After the termination of cooperation with the United States of works on creation of a promising tank MBT-70 in Germany, decided to design a tank of the 3rd generation of their own. By the time the tank in Germany was fully restored, and the German specialists have gained considerable experience in the creation and improvement of the main tank the Leopard 1.

After the termination of cooperation with the United States of works on creation of a promising tank MBT-70 in Germany, decided to design a tank of the 3rd generation of their own. By the time the tank in Germany was fully restored, and the German specialists have gained considerable experience in the creation and improvement of the main tank the Leopard 1.

A new tank was developed in 1967 and 1979 firms Krauss-Maffei AG (“Krauss-Maffei”, the General contractor), Porsche (miscellaneous structural design and the detailed design of the chassis), Wegmann (tower) and AES Telefunker (fire control system). While the German experts used many design solutions obtained in the joint with the Americans project. In particular, the test samples were fitted with a diesel engine, hydromechanical transmission, and other assemblies and systems, intended for the MBT-70. In the period from 1972 to 1974-th year it was built 16 buildings and 17 towers of the Leopard 2. Ten prototypes were armed with 105-mm rifled, and the remaining 120-mm smoothbore gun company Rheinmetal (“Ranma-tall”). Two machines were used hydropneumatic suspension, but the designers gave preference to the improved torsion.

In 1974, Germany has concluded with US an agreement on the standardization of certain components and assemblies in the development of future tanks. In accordance with the agreement, German experts developed main battle tank Leopard 2A/ with a new fire control system and posted a multilayer booking hull and turret.

This option was adopted by the Bundeswehr in 1977, the First production model was released by the factory of the company “Krauss-Maffei” in Munich in October 1979. To date, manufactured more than 3000 units.

Tank Leopard 2 has classic scheme of the overall layout. The driver’s hatch is in the front of the case closer to the starboard side. It partially overlaps the tower at the position of the gun forward. Despite the large angle of the upper frontal sheet (81°), the driver in the firing position operates the machine while sitting. Jobs of the tank commander and gunner are on the right of the gun, and charging — left. The height from the rotating Polycom crew compartment to the roof of the tower — 1650 mm, which is considered the minimum acceptable for normal work conditions charging standing.

Engine-transmission compartment with longitudinally mounted diesel engine is aft of the hull and isolated from the fighting compartment sealed refractory wall.

The hull and turret of the tank welded. The upper front hull has a large angle of inclination to the vertical, along with the use of spaced multi-layer armor like English “Cobham” provides a fairly effective protection against armor-piercing shells and anti-tank At the same time, the roof, the side and the bottom of the tank have a thickness of armor plates 20 — 70 mm, making it extremely vulnerable from attacks from above and laterally. In the roof of the niches of the tower above the ammunition installed expelling panel. Frontal vertical tower leaves beveled at angles of about 35° Additional protection of the sides from the cumulative ammunition is provided through the use of overhead screens, which is a steel box (1/3 the length of the screen) and reinforced rubber (2/3 length). The front section of screens have a thickness of 110-120 mm and reduce the width of the body when transporting the tank by rail and also for inspection and maintenance of the chassis can lean up on special brackets.

The hull and turret of the tank welded. The upper front hull has a large angle of inclination to the vertical, along with the use of spaced multi-layer armor like English “Cobham” provides a fairly effective protection against armor-piercing shells and anti-tank At the same time, the roof, the side and the bottom of the tank have a thickness of armor plates 20 — 70 mm, making it extremely vulnerable from attacks from above and laterally. In the roof of the niches of the tower above the ammunition installed expelling panel. Frontal vertical tower leaves beveled at angles of about 35° Additional protection of the sides from the cumulative ammunition is provided through the use of overhead screens, which is a steel box (1/3 the length of the screen) and reinforced rubber (2/3 length). The front section of screens have a thickness of 110-120 mm and reduce the width of the body when transporting the tank by rail and also for inspection and maintenance of the chassis can lean up on special brackets.

