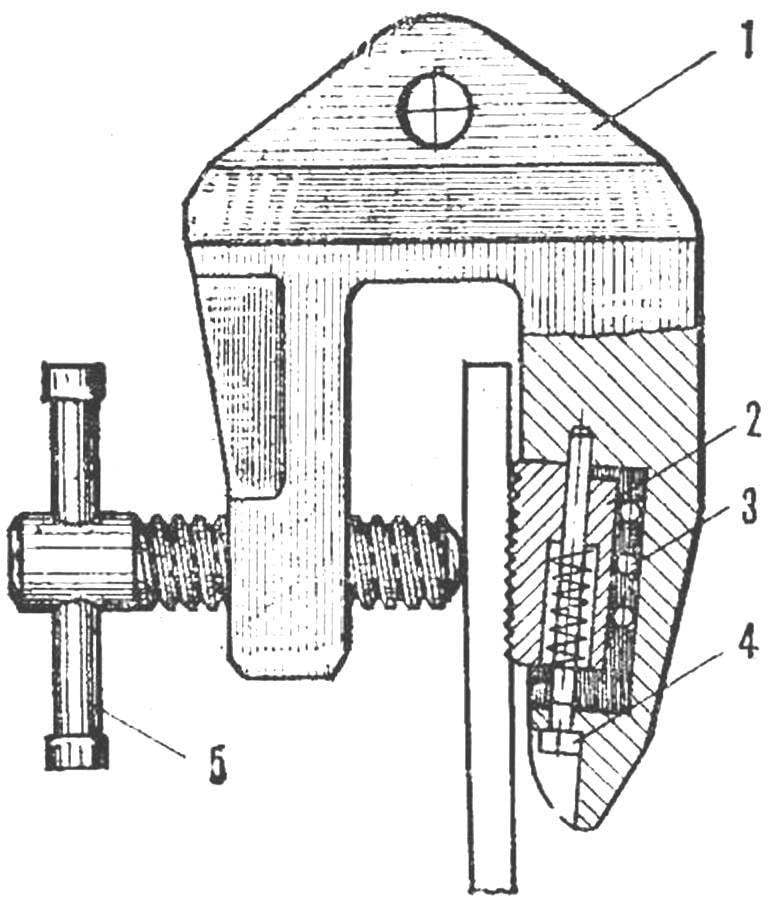

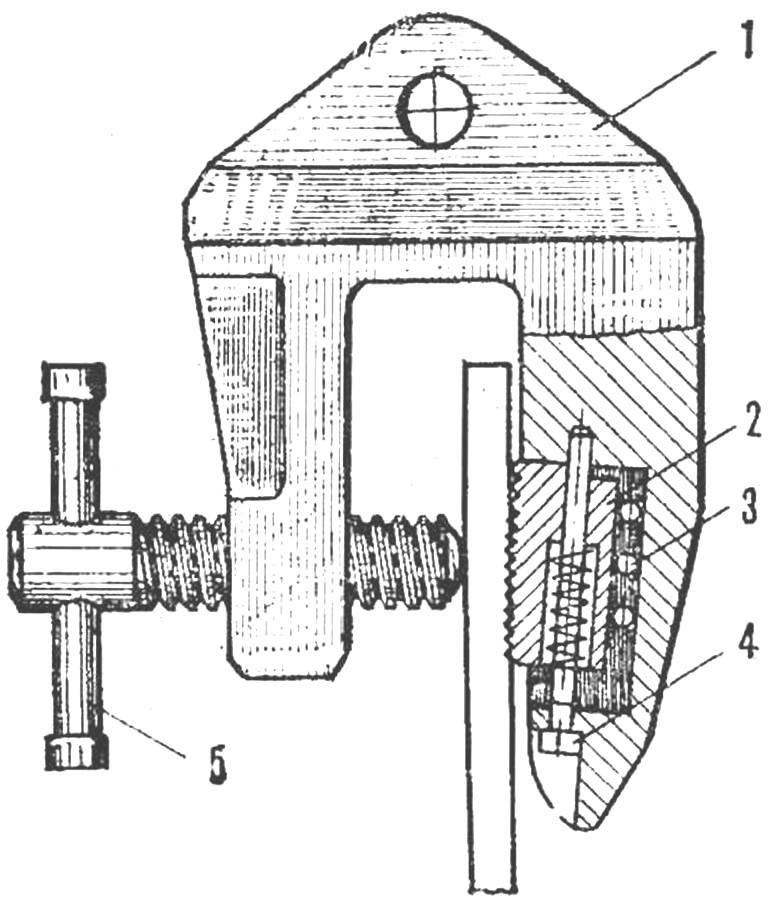

Like focus: sheet metal or plywood easily inwards bracket clamp, and back it not to pull out any effort — so tightly he squeezes. What does that mean? The secret is in the little extra details that distinguish it from similar clamp. The fact that the clip has a special groove in which a guide screw and a support roller moves the spring loaded wedge sponge with a notch.

Like focus: sheet metal or plywood easily inwards bracket clamp, and back it not to pull out any effort — so tightly he squeezes. What does that mean? The secret is in the little extra details that distinguish it from similar clamp. The fact that the clip has a special groove in which a guide screw and a support roller moves the spring loaded wedge sponge with a notch.

The device operates simply and reliably. Depending on the thickness of the sheet in the pressing screw is a minimum gap between it and the bracket. Pushed through the clamp material in a reverse movement touches the notch and moves from place movable jaw, and she firmly jammed sheet.

Self-locking clamp:

1 — clip 2 — wedge sponge, 3 — bearing, 4 — guide screw with a spring, 5 — clamping screw.

Self-locking clamp can be very effective on many auxiliary operations when working with sheet materials in the engineering industry, glass industry, furniture industry, shipbuilding. For each kind of materials possible modifications to fit the size of the throat of the bracket and its load.

With the help of clamps simplifies the transportation of flat parts and pieces. Facilitates storage of sheet materials in a vertical position, and performing Assembly work in case of vertical installation in the shops of the metal.