The idea of making a mini-truck based on the Ant scooter came to my mind a long time ago. While operating a cargo scooter, I encountered a number of inconveniences. The biggest disadvantage of the scooter was the third wheel, located in front and constantly making it difficult to ride on uneven country and forest roads, and it could not drive on sand at all. The lack of a cabin and driving in bad weather, especially in the cold season, created additional inconvenience. Therefore, I decided to eliminate these shortcomings, leaving the basis of the scooter without significant changes, since the very design of this “miracle technology”, its endurance, speed and most importantly, its carrying capacity, were quite satisfactory.

So, the process began with acquiring a donor. I didn’t dare cut and remake my Ant, so I bought an under-equipped scooter with a jammed engine from scrap metal buyers. Having disassembled it down to the screw, I began building my own mini-truck, which I dubbed “Shishiga”.

I left the frame, namely its rear part, unchanged, first of all getting rid of the front fork and the part of the frame to which they were attached (I sawed it off with a grinder). Then I completely cut off the seat and motor mounts, moving the latter to the left side of the frame so that I could install an intermediate reduction gearbox made from the rear hub of an IZH-56 motorcycle. By doing this, I limited the speed of the scooter to 30 -35 km/h and increased its already considerable carrying capacity. The rear reverse gearbox, axle shafts and balancers (aka pendulums) were left basic, while all four wheels were used from a motor scooter, but with tires from an SZD motorized stroller.