The main armament is a 120 mm smoothbore gun company “Rheinmetall” . The trunk has a heat shield, made of fiberglass, and ejector. The ejector is placed eccentric to the axis of the bore to increase the angle of descent the gun, and the barrel length is shifted closer to the breech in a zone of high pressure powder gases with the aim of increasing the effectiveness of its action. The inner surface of the gun tube strengthened by avtomatizovani. The persistence of the barrel is not less than 500 shots.

Shutter vertical wedge.

To improve the accuracy of shooting two brakes rollback located symmetrically on the gun. Pipe connection stem with a quick release breech made in the form of a sector of thread. Mounting and Dismounting the gun in the repair are carried out through the embrasure of the tower, without removing the latter.

The ammunition consists of 42 unitary shots with a partially combustible case, 15 of whom are left in the rear recess of the tower beyond the fences. The loading time of this stacking is 6 s. the Rest of the ammunition (27 rounds) is placed in the compartment to the left of the driver. Gun loading is done manually.

Used for shooting shots with armor-piercing projectiles DM1З with a core of tungsten alloy and multi-cumulative fragmentation shells DМ12. In 1983, the ammunition was introduced selinocarpus armor-piercing projectile and DM23 in the same year, took arms armor-piercing projectiles DMЗЗ core having increased the value of the ratio of length to diameter of tungsten alloy with a diameter of 28 mm.

After the shot tray liner enters hiltulanlahti mounted on the gun and having a suction powder gases. Removal of pallets from the tank and to load ammunition used hatch in the left side of the tower.

In addition to guns, the tank is armed with coaxial 7.62-mm MG3 machine gun and anti-aircraft machine gun of the same caliber mounted on the loader hatch. On the sides of the turret mounted on the block of eight smoke grenade launchers.

The fire control system (FCS) developed by STN Atlas in cooperation with the company Electronic Zeiss Optronik GmbH. The main elements of MSAS are combined periscopic laser sight-rangefinder gunner EMES15; panoramic periscope sight-surveillance device commander PERI-R17, auxiliary telescopic articulated gunner’s sight FERO-Z18; analog electronic ballistic computer FLT2; electro-hydraulic weapon stabilizer WНА-N22, the system of internal control of the functioning of the QMS; collimation system of internal reconciliation.

The main gunner’s sight is combined with a laser rangefinder, has a thermal imaging channel for shooting night at ranges up to 2000 m. Field of view independently stabilized in two planes. The range of measurement range laser rangefinder is 200 — 10,000 m. To protect the gunner’s eyes from laser irradiation in the optical channel sight installed filter. When shooting at night, the button “Shot” to trigger a special curtain that covers the field of view to avoid blinding flash of his own shot.

In the tank provides duplicate control of gun fire from the commander. Day sight-surveillance device РЕRI-R17 has an independent stabilization of the visual field in two planes. It is associated with the main gunner’s sight, allowing the commander to use a laser rangefinder, ballistic computer and night thermal channel. However, in case of failure of the gunner’s sight, the commander loses the ability to duplicate the fire control night.

Information about the distance to the target enters the ballistic computer, which also takes into account the angular speed of the target in the vertical and azimuth, speed and wind direction, air temperature, barometric pressure, and the roll angle of the gun trunnion. Temperature data charges and barrel wear are entered into a computer manually.

Reconciliation of sight is produced without the output of crew from the machine. Through the mechanisms of reconciliation, it is sufficient to match the aiming mark of the sight-rangefinder with observe in his field of vision viverone brand collimator.

The armament is stabilized in two planes. Drives guidance — electro-hydraulic with accumulator. Access to the hydraulic system is provided through a special hatch in the roof of the tower. In case of failure of electro-hydraulic actuator is used backup manual hydraulic vertical and horizontal aiming. The maximum speed of the guidance in the horizontal plane and 48 deg/s vertically — 9.5 deg/s. pointing Angles in the vertical plane from -9° to +20°.

