The idea to build a homemade car did not come to me right away, since I had a Moskvich. However, our terrain is such that you can’t get around in a passenger car, especially in muddy times. At this point you will inevitably think about a vehicle with higher cross-country ability.

I am a mechanical engineer by profession, so my passion is understandable. I followed publications about homemade products, analyzed their advantages and disadvantages. And when I had a chance to study “Niva” and “Volyn” in detail, the desire to build my own all-terrain vehicle became stronger.

Having considered several layout options, I settled on the “jeep” design, but decided to make the front wheels the main driving wheels.

He called his car “Neiva”. Its entire design is based on components and assemblies of Zaporozhets of various brands: this is a power unit, including an engine, clutch and gearbox, final drive and differential, steering and braking system.

Since descriptions of many components and devices of the Zaporozhets are given in specialized literature, I will not dwell on them, but will only tell you about what was made anew or modified.

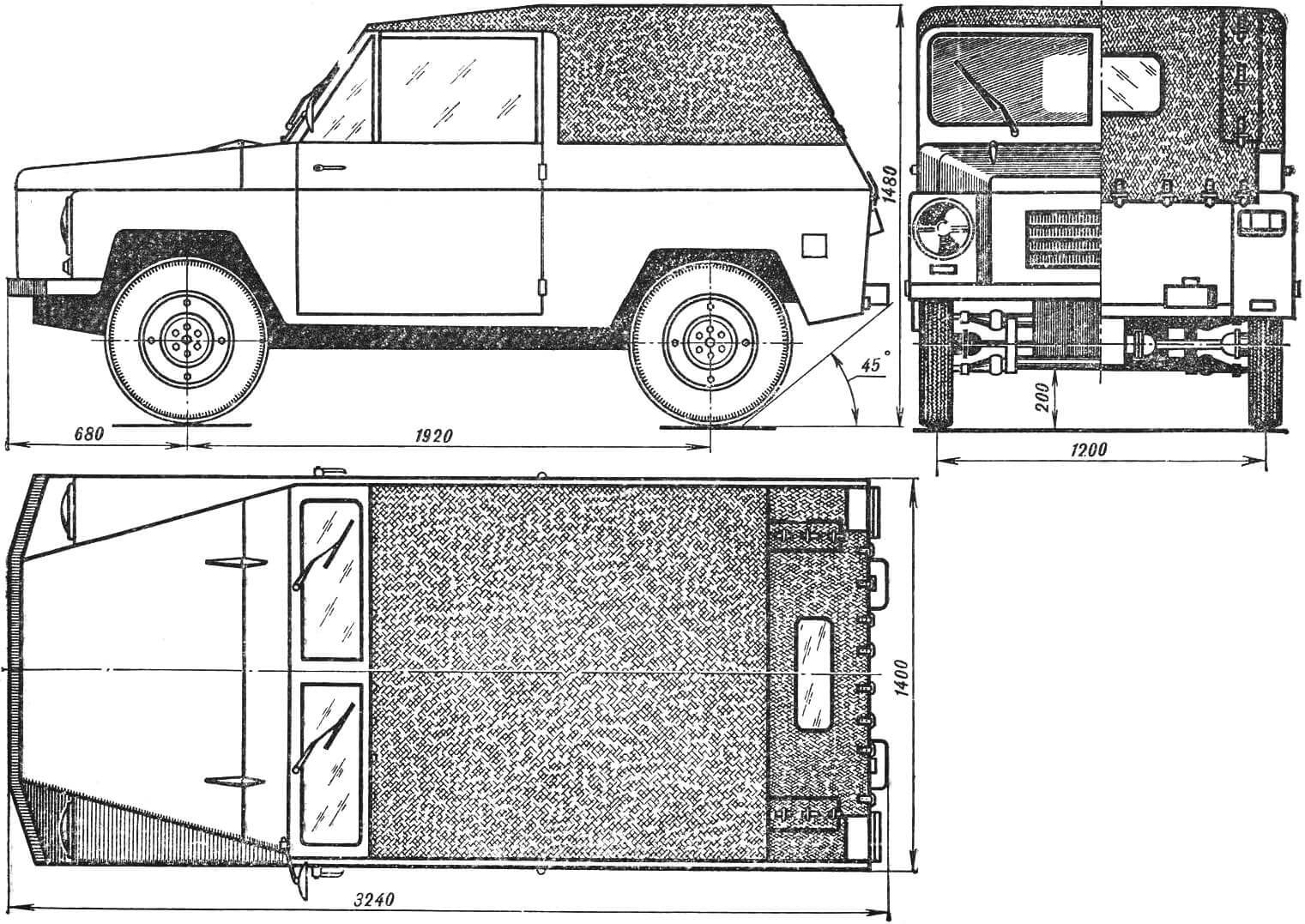

I’ll start with the body. It is open (with an awning) with two side doors and a tailgate. The front fenders and trim are removable. To accommodate additional cargo, the rear seat reclines or can be removed altogether.

The body is completely homemade, welded from sheets of cold-rolled steel 1 mm thick. Only for the door pillars and thresholds a thicker steel sheet was used – 1.5 mm.

For simplicity and manufacturability, straight body panels with edges bent at an angle of 90° were used. The manufacturing technology is as follows. I marked the contours of the workpieces, cut them out with a chisel, filed and bent the edges with a hammer on a hard workbench specially made for this purpose. When flanging, blows were applied to surfaces that did not extend to the front side. Then I welded the panels using the electric arc method. