You never tried to bend metal sections “area” or “channel”? If you had, then you probably know how hard it is, especially if the profile is lengthy. Simple drawing mill, made by me, allows you to run a variety of shaped metal profiles with a thickness up to one millimeter in almost any length. In the case are plastic and metals 3 steel grades and the stainless steel, aluminum alloys and brass.

You never tried to bend metal sections “area” or “channel”? If you had, then you probably know how hard it is, especially if the profile is lengthy. Simple drawing mill, made by me, allows you to run a variety of shaped metal profiles with a thickness up to one millimeter in almost any length. In the case are plastic and metals 3 steel grades and the stainless steel, aluminum alloys and brass.

The main node mill portable draw plate material from St. 45. Good to use for this purpose, the holders of the old turning tools. The sequence of technological operations is as follows: roughing, trimming, grinding, polishing and hardening.

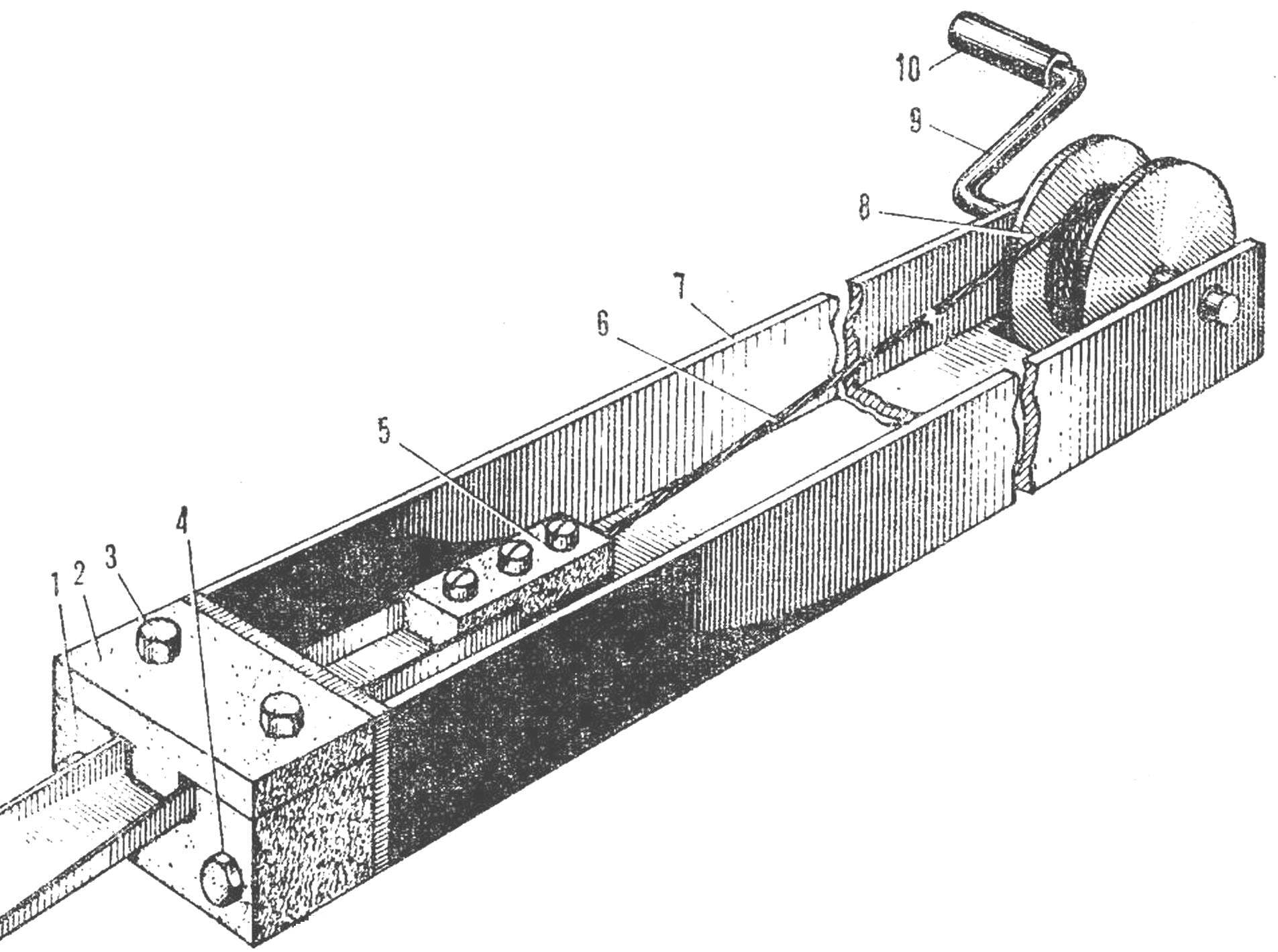

The base of the mill six — foot piece of steel channel with cross section of 50X100 mm. With one of its sides secured to the die, and the opposite — within the elementary gate — shaft with steel side cheeks, between which is wound the cable. The shaft is mounted a lever arm. One end of the rope is fixed on the shaft and the other connected clip. The clip in turn pulls the strip of metal is put through a Spinneret.

