Today we’ll explain how on the basis of a moped or scooter (or rather, their main nodes) to make not too difficult aeropuer – a vehicle driven by a propeller. He walks well on ice and Packed snow. However, try to “teach” him like a snowmobile equipped with ski to overcome the drifts is not necessary, power motorbike engine for this purpose is clearly not enough.

Today we’ll explain how on the basis of a moped or scooter (or rather, their main nodes) to make not too difficult aeropuer – a vehicle driven by a propeller. He walks well on ice and Packed snow. However, try to “teach” him like a snowmobile equipped with ski to overcome the drifts is not necessary, power motorbike engine for this purpose is clearly not enough.

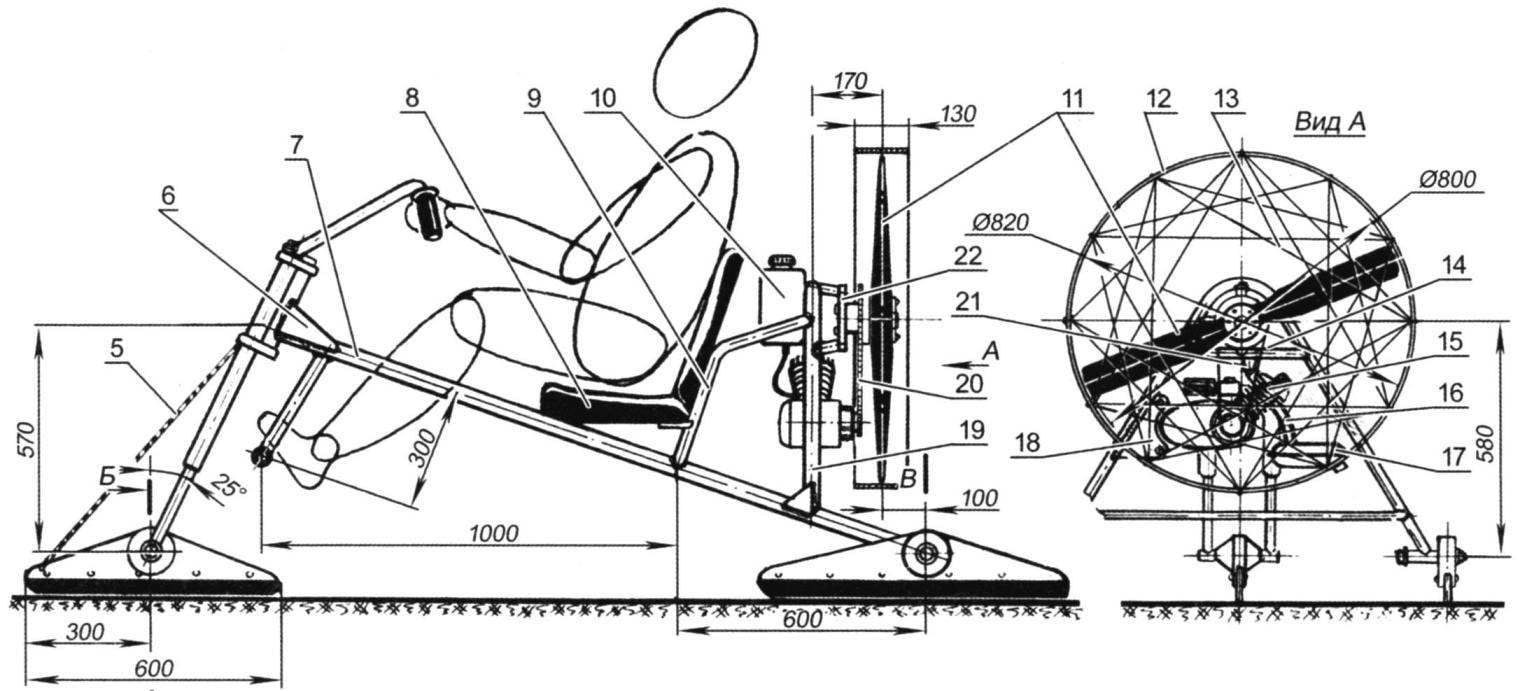

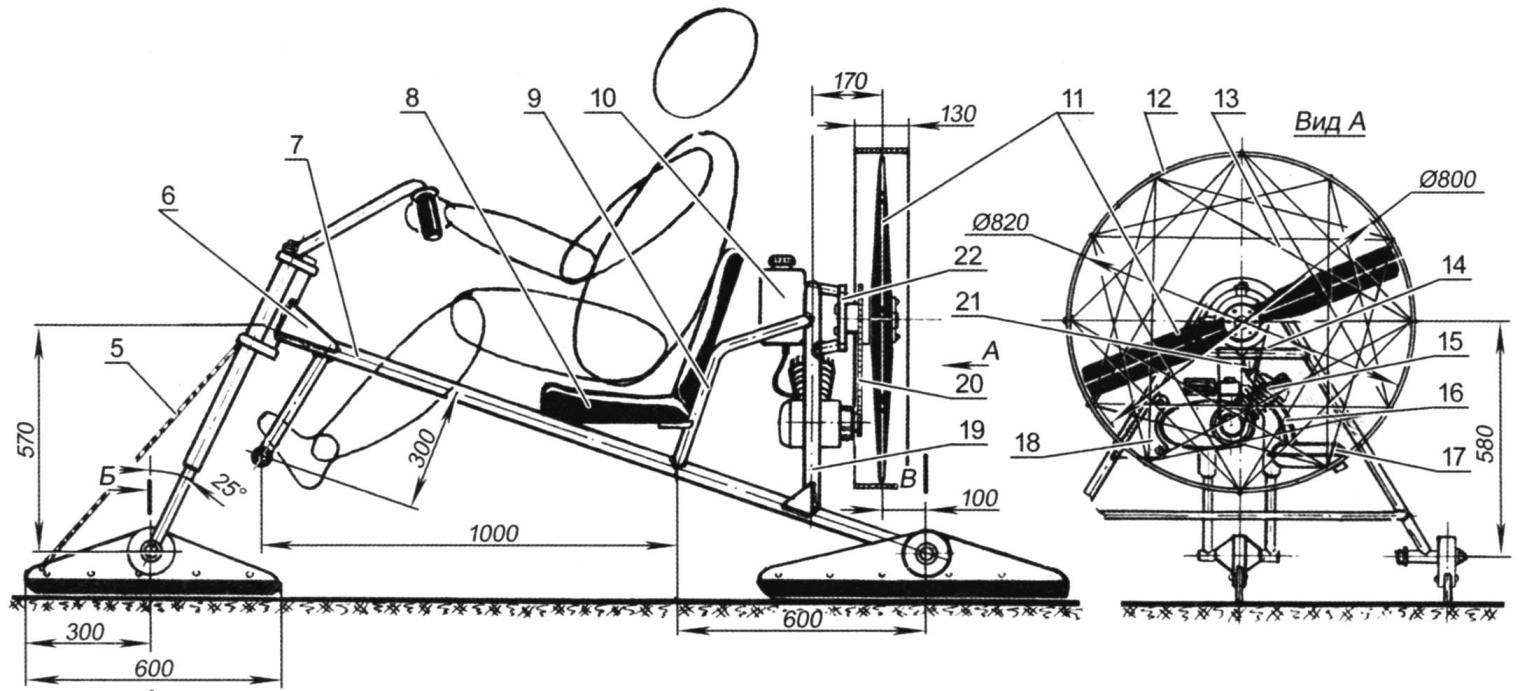

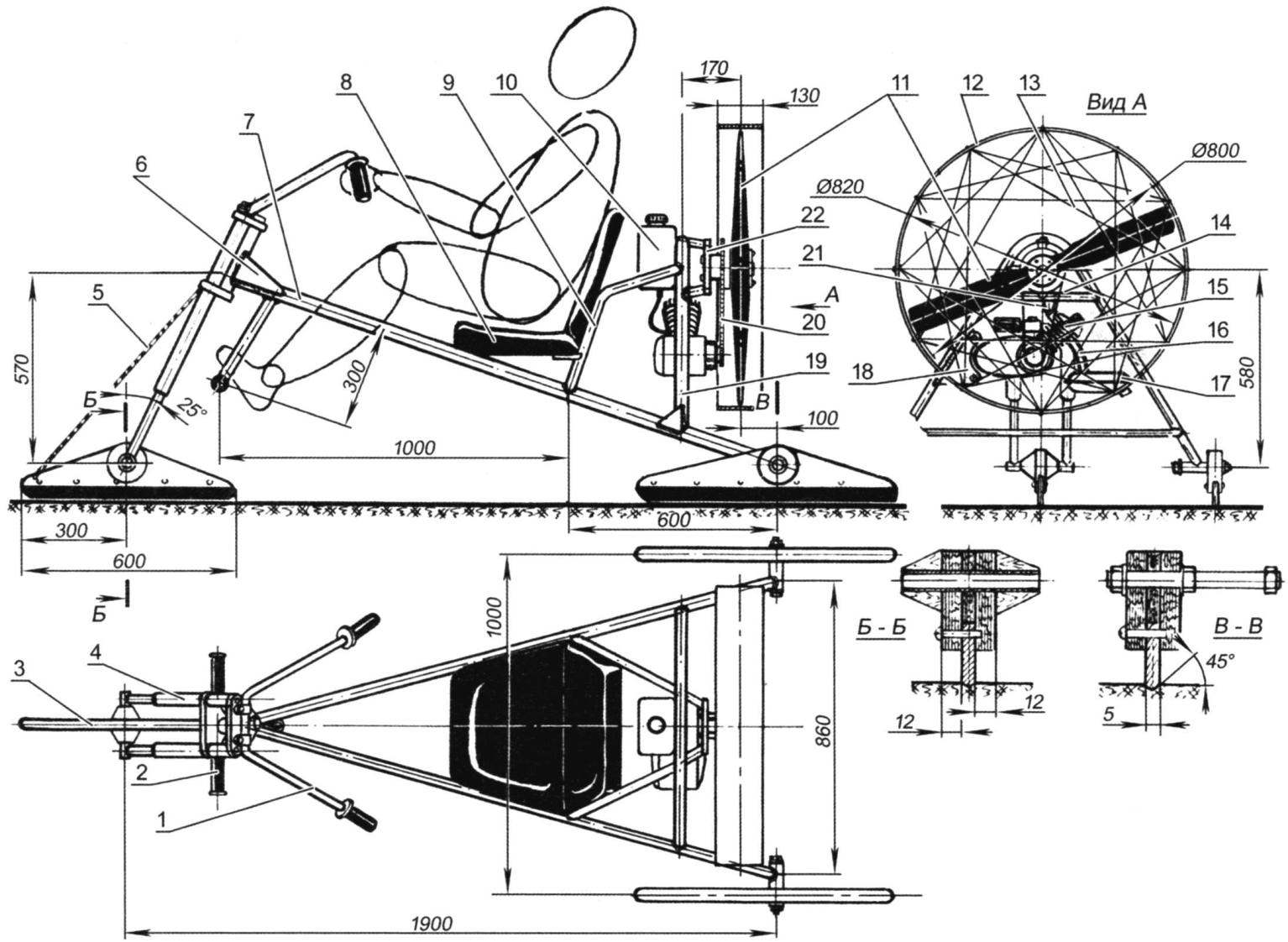

