When decided to do the car (the material about it were published in the “Modeller-designer” № 5, 2007), then I faced a problem — where to work? Not under the same open sky in the courtyard. A temporary shed or even the shed again to be fully rescued in the cold season they also work practically impossible. But because the car manufacturer could drag on for years.

When decided to do the car (the material about it were published in the “Modeller-designer” № 5, 2007), then I faced a problem — where to work? Not under the same open sky in the courtyard. A temporary shed or even the shed again to be fully rescued in the cold season they also work practically impossible. But because the car manufacturer could drag on for years.

Then came to the conclusion that, figuratively speaking, is first to get stable, and then — a horse and decided to first build a garage-workshop. But then came another question: if the front of the house to erect such a structure (and the other appropriate place for it on a site were not found), then it will close not only the view from the Windows, but the house itself, which was extremely undesirable.

In the end, came up with the idea to make an underground, or rather of the recessed garage, the type of basement. But it’s not what is under each house and which might more properly be called underground, but like those that have been preserved in some places in our villages buried in the ground and lined the top of the structure, in which, as in the cellar, the villagers kept the winter supplies, and in the summer even lived, hiding from the midday heat, the night chill or the morning dew — the temperature at any time of day and even year was quite comfortable.

Conditions: relief, geological and hydrological for the construction of the underground garage were appropriate. The drain of rain and melt water from the area provided a slight natural slope of the Foundation Soil is a dry loam, the groundwater was detected at depths of up to 2.5 m (in the neighborhood there was a cellar).

His thoughts on the construction of the garage shared with friends a civil engineer and received a number of helpful tips than can not be neglected to ensure the reliability of structures in pursuit of savings. For example, the mandatory laying of Foundation base (or at least an underlying layer of sand) below the maximum depth of soil freezing the base; the categorical rejection of nonconforming slabs etc.

