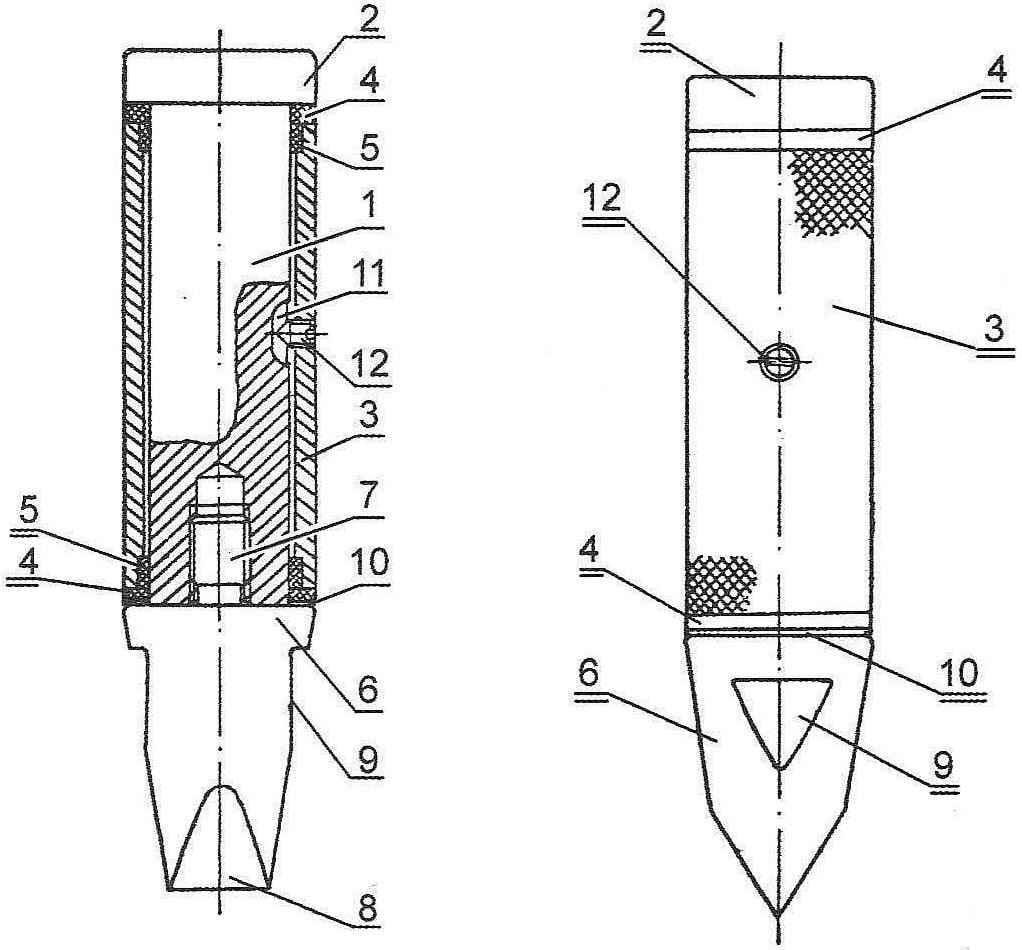

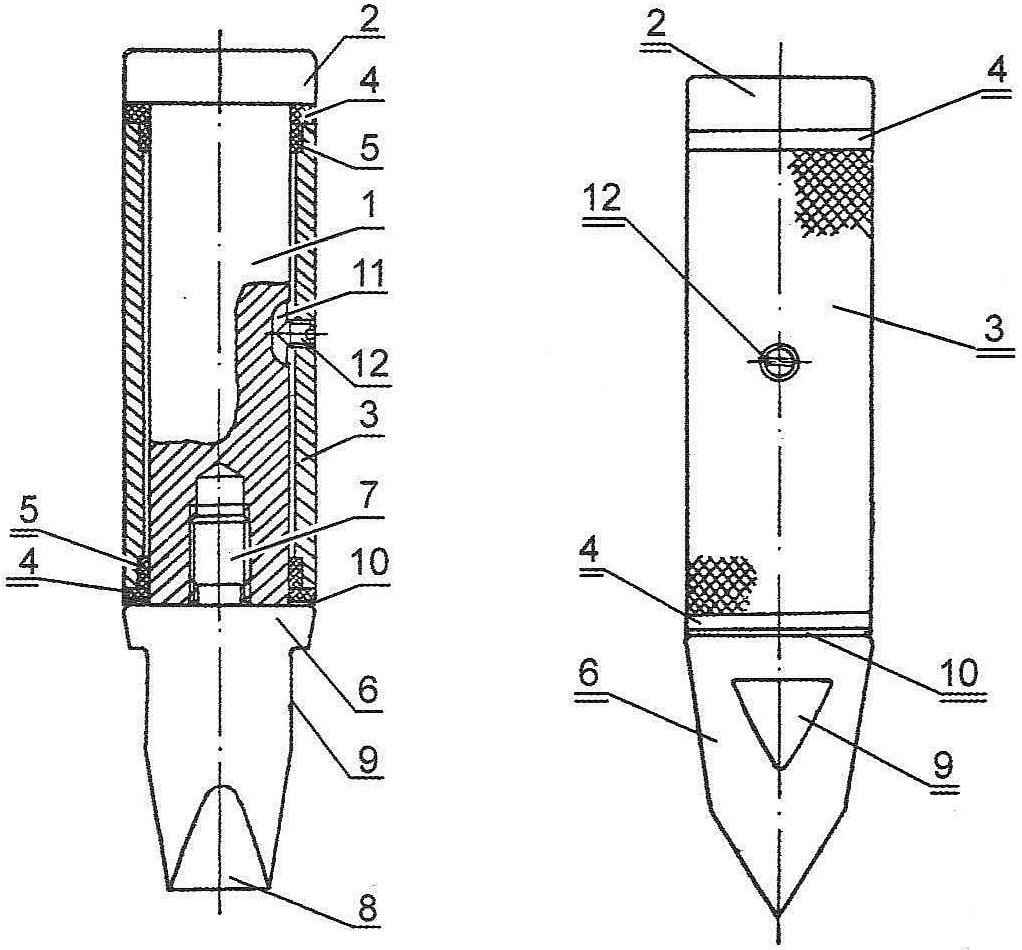

When conducting different kinds of work often have to use hand tool percussion: chisel, punch, jumper and others. To eliminate the negative impact response of the impact on a hard work surface, it seems appropriate to use anti-vibration device (Fig. 1, 2, 3) to which the thread mate replaceable shock elements. The figures shown docked replaceable chisel.

When conducting different kinds of work often have to use hand tool percussion: chisel, punch, jumper and others. To eliminate the negative impact response of the impact on a hard work surface, it seems appropriate to use anti-vibration device (Fig. 1, 2, 3) to which the thread mate replaceable shock elements. The figures shown docked replaceable chisel.

The device includes a tube holder, limited offer ends rubber buffer rings and cuffs, absorbing the energy of the reciprocating motion of the rod and completely insulating the operator’s hand from direct exposure to the work item. Depending on the nature and purpose of the work to stem anti-vibration devices can join a variety of interchangeable percussive elements in docking performance. To exclude a reversal on the surface of the terminal device is docked with the shock element is made a longitudinal groove in which moves a screw, which fixes the direction of movement of the rod.