I want to offer the readers of the magazine the burners for liquid fuel — diesel. It is also possible to use various waste industrial oils, diluted to a more liquid state diesel fuel Believe that this burner will be useful to many people in the household, especially rural residents as a center for the preparation of hot feed or pet in the summer, when many villagers arrange a summer kitchen on the street.

I want to offer the readers of the magazine the burners for liquid fuel — diesel. It is also possible to use various waste industrial oils, diluted to a more liquid state diesel fuel Believe that this burner will be useful to many people in the household, especially rural residents as a center for the preparation of hot feed or pet in the summer, when many villagers arrange a summer kitchen on the street.

Will be fine for heating-stoves”stoves” in the baths are Very comfortable in the repair and execution of roofing work, as well as in many other cases, when no other source of heat. Satisfied burner also and truckers for temporary heating of the house is Important, that at low fuel consumption it creates a high combustion temperature, and in complete heating of the fuel in burner burns completely, with a slight smoke.

To make yourself a burner of difficulty will not constitute a Material are waste steel water pipes with a diameter of 1/2″, which can be found in scrap metal or purchased in the shop “building Materials” You will need 2 — 2.5 meters.

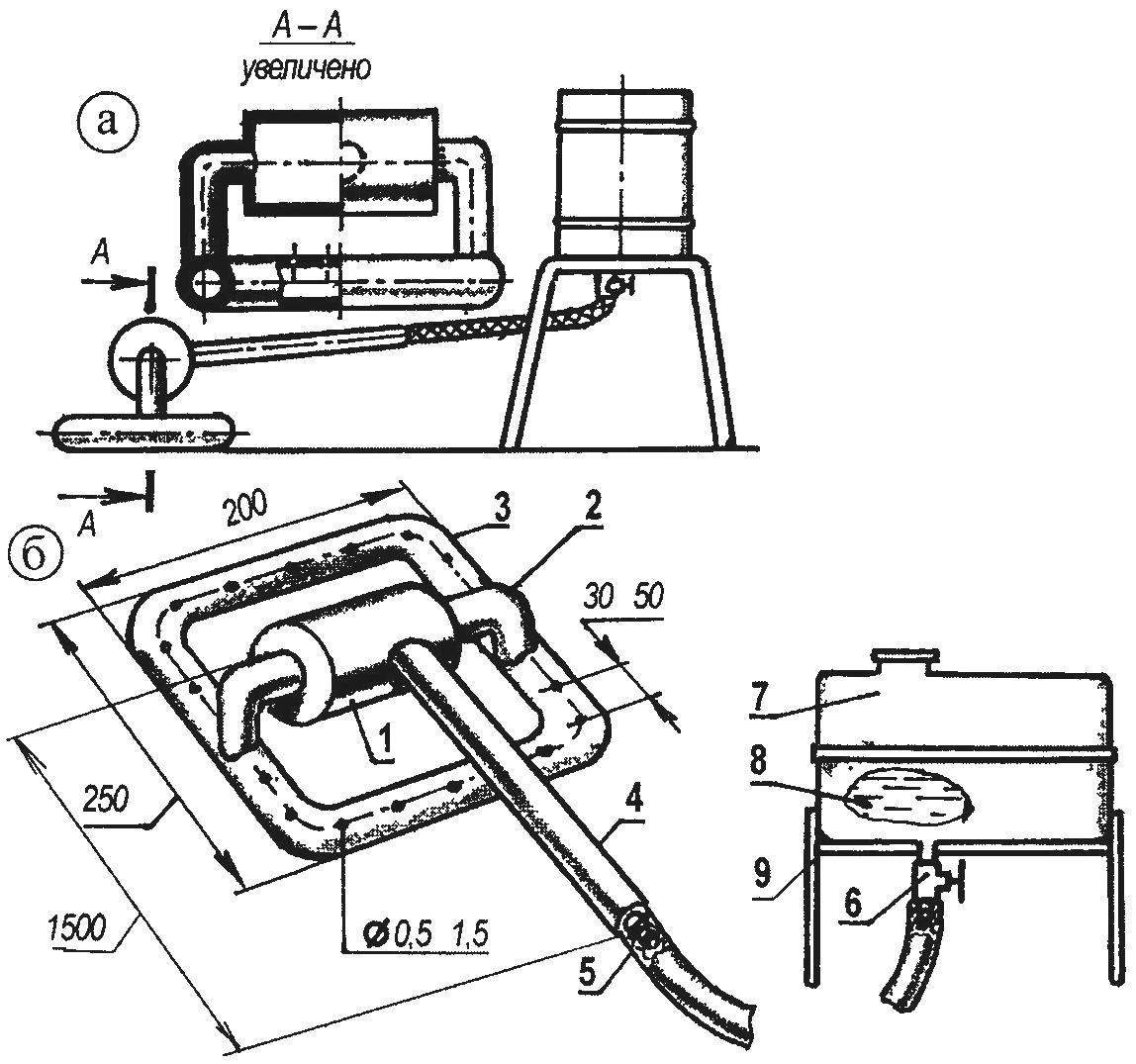

Look carefully at the picture and you will understand the device of the burner Nozzle bending round or rectangular shape. If you can not bend, do butt joints, drank blanks pipes with a hacksaw. All connections are made gas or electric (now there is hardly a fan of tinkering, not having a welder and no skills with it) around the perimeter of the nozzle drill holes-the”nozzle” with a diameter of 0.5 — 1.5 mm, with intervals of 30 — 50 mm it Should be noted that the diameter of these holes determines the fuel consumption and the burning intensity Drill two holes of diameter 8 — 10 mm for connecting the nozzle with the burner drive.