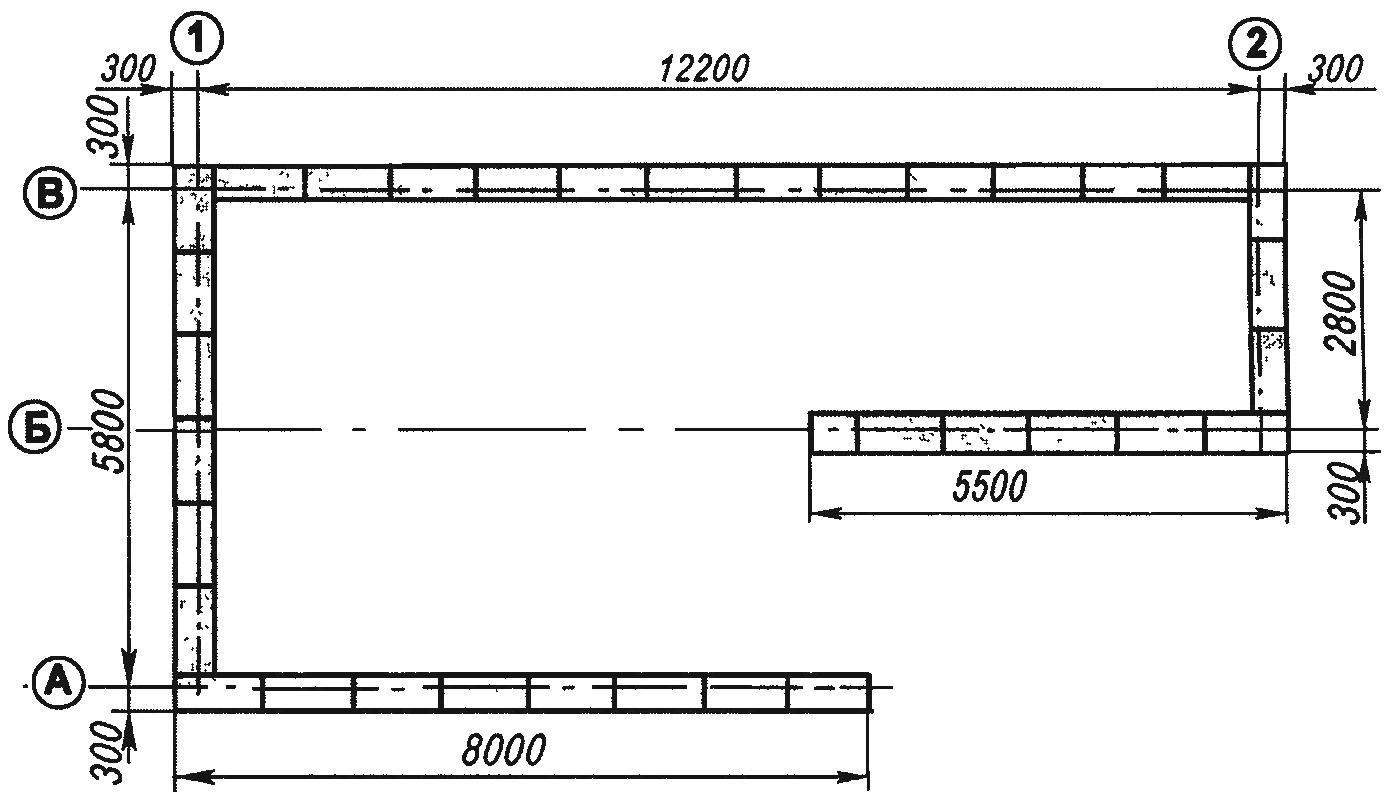

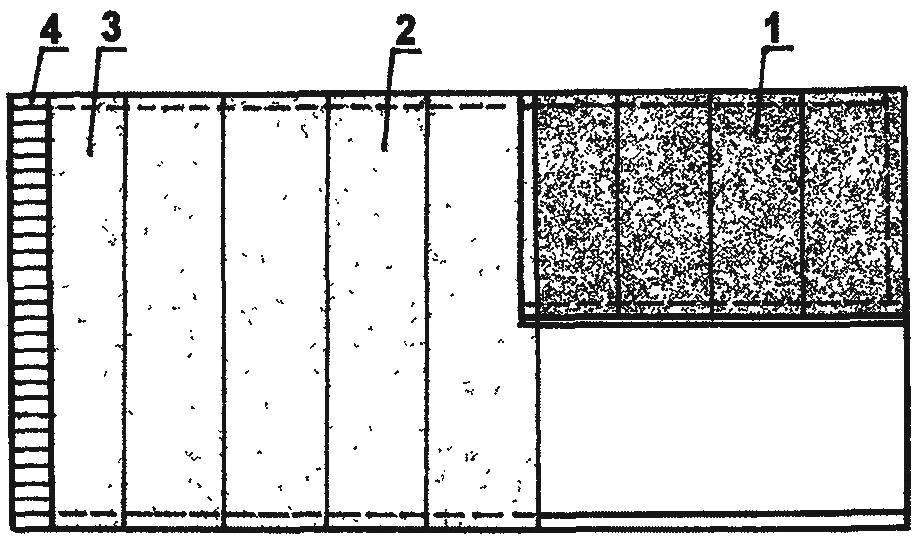

Plan of the foundations (material — concrete blocks FB1 1000x600x400 dimensions mm length height x width, 35 piece); A, B, C, 1,2—building axis

