Try to imagine the street without the usual clatter of wheels passing hundreds of cars. The wheel… what’s special about it? Meanwhile, in its long history has not written the last page. The wheel is one of the earliest inventions of man — as old as the author of it is unknown. Archaeologists have recently established that wheeled vehicles, the wreckage of which was found during excavations near the village of Bekovo in Bulgaria, around 5850 years! For a long time, while the person harnessed in such carriages of animals, the design of the chassis is almost remained unchanged. Decorated with carvings and gold, the wheels of war chariots of Ancient Rome were basically the same as that of the carts of our century: a wooden ring, tied with an iron Hoop, with wooden spokes in the center of a wooden plate with a hole for the axis. However, already in the XVIII century in expensive carriages occasionally could be seen and metal wheels… But those look like wood. Over time four wheel masters began to wear flat rubber ring — bus.

Try to imagine the street without the usual clatter of wheels passing hundreds of cars. The wheel… what’s special about it? Meanwhile, in its long history has not written the last page. The wheel is one of the earliest inventions of man — as old as the author of it is unknown. Archaeologists have recently established that wheeled vehicles, the wreckage of which was found during excavations near the village of Bekovo in Bulgaria, around 5850 years! For a long time, while the person harnessed in such carriages of animals, the design of the chassis is almost remained unchanged. Decorated with carvings and gold, the wheels of war chariots of Ancient Rome were basically the same as that of the carts of our century: a wooden ring, tied with an iron Hoop, with wooden spokes in the center of a wooden plate with a hole for the axis. However, already in the XVIII century in expensive carriages occasionally could be seen and metal wheels… But those look like wood. Over time four wheel masters began to wear flat rubber ring — bus.

Nevertheless, even when at the beginning of the last century, the first steam omnibus, scooter Russian craftsmen Artamonova, and in 1880 the first car Daimler petrol engine, the wheels on them were the same as on the old carriages, differing only in size and weight. And since speed is every year increased, very soon the conflict arose between the motor and the wheel, between the engine and the propeller. In this difficult car time and there was an inflatable tyre. Surprisingly, her appearance was.

…The city of Belfast in Ireland, 1887. Veterinarian John Dunlop watches as his nine-year-old son johnny rides through the garden on a tricycle. The car remained thin deep ruts. Dunlop loved my son but didn’t want to spoil the garden path. To put on the bike wide hoops? But if… It’s so easy! Instead of the old wheels have to do solid wood, with a groove on the outer surface. Then from the old rubber apron to glue the tube to connect the ends and wear on the wheels. Top Dunlop coated each cell stripe fabric, the edges of which are nailed to the wheel. In camera pasted segments thin rubber tubes and pumped them through the air. Now when little johnny went back in the garden, the rut was no more. But the most unexpected was that the bike was much easier on the go! Being a practical man, John Dunlop patented his invention, and inflatable tires are put on cars. True, they often forced the driver to stop and repair the punctured chamber, and sometimes led to serious accidents. That is why the search for a more reliable Shoe for cars continued.

In the late XIX — early XX century was patented multiple elastic wheels had nothing to do with Pneumatics. There were tyres, of rubber woven laces, composed of rubber blocks, finally, the bands of coil springs enclosed in a leather case… has a Special place among the “stretch” of the family held the wheel in which the spokes were fully or partly replaced by springs. But pretty soon the designers made sure that the elastic wheels are not allow to drive fast, difficult to control car and also desperately making noise.

