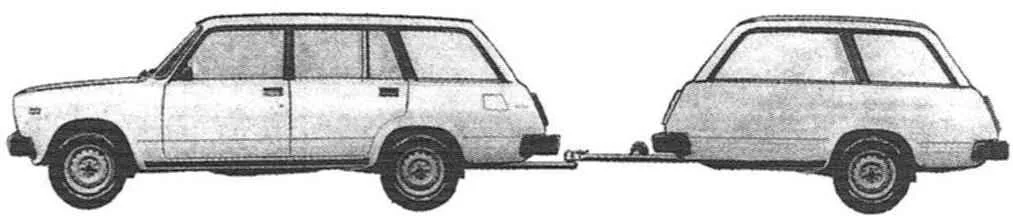

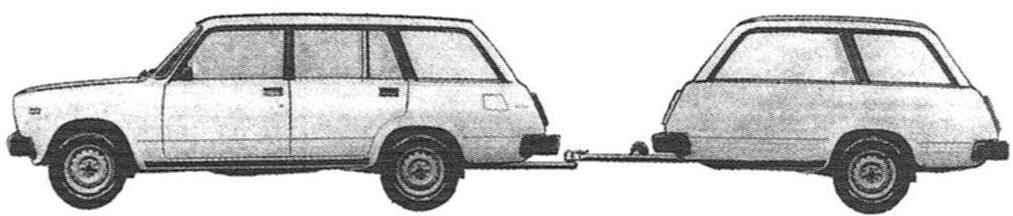

Universal trailer for a passenger car. My wife and I often leave your car in the recent trip to fish on the lake, in the woods for mushrooms. And in these travels we never get enough of the trailer, a kind of compact, camper, and where you can safely sleep and eat, regardless of what the weather today. Of course, you could buy a tent, but we’re not hunters to relax under a fabric roof. While we do not want to buy or build bulky the cottage-trailer (camper) – was enough to dvuhmestnoe bedroom on wheels, which could be easily transformed into a double of the same dining room.

Universal trailer for a passenger car. My wife and I often leave your car in the recent trip to fish on the lake, in the woods for mushrooms. And in these travels we never get enough of the trailer, a kind of compact, camper, and where you can safely sleep and eat, regardless of what the weather today. Of course, you could buy a tent, but we’re not hunters to relax under a fabric roof. While we do not want to buy or build bulky the cottage-trailer (camper) – was enough to dvuhmestnoe bedroom on wheels, which could be easily transformed into a double of the same dining room.

A constructive idea such a mini-camper was borrowed from the description in the journal “modelist-Konstruktor” 1970-ies of the trailer B. Vishnevsky, which he created for his “zhigulenka” from the back of a broken “penny”.

I liked the idea, only as the foundations for the future camper I used body two emergency wagon VAZ-2104. Preliminary exploration showed that road dumping of such wrecked cars lying around a lot now.

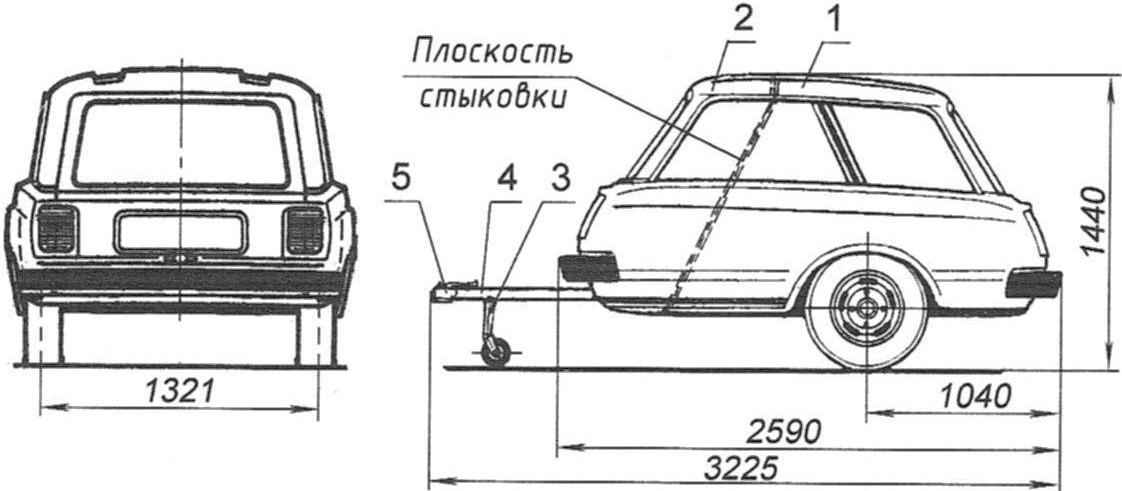

The basis of my camper steel two piece cut out of the rear parts of two bodies – one of them the main with a length of about 2100 mm, measured from the rear bumper of the body (it turned out to be the rear part of the trailer), and a second additional length of about 1150 mm (to front of camper).

Universal enclosed trailer camper:

1 – rear of the trailer (from the back of the body VAZ-2104);

2 – the front end of the trailer (from the back of the body VAZ-2104);

3 – folding suspension with swivel wheel;

4 – the frame of the trailer;

5 – towbar

To start with fragments of the body I cut and cut all unnecessary hardware, then docked them into a single unit so that the total length of the camper body amounted to 2590 mm (bumper to bumper) – it turned out the optimal match curved contours of the front and rear portions of the future trailer. Docking was carried out in several stages, by successive approximations, while for temporary connection of the shells used pads from strips of steel banding and screws M4 with nuts. After the selection of the optimal mutual arrangement of the camper body were finally connected by using a pre-prepared lining of the steel strip section 2,5×40 mm installed from inside body, and 4 mm bolts with nuts. Fasteners are installed with a pitch of about 50 mm. finally, all compounds were docked intermittent seam carbon dioxide-arc welding.

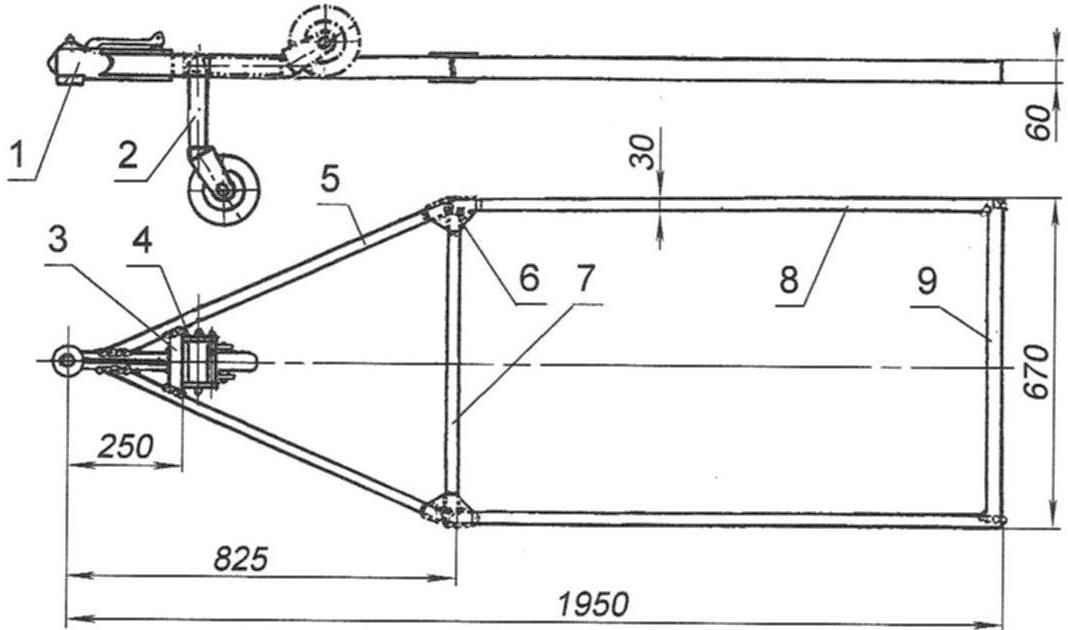

The frame of the trailer, consisting of spars, tiller and cross members, welded from steel pipes of rectangular section 30×60 mm. frame Width is 670 mm, which corresponds to a location on the underbody regular “Zhiguli” of the spars.

In the front part of the drawbar has a standard travostino unit, placed under the ball element of the hitch with a diameter of 50 mm.

In addition to the traction device in the front part of the drawbar mounted retractable auxiliary suspension with swivel wheel with diameter of 250 mm – it moves the camper in the Parking lots is not an example easier.

The frame of the trailer:

1 – standard tow hitch under the ball with a diameter of 50 mm;

2 – folding suspension with swivel wheel with diameter of 250 mm;

3,7,9 – crossmember (steel, pipe 30×60),

4 – hinge-retainer-folding support;

5 – pole (steel, pipe 30×60);

6 – scarf (steel, s);

8 – bulkhead (steel, pipe 30×60)

Suspension of the rear wheels of the trailer is virtually identical from the back “the Zhiguli”. However, solid rear axle with axle shafts and the differential had to be replaced by a steel pipe with a diameter of 60 mm, privaris to her pre-flanges for mounting two hubs “Zhiguli” of the front wheels. Accordingly, a new rear axle welded bearing Cup suspension springs, mounting brackets trailing arms, mounting bracket transverse rod and mounting brackets shock absorbers. In short, the tube was carefully transferred all assemblies regular “Zhiguli” of the bridge.

Camper has two doors (the back doors of VAZ-2104), but in trips, we use only one, rear. However, brewing your front door does not suggest – sometimes you have to carry in the trailer “gauges” (pipes, boards, slats), and in these cases, the presence of the front door facilitates the loading and transport of such materials.

The lack of a propeller shaft and a differential enabled to cut the shell of the tunnel, in which he was located to significantly lower the level of the floor. Formed in the bottom of the holes were patched with patches from a sheet of 1.5 mm steel, fixed intermittent seam carbon dioxide arc welding.

The flooring in the camper is made of 12-mm plywood, which rests on the wooden crossbars. To protect the wooden components from moisture they all covered with two coats of varnish parquet.

About the interior of a camper, I will not tell – it belongs entirely to your discretion. I can only suggest that in my trailer on top of the flooring laid travel sleeping mats, and on top of them – furniture fabric.

I. TEREKHOV