The drive of the ailerons is via dural torsion bars — they’ll need knitting needles with a thickness of 2.5 — 3 mm. At the point of passage of the torsion bar through the ribs in the latter are pasted plastic sleeve — cuts used refill gel ball pen.

The lower wing is fixed to the fuselage by a Central rod made of beech with a diameter of 5 mm (glued to the bulkhead between the wing panels) and attracted by rubber rings to a pair of beech rods with a diameter of 5 mm mounted in the lower part of the fuselage

The upper wing is attached to the bottom and through a set of stands and brackets made of aluminum knitting needles with a diameter of 2.5 mm. the Brackets represent the segments with flattened spokes (after heating in the flame of a candle) ends, in which are drilled with a diameter of 1.2 mm. Each of the brackets affixed to the fake boss, is fixed during Assembly of the wing front and rear spars.

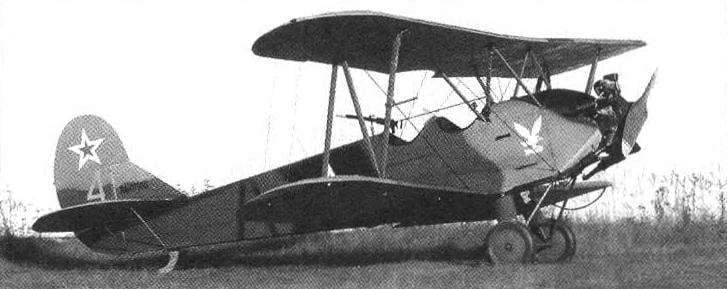

The length of each of the racks mini biplane is determined “at the place”, for which upper and lower wing with the help of wooden beams fixed to the plane chords consoles were parallel to each other, and go forward of the upper wing relative to the bottom was 44 mm.

The ends of each of the stands with both sides flattened (after heating) and they drilled holes with a diameter of 1.2 mm. connecting struts from the brackets on the wing is carried out using segments of nylon twine of the same diameter — they are skipped in the holes in the brackets and racks, after which the ends of the line using the electric soldering iron is attached to the balls.

Mount the wing struts:

1,4,8,9—boss brackets stands (Linden); 2,5,11,12 — mounted wing stands (dural needle with a diameter of 2.5 mm); 3 — upper wing; 6,13,15—axis (segments of nylon fishing line with a diameter of 1.2 mm); 7—wing stand (dural needle 2.5 mm diameter); 10—bottom wing; 14—Aileron

The lower wing:

1—the front edge (lip); 2 — loop Aileron (nylon fishing line with a diameter of 1.2 mm); 3—trailing edge Aileron (lime); 4—torsion actuator Aileron (dural needle with a diameter of 2 mm); 5—elements of the ribs (foam covered with paper); 6—rear edge of the wing (Linden); 7—front spar (foam covered with paper); 8—rear spar of the wing (foam covered with paper); 9—jumper the front edge (lip); 10 — wing (foam s3); And—the leading edge of the Aileron (Linden); 12 — pin-retainer (beech with a diameter of 5 mm); 13 insert (Linden)

Stands and brackets in the Central part mini-biplane mounted similarly.

The finished model is painted — it is best to do this alkyd enamel, which does not dissolve the foam. Alignment of biplane within certain limits you can change the movement of the battery or, in an extreme case, a shift forward or backward of the upper wing. However, the latter measure would require alteration of all bilanich racks.

Before the first flight it makes sense to train, “fly” on the spot, which you need to wait for good wind to hang the model on a solid base of thread to a tree branch or, for example, a rope stretched between two pillars. The suspension point must be located in the center of the center of gravity of the model. By controlling the joysticks of the remote control transmitter, you will learn in the first approximation to control the model’s pitch and roll.

It is not always possible to find for radio controlled models suitable airfield, so the flight will have to take an assistant — at your command throw it will launch a biplane in the air horizontally and towards the wind.

Some radiomodules (those who have not found a helper) use the catapult, consisting of a flat Board and rubber shock absorbers — harness of the model aircraft rubber. The model is fixed to the catapult using a simple stop (e.g., binds to hammered into a Board nail with string, knotted “bow”), and it is attached to the stretched rubber band. After checking equipment and turning on the motor, the pilot pulls a cord, the knot untied and electroanalyt takes to the air.

In principle, a model with a well-chosen center of gravity and not having warps of the wings and tail and without your help can make a straight flight you have to just gently adjust the position of it in space. The fit at first is best done at the parachuting mode, for which the model at low speed is supplied to the ground (also into the wind!), then the engine turns off and at half-meter height, you begin to pick up the joystick rudder itself, until the model finally will lose speed and will not go to the parachuting mode. Well, if it happens on grassy lawn — in this case the model will be more likely to survive, you have to carry out another flight.

I. KHOROSHEVSKAYA

RC model-polyopia motor. Motors together with batteries increasingly gaining ground in the modeling. Today, the growing power motors and improved battery options allow you to create a comprehensive, well-flying model aircraft, including radio controlled.

RC model-polyopia motor. Motors together with batteries increasingly gaining ground in the modeling. Today, the growing power motors and improved battery options allow you to create a comprehensive, well-flying model aircraft, including radio controlled.