Preparation time aimed shot gunner when firing on the move is 15, the commander — 17 C. When firing from the place that time is reduced accordingly up to 9 -10 11 — 12 S.

The tank is installed four-stroke 12-cylinder V-shaped diesel engine MB 873 Ка501 liquid cooling with turbo-supercharging and intermediate cooling in air cylinders. Engine — multi-fuel, can run on fuel of various sorts, including aviation kerosene and gasoline. On engine equipped with two turbochargers and two charge air cooler included in the cooling system. The air supply enters through two air cleaner, mounted on both sides of the engine and connected by short pipes with turbos.

Double-flow hydromechanical transmission HSWL-354/3 provides four forward and two reverse speed planetary transmission with two degrees of freedom has auto-switching. In the transmission part of the rotation mechanism of the differential type, the volumetric hydraulic transmission which allows for rotation from the estimated radius for each gear. Around the axis of the tank takes place for 10 seconds. Stopping brakes are combined with hydrodynamic retarder and two mechanical disc brakes running in oil. They provide a stop of the tank when driving with a maximum speed of over 3.6 s.

The chassis includes a tank (on the side) seven rollers and four support rollers, leading and guiding wheels and tracks with rubber hinge. Truckee have removable rubber cushion. Suspension individual torsion bar with disc friction dampers on the first, second, sixth and seventh support rollers. Rims saddle rollers made of aluminum alloy. Shed support rollers installed in a checkerboard pattern: one is under the internal, near to the Board and the other under the outer part of the upper branch of the caterpillar.