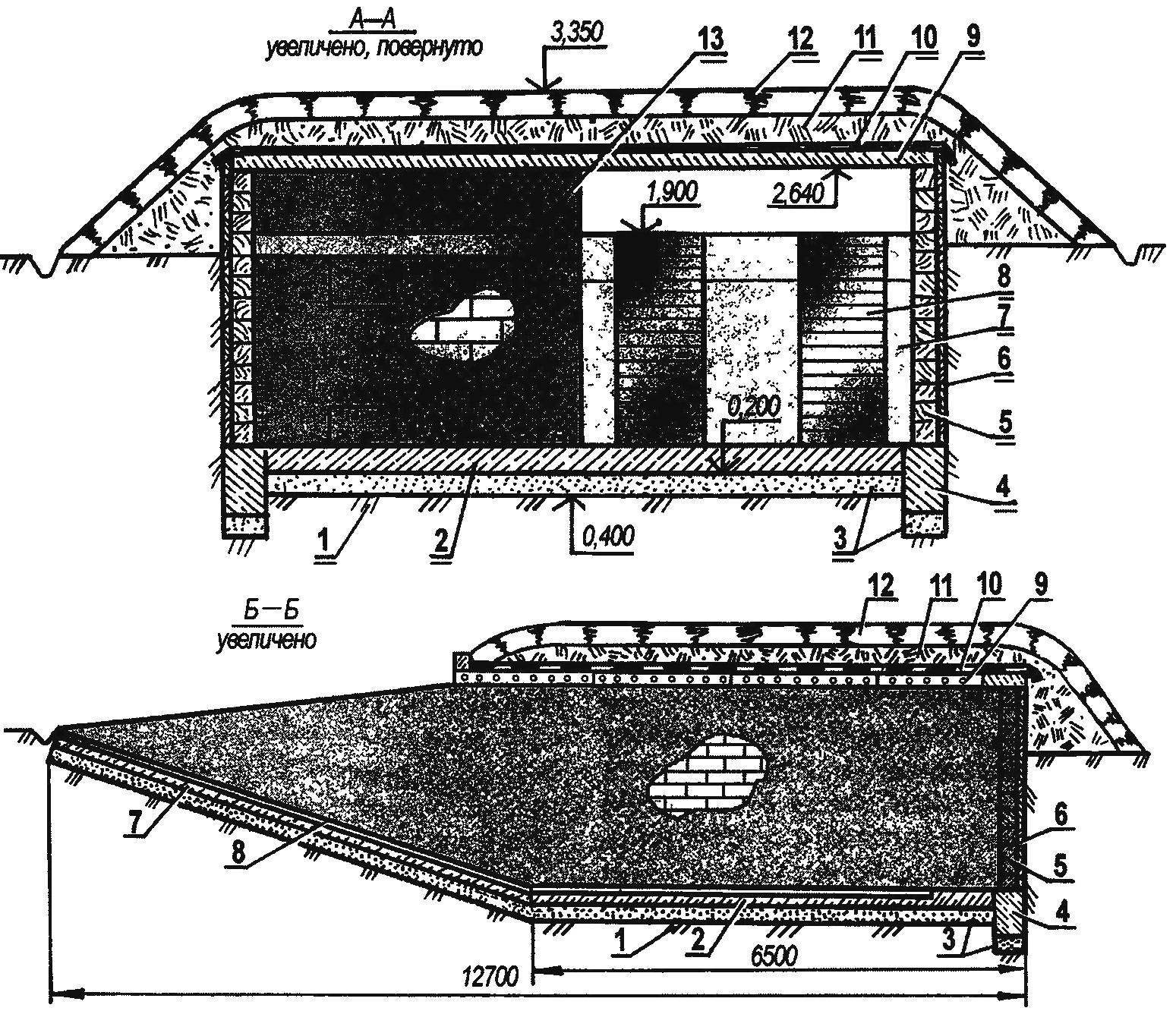

Plan underground garage-workshop at the ground level (Vistahermosa design shown in the breakdown:

1—the Foundation (natural soil—loam); 2—floors (concrete); 3—cushion (sand); 4—the Foundation (concrete block 1000x600x400, needs); 5—wall (concrete block 400x200x200, on demand); 6—pilot controlled check valve (clay); 7—sloping ramp, 8—track (iron plate); 9—overlap (concrete slab), 10—waterproofing (roofing material on bitumen mastic); 11 —embankment (soil); 12—cover (soil and vegetation layer); 13—the lintel-the lintel (concrete beam)

Never once imagined a garage-workshop of the future car design which is also seen in reality. However, the necessary sketches still kept on paper. As it turned out, the drawings of the plan and facades were necessary to obtain building permits in the local architecture. And since the recessed garage practically does not change the surrounding landscape and the overall architecture of the existing building, and permission was granted without problems. I took the drawings to a greater extent for the calculation of volumes of construction materials, and according to them reckoning their value and identifying their possibilities of financial support for the construction of the garage.

There were doubts in the location of the ramp (inclined exit-exit): outside or inside. In the end I chose the latter and, as it turned out, not lost. In the winter it is not necessary to clear of snow and ice (the outer ramp would require a thorough winter service, and in the summer it would be necessary to remove trapped it rainwater.

Building a garage-workshop started with a markup of his plan for the selected site (or, as they say the builders — breakdown structures in nature).

First, determine the location of the outer corners (the intersection of the projections of the external walls) the future of the garage by driving small pegs. Checking the Squareness produced by the method of equal diagonals. Then on the continuation lines of the walls, approximately 2.5 metres from the corner pegs dug posts “solid”. A more accurate position lines marked with nails-“dvuhletkami”, by driving them halfway into the ends of the bars, and nails stretched nylon cords.

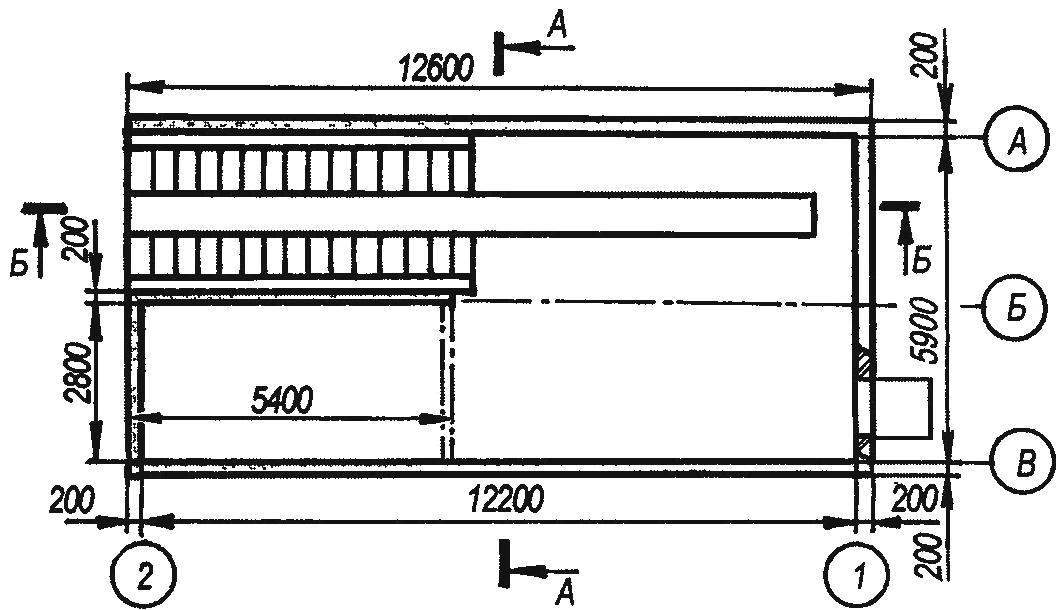

Plan of ceilings:

1 — reinforced concrete hollow plate 3000x1500x200 (4 PCs); 2 — reinforced concrete hollow plate 6000x1500x200 (4 pieces); S —concrete hollow-core slab 6000x1000x200; 4 — slotted concrete block (400×200)

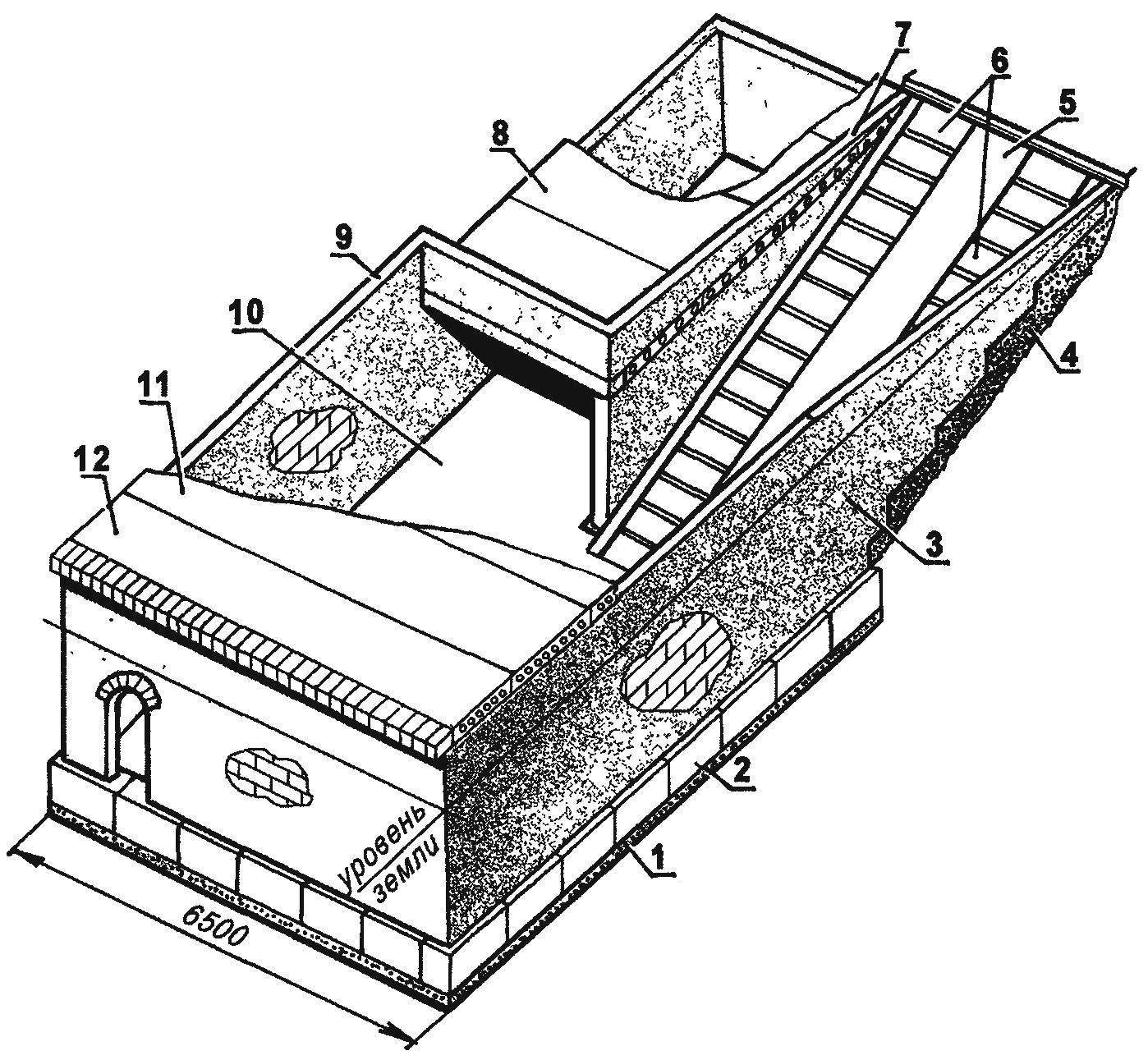

Design underground garage-workshop:

1 — sandy modfun; 2 — dementa pillow; 2—Foundation; 3—side (left wall); 4 — underlying sand layer; 5 — ramp; 6 — track (iron plate); 7 — slant (in-situ concrete, 2); 8 — short slab corner; 9 — right side wall (ledge); 10 — half; 11 — a broad slab; 12 — narrow slab

The development of the pit produced in a mechanized way — hired bulldozer-excavator on base of tractor “Belarus”. It should be noted that excavation work excavator was made very carefully: moved to three points of the topsoil, dug a pit with partial loading of the clay soil export in a dump truck; planned bottom of the pit and sloped exit ramp. However, in some places it was necessary to modify manually trim the walls, to deepen almost on the perimeter of the trench under the Foundation blocks — but it’s better than if it took to pour and compact the soil in place, too chosen by the excavator.

The Foundation of the garage is made of concrete blocks sizes mm 1000x600x400 just one a number of underlying sand layer 200 mm thick. the Under part of the outer wall, coupled with a ramp — or rather, under cover-gates Foundation blocks not laid at all, and the wall here is lined with benches, with a gradual rise to the surface of the earth. Foundation blocks put under a partition as forming it and the outer walls of the cubicle also blocked with concrete slabs having a large mass.

Wall thickness “a half-brick” (long side along the wall) made of lightweight concrete blocks (stones) with a size of 400x200x200 mm with slit-like voids. The walls were made of cement-sand mortar with a seam height of about 20 mm, the most common chain in a way that each vertical seam between adjacent overlapped blocks of the overlying unit.

In the slot of each block inserted pin — cut not thick pipe or reinforcing bar that penetrated and the underlying stone and sometimes a stone the next row. Within the aperture the outer wall and the partition laid out staggered, with a gradual decrease to the surface of the earth. Ledges aligned to the sloped edge in-situ concrete On the edges along their inner edges laid and secured with anchor pins parts 70×70 mm —lodgements for the gate. In the back wall (diagonal from the entrance) left arched doorway to door. Subsequently, the outside was making a pit with a ladder, and above on the racks — canopy-canopy.

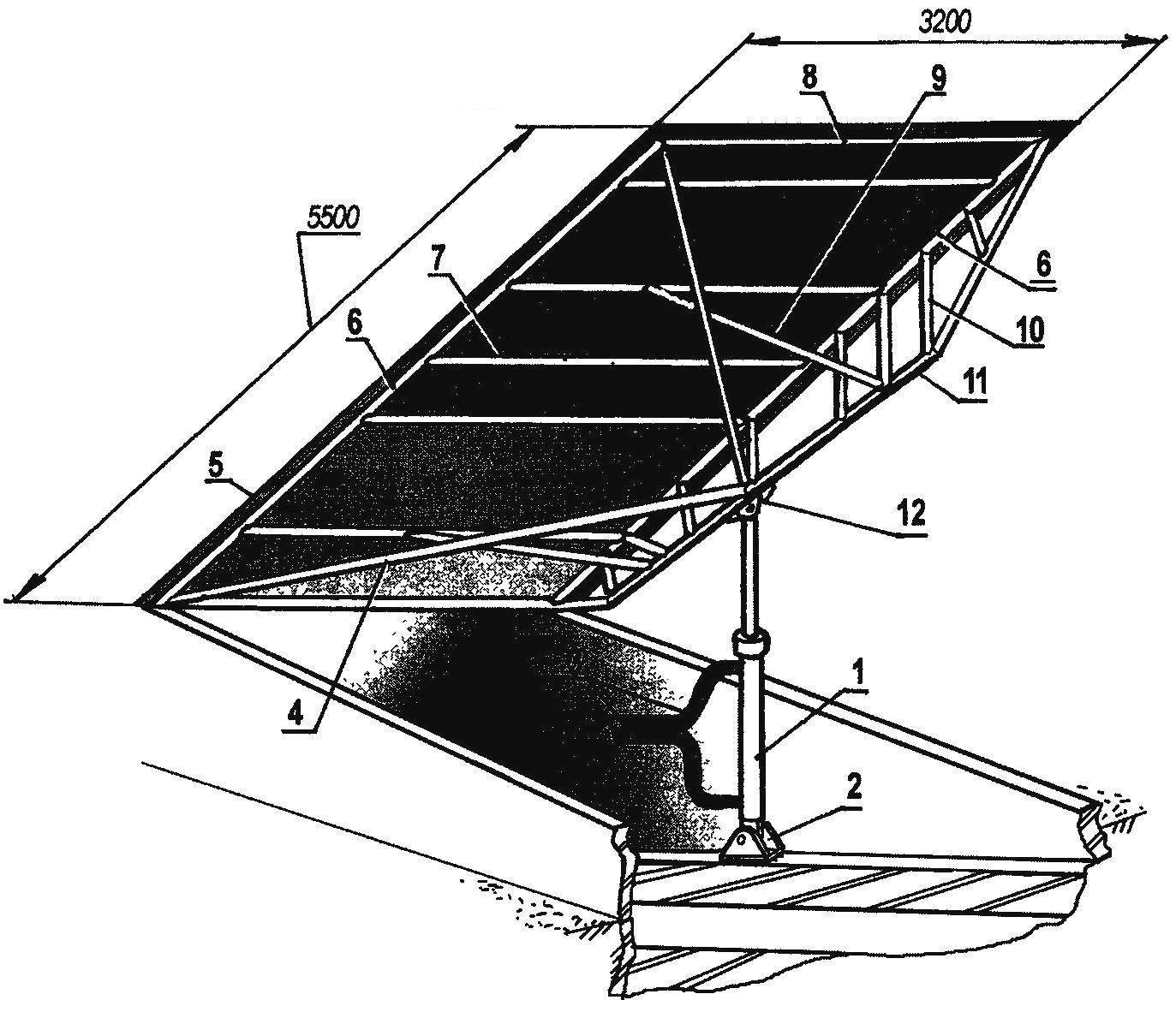

Garage doors (they can be called a manhole cover) is made of sheet steel two-millimeter thickness. But because the area of the gate caps is quite significant (length above 5 m and a width of about 3 m), then they took power and the frame in the form of a lattice, which is welded from round steel pipe outer diameter 60 mm. the dimensions of the strapping grille — the entrance doorway to the garage.

Open-close (or to lift) these gates manually was not possible. So I decided to equip it with a hydraulic lift mechanism such as that which upset the body of the car-trucks. However, the hydraulic cylinder could be installed only on the side of the wall. When opening the gate is curved and warped. To avoid this I had to make a special design, like a farm. Her stand was welded to one of the longitudinal pipe strapping, and the lower zone connected by struts with the opposite pipe strapping.

The floor of the garage — monolithic slab over 200 mm, made of reinforced concrete, on sand underlying layer, the cushion thickness is also approximately 200 mm. grade of concrete is difficult to determine, the composition of the mixture will result.

The approximate ratio of ingredients (aggregate:sand:cement:water) 4:2:1.1. As a binder used Portland cement grade 400.

Reinforcement was mainly scraps of various steel and cast iron materials: tubing, wire and even an old heating radiator, annealed from the paint. All this “scrap” laid on the floor, and combined the individual elements into a single lattice by welding or wire twisting.

The concrete mixture for the floor distributed without the vibrator, and therefore made it sufficiently plastic to fill the space between the armature with no voids.

In place, planned for Parking cars in the garage, semi fenced with boards and left nedzarici a shallow sump to collect stekaemoj from the bottom and arches of the wheels of the car remaining water or melting snow.

But for ramp concrete mix used is quite hard, so she’s not crawling on an inclined plane. And after its setting has imposed on the ramp along the track of wheels of cast-iron corrugated plates (including trim and floors in industrial buildings).

Lift gate hatch cover:

1 — hydraulic cylinder with piston (grader); 2 — support bracket (sheet s5); 3 — hoses (dump); 4 — corner brace (steel pipe Ø30, 2 PCs); 5 sheathing (galvanized steel sheet s2); 6 — longitudinal connection of piping (steel pipe Ø40, 2 items); 7 — cross bar (steel pipe Ø30); 8 — cross connection piping (steel pipe Ø40, 2); 9 — the middle strut (steel tube Ø30, 2); 10 — the farm stand (steel pipe Ø30, as required); 11 — bottom chord (steel pipe Ø40); 12 — thrust bracket (steel, sheet s5)

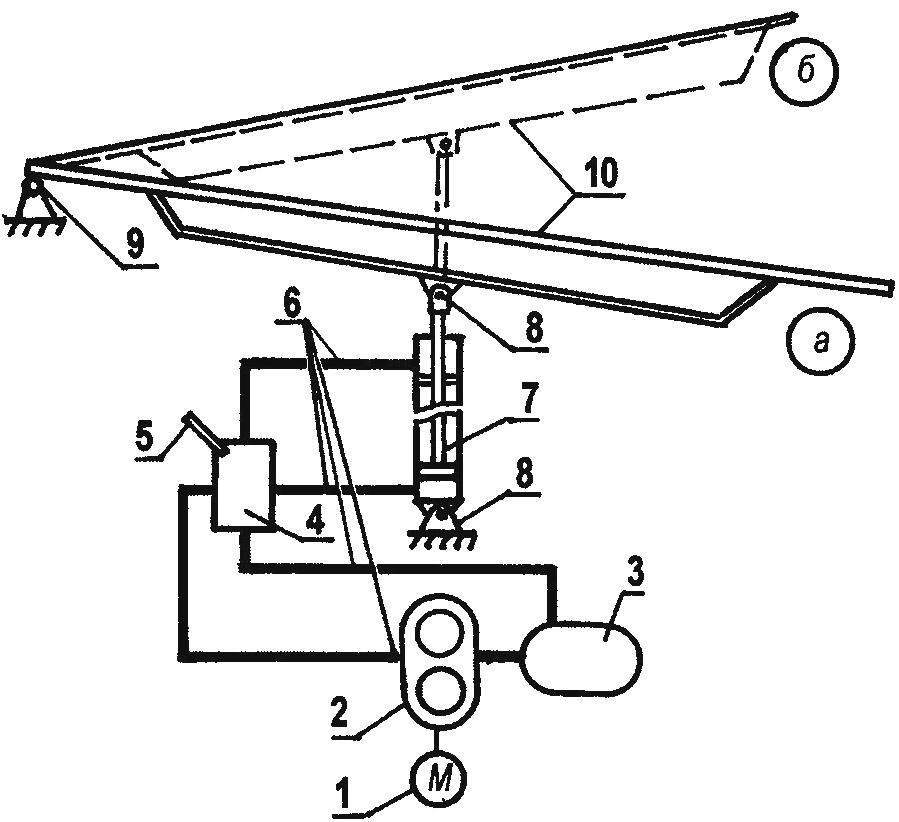

The scheme of a hydraulic actuator opening and closing the gate-hatch:

