what tricks do not go to the fishermen, to much success. One day, my buddy is a big fan of fishing, lamented that it is often the catch is scarce only because of the fact that there is no way for you to go fishing-“the Donk” in the place where, by assumption, must be fish the bushes in the way, the strength is not enough. Then the idea was born to ship to fishing spots, tackle, and along with “baits” (complementary food in the form of pellets) to build a mini boat — RC small ship the size of a model.

what tricks do not go to the fishermen, to much success. One day, my buddy is a big fan of fishing, lamented that it is often the catch is scarce only because of the fact that there is no way for you to go fishing-“the Donk” in the place where, by assumption, must be fish the bushes in the way, the strength is not enough. Then the idea was born to ship to fishing spots, tackle, and along with “baits” (complementary food in the form of pellets) to build a mini boat — RC small ship the size of a model.

Various RC boat available for sale But, first, they are not cheap (from thirty thousand virtually any), and secondly, they still need to adapt, adapting to fit his needs.

The hull of the ship, it was decided to produce a foam, paste over it from the outside fiberglass into the epoxy binder is cheaper and easier than a shell housing with a power set is.

As the power plant is to use a DC motor powered by a small battery (the internal combustion engine for the vessel was not suitable because of noise).

The office to carry out radio the cheapest was the instrument of proportional radio control Sanva sold in stores “Pilot” Transmitter commands (command device), a receiver and two servos cost about 4 thousand virtually any To this amount is added 1300 virtually any for a reversible speed controller of the company “hi-Tech” you Can certainly do without it, but then it would take another servo to supply or disable power to the motor But it greatly limits the ability of the ship’s Reverse speed controller allows you to change the speed of a watercraft (which is important at the approach to the place of discharge of the gear) and also give back in terms of maneuvering in the reeds or seaweed.

Tough enough foam for the body picked up from discarded packaging from appliances, Fiberglass and epoxy glue purchased at the hardware store.