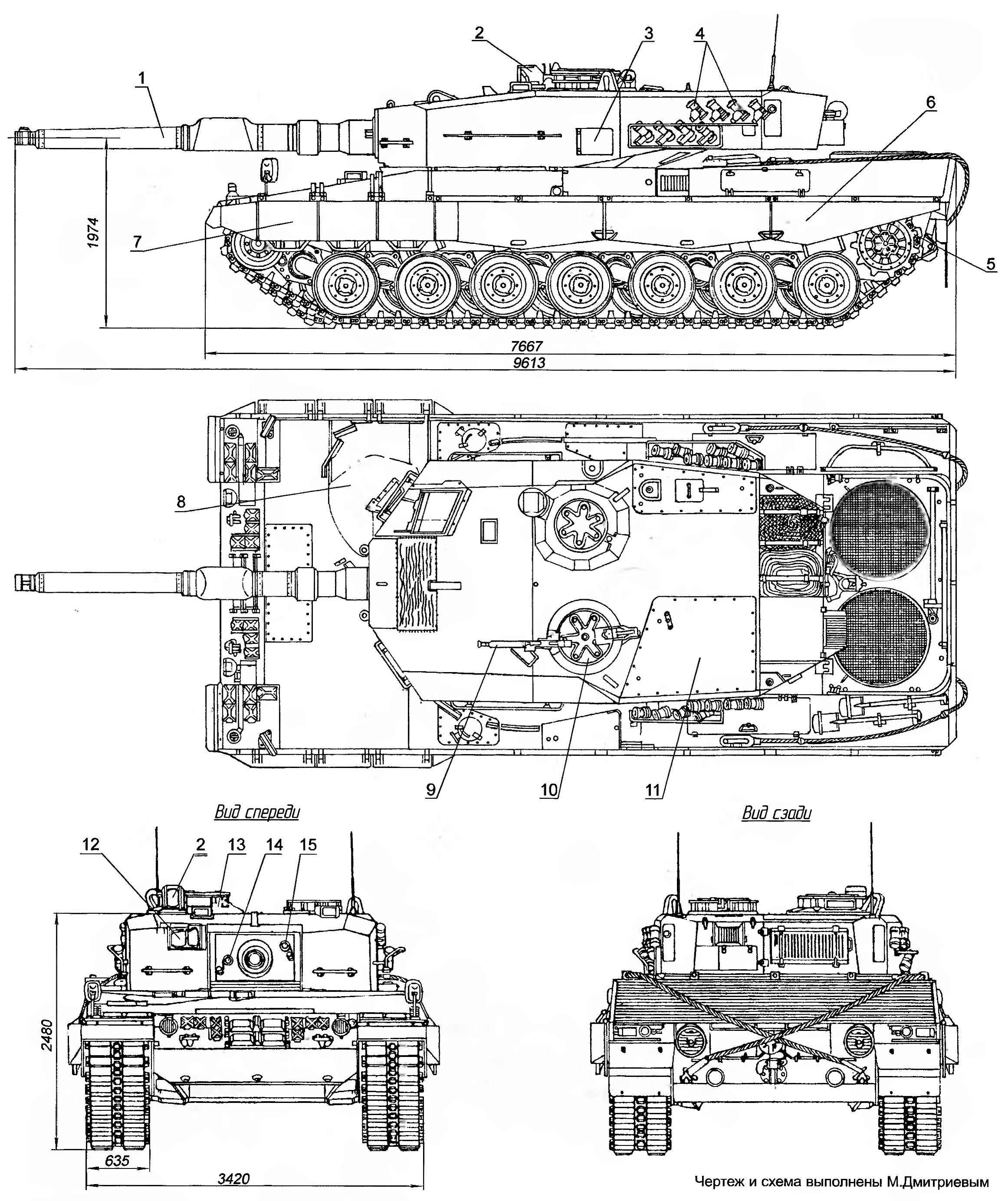

Main battle tank “Leopard” 2А1:

1 — 120-mm gun “Rheinmetall” Rh-120;

2 — periscope sight-surveillance device commander РЕRI-R17;

3 — Luc for removal of pallets from the tank;

4 — 76-mm smoke grenade launchers;

5 — driving wheel;

6—anti shaped-charge hinged screen is made of reinforced rubber;

7—the front section of the screen (steel box);

8 — driver’s hatch;

9 — anti-aircraft gun MGЗ (views from the side, front and rear conventionally not shown);

10—Luke loader;

11 — lifting the bar above the ammo rack 120-mm rounds;

12 — laser sight-rangefinder ЕМЕЅ15;

13 — commander’s cupola;

14 — loophole telescopic sight FERО-Z18;

15 — recess coaxial machine gun МGЗ.

The tank is equipped with system of protection against weapons of mass destruction (WMD), a heater of the fighting compartment and high-speed automatic fire-fighting equipment (PPO). In overcoming water obstacles along the bottom above the hatch of the commander of the installed pipe-a manhole, the support tower is sealed rubber chamber to which air is supplied from a manual pump on the exhaust nozzles of the engine are mounted check valves and put the seal of sight and coaxial machine gun.

The above description corresponds to the first basic modification of the tank Leopard 2. In 1979 — 1982 factory shop left 380 such machines.

On the tank “Leopard” 2А1 (produced in 1982-1984) was installed thermal sight, reinforced body armor (new filler in the combined armor), improved reliability of several systems and components. There were produced 750 units, and in addition, all the tanks Leopard 2 has been upgraded to the level of 2А1. These tanks were designated Leopard 2A2.

300 tanks modifications “Leopard” 2АЗ (1984 — 1985) established a new radio station IM 80/90, upgraded Parking brake and made other small improvements. Introduced three-color camouflage pattern.

Tanks “Leopard” 2A4 (1985 — 1990, 695) appeared digital ballistic computer, the new system of PPO, the ammunition was introduced DМЗЗ shot with armor-piercing projectile with a core.