Some advice on drawing technology. Before working the metal strip is lubricated by an oil-graphite lubricant, and then dressed in a Spinneret. The initial portion of the profile must bend with a hammer, vise and pliers.

Fig. 1. Drawing camp:

1, 2 — parts of the die, 3 — bolt, 4 — bolt the die to the substrate, 5 — clamp, 6 — rope, 7 — base, 8 — cheek, 9 — shaft, 10 — arm.

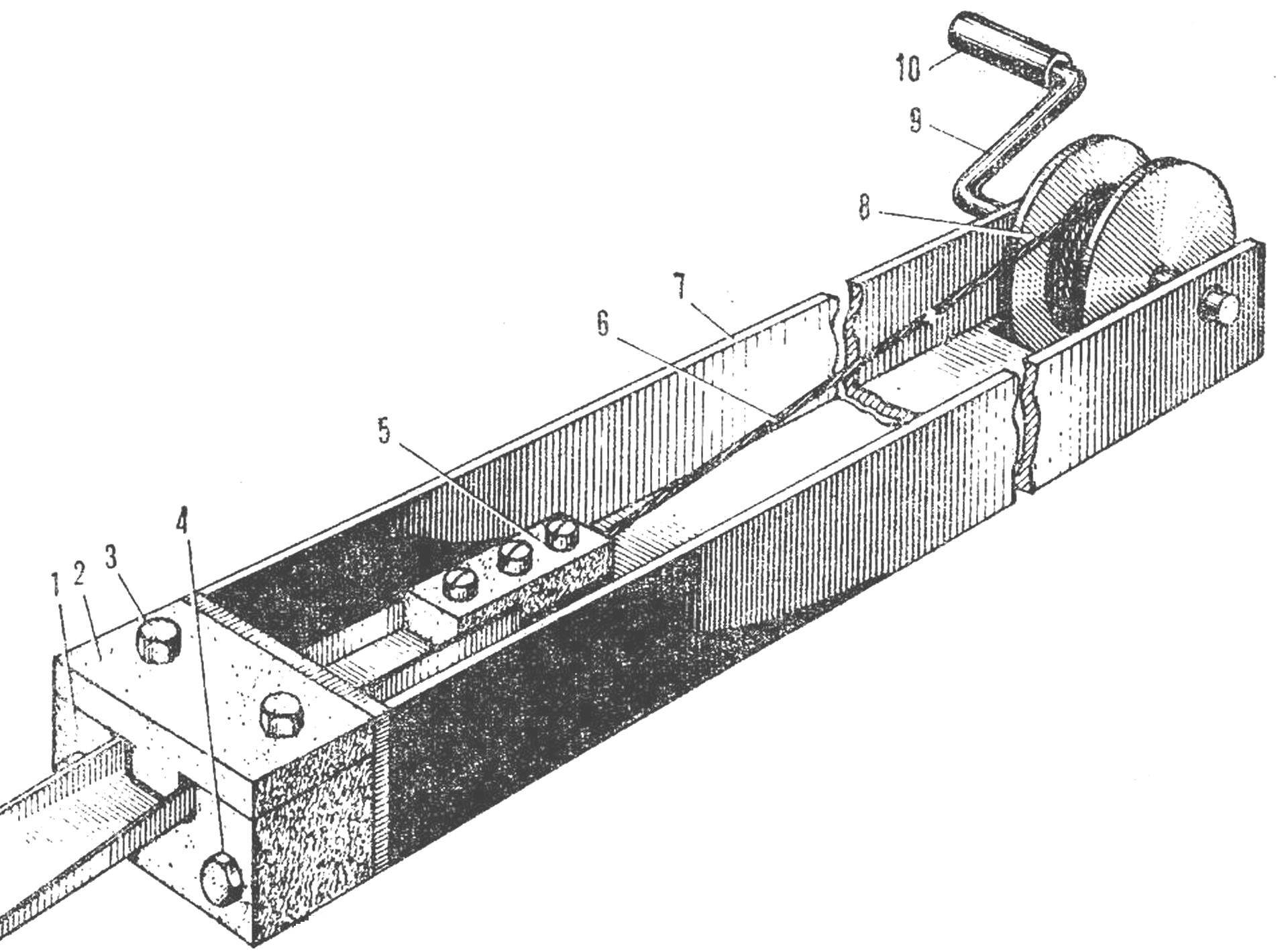

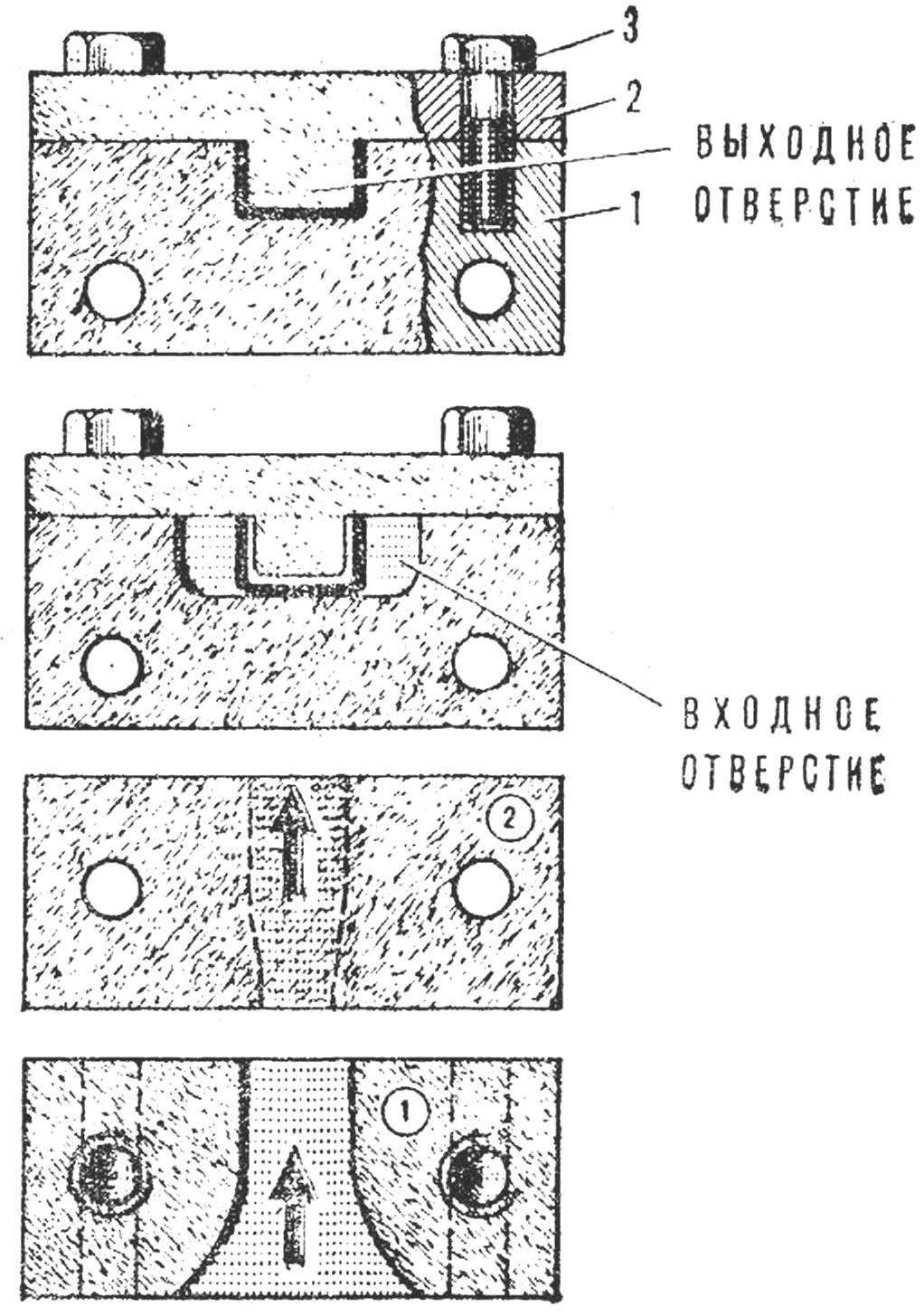

Fig. 2. Die for pulling the channel:

1, 2 —parts of the die, 3 — the pinch bolt.

