Many accidents occur due to technical reasons, including due to faults of the brake system of the vehicle. One of the indicators of the effectiveness of this system is the braking distance, which for different categories of vehicles is regulated by state standard. Determined he may be on a special stand.

Many accidents occur due to technical reasons, including due to faults of the brake system of the vehicle. One of the indicators of the effectiveness of this system is the braking distance, which for different categories of vehicles is regulated by state standard. Determined he may be on a special stand.

However, the lack of these costly installations in private service areas, many transport companies and, often, even service stations can not objectively judge the usefulness of the adjustment or repair of the brake system of the vehicle before releasing it outside the gate. In such circumstances replacement of desktop stand are simple, cheap and mobile device—the task is very urgent.

Device “uatk-70”, developed at the Ufa motor transport College, helps as the stand, to determine the absolute value of the braking distance. The advantages of the device is simplicity of construction and operation, as well as the possibility of manufacturing in any production environment. In addition, it allows you to more objectively assess the value of the stopping distance compared to the stationary stands—through the use of the calculator in the overall scheme of the deliverer rpm and a torque sensor incorporating the brake.

For measurement accuracy, regardless of the nature of the inhibition and exclusion of additional operations in preparation for work in the design of the device is applied to the additional wheel easily coupled to the subject vehicle.

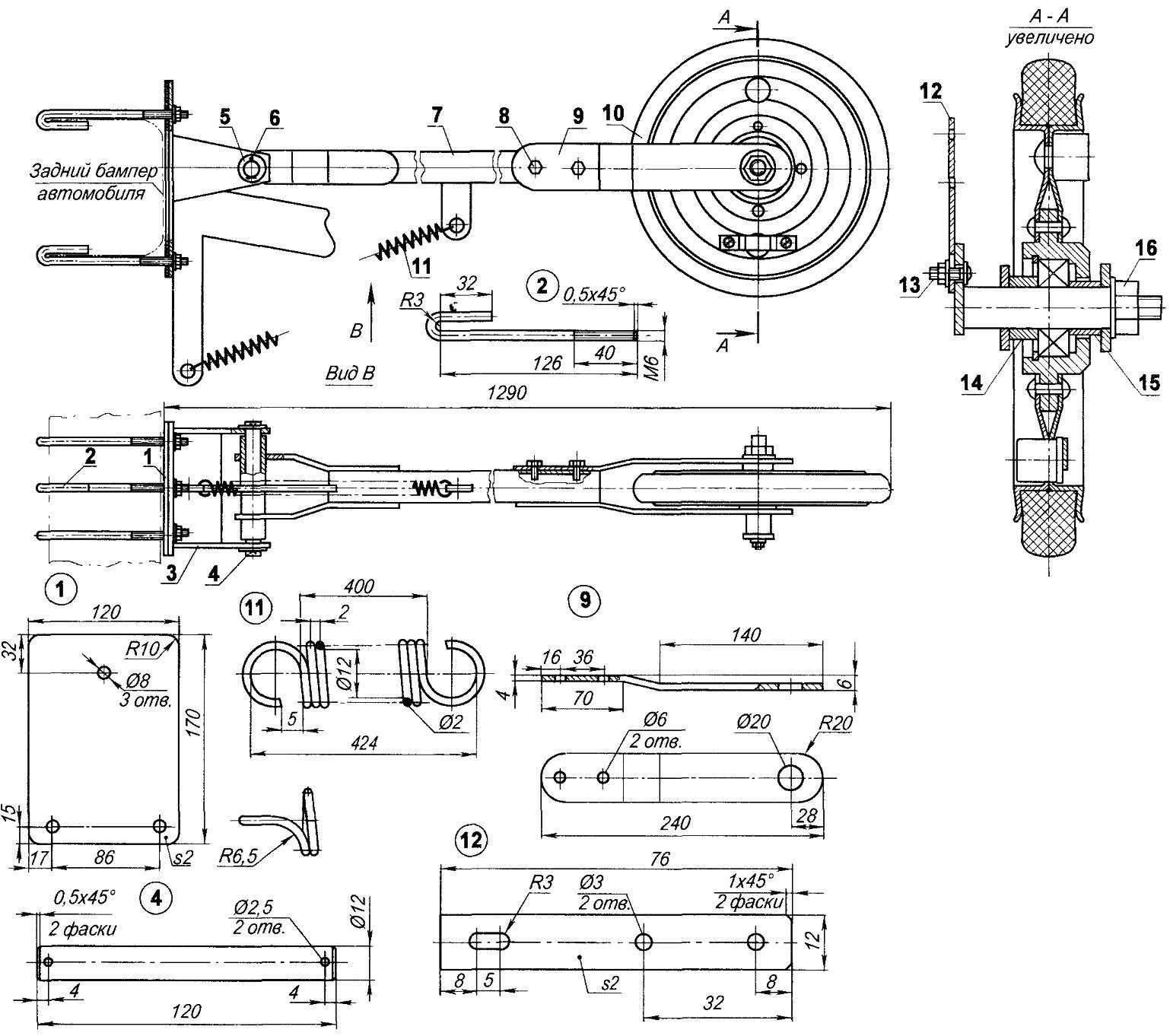

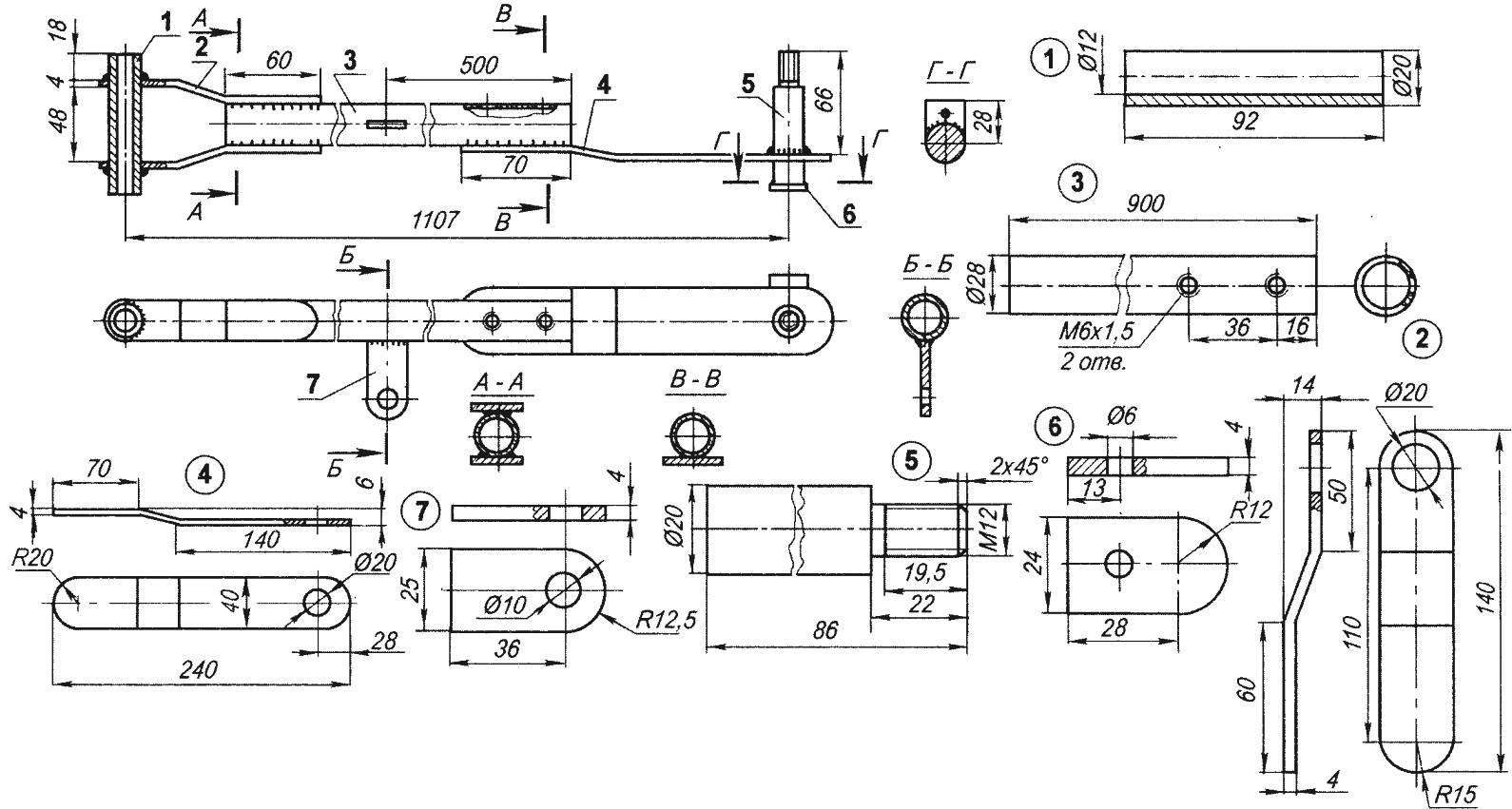

Thus, the device is divided into two parts: mechanical and electrical. In turn, the mechanical part consists of an outdoor unit (wheel Assembly with a permanent magnet, a bracket, rod and speed sensor) that is attached to the rear bumper, and interior (strap sensor power brakes), which is mounted at a bracket of a brake pedal in the cab of the vehicle.