The most significant changes were made to the design of the tank Leopard 2A5 (1995 — 1998 up to this level, upgraded 225 vehicles 2A4). In the frontal parts of the tower and machine body mounted modules armour with elements built-in dynamic protection, introduced spall liners, electric stabilizer, upgraded FCS Krupp Atlas. In the commander’s panoramic sight built in to the infrared camera, the image of which is displayed on a special indicator. This enables the tank commander to independently monitor the situation on the battlefield in the dark. In the laser rangefinder combined gunner’s sight uses an advanced processor eliminates the secondary, a false echo. The combat weight of the tank made up to 62.5 t

The last modification of the main German tank was the Leopard 2A6 (2001 — 2003), which is “Leopard” 2A5, armed with 120-mm cannon with a barrel length of 55 calibres. The ammunition introduced the DM 53 projectile with an initial velocity of 1750 m/s. Fire these projectiles can be carried out at ranges up to 5000 m. the High efficiency of the projectile on the target is achieved due to its long length, mass, flight speed and high-strength material used for its production. He holds a solid of a special alloy of depleted uranium. In a variant of the 2A6 has been upgraded all 225 tanks Leopard 2A5.

The last modification of the main German tank was the Leopard 2A6 (2001 — 2003), which is “Leopard” 2A5, armed with 120-mm cannon with a barrel length of 55 calibres. The ammunition introduced the DM 53 projectile with an initial velocity of 1750 m/s. Fire these projectiles can be carried out at ranges up to 5000 m. the High efficiency of the projectile on the target is achieved due to its long length, mass, flight speed and high-strength material used for its production. He holds a solid of a special alloy of depleted uranium. In a variant of the 2A6 has been upgraded all 225 tanks Leopard 2A5.

All the above modifications were done by the Bundeswehr. However, it is impossible to ignore and variants of this tank, arrived and entering the army of other countries. Especially that Leopard 2 is one of the few modern tanks, whose production continues to this day, mostly for export.

The first “foreign” version was Leopard 2NL, intended for the armed forces of the Netherlands. In 1982 — 1986 in this country was delivered 445 tanks. They represented the variants of the A4, equipped with a 7.62-mm machine guns FN МАG, 12 smoke grenade launchers (6 on each side of the tower), radio station and a surveillance device of the driver of the Dutch production. In 1997 — 1998 114 tanks the Dutch put Austria, and in 2001 — 2002 57 tanks — Norway. From 1996 to 2000, 180 tanks were refit in the version “the Leopard” 2А5NL. Since 2003, 180 tanks Leopard 2NL. undergo refurbishments in the version “the Leopard” 2А6NL.

In 1995 and 1996, Spain received under lease 108 tanks “Leopard” 2, operated in the Spanish army, but belonging to the Netherlands.

In December 1998 between Germany and Spain was awarded the contract on licensed production of 239 tanks Leopard 2A5. Their serial production was to be carried out on the company’s General Dynamics Santa Barbara Sistemas. Almost immediately after the appearance of the 120-mm cannon with a barrel length of 55 calibres project 2А5Е turned into 2А6Е.

The first production tank made in Spain, left the factory shop in the end of 2003. The production program was scheduled for completion by March 2008. However, to date, apparently due to financial difficulties, made only 20 cars.

There is evidence of a new contract providing for a release of 249 tanks in the period from 2006 to 2016. Probably talking about renegotiating the old contract with extension of terms of deliveries and a slight increase in their volume.

In December 1985, the Swiss Parliament decided to purchase 380 tanks “Leopard” 2 and taking them into service under the designation PZ.87. The first 35 machines manufactured in Germany, and the rest — the Swiss state tank factory RUAG Land Systems in Thun until 1993 with the tempo build 73 cars per year. RZ.87 corresponds to the option A4, but it has machine guns the Swiss model, the American radio station AN/VRS-12, the new English system of PPO and an improved system of anti-nuclear protection, there are a number of other, smaller improvements.

