In one of the reports of competitions rocketmodeler I noted an unusual model sports class Ѕ6А famous athlete Nikolay Sergeeva from Belgorod. How many know it, and you know we have more than 30 years, never ceases to amaze his creative imagination. Was no competition, so he brought them his “brand” new. So it was this time.

In one of the reports of competitions rocketmodeler I noted an unusual model sports class Ѕ6А famous athlete Nikolay Sergeeva from Belgorod. How many know it, and you know we have more than 30 years, never ceases to amaze his creative imagination. Was no competition, so he brought them his “brand” new. So it was this time.

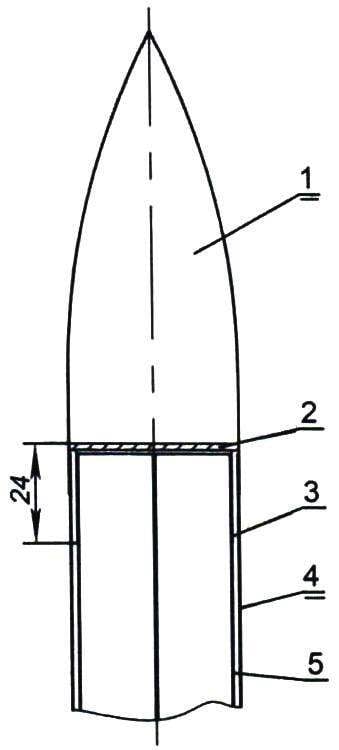

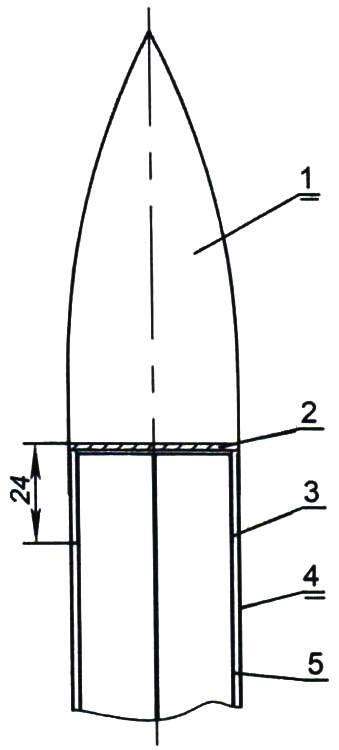

Sometimes ask myself a rhetorical question: “What can I propose a new class of models with tape (Ѕ6А)?” And like Sergeev says: “you Can!” Indeed, provided the original design, where the braking device reduces the speed of descent of the model that is used not only tape, but the case made the drop-down. This innovation allows several times to increase the area of the braking surfaces of the model. In the expanded form (descent mode) it is similar to a funnel or cone with an upper diameter of about 500 mm.

I must admit that model-“folding beds” for the first time I saw in the distant 1979 and 1981 in the European Championships. The authors were josé Ignoto (Spain) and Anton Repa (Czechoslovakia). Case in the models decomposed in only two folds, and the additional braking surface was quite small and not always effective, although the structure was complex. Apparently, therefore, this scheme is not widespread.