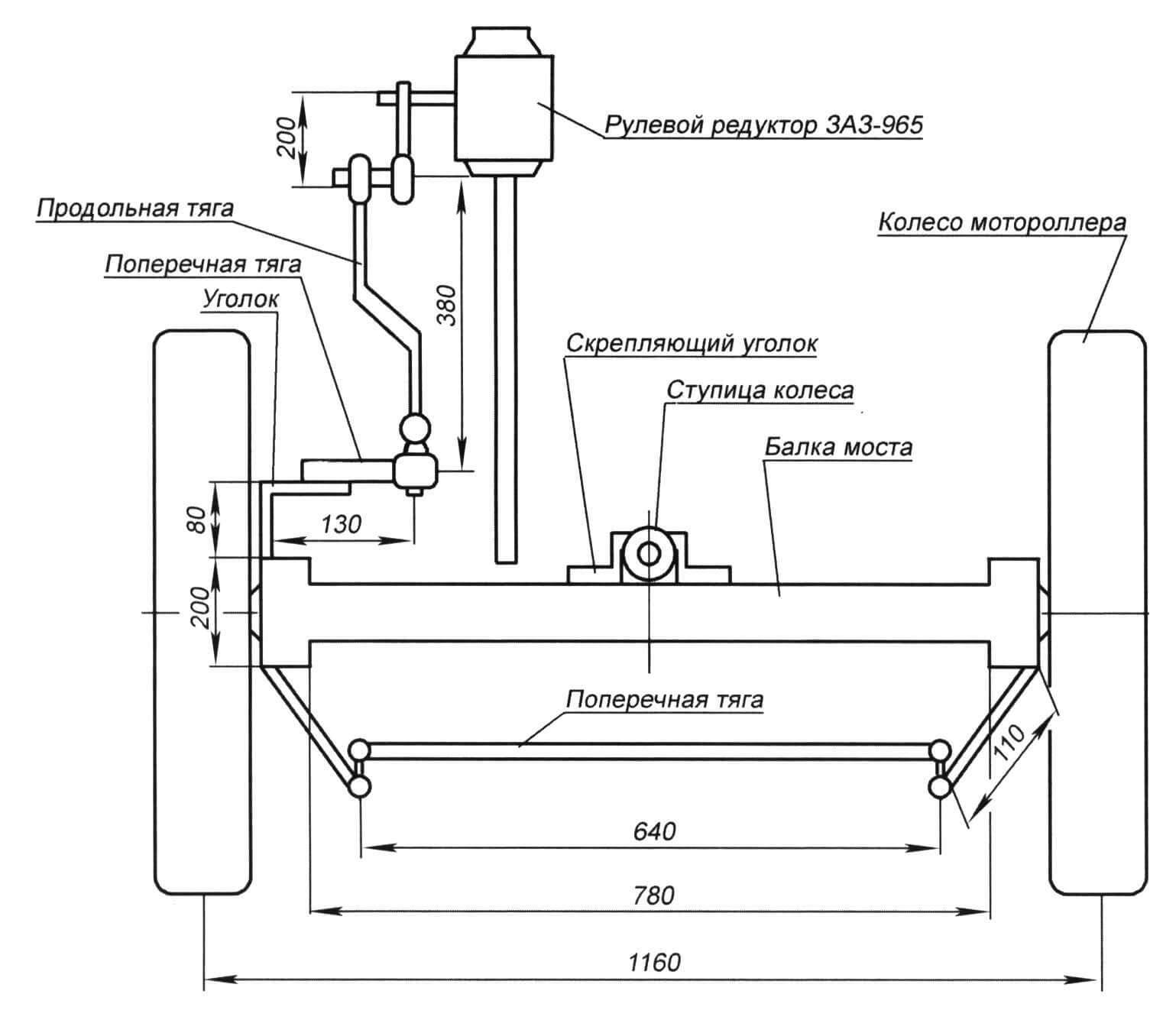

The front axle is completely homemade using parts and elements from the ZAZ-965 car, the steering gear and part of the transverse and longitudinal rods, as well as part of the longitudinal rods from the Moskvich-412 car, were also borrowed from it. The front beam was made from a square tube and a bicycle rear hub.

