installation of the stabilizer on the tail.

Fig. 5. The design of the Central part of the wing.

Through the day enjoy a final draft of the farm. You need to sew fake plates nasal sections, install the front frame and sew up the fuselage, through which will pass back pin fastening rubber motor.

Glued the fuselage as well as wing — macalintal paper. Just varnishing it is necessary five times. Pylon made of plates of PVC foam stamps, set him on the bed of the wing (plywood with a thickness of 1 mm) and transparent black (color celluloid film). Fit the pylon to the fuselage and checking the mounting angle of the wing, fit an his paper and set aside. Glue the item to the place it will be possible only after complete Assembly of the model — selection its provisions achieve the desired alignment.

Rotor group. Rubber band that serves as a motor, consists of 20 threads cross-section of 1×3 mm. Weight — 25 g grade rubber Pirelli.

In an extreme case, you can use the Hungarian round. Then the wiring should consist of 45 strands.

The screw is made from a lightweight, well-dried lime. Its diameter is 480 mm, 580 mm. the boss and the machine the folding of the blades is of the usual type. The axis of the propeller is bent from wire OVS Ø 2 mm. Particular attention to the correct shape hook, PA which is put on the rubber motor. If the suspension point of the harness will not be on the axis of rotation, during operation of the motor will be strong vibration, so they will interfere with the rubber to give all the stored in it energy.

In the butt of the blades glued copper bushings in them freely, but without large gaps, are bent from the ends of the wire soldered to the screw axis. Folding occurs under the action of the stretched rubber rings mounted on the axis and on small hooks embedded in the blades.

Profile convexo-concave, thin, reminiscent of the widely known G-417в. External finish blades — full lining with long-fibre paper and a partial (in the butt), thin fiberglass. After painting it is desirable the surface of the blades polished.

BALANCING BASIC DATA

Wing setting angle is +3°, the stabilizer is 0°; the angles of inclination of the axis of the screw — down 3° right / 3° (just selected when adjusting the models); the position of the center of gravity 50 to 60% of the chord of the wing (depending on weather conditions). The model flies in a motorized honor to the right, on the planning side.

MAIN TECHNICAL DATA MODEL

Weight, g:

fuselage – 29

wing pylon – 36

stabilizer – 8

want with the boss 29

The weight of the lubricated rubber motor into condition, g – 25

The mass flight, g – 127

In particular the area of DM2 – 13,76

A. DMITRIEV, athlete 1-th digit

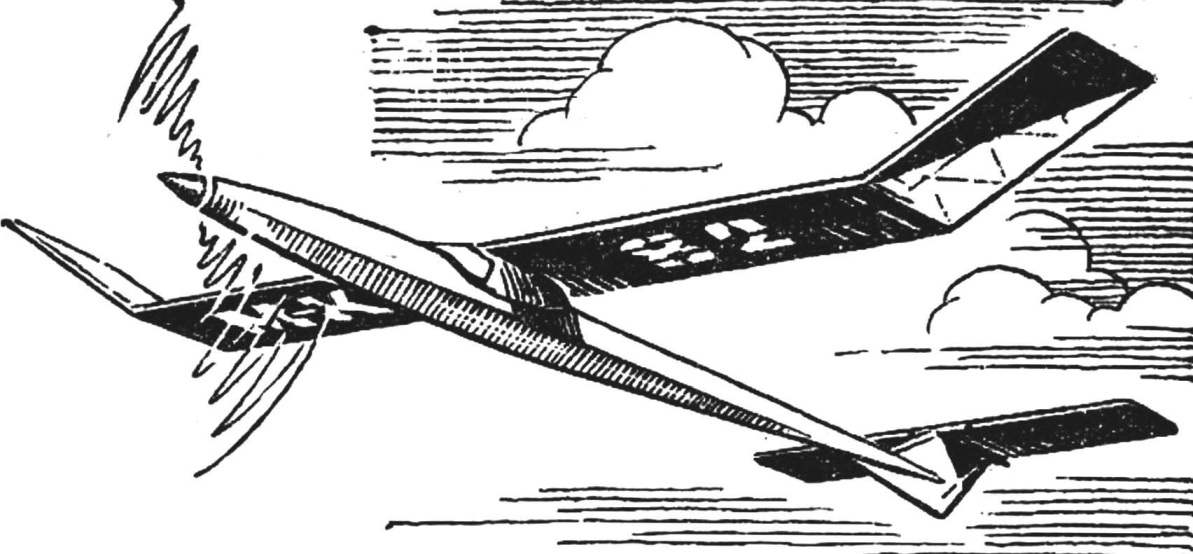

Today I want to introduce You to the model class B1, having almost the same set of wings. This force diagram consoles with a transverse set of pine slats is fully justified, since for such models, the requirements of stiffness, processability and low weight is no less important than for a glider.

Today I want to introduce You to the model class B1, having almost the same set of wings. This force diagram consoles with a transverse set of pine slats is fully justified, since for such models, the requirements of stiffness, processability and low weight is no less important than for a glider.