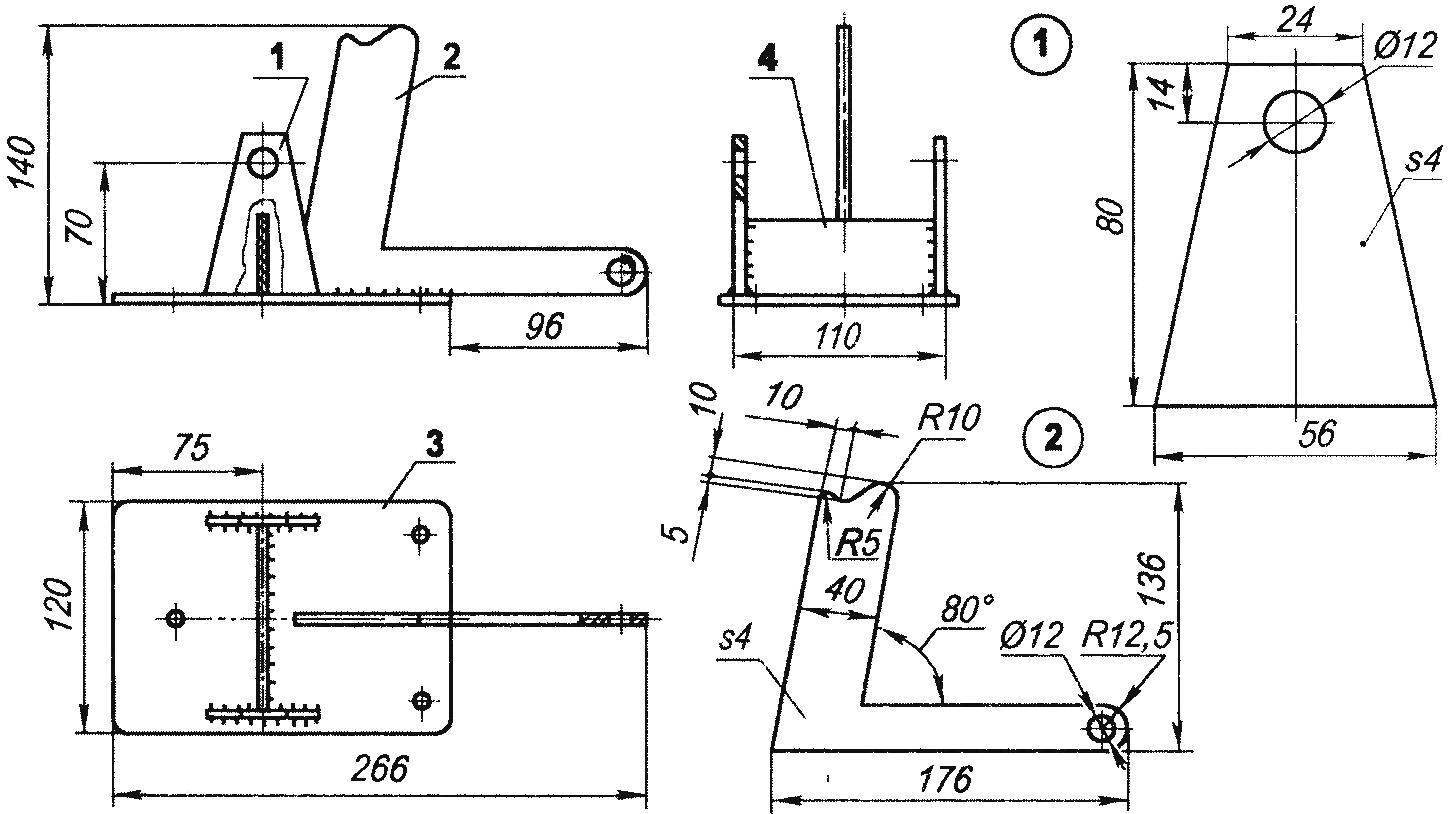

A device for determining the braking distance of the car:

1 — strip (technical rubber); 2 — hook (steel rod Ø6, L176, 2); 3 — bracket; 4 — roller (steel 20X); 5 — washer (2 PCs); 6 — cotter pin 2×18 (2); 7 — rod; 8 — screw М6х1,5 (2); 9 — left feather fork wheel (steel sheet s4); 10 — wheel; 11 — coil spring (wire Ø2. number of coils — 170, the direction of coiling — right); 12 — the basis for the reed switch (Bab-bits B16, strip 12×2); 13 — bolt М5х1,5; 14 — right spacer (steel 45KH, pipe 30×5, L12); 15 — left spacer (steel 45KH, pipe 25×2,5, L14); 16 — nut M12

Rod:

1 sleeve (steel 20KH, pipe 20×4); 2 — cheek (steel sheet s4, 2); 3 — holder (steel pipe 28×2); 4 — the right pen fork wheel (steel sheet s4); 5 — wheel axle (steel 40X, rod Ø20); 6 — loop (sheet s4); 7 — eyelet (steel sheet s4)

Bracket:

1 — front (steel sheet s4, 2); 2 — gon (sheet s4); 3 — the base (steel sheet s4, 94×40); 4 — jumper wire (steel strip 94x40x4)

The electrical circuit of the device is connected to the terminals of the button “=” calculator, located on the front panel of the cab. Nearby there is a notebook with the reference data of the brake paths of different cars, used to record test results.

Before working on the buttons of the calculator dial, an amount equal to the length of the circumference S1 in mm additional wheels. And click on the “=” of the calculator.

After that the car accelerates to a speed of 40 km/h and press the brake pedal. Immediately actuate normally open contacts of the sensor, including the brakes, which connect the electric circuit of the speed sensor (reed switch) with a calculator. And the switch takes on the terminals it “=” so many pulses, how many revolutions does an extra wheel with a permanent magnet to a complete stop. The test remains only to consider the testimony of the calculator is the product of the value S1 to the number of pulses, that is, the required braking distance.

To estimate the parameters of braking, taking into account the speed of reaction of the driver (at the time, e.g., qualifying examinations), the device can connect on a different scheme.

As you know, between the time of taking the decision on driver braking and the beginning of the deceleration passes a certain time. In particular, fractional seconds are spent to move the foot from the accelerator to the brake pedal.

In this case, the beginning of a braking distance should be associated with the accelerator, which with a sensor bar power brakes with normally open contacts must not be installed on the bracket of the brake pedal, and accelerator pedal.

With a sharp reset throttle switch is closed and starts counting the value of the braking distance for a split second before the driver’s foot touches the brake.