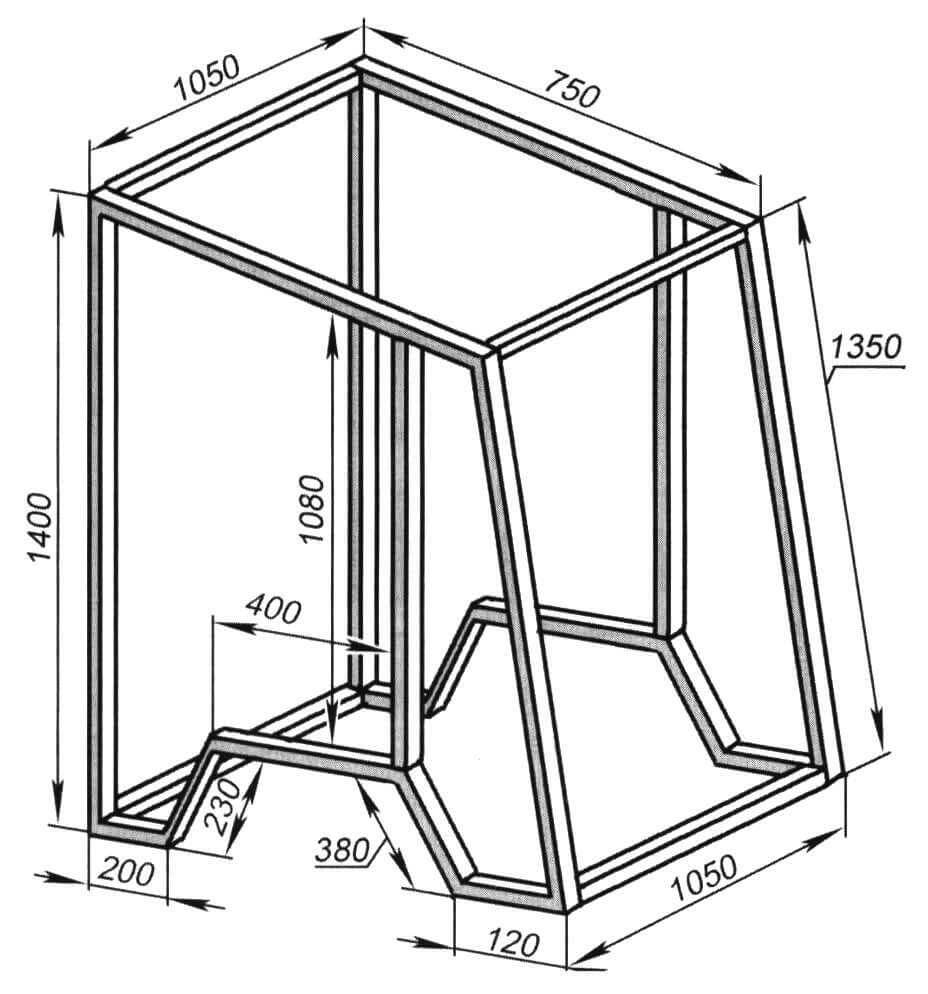

The cabin frame was made from a square pipe with a cross-section of 25×25 mm and the outside was lined with steel sheets from old refrigerators, which were perfect for this. The bottom of the cabin was made of galvanized sheet metal, which, in my opinion, will significantly prolong the operation of this machine.