The drive is made from a section of a pipe of larger diameter 70 — 120mm or rolled from steel strip It is used for receiving and heating fuel, which turns to steam and exits through holes”nozzles” are already under pressure mixed with air, it burns.

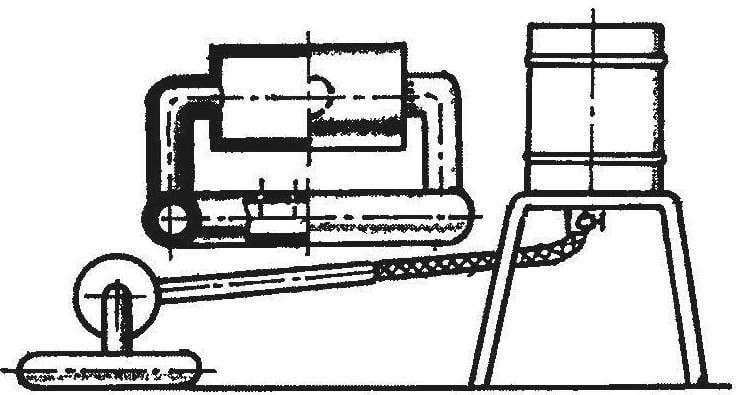

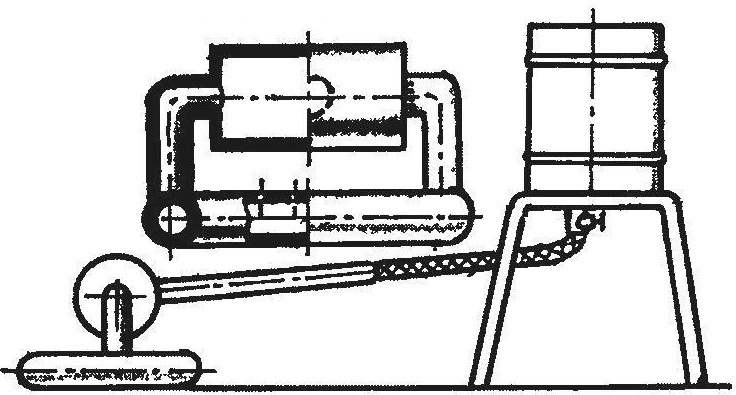

The burner is operating on liquid fuel (a diagram of the installation of the burner b — burner design):

1 — drive, 2 — connecting tube, 3 — injector, 4 — fuel feed pipe, 5 — pipe connection fuel hose, 6 — outlet tap of the tank 7 —fuel tank 8 — fuel (diesel), 9 — tank stand

Fuel container, any suitable metal barrel, canister, tank from decommissioned equipment On the tank mounted tap fitting for fixing the rubber hose which is the fuel line to the burner. The capacity is set on a hill, in order not to complicate the device by forced flow of fuel.

The start-up of burner is that you must first warm up drive with fuel enough to open the fuel valve and light the torch under the drive. As the heating happens fire and fuel coming out of the holes Then when fully warm-up the burner will enter the peak of combustion and will work to stop the flow of fuel due to its completion or ceiling crane of its submission.

The fire intensity by regulating the fuel valve and the height of the fuel tanks.

After starting of the burner it does not require constant supervision — unable to perform other work. Of course, the operation should not forget about the basic rules of fire safety, for example, to operate the burner away from flammable objects Tank with fuel, place on the greatest possible removal from the flame of the burner.

N. LOGACHEV, Kursk