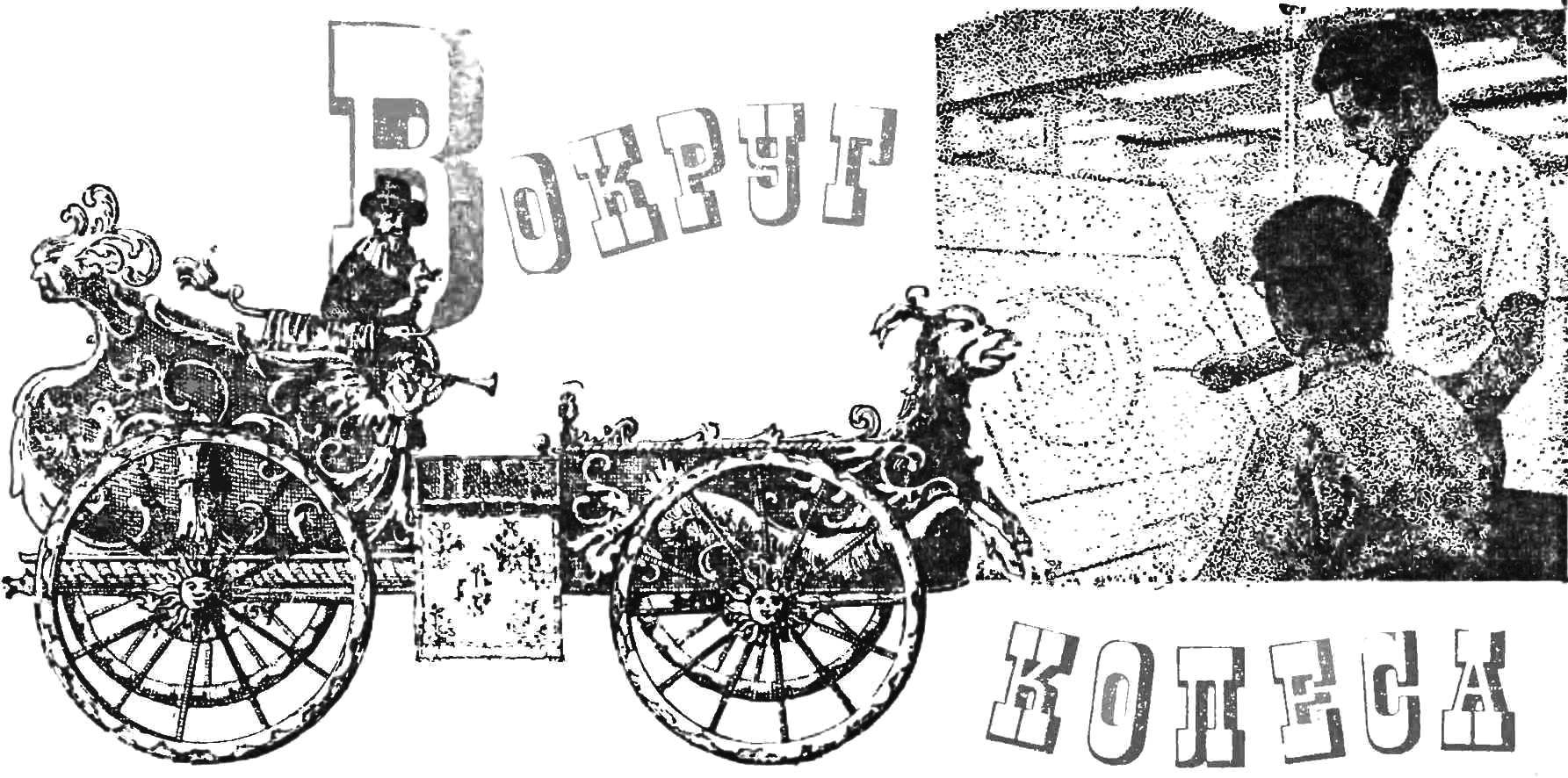

Fig. 1. Wheel armored car of the century — tyre solid rubber and a ribbon of snow.