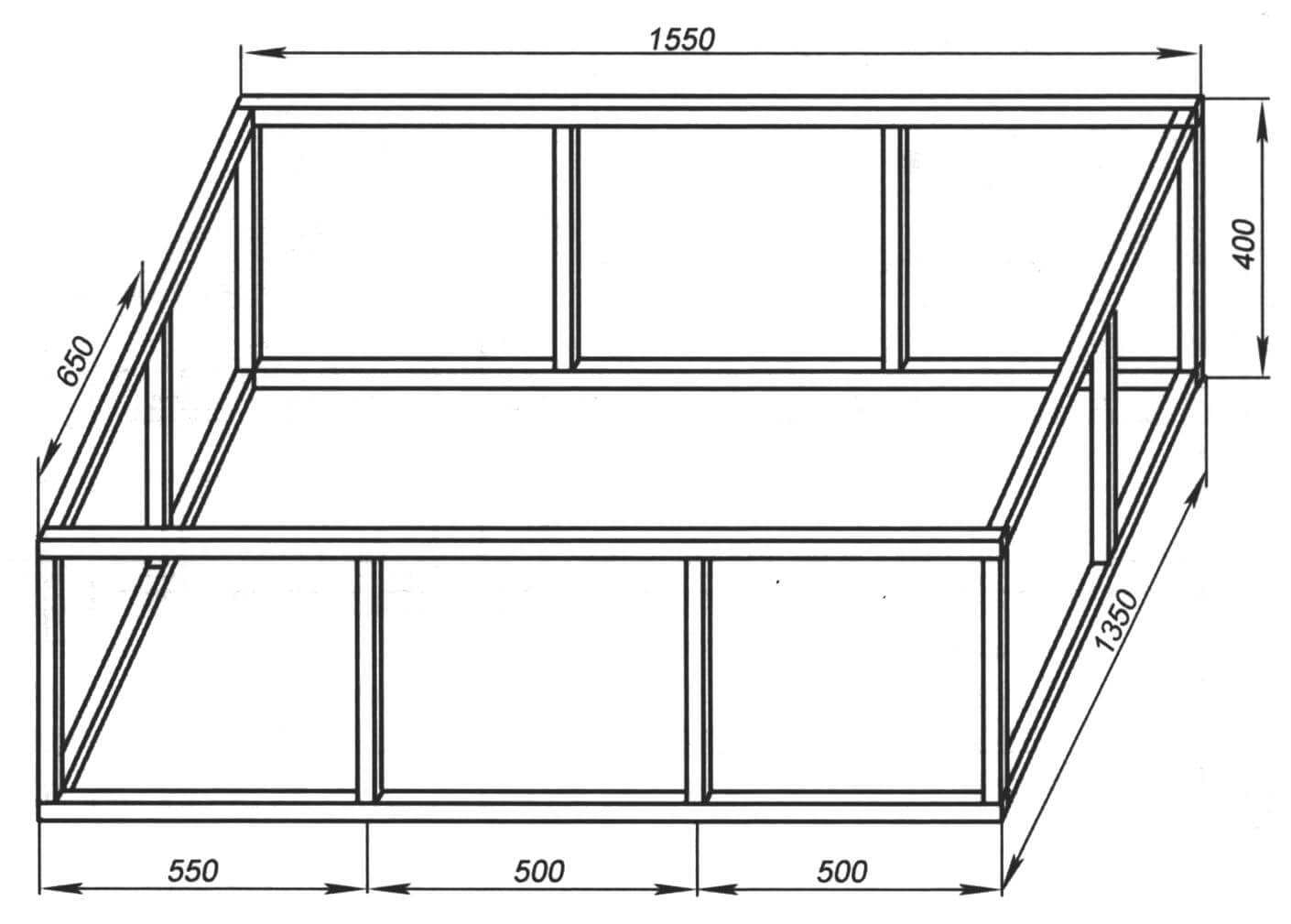

The more spacious body, compared to that of the Ant, is also made of a square pipe of the same cross-section, with the only difference being that the inside is lined with sheets of aluminum alloy 1 mm thick. The carrying capacity of the mini-truck and its cross-country ability have increased, thanks to a reduction gearbox that has changed the gear ratio.

The front axle of the car is made from components and assemblies of the ZAZ-965 Zaporozhets car, in particular, steering knuckles, transverse rods and front wheel hubs are used. The steering knuckles were taken unchanged, except for the dismantled supports for the brake pads and the working brake cylinder. The transverse rod was extended using a pipe of suitable diameter.

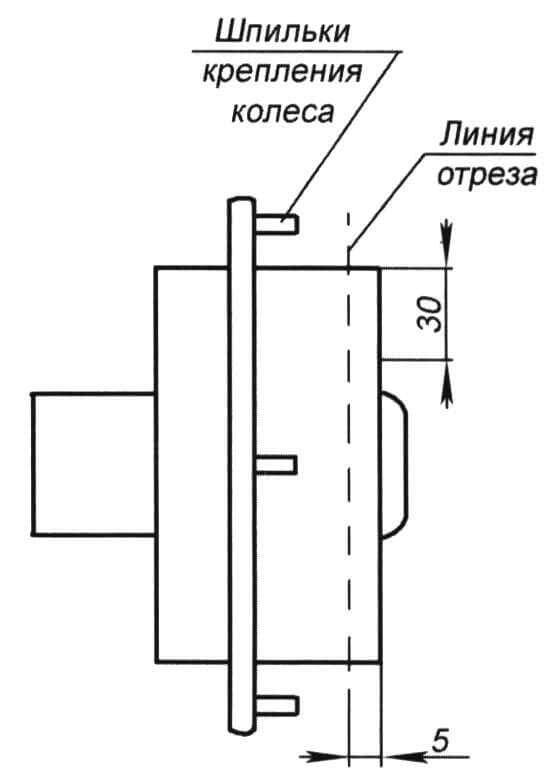

The main modifications were made to the wheel hubs, with the entire rear part of the hub being cut off 5 mm from the outer edge. On a lathe, I cut edges 30 mm deep and 1 mm thick for car wheel rims , or you can take rims from an Ant scooter. Then I drilled four holes with a diameter of 10 mm for the mounting bolts of the scooter rims. Holes were drilled at the location of each disk. Of course, it was possible to leave the hub without noticeable changes, cutting off only the studs securing the ZAZ wheels and installing standard hydraulic front brakes. But I didn’t do this, because I installed an intermediate gearbox, thereby reducing the speed of the truck, and the standard rear drum brakes of the scooter are quite enough to stop it.

Then I made a front axle beam in the shape of the letter “P”, the long side of which is 1024 mm, and the sides are 250 mm each. The beam is made of a square pipe with a cross-section of 50×50 mm and a wall thickness of 3 mm. I selected the dimensions so that the front and rear tracks were the same, and the ground clearance (280 mm) was increased in relation to the rear axle (115 mm).

The front beam is attached to the frame using a rear wheel hub from a bicycle, welded exactly in the middle of the beam and reinforced with corners measuring 25×25 mm and 3 mm thick.

Attached to the left steering knuckle is a steering axle made from a 100 mm wide angle, it is secured from below with two bolts, and an eyelet is welded to the top of the axle for attaching the steering longitudinal rod, borrowed from the Moskvich-412 car.

The steering gearbox is used from a ZAZ-965 car, which is attached directly to the frame on a stand specially made for this purpose. A transverse rod was taken from the same car, which is attached to the standard places of the steering axles. The steering rod was shortened locally to suit my height (Fig. 1).