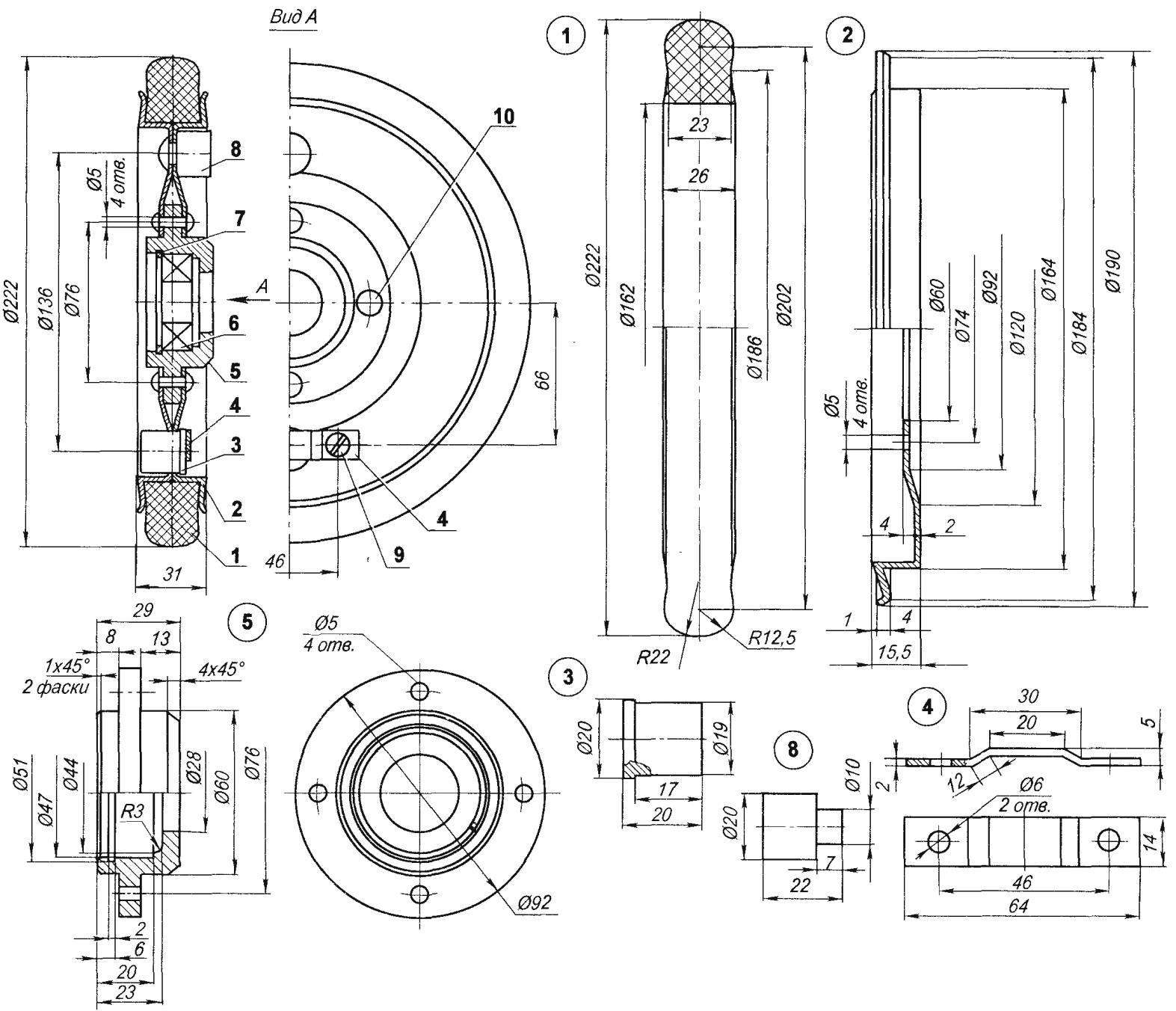

Wheel:

1 — bus (technical rubber); 2 — the drive (45 steel, sheet s2, 2); 3 — magnet; 4 — mounting plate (St3, sheet s2); 5 — hub (steel 20X); 6 — bearing 204; 7 — Circlip; 8 — balance weight (steel 45); 9 — M6 screw (2 PCs); 10 — 5×20 rivet (4 PCs)