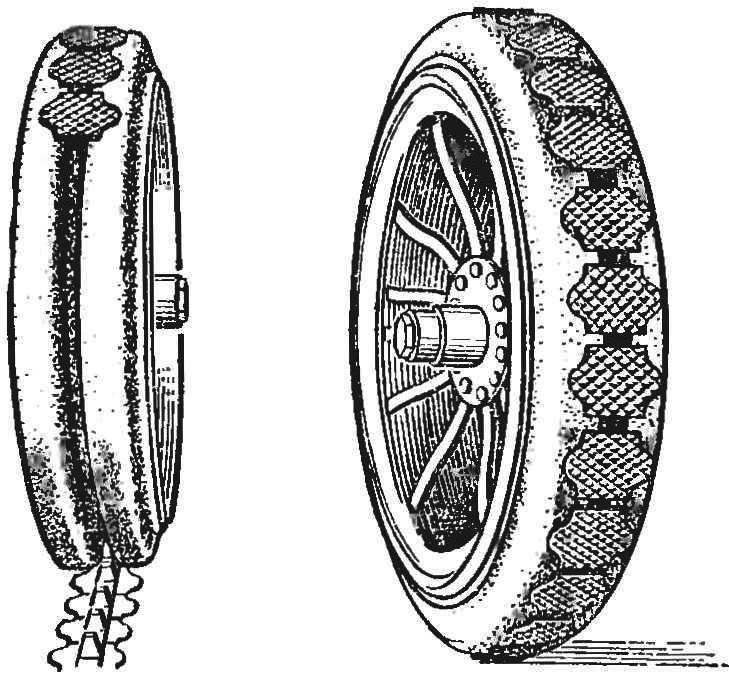

Fig. 2. Spring wheel and tire springs in a leather case.

Fig. 3. The car on the spring wheels.

Fig. 4. Sliding wheel.

In a word, anything better Pneumatics could not be found. And how to deal with sudden punctures? First, the inventors tried to pour in tires liquid that filled the holes, filled the tires with small balls or different elastic materials. During the second world war for the guns and trailers were widely used wheels filled with porous rubber, but they were heavy and hard, is heated and collapsed while moving at high speed.

Only recently, the company “Goodyear” failed to create filled with foam tire equivalent of operating data normal air. Punctures it was not terrible, and the durability was acceptable… that’s just weight in 2-3 times exceed accepted industry norms. In short, the work in this direction and still not out of the experimental stage.

Meanwhile, not asleep, and supporters of the traditional Pneumatics. It was here in the past years suggested many new products. These tires are more safe after they started to install the emergency light of the support ring. Now in case of sudden tire punctures no breaks from the rim, and rests on the inner surface of the support ring that allows the driver to safely stop the car. Enhanced security and multi-tyres: puncture one chamber only leads to a partial pressure drop inside the container.

Have pneumatic tires have one important advantage. To increase the car’s traction on sand, mud or marshy soil, is sufficient to reduce the pressure in the chambers. This will increase the area of tire contact with the road. In a way this is nothing new: in modern lorries tyre pressure can be adjusted on the go, right from the driver’s seat. However, the tires at low pressure quickly deteriorate to bend the ground to the same system pressure control articulated machines that comprise a significant part of the modern fleet, it has been very challenging and capricious.