The production of the front hubs is shown in Figure 2.

The intermediate gearbox is made using 5 mm steel plates with a width of 30 and 50 mm, rods with a diameter of 8 mm, an axle for the diameter of the 203rd bearing, drive and driven sprockets, part of the secondary shaft and the very hub of the IZH-56 motorcycle. The choice of this hub was not accidental, since it is made of metal, which allows certain parts to be welded to it, namely the threaded part of the secondary shaft of the drive sprocket from the IZH-56 motorcycle. I also used chain tensioners from him. All this was assembled as shown in Figure 3 and installed on the Shishigi frame by welding.

The gear ratio of the intermediate gearbox is 1/2, which reduces the speed by half and increases the thrust by the same amount. This is provided that the drive sprocket of the motor has eleven teeth.

You can also increase the speed by installing drive sprockets with a large number of teeth: 13, 15, 17, 19. With a nineteen-tooth sprocket, the mini-truck returns to the traction and speed qualities of a regular Ant scooter.

The body is sheathed with profiled sheets of aluminum alloy, using fillets measuring 8×3.2 mm. The width of the body on the outside is 1350 mm, and on the inside – 1300 mm. The internal length of the body is 1500 mm, at the outer edges – 1550 mm (Fig. 4).

The rear side of the body is folding, but not removable. Body depth – 400 mm. The tailgate is attached to three door hinges. The tailgate latches are homemade, made of a plate 3 mm thick and 50 mm wide and a rod with a diameter of 8 mm, as well as large nuts of the same diameter. Between the body and the frame there are rectangular wooden beams with dimensions of 50×70 mm.

The cabin, like the body, is made of square pipes measuring 25×25 mm and covered with steel sheets using rivets measuring 8×4 and 8×4.5 mm. The bottom of the cabin and fender liners are covered with galvanized sheet metal, the inside of the cabin is covered with automotive sound insulation. The seat is made of 10 mm thick plywood and covered with leatherette with foam rubber from car seats underneath.

The dashboard is also made of 10 mm thick plywood, painted with nitro enamel and varnished. The devices are used from motorcycles and scooters, in particular, the speedometer is borrowed from the Ural motorcycle, the ignition switch is from the Ant scooter, toggle switches and warning lamps are from ZAZ-965. The panel also contains an ignition switch, toggle switches for turn signals and high and low beam headlights, as well as an engine switch. There are indicator lamps for all lights, an indicator for the gearbox lever in the neutral position and for charging the battery. A horn button is also installed.

The pedal assembly is adapted from a Moskvich-412 car, the lever is homemade, made using a tube with a cross-section of 12 mm and the front brake foot of an IZH motorcycle, removed from the front wheel support.

The reverse lever is from the gearbox of a ZAZ-965 car, and the rocker is also taken from it, which is lengthened and adjusted to the location. The headlights are from a ZAZ-965, the rear ones are from a GAZ-51 truck, and the headlights are from a scooter.

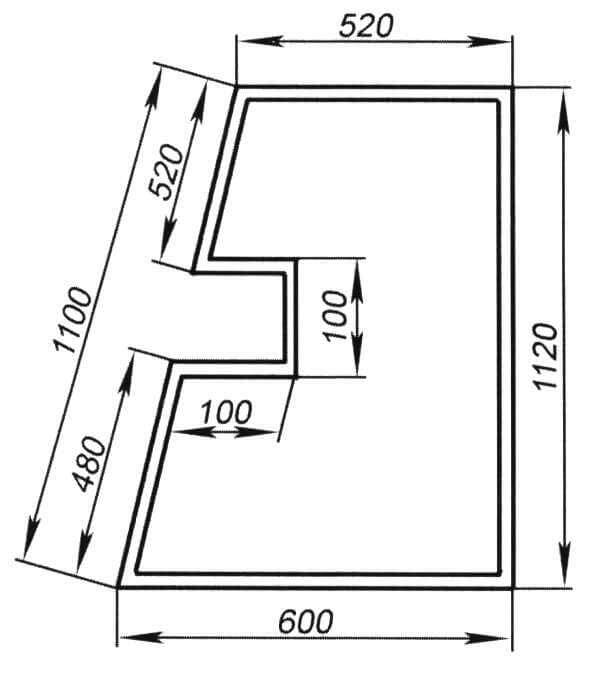

The windshield is two side windows of a ZAZ-965 car connected together using a plastic plate of the “H” configuration. The side windows of the “Shishiga” were borrowed from the old “treillage”, framed by a wooden frame riveted to the side doors. Handles with locks and hinges are from home interior doors. The dimensions of the cabin and doors are shown in Figure 5.