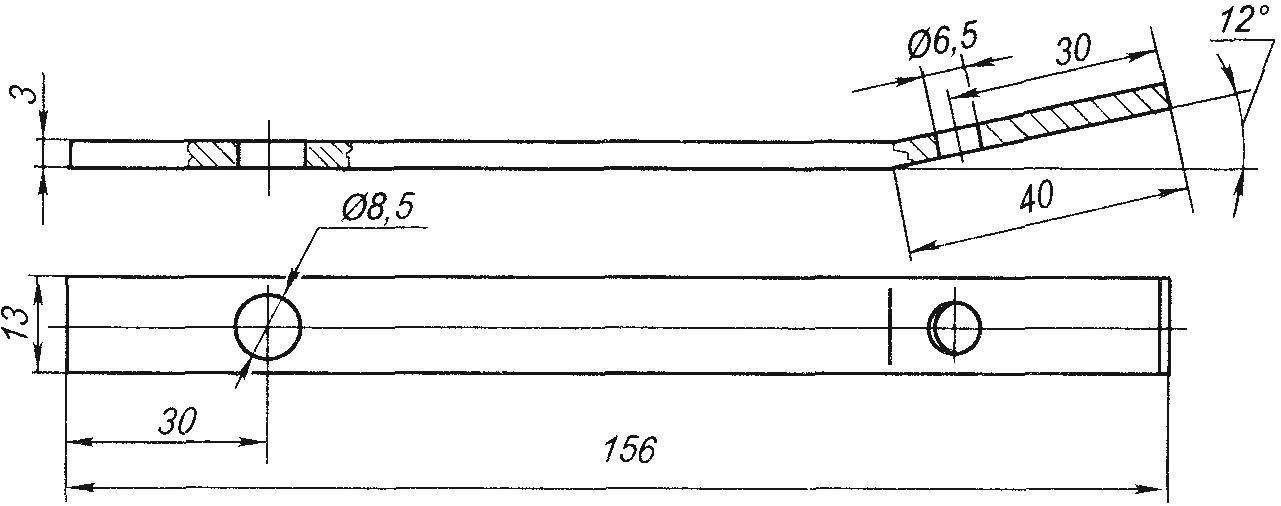

Strap sensor power unit (St3, is attached to the brake pedal bracket; sensor mounting — hole Ø6. 5)

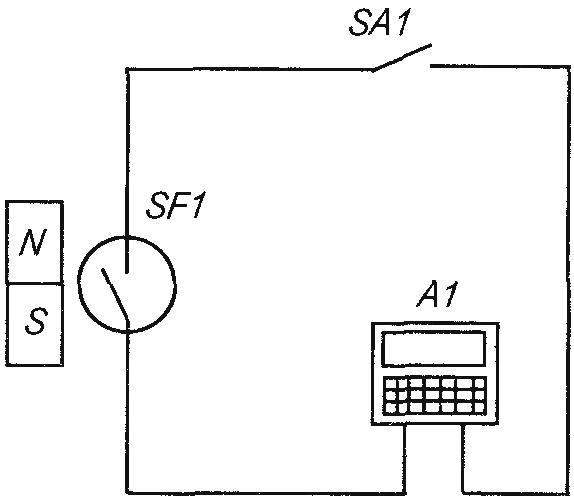

A circuit diagram of the device:

N — S permanent magnet; SF 1 —sealed contact (reed switch); ЅА1 —sensor power device; A1 —calculator

Inoperative calculator, Notepad and strap with sensor power unit are stored in the portable box, and an extra wheel to the pole and bracket in the case.

Device “uatk-70” is designed and manufactured in the circle of technical creativity of students in performing research work on “Effect of various factors on the value of the braking distance of car”. However, it can be successfully used in private garages and transport companies for the prevention of accidents due to faults of the brake system.

Employees of various services of traffic police can apply “uatk-70” for Express-diagnostics during the technical inspection of vehicles and to assess the responsiveness of the drivers on the qualifying exams. Probably not refuse to have a simple and reliable device and private individuals in any garage cooperative.

R. SALIKHOV, I. VASILYEV, A. ACHALOV, R. SHAIMUKHAMETOV, Ufa