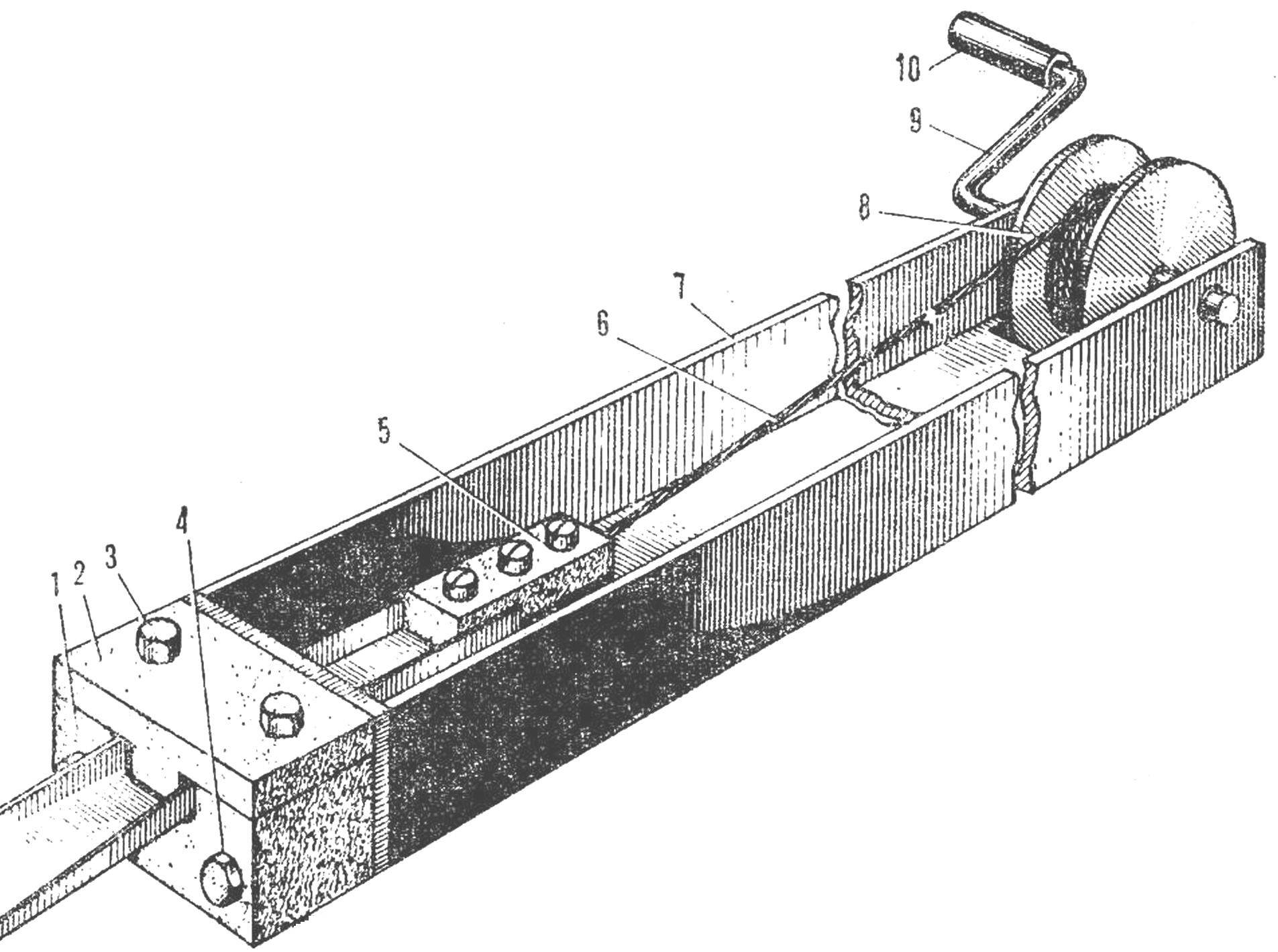

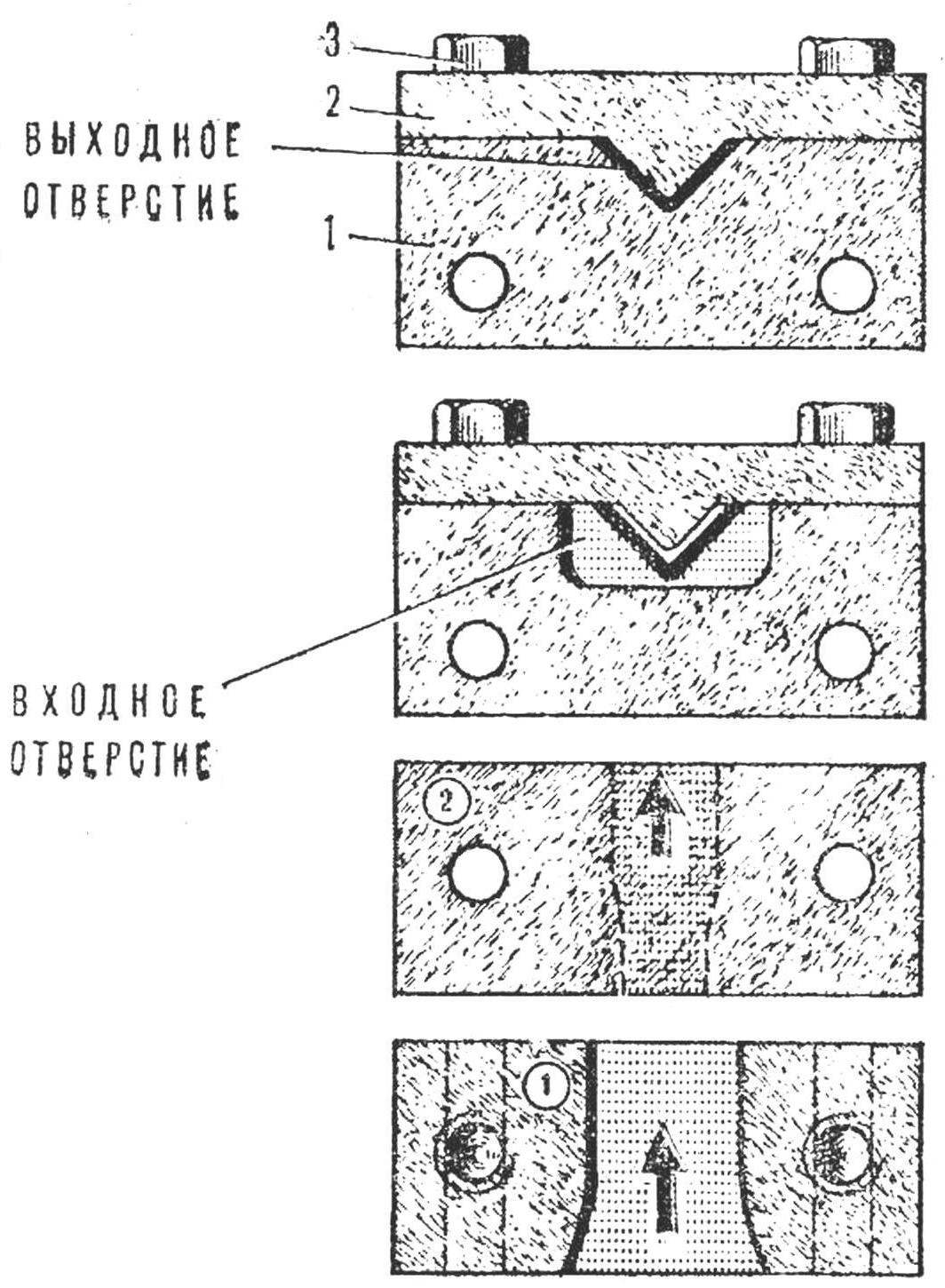

Fig. 3. Die for pulling area:

1, 2 — parts of the die, 3 — the pinch bolt.

On this device it is possible to obtain channels with a height adjustment of shelves 15 mm and a width of from 15 to 50 mm, and “corners” — with shelves up to 20 mm. I Want to warn you that the camp “provides” the product somewhat twisted around its longitudinal axis, but the disadvantage is this easy to fix manually straightening.

Notice that the product quality is greatly affected by the cleanliness of the processing stream, i.e., the inner surface of the die. Considerable importance is the quality of the transition — they should be fairly smooth. Clearance of the die is necessary to make 10-20% more of the cross section extend of metal. Steel billets-strips in front of the lug is better to anneal. Band width is chosen experimentally, which is passed through a die a piece of cardboard. If the strip is narrow, the width of the shelves will be uneven, otherwise, the side edges of the cardboard will be flattened.

It remains to wish the homebrew, decided to follow my experience, to replace the gate on the chain drive on the shaft to impose an asterisk, and the rope replaced with chain, this significantly increases the quality of the produced profiles.

V. GESTURES, locksmith, Irkutsk