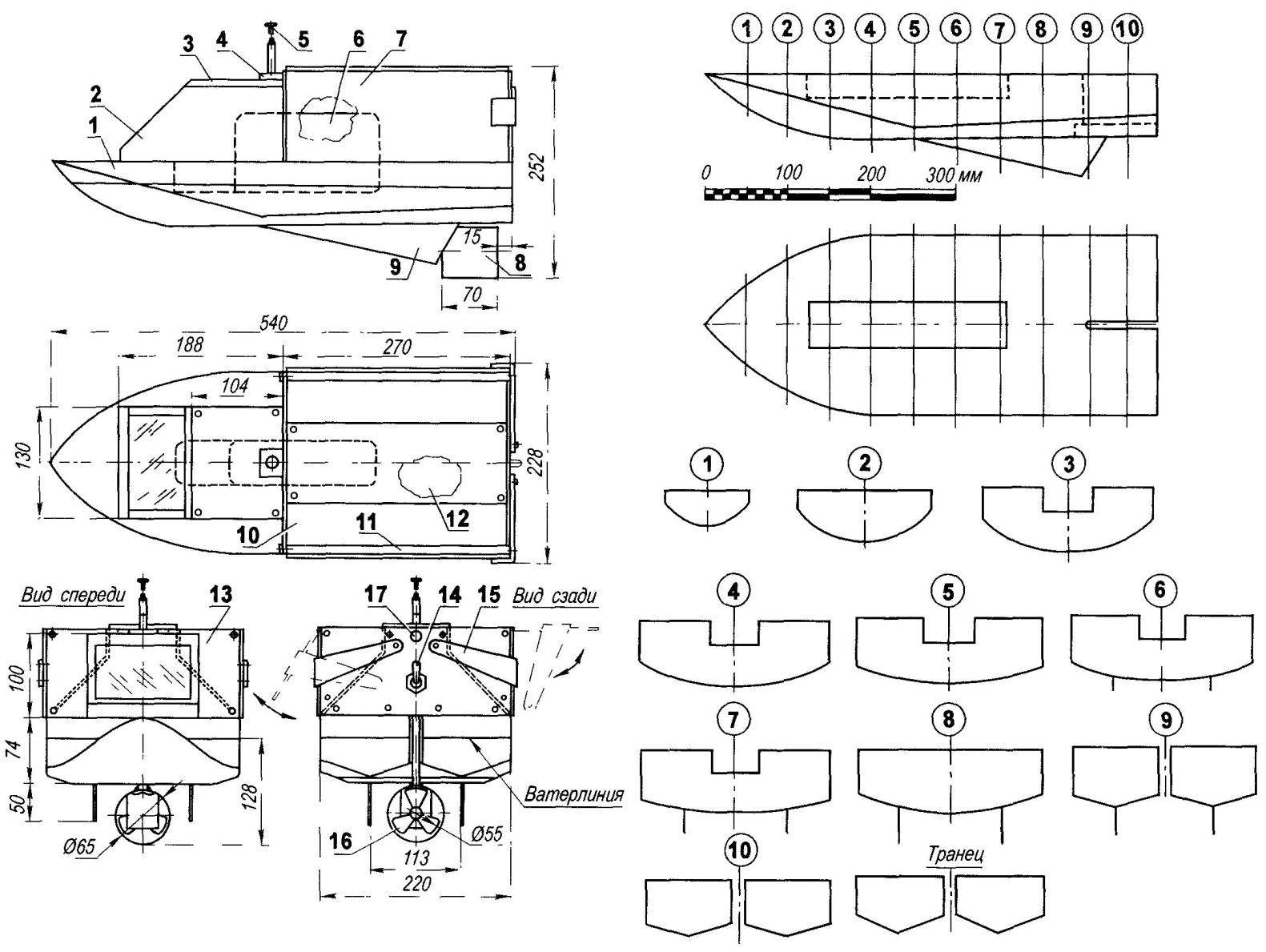

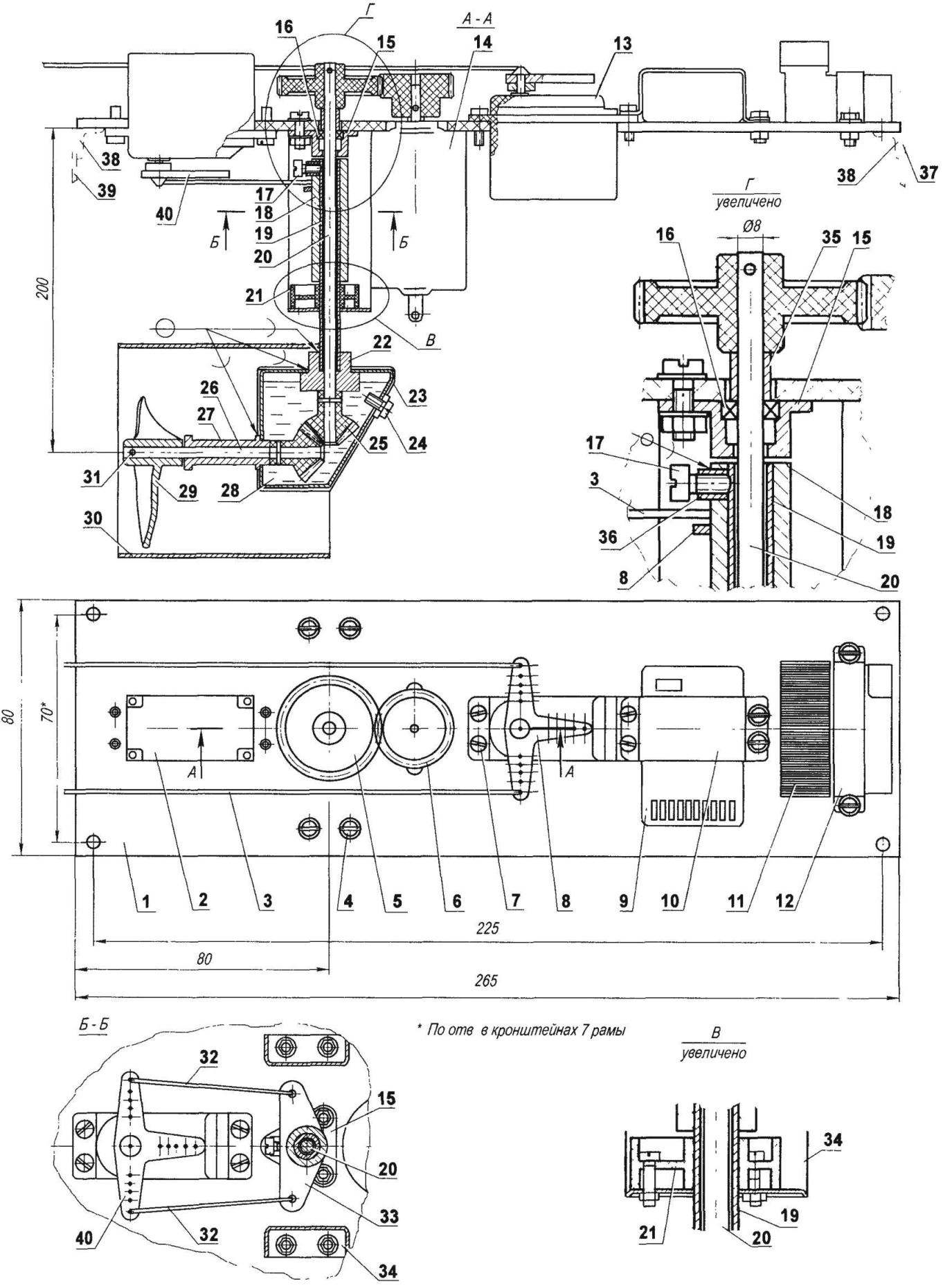

Radio-controlled “mini boat” for fishing:

1 — body (foam), 2 — cabin (foam), 3 — cover felling (PU s10), 4 — antenna bracket (stainless steel, sheet s1,5), 5 — telescopic antenna (purchased product), 6 — battery (purchase the product), 7 — left side (right — mirrored, aluminum, sheet s1,5,2 PCs), 8 — ring vish propeller (brass, sheet s1), 9 — keel (fiberglass, sheet s2, 2-piece), 10 — cover-slide, 11 — Bush axis side (made of anodized aluminum, square 6×6, 2 pieces); 12 — platform with power unit and controls, 13 — frame 14 — power switch (third party product), 15 —bracket locking wall (made of anodized aluminum, the sheet s1,5), 16 — propulsion-steering unit, 17 — signal fire

