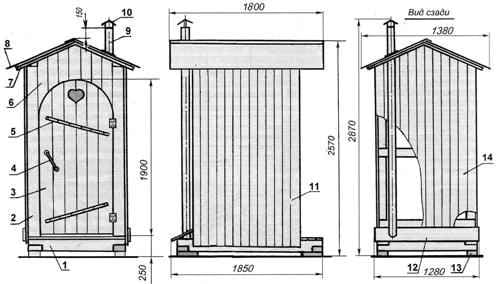

When choosing a location is necessary to observe certain sanitary requirements. If the area is well, the toilet must be positioned not closer than 20 m from it and at a distance of not less than five metres from a house. In the presence of a cesspool is necessary to leave and travel to the toilet for special vehicles. Version of the toilet to pit latrine shown in the drawing the frame of the booth.

As for the sump, its the sides and bottom I made a concrete and a depth of about 2 m and the bottom was executed with a slight slope to the rear. The sides and bottom of the pit can be made out of ceramic (red) solid brick, natural stone and even wood. But to ensure integrity in the first (brick) version of the hole from the inside should be plastered, and the second seams tarred oakum. In sandy soils outside of the walls and under the bottom of the pit it is necessary to arrange the clay lock with a minimum thickness of 250 mm, and inside (all versions), to cover with bitumen. Preferably the wall is slightly raised above the ground level to the pit did not get rain and melt water.

Booth toilet — frame construction. The basic power elements of the frame is made from boards with a thickness of about 40 mm, a width of 150 mm and nailed together.

Booth WC’s:

1—tying (beam 150×150); 2 — (150×40 Board, 4 pieces); 3—door (lining s20); 4—door; 5 — crossbar door (bar 40×40, 2); 6—front wall-gable (lining s20); 7—rafter roof (Board 150×40, 3). 8—roof (galvanized steel sheet s0,8); 9—vent riser (asbestos cement pipe d100); 10—cover-vent vent riser (galvanized steel sheet s0,8 ): 11, a side wall (20 boards); 12 — cover the sump (plywood s6), covered with roofing material); 13—stand (solid ceramic bricks, 4 pieces); 14—rear wall

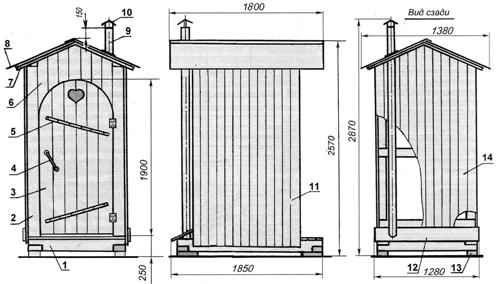

Installed the box on a fairly powerful concrete beams (150 × 150 mm) larch (can be oak or other hard-to-decay wood). Bars strapping carefully pre-treated (soaked) with antiseptic. Pairing between the “half-tree without a trace” and fastened with nails. The length of longitudinal and transverse framing bars correspond to the size of the sump and laid on her wall through a strip of roofing material.

Looking ahead, I note the following Because the length of the piping is greater than the length of the booth of the toilet, then had to lengthen the front and rear overhangs of the roof. The protrusions strapping outside the booth is also used: front — steps and back — as a hatch for access to the sump.

The base of the box serves as the floor. He made a step out of the Board-the forty and below, as the timbers trim, thoroughly treated with preservative.

The frame of the booth is a version of a toilet to pit latrine (details unspecified items made of boards, s40):

1—cross strapping (timber 150×150, 2); 2—(150×40 Board, 4 pieces); 3—rear crossmember (3). 4 — front cross-member; 5—ridged strut (Board s40); 6—rafter (Board s20, 3 pieces); 7 — skate (Board s20); 8—bolt (2 pieces); 9 — shelf railing (2 PCs); 10—brace (2 PCs.); 11—front raised part of the floor (2); 12—step (protruding out of the floor); 13 — rising part of the floor; 14—a sole (2); 15—the sunken part of the floor; 16—seal (roofing material); 17—wall and the bottom of the sump (concrete); 18—waterproofing (bituminous coating); 19—clay lock; 20—ground

In the rising part of the cut oblong transverse hole and the planks along the connected pads-employees of both the soles At the corners of the floor are carved the grooves in the cross section boards / posts. Stands inserted into the grooves and nailed to the floor and sealed with the cross members, beams, struts, and roof elements.

Side girders, intermediate, and top, laid flat — the first are still a kind of shelves and railings, while the second is more convenient to attach the rafters of the roof.

The gable roof of the booth, which gives the toilet the form of a house. As roofing used galvanized steel sheet. Alternatively, bring the drawing the device of the roof sheathing under slate roof. Its difference is that the role of the rafters in this case carry out the Gables, and crate serve runs — the ridge and the bottom. Since the roof is metal and in the heat gets very hot, as insulating layer I in the booth did the ceiling of gorbylkah boards of different thickness, only viewnav their edges.

The device of a roof under the slate roof:

1-front frame box (4 PCs); 2 — crate overhang (2); 3 — crate skate 2pcs.): 4 — gable (2); 5 — cross member of the frame of the booth (2); 6—ceiling (Gorbulina gloss s20)

The walls of the booth it is best to upholster lining. The rallying of these boards is in itself almost eliminates the cracks: if the toilet is not insulated, but the draughts in it are unnecessary, too.

The lower section of boards made with “oblique” — trapped on the walls of the rain water rolls down and drips from them as from Lesnica.

The door was made of arch type — I like this more than rectangular, although this is a matter of taste. It, like the walls, made from lining. Between the floor and bottom of door left a small gap, and at the top of the door cut out a small window. These holes are well ventilated interior space of the booth without creating a draft. Board doors sealed from the outside two slightly sloping (and in different directions) with crossbars. In addition to the necessary stiffness, these cross-members attach to the toilet some vintage look and makes it look like the box Outpost on the tract at the entrance to the city.

To protect against moisture, all exterior wood surfaces of the booth (walls, door) treated water-repellent cheap texturology. For hygienic reasons, if necessary, can be washed, covered the floor and walls and door to a height of about one metre cold-resistant varnish. The remaining inner surface of the walls and the ceiling left unpainted. Because the booth is made of wood of coniferous breeds, and they exuded the scent serves as a natural ozonizer toilet.

To reduce the hit of unpleasant odors inside the toilet from the sump outside else installed asbestos cement pipe with lid-vent. The very same pit in the back covered sloped plywood cover with a small overlap to precipitation did not fall into the pit. Bottom cover treated with an antiseptic, and the top is studded with roofing material. For the pipe in the lid of the carved groove, which serves as a retainer (or a limiter).

A. MATVEICHUK, Zavodoukovsk, Tyumen region.

Recommend to read EN-ROUTE — ON THE FLOW To accelerate the construction of highway performance in the circle of Taldy-Kurgan regional station of young technicians was created a set of tools: - the matrix and the punch for... “ANT” OF SHOSTKA Isn't it interesting microntroller built young designers syut city Shostka in Sumy region? "It is easy and convenient to operate by the authors of the letter. The wheel we took from the...

Any individual developer, since the development of the site or the erection of a house on it, just have to first build at least a small and simple toilet. Although I would note that great solidity of this building is no different even in areas with mansions. But for modern portable toilets easy booth with a flat floor is required (which is installed on the bricks, and shown on the General arrangement drawing).

Any individual developer, since the development of the site or the erection of a house on it, just have to first build at least a small and simple toilet. Although I would note that great solidity of this building is no different even in areas with mansions. But for modern portable toilets easy booth with a flat floor is required (which is installed on the bricks, and shown on the General arrangement drawing).