Layout scheme of the tank “Leopard” is the 21st production of the series:

1 — 120-mm gun;

2 — ejector;

3 — rear view mirror;

4 — cover of the driver’s hatch;

5. the damper loopholes laser sight-rangefinder;

6 — periscope surveillance device;

7 — panoramic periscope sight-surveillance device commander;

8 — the commander’s seat;

9 — commander’s cupola;

10 — electronic ballistic computer;

11 — wind sensor;

12 — the ammo rack in the turret for 15 shots;

13 — launcher;

14 — hatch for discharge of pallets;

15 — Luke loader;

16 — seat charging;.

17 — coaxial machine gun;

18 — the ammo rack in the hull on 27 shots;

19 — the seat of the driver;

20 — fan

21 — ring radiator;

22 — battery.

In 1994 a contract was signed for the supply of 160 tanks “Leopard” 2A4 from Bundeswehr in Sweden where these machines received the designation Strv 121. In December 1997 the Swedish army gave the first of 120 ordered the Leopard 2A5. While 29 of them were manufactured in Germany and Sweden (firm BAE Systems Bofors carried out production of the towers, after which they were equipped in Germany with the company Wegmann and returned to Sweden, just as firms BAE Systems Hägglunds and “Krauss-Maffei” going hull), and 91 only in Sweden under license. The tank, called Strv 122, became the first in Europe fighting machine, equipped with TIUS.

In 2002, the Greek army selected the latest modification of the tank Leopard 2 as their main battle tank for the future. In 2003 a contract was signed for the supply of 170 tanks Leopard 2А6ЕХ in the period from 2006 to 2009, received in Greece the designation “Leopard” 2НЕL. The first 30 machines have been collected by the company “Krauss-Maffei” Wegmann, and the remaining 140 — Greek company ЕLVO. 56 of the 170 tanks of cars made in the commander’s variant with additional communications equipment. All the tanks “Leopard” 2НЕL feature TIUS Iniochos Rheinmetall Defence Electronics, computerised FCS and a thermal imaging system Ophelios. The first tank “Leopard” 2НЕL enrolled in the trial in 2005. The exact number made combat vehicles of this type currently difficult to tell, but there is every reason to believe that due to the financial crisis, the arrival of tanks seriously behind schedule.

In 2005, Greece was set 183 Leopard 2A4 from Bundeswehr.

It should be noted that a large family of combat and support vehicles, as was the case with the Leopard 1, based on the tank Leopard 2 was not created. The only exception was armored reconnaissance and recovery vehicle (BRAM) and training tank, without which it was impossible to do.

BRAM ВРz 3 Büffel (“Buffalo”) was developed in 1986 to 1989 for technical support tank units of the land forces of the Bundeswehr. The machine is equipped with a crane, load capacity (up to 30 t by relying on the dozer blade) is limited to special electronic unit.

The latter takes into account the sideways movement of the machine, the angle of elevation and the boom, preventing overload and ensuring safe operation. Boom can rise to a height of 7.9 m, its forward flight is 4.7 m, the right — 5,9 m Suspension is designed for towing equipment weighing up to 61 tons In a combat situation or on the infected area the crew (three people) from the comfort of BRAM, can install rigid hitch on the damaged car. On ВРz 3 there are a variety of remotemachine equipment and accessories: pullers, blocks, hooks, cables, apparatus for electric welding and metal cutting, pumps for fuel filler neck reconditioned. Booking offices for the crew provides protection against projectiles caliber 20 mm. the Machine is equipped with an air conditioner (used for heating), system of protection against weapons of mass destruction and fire fighting equipment. BRAM armament: 7.62 mm machine guns and 16 smoke launchers (eight front and back of the case). Vehicle weight — 54,3 t, the maximum force of the main winch — 34, 4 t, the length of the cable of 180 m. the Maximum speed is 68 km/h.