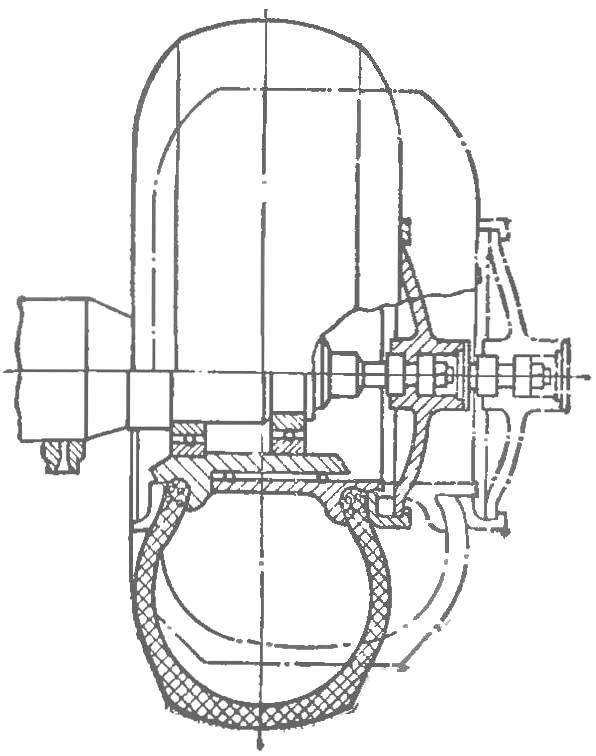

A new design recently proposed by the Soviet inventors L. Vakhrameev, V. Charles and M. Malin. Their wheel without adjusting the air pressure allows you to increase or decrease the contact area with the road more than twice. This is done so. Hub freely rotates around the axis on two bearings and can be moved apart under the influence of a hydraulic or pneumatic actuator that is installed in a fixed axis (axle) of the wheel. The movable part of the hub carries fixed on its side tires. The other Board is fixed on a stationary part of the hub. The whole system is sealed and allows the use of tubeless spikes.

Before such propulsion has opened an unexpected field of application. It turned out that by changing the diameter of the wheels located on one side of the machine, you can change the direction of its travel. Moreover, the new control method provides better cornering stability and prevents the steering mechanism from a brittle and wear out quickly rods, hinges and rotary components.

From profile changes to the convertible wheel — one step. Isn’t it?

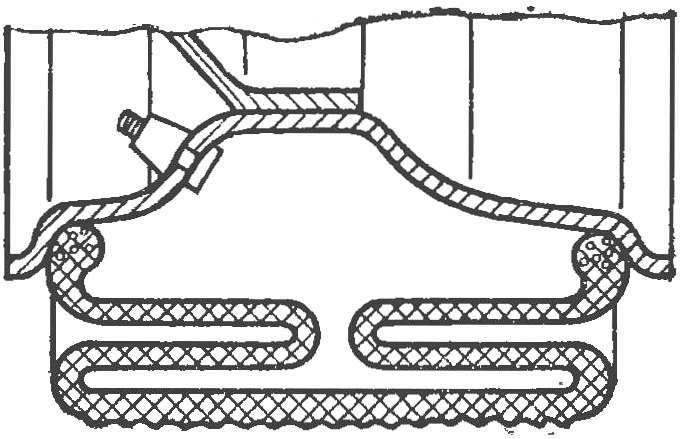

Imagine yourself now, what a normal size Bicycle wheel freely fits in a pocket if the tire release the air. We emphasize: we are not talking about camera lid, and the whole of the wheel with spokes and hub. The secret is what it is. The tire is made of durable unstretchable film, and without the rim connected with Cycling nylon bushing vein, replacing spokes. If inside the spikes to pump air, the more pressure, the harder will be the wheel film is not stretched.

Engineers have calculated that, for example, when the tube diameter is 40 mm and the weight of the cyclist and his machine 90 kg the pressure of air in the spikes should be only 1.8 a. A tire without a rim will be quite efficient and tough. However, to provide the desired transverse rigidity of the sleeve will have to make wider than normal, otherwise the wheel with narrow sleeves will tend to curl into the top eight.

Experts are already thinking about and applying bezobidnyj wheels on heavier cars. After all, the ability to withstand heavy loads such wheels depends on the tube diameter, air pressure in them, and, of course, from the properties of the film. So, in principle they can be used on cars, for example, as a spare almost no space in the trunk.

For all the variety of wheels they have one essential characteristic: they are round, because round wheels can ensure a constant distance from the axis to the road, and hence smooth movement of the crew. But in mud and snow wheels often slip, causing much trouble to the drivers.

Fig. 5. Folding tire.

Fig. 6. Bus from several separate chambers.

