There is a whole range of different mechanisms for various kinds of sealing and tamping in construction from rollers to vibrotables. The device, created at the Central scientific-research and design-experimental Institute of organization, mechanization and technical assistance construction, will be indispensable where you want a layered soil compaction when backfilling the dug-up trenches, especially if the work is performed in cramped conditions in close proximity to foundations, pipelines, sewers.

There is a whole range of different mechanisms for various kinds of sealing and tamping in construction from rollers to vibrotables. The device, created at the Central scientific-research and design-experimental Institute of organization, mechanization and technical assistance construction, will be indispensable where you want a layered soil compaction when backfilling the dug-up trenches, especially if the work is performed in cramped conditions in close proximity to foundations, pipelines, sewers.

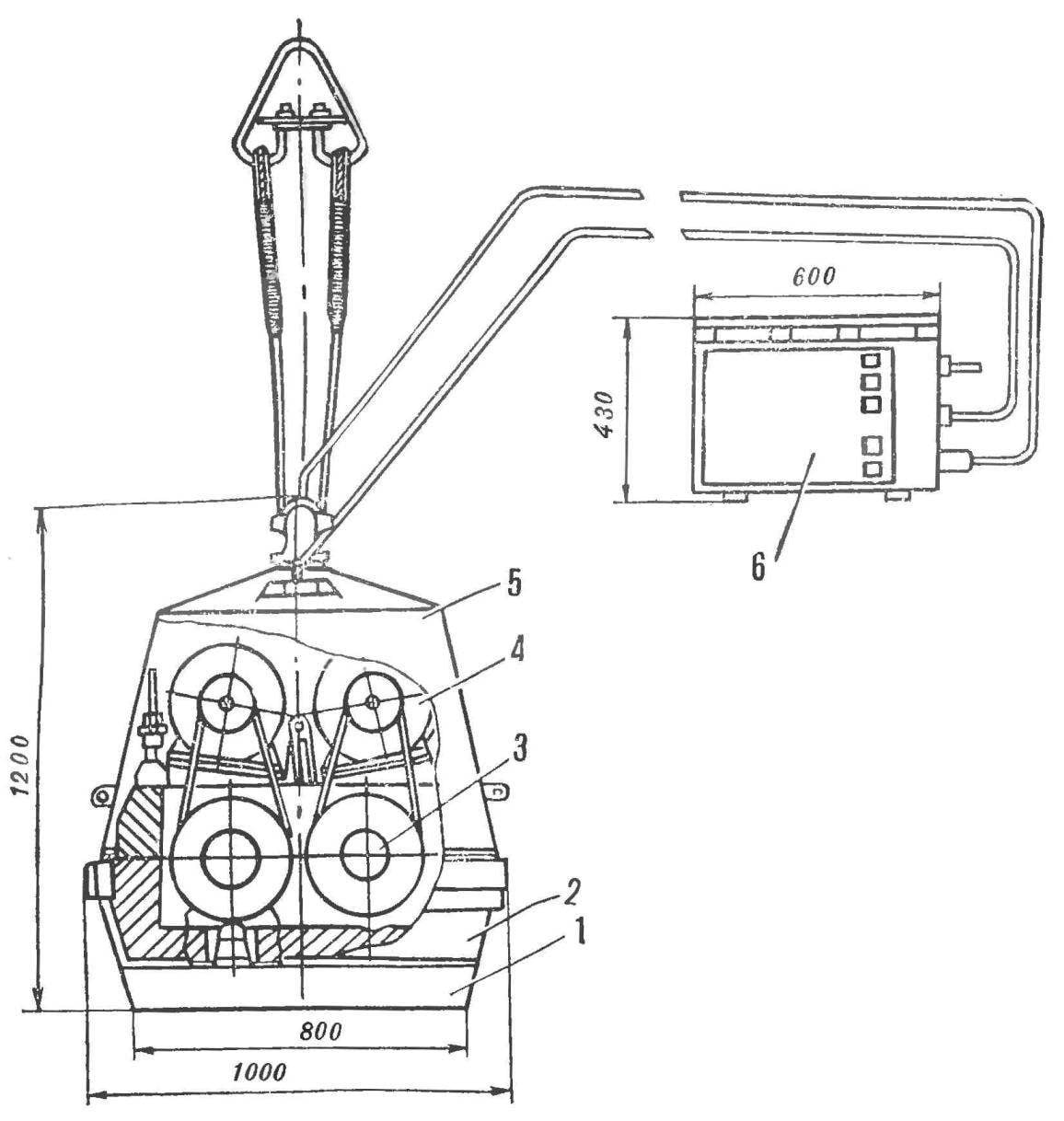

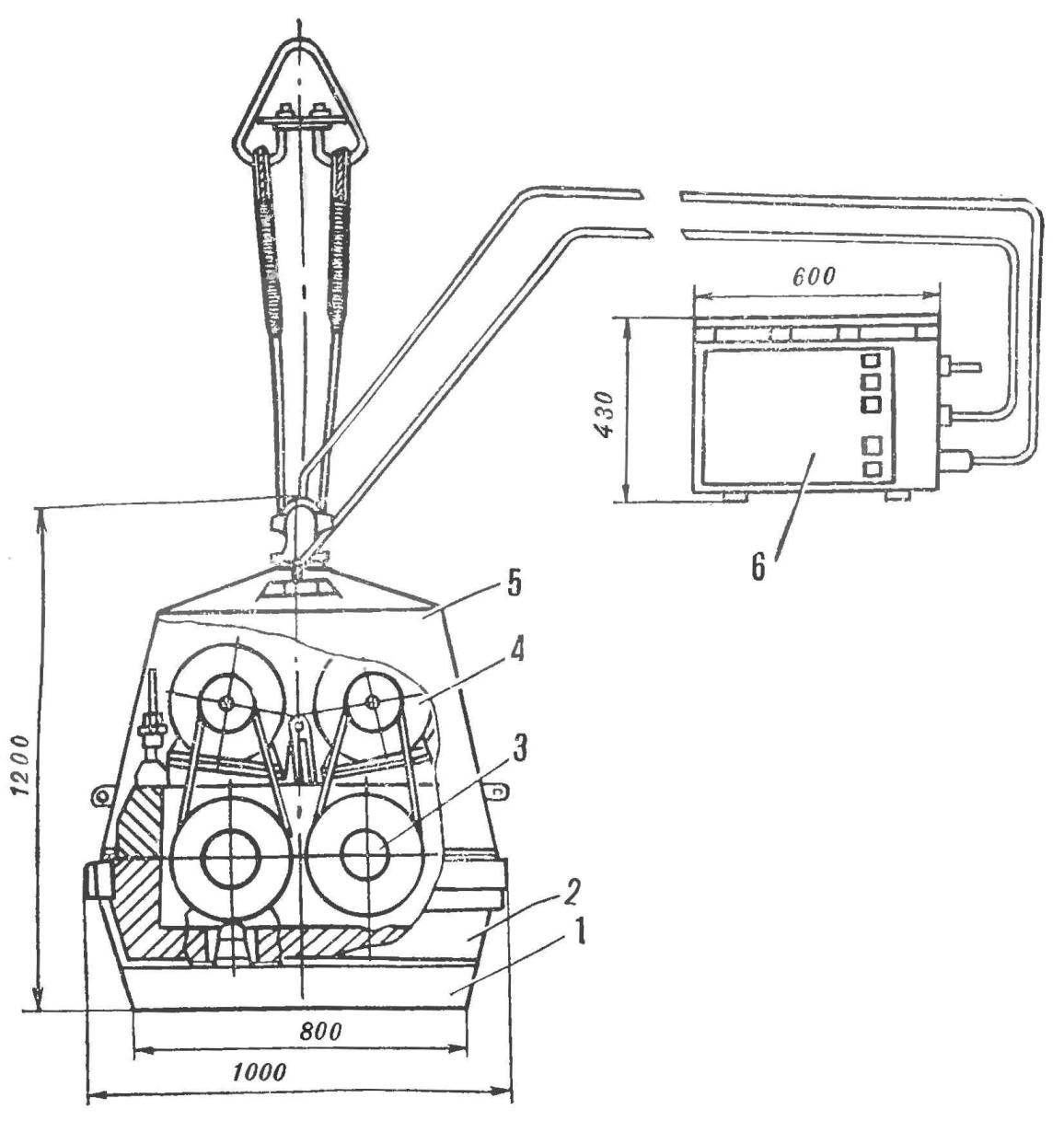

One of the main advantages rammers HTP-3 (see Fig.) is that it hanging: with a crane or excavator can be enjoyed where to get another gear is hard.

On the device OEM 3 refers to the eccentric vibratable with unbalanced vibro-exciter of vibrations of the base plate. However, such mechanisms it differs in that it is the causative agent of oscillations and “disturbing” as the builders, weight serves as a monolithic body constituting the main weight and the swing weight is lighter underside of the sealing plate. Due to this, the HTP-3 can significantly increase the energy of the blows and the time of exposure to the soil, reducing at the same time several times power consumption.

Suspended tamper:

1 — plate, 2 – body, 3 — eccentric shaft, 4 — actuator, 5 — casing, 6 — the control Cabinet.

To eliminate dynamic loads on the machine to which the tamper is suspended, it is only activated after the installation on the ground, and turns off when lifting to move to a new location. Control HTP-3 is focused on a special case-the remote.

Performance of ramming up to 80 m3 of compacted soil per hour. The use of rammers OEM 3 showed that the annual economic effect from implementation of each machine can reach 8 thousand.