The latter takes into account the sideways movement of the machine, the angle of elevation and the boom, preventing overload and ensuring safe operation. Boom can rise to a height of 7.9 m, its forward flight is 4.7 m, the right — 5,9 m Suspension is designed for towing equipment weighing up to 61 tons In a combat situation or on the infected area the crew (three people) from the comfort of BRAM, can install rigid hitch on the damaged car. On ВРz 3 there are a variety of remotemachine equipment and accessories: pullers, blocks, hooks, cables, apparatus for electric welding and metal cutting, pumps for fuel filler neck reconditioned. Booking offices for the crew provides protection against projectiles caliber 20 mm. the Machine is equipped with an air conditioner (used for heating), system of protection against weapons of mass destruction and fire fighting equipment. BRAM armament: 7.62 mm machine guns and 16 smoke launchers (eight front and back of the case). Vehicle weight — 54,3 t, the maximum force of the main winch — 34, 4 t, the length of the cable of 180 m. the Maximum speed is 68 km/h.

The initial production program provided release 100 BRAM Buffel: 75 — for the Bundeswehr and 25 for the Dutch army. As of 2007 BRAM this type are in service in Germany (75 units), the Netherlands (25), Greece (12), Spain (received 4 from Germany, another 12 should be manufactured in Spain), Sweden (14) Switzerland (25).

The initial production program provided release 100 BRAM Buffel: 75 — for the Bundeswehr and 25 for the Dutch army. As of 2007 BRAM this type are in service in Germany (75 units), the Netherlands (25), Greece (12), Spain (received 4 from Germany, another 12 should be manufactured in Spain), Sweden (14) Switzerland (25).

For the training of tank drivers, the Leopard 2 was developed by the educational tank, similar in construction training tank “Leopard” 1. Bundeswehr delivered 22 cars, the Dutch army — 20. On the body of the tank is installed a rotating cabin, the layout of the gun barrel. In the cockpit are an instructor and two trainees. The instructor installed redundant controls of the tank, so he can correct the mistakes of the third student, sitting in the seat of the driver.

The first serial tank Leopard 2 was handed over to the Bundeswehr October 25, 1979. Currently these cars equipped all personnel of tank battalions. In the fighting tanks “Leopard” 2 never participated. From 1999 to the multinational peacekeeping force in Kosovo — КFOR — were part of 214th tank battalion (PZ.Вtl.214) of the Bundeswehr, armed with tanks “Leopard” 2A5. As part of the multinational forces in Bosnia — SFOR — in 2003 was the 101st tank battalion of the Dutch army, also equipped with tanks Leopard 2A5.

As of 1 January 2010 tanks “Leopard” 2 of various modifications was in service with Austria (114 units, the former Dutch), Germany (over 1000, of which 225 Leopard 2A6), Greece (183 Leopard 2A4), Denmark (57 “Leopard” 2А50К), Spain (128, 20 “Leopard” 2А6Е), the Netherlands (262 A5 and A6), Norway (57, former Dutch), Poland (128 Leopard 2A4), Portugal (37 Leopard 2A6), Singapore (96 Leopard 2A4, 30 of them are designed for disassembly for spare parts), Turkey (298 Leopard 2A4), Finland (124 Leopard 2A4), Chile (118), Switzerland (380) and Sweden (280).

The PERFORMANCE characteristics of the Leopard 2

Combat weight, t……………………………….55,15

Crew.,………………………………………4

Crew.,………………………………………4

Overall dimensions, mm

— length…………………………………………9670

— width………………………………………3700

height (over turret roof)…………..2790

— clearance………………………………………490

Engine:…………….МТ11 MB 873 Ka-501,

power 1500 HP (1100 kW) at 2600 rpm.

Maximum speed, km/h……………..72

Reserve, km…………………………………..550

Overcoming obstacles:

— the angle of elevation, deg…………………………30

— the width of trench, m………………………………….3

— wall height, m……………………………1,1

— fording depth, m………………………….0,8*

*OPVT — 4 m

Atideo: