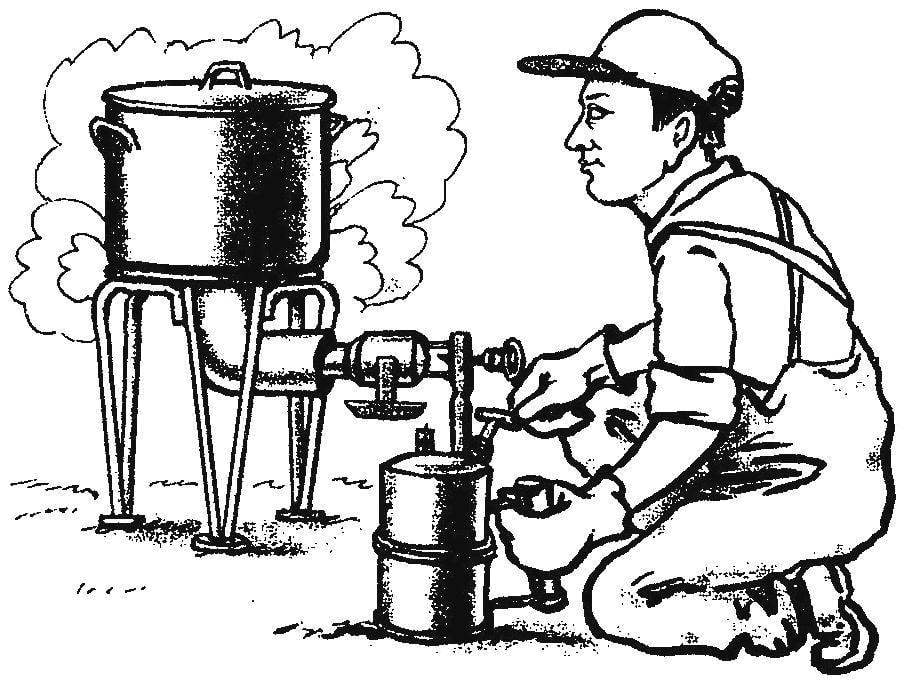

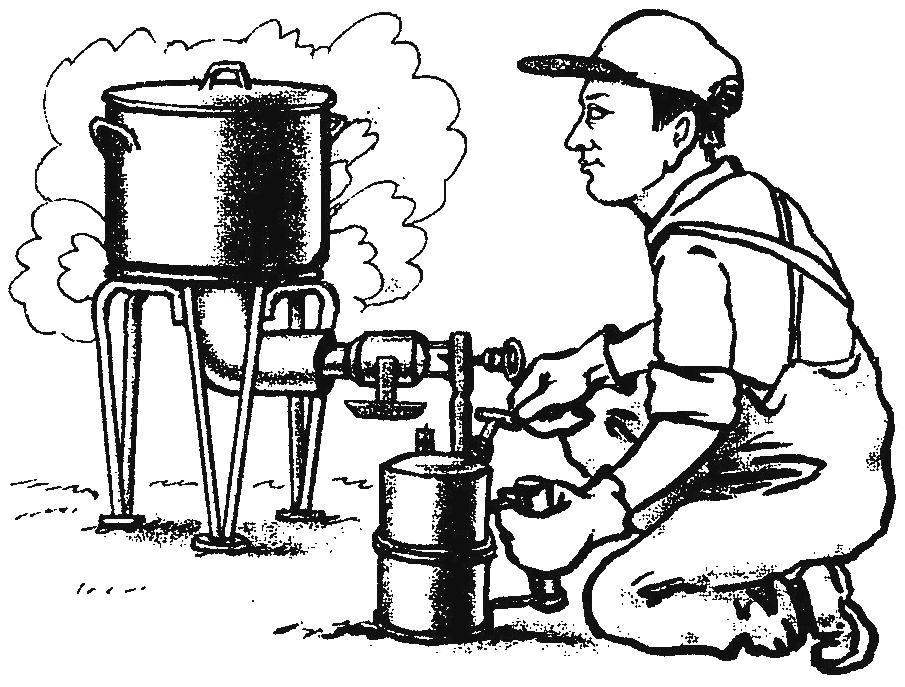

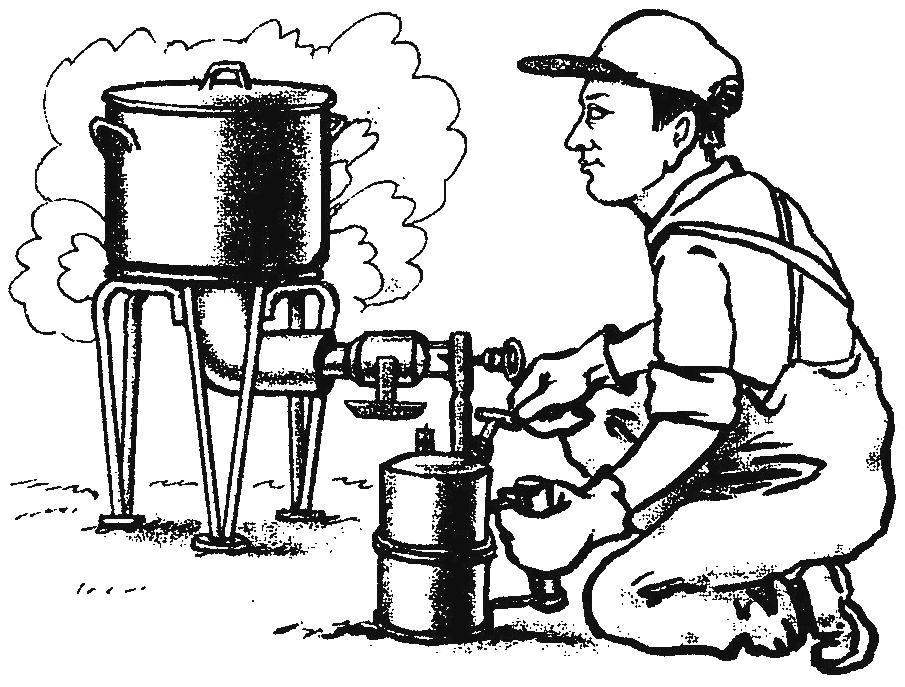

Blowtorch both the heater has long occupied a place in the Toolbox as a professional and many Amateur designers because fuel for it is always available gasoline. It finds wide applications also in the economic practices of rural residents and cottagers in certain situations: very rescued their owners, for example, when you need to quickly boil water, “calcined” or heated metal, in many other cases. One bad: this lamp is not always convenient to use—for example, you cannot direct the flame upwards, which is needed quite often. To resolve this shortcoming, the lamp can be equipped with additional device—support-a tripod with up curved elbow-knee.

Blowtorch both the heater has long occupied a place in the Toolbox as a professional and many Amateur designers because fuel for it is always available gasoline. It finds wide applications also in the economic practices of rural residents and cottagers in certain situations: very rescued their owners, for example, when you need to quickly boil water, “calcined” or heated metal, in many other cases. One bad: this lamp is not always convenient to use—for example, you cannot direct the flame upwards, which is needed quite often. To resolve this shortcoming, the lamp can be equipped with additional device—support-a tripod with up curved elbow-knee.