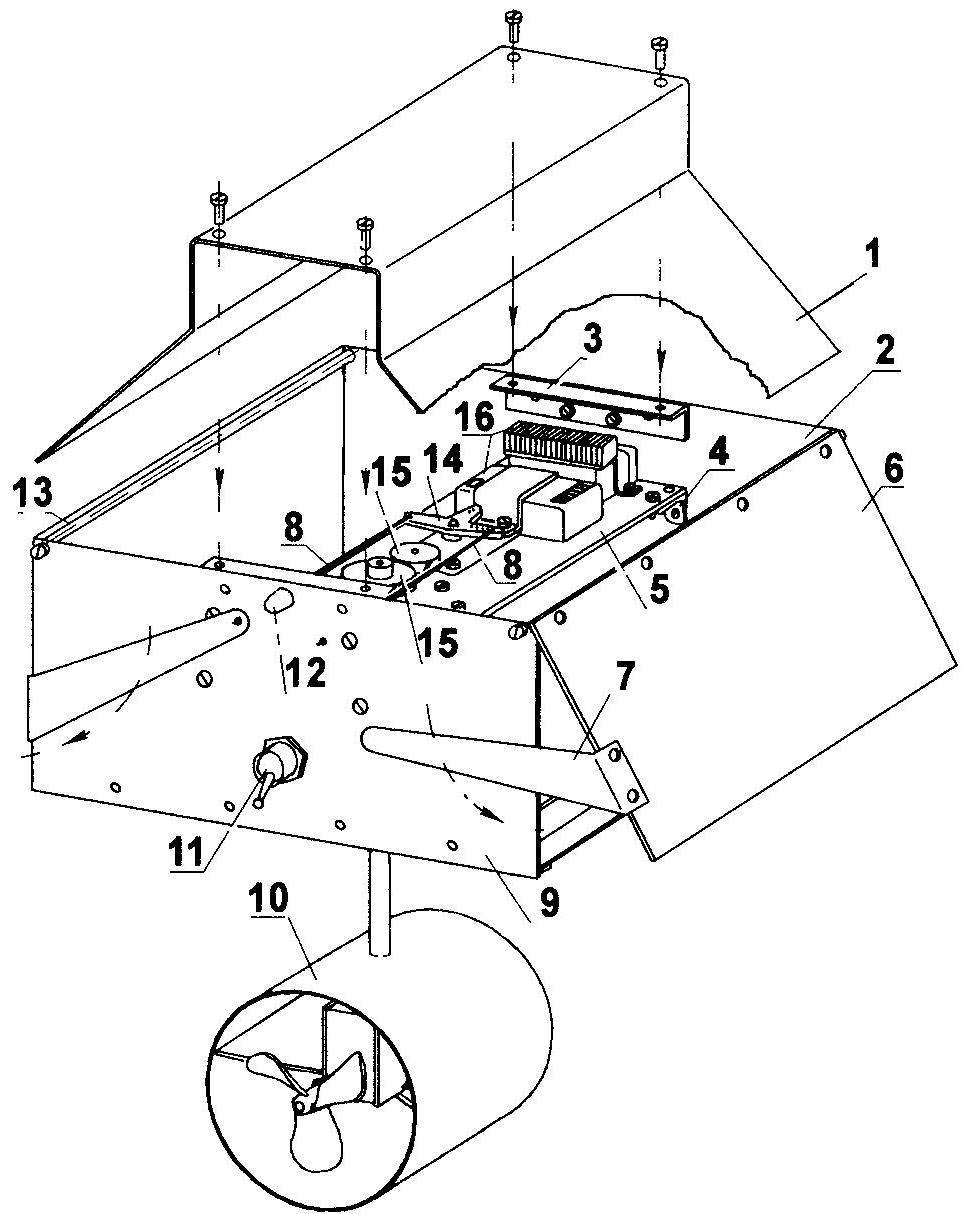

Layout of the actuators:

1 — cover-slide, 2 — to the front wall, 3 — support bracket cover-slides, 4 — angled mount platform 5 — platform 6 — Board 7 — opening bracket-locking side, 8 — traction control sides, 9 — back wall, 10 — propulsion-steering unit, 11 — the toggle switch, 12 — signal fire 13 — bushing axis side, 14 — rocking cars of the open sides, 15 — gear reduction gear mechanism, 16 — silo

The electric motor 12 V with gear — power window cars imported cars found in the garage of the spare parts. They consumed current was meager — only 150 mA, which promised the ability to operate the boat without recharging the battery for the entire fishing Momentum on the output shaft of the gear was small, and it is convinced to make a boat with paddle wheel propulsion, like the old steamers, which gave him a peculiar look.

As for the flush mechanism of the fishing rod and lure, the first thing that came to mind — to make the above deck saddle hill slopes to the sides, covering her bulwarks This solution was allowed to load on the mini-Seiners from two rods — one in each side compartment and dump their Autonomous opening of the bulwark With this arrangement, the motor, servos (control rotary-screw column and opening bulwarks), the batteries were placed in the hold of the hull For visibility mini-seiner in the dark on the bow and stern were mounted flashing LEDs.

However, trial runs showed that the first pancake was lumpy, the ship was moving sluggishly — swam against the tide with great difficulty and he was even blown away by the wind and over To the same through the axis of the wheels in the hold were filled with water, which disabled the motor and almost ruined the servos But the reset mechanism of the fishing rod and the lure was effective and worked flawlessly.

The conclusion suggests disappointing need a different arrangement of the actuators, high-speed power unit and the other mover — no wonder our ancestors long ago replaced the impeller on the screw propeller For the new mini seiner purchased motor “Spid-500” (500 virtually any), working voltage is 6 V, and for him — and lead-acid battery (worth 400 virtually any) the size of the battery is quite impressive length x width x height — 150x150x100 mm, and weight about 1.5 kg, But its capacity is more than enough for the whole fishing.