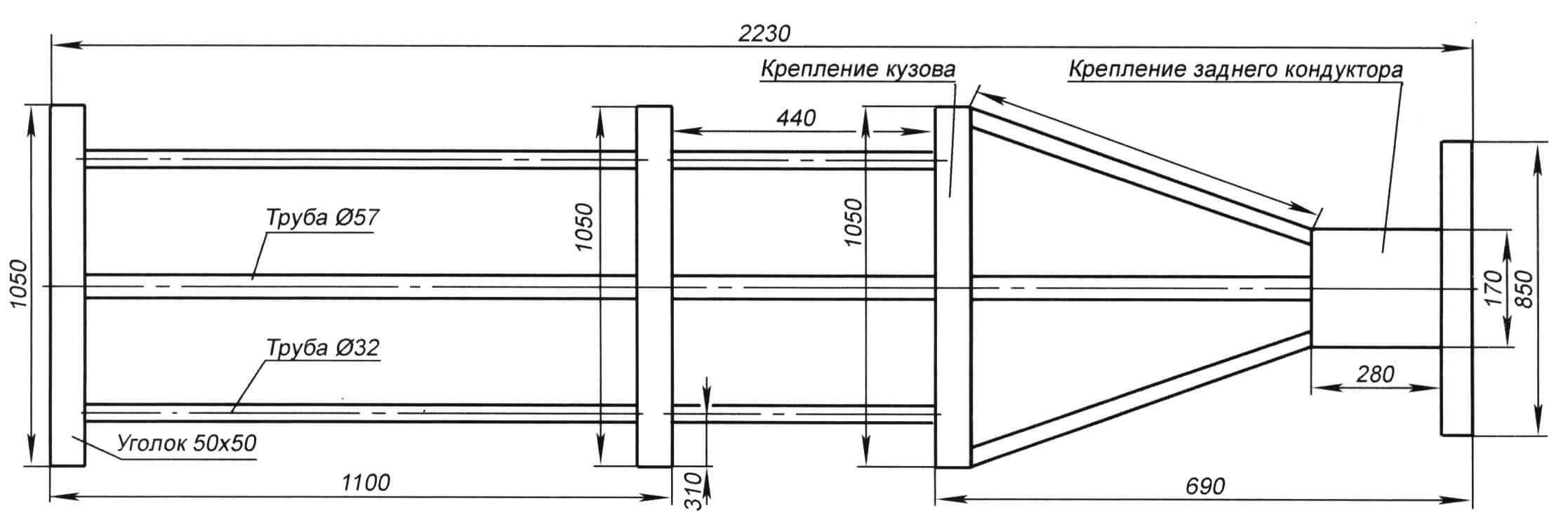

The frame of the mini-truck is made from 57mm diameter water pipes (2mm wall thickness) and 32mm diameter pipes, as well as 50mm wide angles welded across the frame pipes, the rear of which is left unchanged. The following additional attachments were welded to the frame: in the rear part there was an intermediate “reducing” gearbox, and in the front there was a mount for the steering gearbox. To the central pipe under the steering gear mount for installing the front axle beam, lugs are welded, cut from the front wheel on the pendulum of the Ant scooter fork.

Instead of a standard engine mount, a homemade one was used, made from 50 mm wide corners and moved to the left side of the frame. The engine mount was moved locally with chains put on all the sprockets; this is necessary in order not to disturb the alignment between the sprockets of the engine and the intermediate gearbox, as well as between the intermediate gearbox and the rear axle gearbox. The chain was used from an IZH motorcycle with a pitch of 19. To complete the work, I welded the cabin and front wheel fenders to the frame. The frame diagram is shown in Figure 6.

V. BELOUSOV