The Rover is assembled mainly of serial units and components of various automobiles and agricultural machinery. Her stripped, still a lot left on the “technologisch” in abandoned quarries and ravines of the Russian hinterland; to her, there are things even the “Vtorchermet”. The important thing is that all these variegated, but reliable mechanisms which is arranged in one design and work it very smoothly. This suggests whether sometimes our engineers to fight on a “personal” units for each new machine. Is not it easier to adapt appropriate and tested the unit, even from the other design.

The Rover has a simple frame consisting of two longitudinal side members made of channel No. 16A, and five cross beams. Ahead distance between the frame 700 and the back — 720 mm.

The acquisition of Rover engine Amateur designers faced a choice: to install petrol (volgovskoe or uazovskij) or diesel? The choice fell on diesel D-37 from the tractor T-40 (four-stroke, four-cylinder, the working volume of 4.2 liters and power of 40 HP at 1600 rpm).

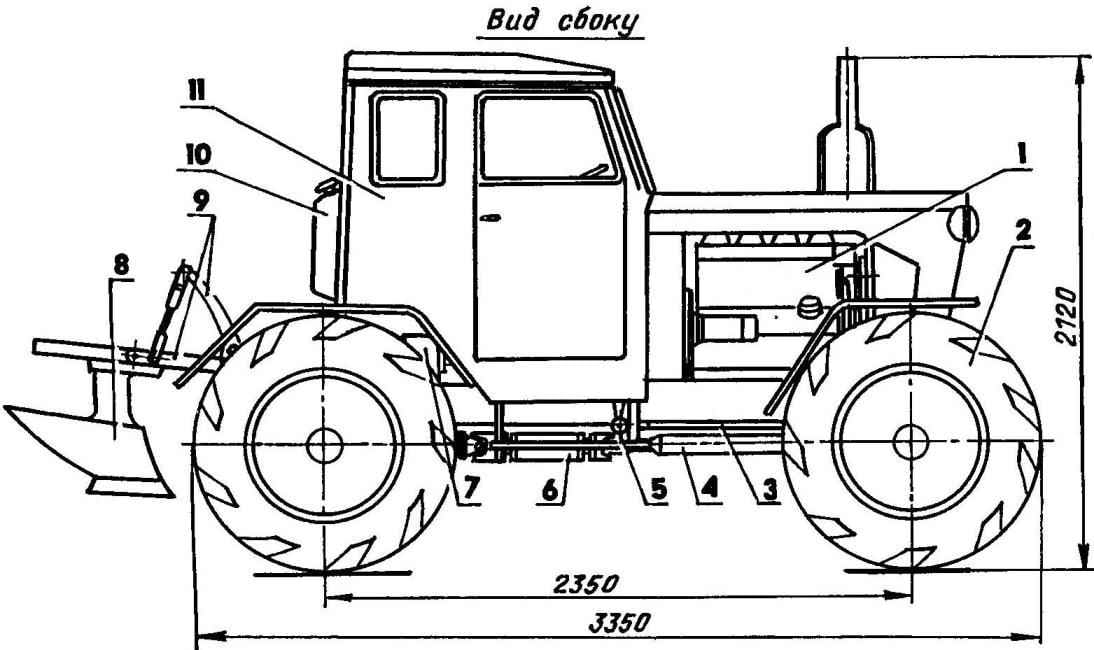

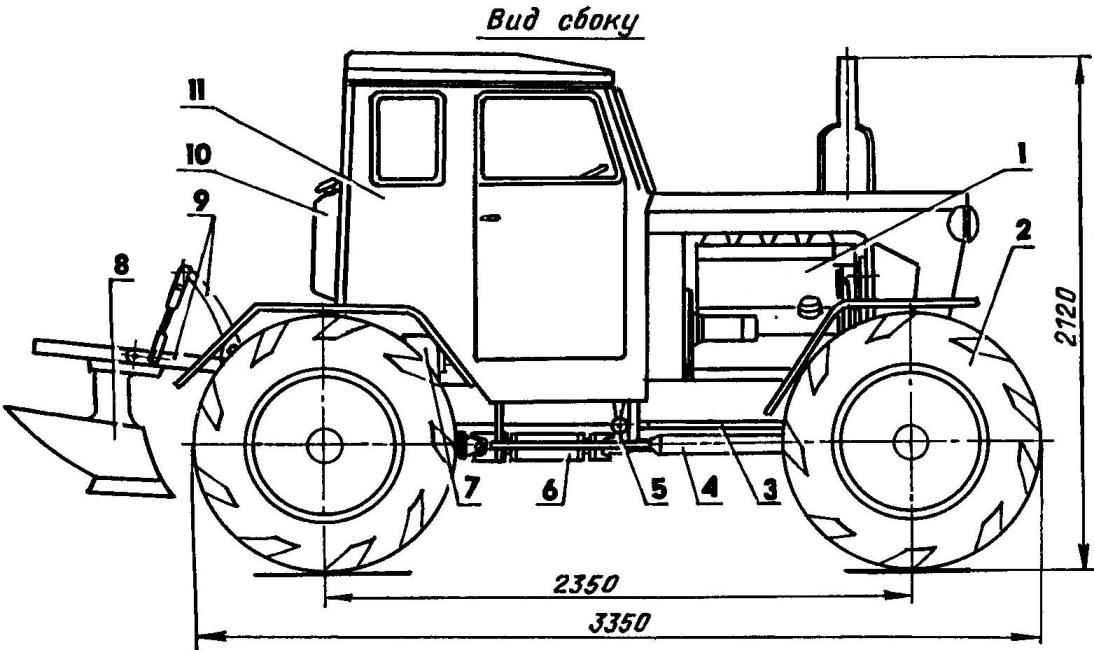

ATV-tractor:

1 — engine (D-37 from the tractor T-40); 2 — wheel (18″ from GAZ-66,4 PCs); 3 — longitudinal steering rod (from the tractor “Belarus”); 4 — propeller shaft front wheel drive; 5 — a Pitman arm (from a tractor “Belarus”); 6—mechanism of the front axle drive; 7 — speed transfer case (gear from foragers); 8 — trailed farm implements (plow) or a transport truck with a lifting capacity 4.5 t; 9— the levers of attachment; 10 — fuel tank (tractor DT-75); 11 — cabin (from tractoras-4); 12 — exhaust pipe-muffler; 13—pivot suspension of the front axle (steel, range d40); 14— front axle (from the GAZ-66, short); 15 — mount bracket to the front of the bridge (steel, sheet s16); 16 — the lever of steering gear (from the tractor.”Belarus”). Buffer the frame and hood not shown

With bridges such problem did not stand, although the choice also was to take them from “UAZ” or GAZ-66? But since the car involves the installation of large-diameter wheels to provide better flotation, otrisovka chassis immediately rejected — there was fear that in overcoming the “normal” off-road they can not withstand the load.