Frame aeropuer flat, A-shaped, consists of two longitudinal spars – steel pipes with an outside diameter of about 40 mm and a wall thickness of 2.5 mm and cross member is steel pipe with a diameter of 22 mm and a wall thickness of 2.5 mm. the Front frame ends on the steering column, taken from the frame of the old bike. Detail this is not so difficult and can be done independently on the model of the moped. The steering column and the frame are joined by welding, and the junction is enhanced by two steel gusset plates from a sheet thickness of 2.5 mm.

The free rear ends of frames over steel bushings with an inner diameter of 20 mm and outer 26 mm. They are mounted to the frame strictly on the same axis. Therefore, before welding fit them on a pre-straightened steel rod, and then cook.

In the rear of the frame is the motor mount is bent-shaped And the pipe diameter of 32 mm with a wall thickness of 2.5 mm. the Place of its junction with the side members reinforced by steel gussets. On Motorama welding fixed attachment points of the engine. Structurally they do not differ from those available on mopeds with engines of the type W-62. The installation easier to perform in stages. First, a cardboard cut out templates of nodes and carefully adjust them to the frame and the engine. After that, from a steel sheet with a thickness of 23 mm cut out template the corresponding elements of the drill 8.5 mm diameter holes for the mounting bolts and attach. But not to the frame, and first to the engine. By doing this, the engine hung on the mount and screwing a soft wire, carefully verify its position relative to the plane of symmetry of aeropuero, after which the clamping units bring to Motorama welding, removing the engine, carefully boil the joints.

