On lathes one of the most common operations — machining centers. And here a lot of time is usually lost on such auxiliary stage, both the clamp and release the part in the Chuck. Especially noticeable these losses in large-scale and mass production. Participants NTTM-78 with the Moscow machine-tool plant named after Sergo Ordzhonikidze has developed a cartridge that at the beginning of the rotation he grips the workpiece. In what way?

On lathes one of the most common operations — machining centers. And here a lot of time is usually lost on such auxiliary stage, both the clamp and release the part in the Chuck. Especially noticeable these losses in large-scale and mass production. Participants NTTM-78 with the Moscow machine-tool plant named after Sergo Ordzhonikidze has developed a cartridge that at the beginning of the rotation he grips the workpiece. In what way?

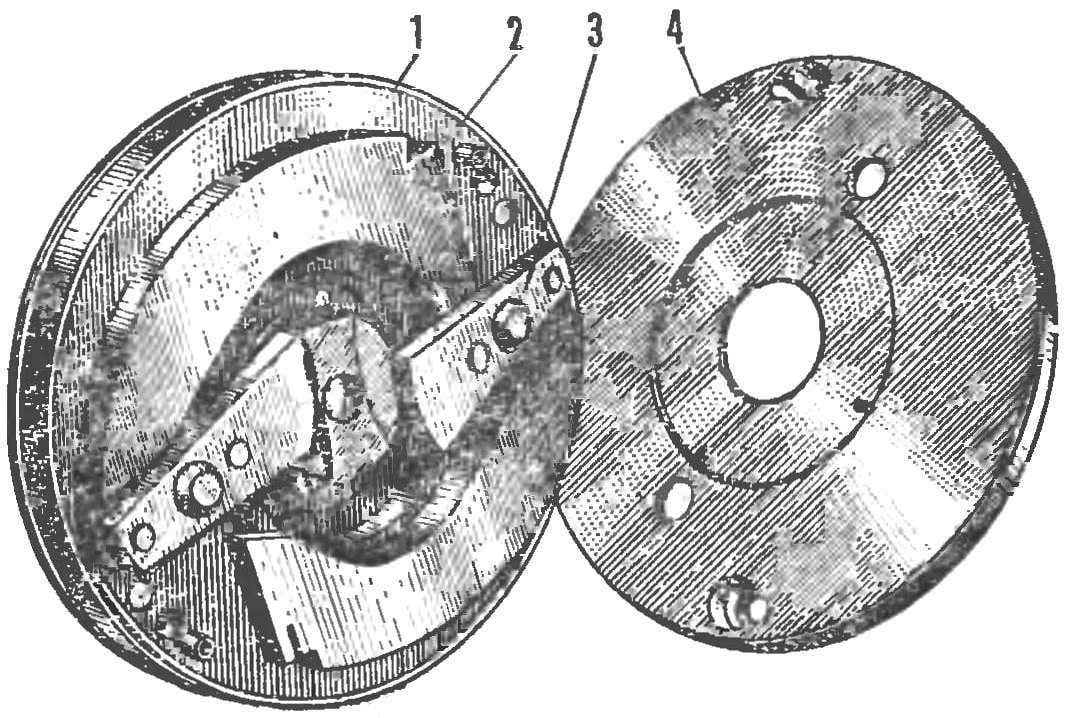

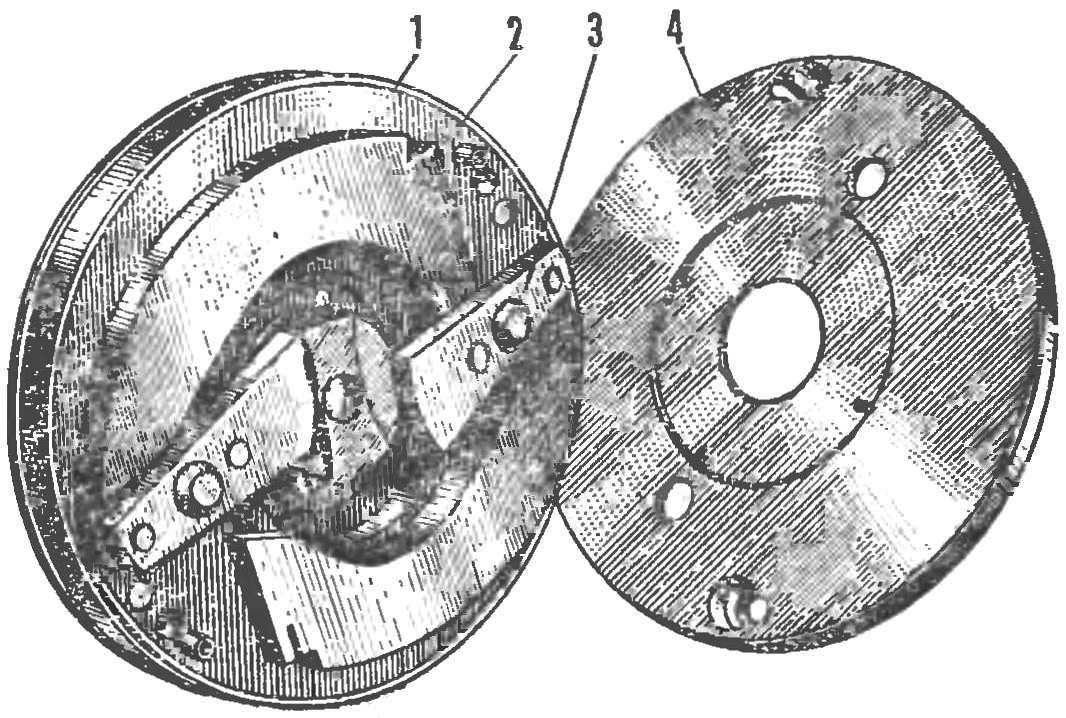

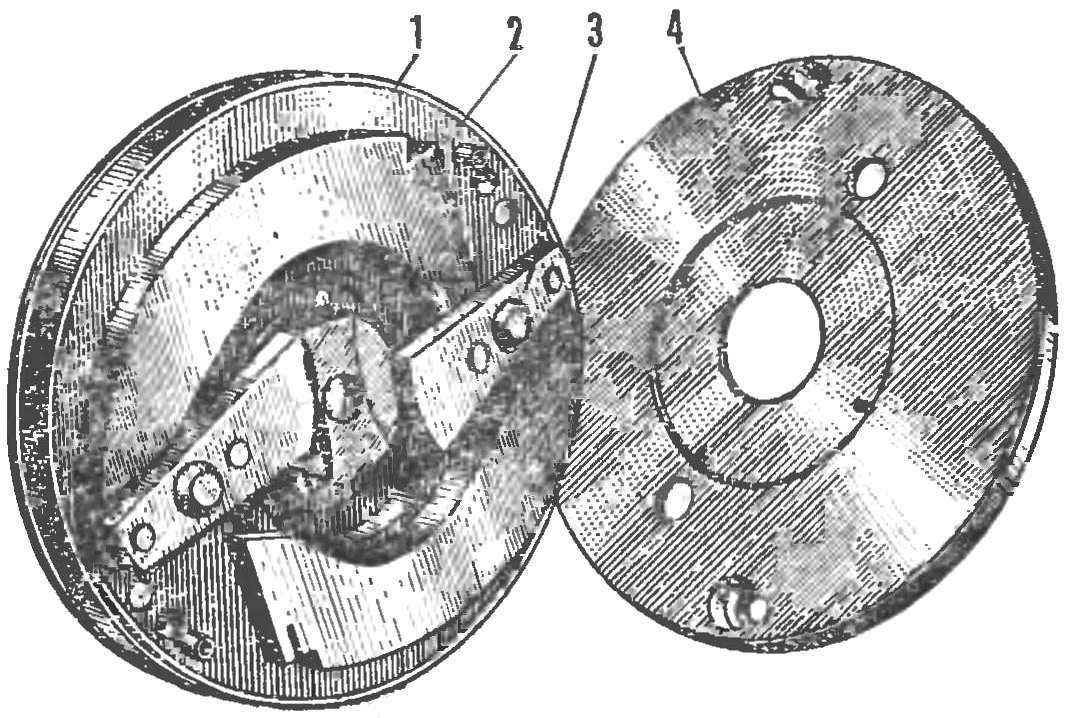

The fact that it has centrifugal weights connected in pairs with two eccentric clamping Cams. When the cartridge starts to rotate, the weights shifted, instantly feeding to the details of the Cams that firmly embrace and clamp it.

Self-locking cartridge:

1 — casing 2 — centrifugal weight, 3 — locking Cam, 4 — cover

In contrast to the known self-locking fixtures new cartridge securely captures detail even at low speeds of rotation of the spindle since the 90 rpm because of the exclusion of accuracy errors in the machining of the part, thereby enhancing the quality of work.