Bridges from GAS-66 (with Cam limited slip differentials, ground clearance of more than 300 mm, Central pneumatic system of pressure in tires of wheels with a diameter of 18″, well “developed” lugs) that fits the vehicle perfectly. In addition, these bridges are tested and reliable, and to ride on the back roads they can set the wheel and of larger diameter (20″) — ZIL-131 Ural, as do the army version Gusovskogo “Sadko”. So I was not surprised when I read on the pages of any automotive magazine article about “the Wild GAZelle”, which is for use in heavy traffic conditions is also applied to the bridges on the GAZ-66. A considerable advantage was the fact that the old “sixty-sixth” can be purchased for a symbolic price. The only drawback

Rear axle fixed to the frame rigidly, through four corners and ladders, is a classic front wheel tractor beam pivot suspension. To do this to him from above prevernal bolts M16 bracket, welded from a steel sheet with a thickness of 16 mm Pin with diameter of 40 mm. Both bridges are cropped to have the same track gauge 1440 mm. Then the halves of the bridge before welding was docked and centered with the pipe, precisely matched internal diameters of the ends Chul-kov bridge. The front axle was shortened only by the longer grip, and the distance between the flanges amounted to 835 mm, but the gearbox was located right in the middle.

Chassis, engine and transmission:

1 — engine; 2 — king pin suspension front axle; 3 — front cross beam; 4 — the buffer (GAZ-66); 5 — bracket front axle; 6— rear axle; 7 — propeller shaft front axle drive; 8 — firing mechanism actuator front axle; 9—cross (5 PCs); 10 — flange coupling (5 PCs); 11 —linkage (remote-cylinder); 12 — gear box; 13 — intermediate propeller shaft; 14— gear shift (from car ZIL-130); 15 — clutch basket (ZIL-130). Right wheels and hubs are not shown

This alteration allows the bridge on the former site of the long axis to use the standard short, if you’re able to get. If not, you will have to shorten the long side shaft. For this purpose it is cut off from the swivel (the rear wheel) part, and the spline is truncated in size; on a lathe is prepared by connecting the mate.