Motor mount is enhanced by two struts that serve to all the supports of a seat back of the driver. They are made of steel pipes with a diameter of 22 mm.

Steerable fork aerobar – from moped of any type. From the moped and the steering wheel – we just have to pick one that was convenient to operate the machine.

Skates aeropuer wooden with metal snake. Front and rear design is the same, the only difference is in the way of their fastening to the frame of the machine.

Two sidewalls of the ridge are cut from 12 mm plywood.

Between them is inserted a gasket of 5 mm plywood and snake, carved from a strip of aluminum with a thickness of 5 mm. All items are collected on epoxy glue and screws with thread M5 or M6. Poloz is sharpened as shown in figure – cross section b – B or b – B. the Angle at the apex should be about 90°.

The layout of aeropuero:

1 – the wheel (moped or motorcycle); 2 – T-shaped footrest; 3 – ridge front; 4 front fork (moped or scooter); 5 – guy in front of the skate (the rubber recoil absorber); 6 – reinforcing gusset plate (sheet steel thickness 2.5 mm); 7 – frame rails (steel pipe with a diameter of 40 mm); 8 – seat 9 – struts engine mounts (steel pipe diameter 22 mm); 10 – fuel tank (plastic canister with a capacity of 2 l); 11 – propeller (birch); 12 – the plug screw (plywood thickness 4 mm); 13 – wire mesh fence; 14-jumper; 15-engine type W-62; 16 – exhaust pipe; 17 – muffler; 18 – rear mount engine (steel sheet thickness 3 mm); 19 – engine mount (steel pipe with a diameter of 32 mm); 20 – Bush roller chain drive of the propeller; 21 – front bearing of the engine; 22 – flange mounting axis of the propeller

For the front of the skate will need another section of pipe with an inner diameter of 12 mm and two wooden pillars. Glued to the ridge, they serve as a bushing through which the skate is attached to the front fork. The connection is exactly the same as that of moped wheels with plug – on regular axis.

To the rear of the skate will need two pipe axis threaded rods with a diameter of 12 mm. Two nuts and washers from the studs firmly fixed on the skates, and a nut and jam nut in the rear hub of the frame aeropuero. Fixing them to the sleeve, of course, hinge. And that stud was sitting tightly in the sleeve, put in plastic liners, cut off from the plastic hose.

Final installation of the skates always make sure that the runners were strictly parallel to each other – otherwise much will increase the resistance to movement.

Seat aeropuer the easiest thing to do from an old metal chair or chair using the frame. Then it is easy to fit and faux-leather, tucked it under the foam. For fixing the seat to the frame weld the small plate of sheet steel with threaded holes.

To the front of the frame is attached to the kickstand – its location is recommended to clarify at the place. It is welded from steel tubes with a diameter of 22 mm and has an inverted T At its horizontal portions are tensioned segments of rubber hose or, even better, a rubber cap motorcycle foot pegs.

Aerobar is desirable to provide a drag brake. It is not complicated in design. The simplest is a lever, one end of which is a handle, and a second, serrated teeth brake Shoe. When pulling the lever towards you, the brake Shoe will cut into the ice, and the Buer will stop. However, the brake design can be different. Think what.

Well, now let’s get to the most important part of the job – installation of propeller installation. Note that the transmission for the engine of aeropuero is not necessary, therefore, to make substantial changes in the design of motor is not necessary. So in the summer it is possible to use the engine for its main purpose. Will need only minor improvement on the magneto rotor is necessary to secure the leading asterisk, for example, from rear wheel road bike. The number of teeth it should be such that the gear ratio chain transmission was 1:1.5 or 1:2.

Sleeve of the air screw is a modified hub moped wheels and it cut the brake drum, after which the flange is mounted on a cantilever axle mounted on a round steel plate. The latter through pipe lengths welded to the top of the motor.

On a modified wheel hub mounted sprocket driven from the rear wheel of a moped, which with the help of roller chain is transmitted torque from the engine.

The propeller is mounted on the flange by six bolts with thread M5 nuts. The locking nuts are mandatory, it is done using a soft wire or special washers.

How to make a propeller and a protection to him, we will tell in one of the next issues of the public KB.

After the Assembly aeropuer disassembled, welded joints are cleaned, individual components are covered by nitrogenatom and after treatment the skin is painted with several layers of nitroenamels.

I. EVSTRATOV, engineer