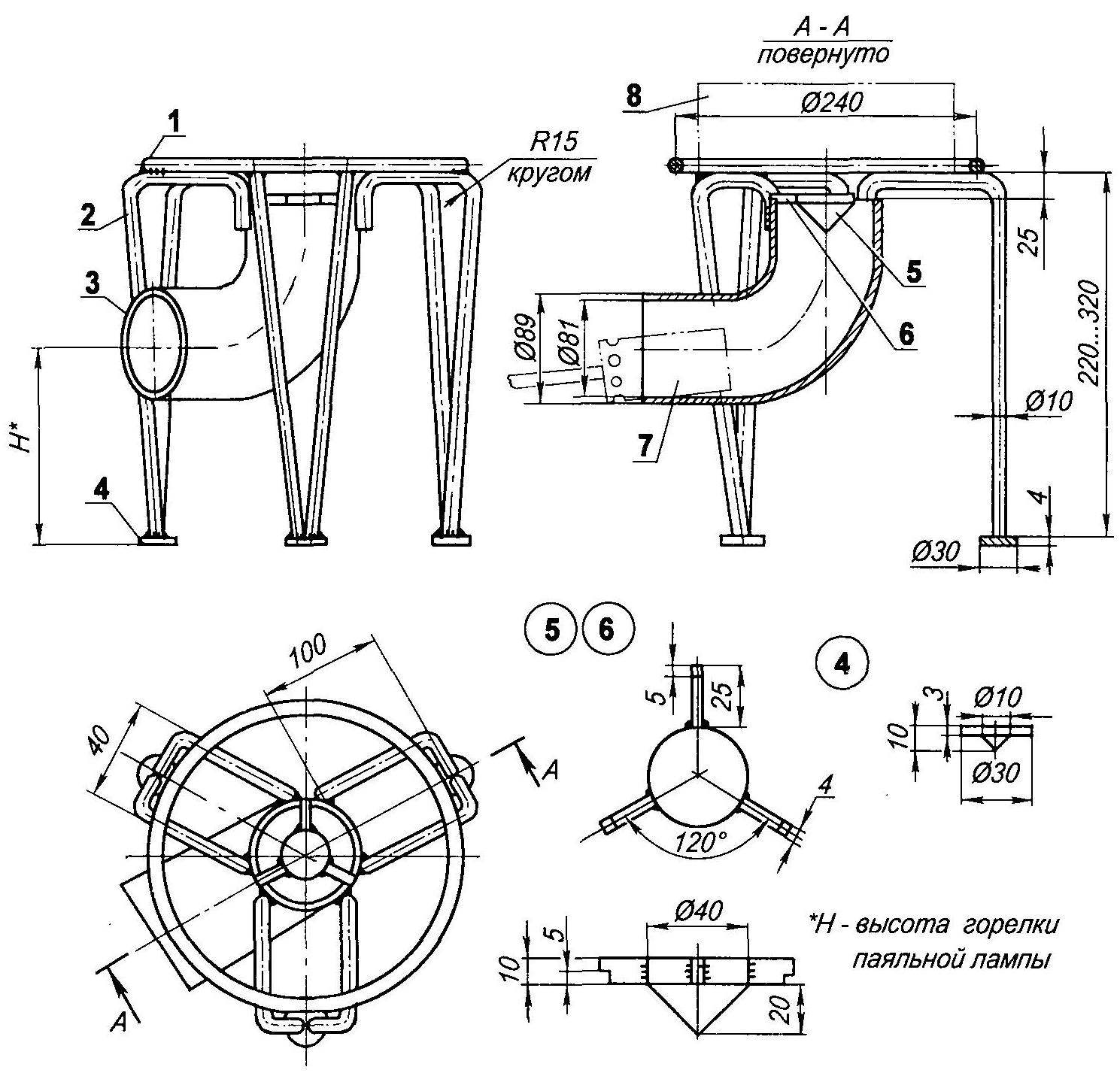

Wrap legs and andirons are made of “calibration”—steel smooth rod with a diameter of 8 mm. the Hoop is easy to bend and “cold”. The internal radii of the bends of the legs is small — only 15 mm, so the space bends better pre-heating the same with a blowtorch, which made the trivet. The legs of all three (as we know is the most rational and this design is stable on uneven surfaces). The bottom legs are welded to the thrust of a steel plate with a thickness of 3-4 mm (detailed drawing given the option, turned the bearing with the locking cone).

Elbow-knee it is possible to find a ready to bend or cut a three-inch pipe, and from it to cut the knee part.

After fabrication all parts in contact are connected by conventional arc welding processes: legs welded to the top of the pipe, and the under—laid on top of them wrap.

The trivet for a blowtorch:

1 —Hoop (steel, lap 8); 2—leg (steel, circle 10, 3 PCs); 3 — elbow-knee (pipe 3″); 4 — thrust bearing (steel, sheet s3): 5 a flame spreader (steel, lap 40); 6—beam (steel, sheet s4, 3 pieces); 7—burner blowtorch; 8—capacity (bucket)

This trivet I used a few years and then upgraded it, made it still the flame spreader: a cone-shaped part, the tip is directed inside the pipe. To the forefront were on the axis of the pipe, the divider is secured to the three beams—plates of 4-mm steel sheet. One ends of beams was welded to the divider, the other to the walls of the pipe. With the divider area of the flame became larger, the flame itself is smoother, and most importantly, it became faster to heat up water in a large container—a bucket or a pot.

By the way, the tripod is very convenient to use as a support for the container and above the ordinary wood-burning fire.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.

Recommend to read

AS PRINTED!

AS PRINTED!

Any risks or scale deposited on metal or plastic surfaces of objects, will be seen more clearly if they are first covered with paint, and then wipe: deepening will save the leftover... WICKET — A DIFFICULT

WICKET — A DIFFICULT

The gap exposed between the gate and the column will cause respect for the skill of the Builder from any incoming to the site. To do it by using two identical plate thickness-supak...

Blowtorch both the heater has long occupied a place in the Toolbox as a professional and many Amateur designers because fuel for it is always available gasoline. It finds wide applications also in the economic practices of rural residents and cottagers in certain situations: very rescued their owners, for example, when you need to quickly boil water, “calcined” or heated metal, in many other cases. One bad: this lamp is not always convenient to use—for example, you cannot direct the flame upwards, which is needed quite often. To resolve this shortcoming, the lamp can be equipped with additional device—support-a tripod with up curved elbow-knee.

Blowtorch both the heater has long occupied a place in the Toolbox as a professional and many Amateur designers because fuel for it is always available gasoline. It finds wide applications also in the economic practices of rural residents and cottagers in certain situations: very rescued their owners, for example, when you need to quickly boil water, “calcined” or heated metal, in many other cases. One bad: this lamp is not always convenient to use—for example, you cannot direct the flame upwards, which is needed quite often. To resolve this shortcoming, the lamp can be equipped with additional device—support-a tripod with up curved elbow-knee.