Then the both parts of the rod are connected, centered and welded.

Drivetrain Rover: clutch basket, gear shift (transmission) — ZIL. For mounting the clutch basket from the engine was removed polyerter flywheel and a steel 8-mm plate. For mounting the transaxle 10-mm steel plate was made drive an outer diameter of 370 mm from the groove 317 mm. mounting of the transmission units is much easier if you use the flywheel housing from welding diesel generator engine D-37.

With torque transmission through a short propeller shaft is transmitted to the input shaft of a transfer box. As the gear box is adapted forage harvester stirrup identical cylindrical gears (one idler), so its ratio is equal to one. Box is mounted on the frame so that the axes of all its shafts are in the plane of symmetry of the machine.

One end of the transfer case output shaft rigidly, via a flange coupling, is connected to the rear axle. From the other end of the shaft through intermediate mechanism is the actuator on the front axle. The casing mechanism made from steel pipe with outer diameter 120 and a length of 300 mm, rigidly fixed to the frame of the vehicle, her office is on the floor of the cab.

The basis of the mechanism are two coaxial shaft. Primary rotates in two bearings. The output shaft bearing are single bearing and a bronze bushing pressed into the end of the socket shaft. At both ends of each shaft there are slots. On the outer fixed flanges and internal splines mounted on moving them slidably splined coupling enable (disable) the front axle. Clutch control is a lever mounted on the floor of the cab with a fork.

The cabin of the vehicle from the tractor T-4, three-and comfortable enough, equipped with heater and radio. Behind the cab mounted fuel tank 180 l from the tractor DT-75.

The steering mechanism with longitudinal rod from an old tractor “Belarus” is mounted with no modifications. Tie rod used car GAZ-66, short.

Electrical equipment — from tractors T-40, battery 180 amp/hours.

The mechanism vkljucena/wykluczenia front wheel drive:

1 — flange (2 PCs); 2 — housing cover (2 PCs); 3 — casing (steel pipe 120×20); 4— the bearing 208 (3 PCs); 5 — switch; 6 — M6 screws (8 PCs); 7 — screw M10 flange mounting (2 pieces); 8 — shaft; 9 — the coupling connection; 10 — the bearing; 11 — spacer; 12 — a primary shaft

Transfer box:

1 — housing; 2 — input shaft; 3 — intermediate shaft; 4 — output shaft; 5 — flange (3 pieces); 6 — cuff (3 pieces); 7 — the bearing 206 (6 PCs); 8 — bearing cap (3 pieces); 9 — the plug (3 PCs); 10 — gear (3 PCs.)

Before you start designing the Rover, its creators have determined that along with working in shipping not his last task will be the cultivation of the land, and equipped it mounted aggregate from T-40. (With orientation mainly on transport work to save spring suspension bridges and to leave unchanged the track GAZ-66.) With the help of a modular system can be mounted on a machine dwuhlopastny a plow or other necessary agricultural tools. For the transport of goods the most appropriate will be the standard two-axle tractor truck with a lifting capacity of 4.5 tons.

There was another reason to make an all-terrain vehicle in the tractor version: now register with improvised equipment in tractor inspection still easier than in the traffic police. Thus the speed of the vehicle is imposed restriction — no more than 55 km/h. The same speed on a good road is “cruising”.

P. SPEAR, the city of Beloretsk, Bashkortostan

Recommend to read NOT LEVER AND SWITCH The development of the garden or suburban area, many owners have to start with providing it with water. Since this problem started and I. The water in the area lies relatively close to... COMPASS — DRILL ASSISTANT If you need to drill through wall, out the other side exactly in the right place — use...a compass. Of course, in collaboration with the magnet, which should be put behind the wall...

Scroll back to top

Not so often, unfortunately, in the magazine there are descriptions of the improvised structures that exceed the current level of production of the Russian, and especially Western technology. And this is understandable: after all, do these Amateur machines, usually in a shed or garage where all the equipment consists of a drill and a welding machine.

Not so often, unfortunately, in the magazine there are descriptions of the improvised structures that exceed the current level of production of the Russian, and especially Western technology. And this is understandable: after all, do these Amateur machines, usually in a shed or garage where all the equipment consists of a drill and a welding machine.