1 — motor (N = 5 kW, n = 1380 Rev/ min); 2 — oil gear-type pump NSH-10; 3 — hermetic tank (from tractor T-25); 4 — spool directional control valve (motor grader); 5 — handle control valve (3 pieces), 6 — oil lines (tractor “Belarus”); 7 — force hydraulic cylinder (dump); 8 — joints (2pcs), 9 — gate hinge (2-piece), 10 — gate-hatch: and in the lowered (closed) condition b is in the raised (open) condition

The overlap (or coverage) of the main part of the garage-workshop produced a hollow-core concrete slabs 6000x1500x200 dimensions mm (length x width x height), and cubbyhole — like plates length of 3 m. Here note that the entrance to the cubicle at a height of 2 m even with masonry walls and partitions blocked the lintel-the lintel, on which was laid three rows of concrete blocks up to the ceiling making a kind of wall hanging. Subsequently assembled to isolate the cubicle from the garage door with the side walls and to organize the room. But this idea is never realized, and the nook has become a warehouse of spare parts and tools.

When laying slabs it turned out that somewhere I made a miscalculation and between the end plate and the rear (end) wall left a gap width of about 100 mm. This blemish fixed that put him on the wall a number of blocks, only now deploying them across (poke to the plates), and cracks-voids — in a horizontal position. Above the gate, on the edge of the plate put low (in single unit) wall-parapet — not crumbled subsequently, the soil embankment from the roof.

On top of slabs laid two layers of roofing material, glue molestie edges with molten bitumen. The fabric of the first layer unrolled along the floor slabs, and one across, making a small lap around the perimeter.

But these asphalt layers do not perform the role of the roof, but only waterproofing, as the top closed (or covered) with a thick layer of soil, mostly what was removed from the pit during its development. First it was clay soil. Soaked in water the clay is laid into the cavities between the walls of the pit and lined with concrete walls of the garage and was stamped handmade wooden tamper is arranged the so-called clay waterproofing the castle.

Then the same clay, but the natural moisture is superimposed a thick layer (about 300 mm) on the floor and leaning against the wall of the garage with the device of the slope with a slope of approximately 1:1. Thereafter, formed above the garage clay shaft distributed humus — soil vegetation (otherwise fertile) layer of soil. The front and sides of the shaft arranged shallow concrete lined drainage groove to drain on the natural slope of the terrain back from the garage.

Ventilation of the garage if necessary, through the gate and the front door located in opposite (diagonal) corners.

The shaft slopes planted with grass; and on a horizontal platform wife planted flowers — get a big beautiful flower bed. But also enjoy admiring the flowers my family received quite tangible savings. According to estimates, the construction of a garage I would have spent about a third more.

Subsequently, during operation, revealed some other advantages of underground garage in front of the ordinary. First, the inside temperature never dropped below 0°C even in the cold (not freezing water in the pit). Second, the noise, the crackle, the sound generated inside the garage, especially when working with metal were barely audible even in the street, and not only in the house.

Here in the garage workshop began, and two years later completed construction of the car “Geranium”.

But the construction process didn’t stop. A few years later an opportunity to implement long-conceived plan: to build a house on the second floor. For the implementation of the plan was the necessary supply of various construction materials, which had to be stored somewhere. A more appropriate option than to make the stock add-on to the lined garage, not invented. And the pity of it was a bed — even derationalize it would take under a barn-warehouse other part of the garden. In addition, the wall of the underground garage is ready the Foundation for a new superstructure, and the ceiling will serve as a floor.

This final version of the building — underground garage-workshop with a warehouse and side pristrom the pictures in the Intro to the article.

Later he made an entrance to the garage via an underground tunnel straight from the underground house. The house was erected the second floor, which is now residential accommodation and on the ground — household. So the view from the living rooms garage-storage does not prevent.

V. ABRAMOV, Saransk