Again the question arose about the layout of the boat typical scheme of transmission of torque from the electric motor through a reducer and an inclined shaft to the screw would stretch almost the entire length of the mini-Seiners, and therefore no longer itself — for large and heavy battery inside your case is not stayed, the more that it had to be placed as low as possible and in the middle of the boat But the output is still there — has been used quite rarely used scheme of transmitting rotation from the engine to the propeller through a vertical shaft and an angular gear (rotary-screw the column or the other — propulsion-steering block) With all of the major parts and mechanisms of the RC mini-seiner a motor, servos and rotary-screw column mounted on one platform — glass fibre laminate strip 3 mm thick (you can use duralumin with a thickness of 1,5 — 2 mm).

Approach a “mini-seiner” fish place

a Return to “native shores”

Seats under the servos and the electric motor are cut by a fret saw with a blade for metal or on the perimeter of the hole is drilled and then treated them with a file the Mounting holes are performed as usual — appropriate drill and tap.

Mount to the platform of mechanism parts and devices that do not have their mounting holes, realized by means of staples, made of duralumin sheet thickness of 1 mm, with screws or bolts M3.

When linking on the platform of parts and mechanisms is necessary to accurately align the distance between the centers of the shafts of the motor and the column diameters of the driven and driving gears. The details column should not come into contact with the motor housing of the Gear I took from the old printer and its cartridges, They are nylon, cylindrical, helical Desired lowering speed at this stage is 2 — 3 times. But it is not critical to the Engine high-speed, and to reduce the speed can be zero, and using the knob from the radio.

The column consists of a vertical shaft mounted in two bearings upper and lower rolling — sliding Strictly speaking, in the lower bearing installed not the shaft itself, and the Assembly in the tubular rod. The bar still wearing the same spacer with rocker and fixed on her, locking screw This screw adjusts (restricts) the rotation angle of the column For attaching the column to the platform using U-shaped (but upside down) clip on shelf which is mounted the lower bearing.

The lower end of the shaft conducted through another bearing (bronze) it is inserted and the rod bearing But the rod is the tip, because the parts are soldered to one another Subsequently to the same end is soldered and the body angular gear, and the bar — ring of the screw.

It should be noted that the ring was found later, after one of the trips where the screw is wrapped around seaweed and mini seiner barely managed to return to shore After installing the ring it never happened, but also improved the handling of the boat.

Rotary-screw column (propulsion and steering unit):