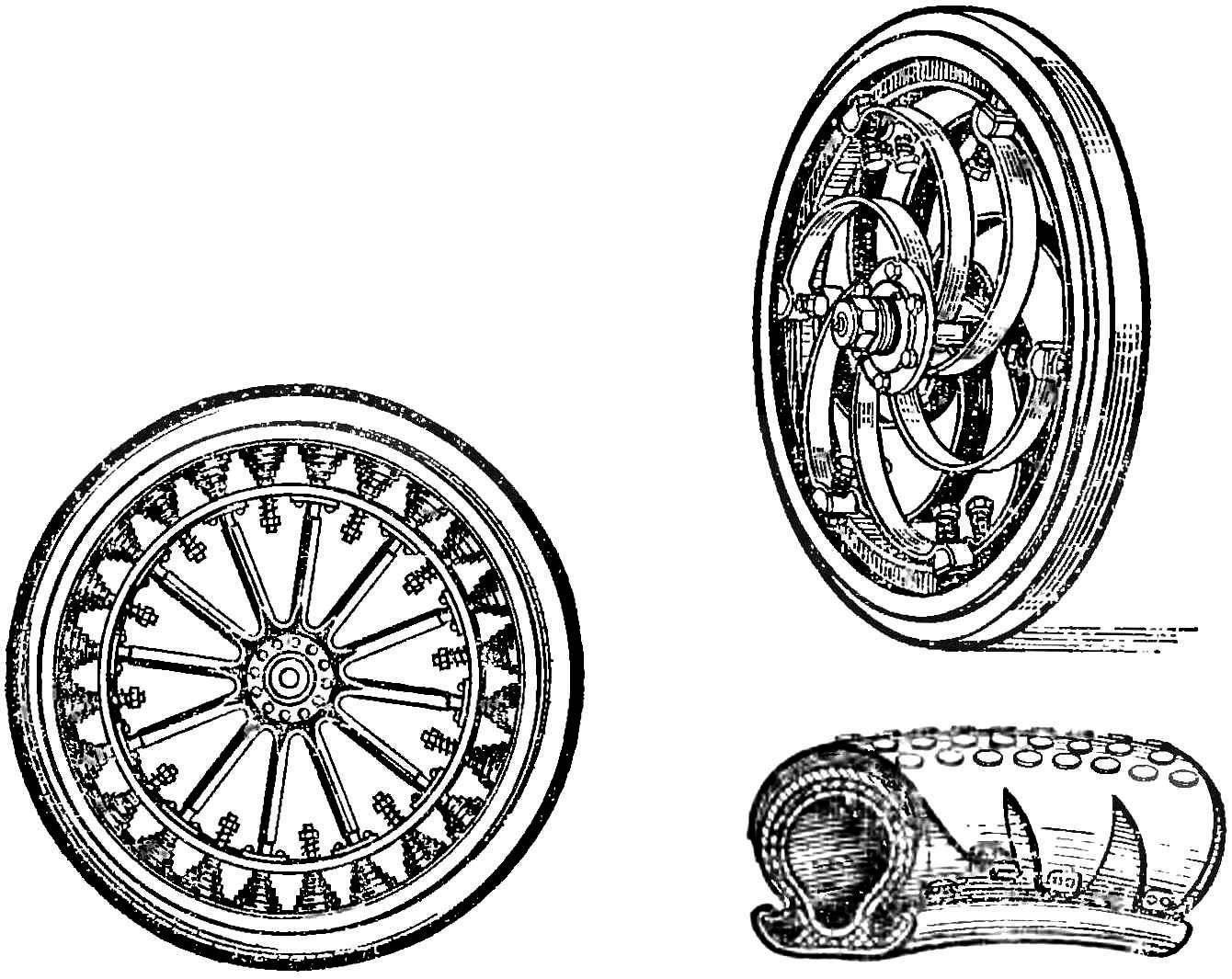

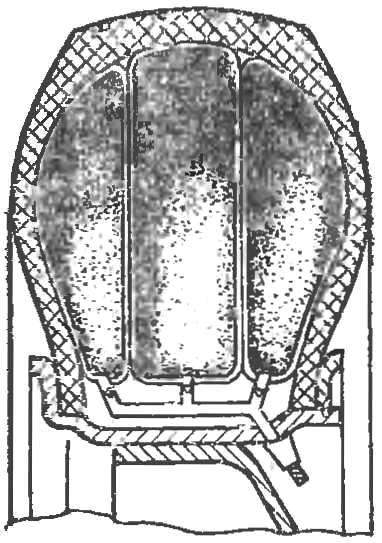

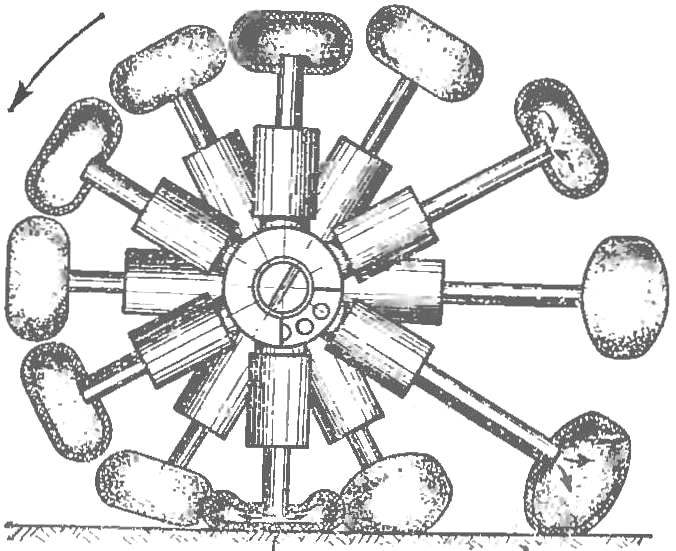

Fig. 7. Walked the wheel cylinders.

And why not make the wheel… square? — American A. Sfreddo. His idea was considered reasonable and in 1959 issued a patent for the invention. On the cars with square wheels so easily overcame snow, sand, mud and bumps on the way, some time later, such wheels were built ATVs for polar expeditions. And to remove the shaking of the car on “squares” — it is a matter of technique. You can, for example, to put twin wheels, moving them half a right angle. You can use the control mechanisms or witness hydraulic, which motion will maintain a constant distance from the axis to the road. However, all this is quite difficult. That’s why working on simplifying the design of the ATVs, the restless, the inventors came up with another option — walked the wheel. Invented in Czechoslovakia by the engineer Yu Mackerle, it consists of separate rubber cameras. If one of those who rely on the road, increase the air pressure at the time when this camera will be behind the vertical axis of the wheel, it will increase in volume and move the wheel forward. This camera will be different, which, swelling, will provide the next “step”. The time of supply of compressed air to the desired camera is selected with the help of spool valve. With the rise of “exhaust” chamber the pressure in it, and, therefore, its volume back to the original.

However, the wheel well Mackerle were walking only on a flat road, that is where work reliably and its classical prototype. If pushing the camera was in the pit, one increase the volume of the chamber is not enough…

The idea Mackerle not found wide practical application as long as the Soviet scientists N. Bocharov, V. Semenov, A. Pologne and Yuri Arkhipov is not established between the cameras and the axis of the wheel cylinders with rods. These devices are similar to wheel spokes, but when submitting them in camera compressed air to the moment of take-off from the road longer. Now the wheel and the pit became not terrible.

I think that this is not the last word in “colocotroni”. Design ideas tend to look. Along with the little floor machines gliding above the ground on a hovercraft, or racing on the monorail by means of an electromagnetic field, the inventors will still capture the imagination of his contemporaries unexpected versions of old inventions, is the most common element ground transport — wheels, by no means exhausted even the variety of possible design solutions.

M. MIKHAILOV, Kursk