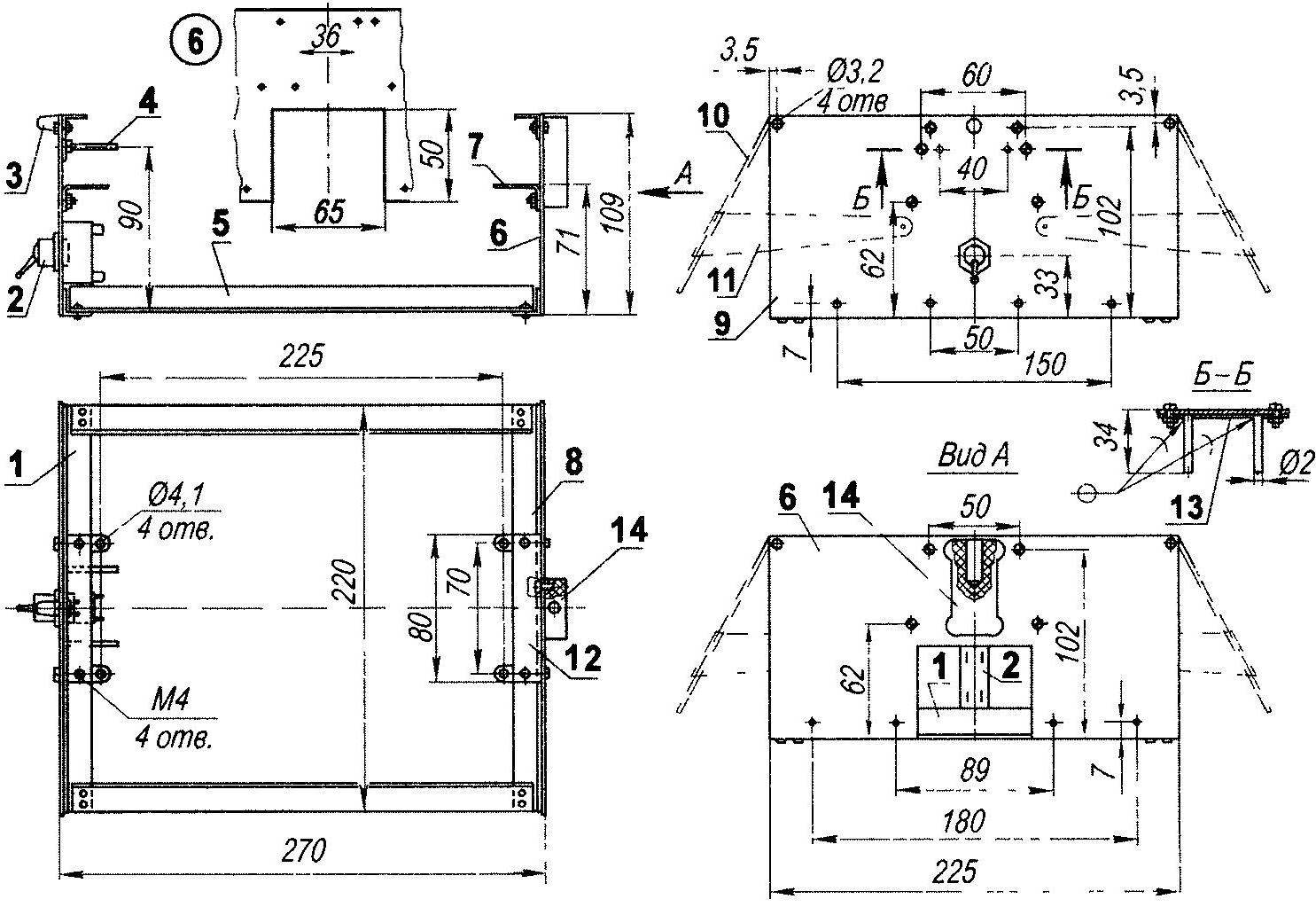

1 — platform (hlinkova plate s3), 2 — the steering machine winterholiday column rudder (purchase the product), 3 — pull to unlatch the sides (wire OVS O1,0, 2 units), 4 bolt mount hub (bolt M3 nut M3 washer, 8 sets), 5 — the driven gear column shaft (38 nylon cartridge from Xerox), 6 — a leading helical gear of the motor shaft (nylon + 18 cartridge from Xerox), 7 — screw mount-Assembly (screw M3, 8 sets), 8 — rocking cars of the open sides (purchased product), 9 — receiver (purchased product), 10 — mounting bracket of the receiver and the platform (duralumin, sheet s1), 11 — reverse ESC motor (third party product), 12 — mounting bracket of the controller to the platform (made of anodized aluminum, sheet s1), 13 — machine open sides (purchased product), 14 the motor (Spid-500, 9000 Rev/min, N=100 W, the purchase of the product), 15 — case bearing (bronze), 16 — ball 1000095, 17 — locking screw, 18 — swivel bushing lever (dural tube O10x1), 19 — rod column (brass tube O8x1), 20 — Val column (steel, circle 5), 21 — bearing rods (nylon), 22 — bearing shaft (bronze), 24 — gearbox housing (brass, sheet s1), 24 — tube regulator body (M3 screw with a nylon washer), 25 — bevel gear reducer (nylon, cartridge copier 2 PCs), 26 — propeller shaft (stainless steel, round 5), 27 — propeller shaft sleeve (bronze), 28 — greasing (Litol), 29 — propeller (brass, sheet s1), 30 — ring (brass, steel s1), 31 — pin (wire OVS, O2, 5 PCs), 32 — traction cars of rotation of the column (OVS wire O1, 2), 33 — swivel rocker column (stainless steel, sheet s2), 34 — clip installation unit rotary speakers to the platform (stainless steel, sheet s1), 35 — thrust hub 36 — threaded sleeve, a 37 — front wall 38 — corner bracket mounting platform (2 PCs), back wall 39, 40 rocking cars turning column

The angular gear consists of two bevel gears, In this case they are the same, nylon and also taken from the old printer (but you can apply and different, using the angular reducer also as step-down) a gear mounted on the end of the vertical shaft and the other on the screw shaft To the screw shaft still wearing bronze sleeve-bearing, and the screw Gear placed in the gear case, a soldered sheet brass and the housing is Packed with grease.

Platform with actuators mounted on the frame, the Frame is a two wall (front and back) held together by duralumin angles Through the holes in these parts subsequently the frame is attached with screws to the deck of the mini Seiners In the front wall is cut through the thickness of the battery, and in the rear made the holes for the power switch and thrust of opening and locking collars in addition, both walls of the drilled different mounting holes and holes for signal lights — led inside and attached two angle bracket — and on them mounted the platform from the Top platform is closed by a lid with a sloping “wings”-the walls, which are the slopes of saddle hill.

Between the front and rear walls of the frame is pivotally mounted on the axes of the rotary lifting side of the Lifting boards can be carried out under the action of the twisted torsion spring installed on the axes (one end of each spring is secured while on Board and the other on the wall), and under the action of gravity drop gear.

Retention of the flanges in the closed position produces rods for steering the machine through the open sides attached to the sides and behind the posterior wall of the bracket Side open command in turn, that allows you to drop the load in different parts of the area.

The body of the new “mini-seiner” as first made from solid foam and covered on top with fiberglass epoxy binder, It is almost flat bottomed, and therefore for better stability there are two keel glued fiberglass In the vertical median plane approximately midway of the length almost to the bottom in the housing of the sample — storage niche Niche in one and a half times longer than battery — for easy slide under the gable of the last hill.

In the rear of the hull also on a diametral plane is made narrow, but through the groove under the column. The through-groove, not a hole made just for ease of installation (or disassembly) of the column (or platform with all the mechanisms in the collection).

Now, about the delivery process of fishing rod and lure to fish with Two rods places released for free reeling spinning reels are set in between rogatica on the shore at a distance of about two meters from each other Between the rods on the water descends “mini-boat” nose to the target On the hooks of the rods must be mounted “Boyle” or other bait and they, along with gruselle start from the bottom of the boards to slope slides (from each of the fishing rods on your own) — and the Board Then closed the compartment is filled with the desired quantity of food, turn on hardware radio switch on-Board power and a smooth squeeze of the handle move “forward” to send the boat to fish place.

Frame:

1 — rear cross member (dural area 15×15), 2 — toggle switch power actuators (purchased product), 3 — signal fire (led), 4 — directing the thrust of opening and locking collars (MN95, pipe O3x0,5, 2 PCs), 5 — spar (dural area 15×15, 2-piece), 6 — to the front wall (made of anodized aluminum, the sheet s 1,5), 7 — angle bracket mounting platform (steel sheet s1, 4-piece), 8 — front crossmember (dural area 15×15), 9 — the back wall (made of anodized aluminum, the sheet s1,5), 10 — opening side (made of anodized aluminum, the sheet s 1,5, 2 PCs), 11 — bracket locking wall (made of anodized aluminum, the sheet s1,5, 2 PCs), 12 — bracket cover-slides (duralumin, sheet s1,5, 2), 13 — plate soldering guide tubes (brass, sheet s1), 14 — antenna bracket (Micarta)

“Mini-boat” moves to the target, the led flashes, and the scaffold is unwound and stretches after At the approach of the craft to the desired point slow down his progress (up to stop) and give the command to open the side of the reaction rod and reel (they stop at first too, but then again, a little spin) determine that there has been a reset by the Way will say that failures in this process have not yet been observed Then divert socket the “mini-boat” to another the target point and throw the rope on the opposite side then send the boat back to the shore On the first tests “miniseminar” exceeded our expectations and ensured the successful fishing At low atmospheric pressure when the fish is none of the anglers next to no bite, my friend caught a couple of five-pound carp that was repeated several times.

When the task “mini-boat” shows steady and rapid progress, even against the current, takes place virtually in “the patch”, wades through the reeds and algae Known rephrasing of the proverb “a Fish looking for where it is deeper, man — where’s the fish” sure applies to my “mini-seiner”.

To find such a place, additionally equipped “mini-boat” fish finder And now open side not on intuition, and in that deep place, to indicate that the device.

IVANOV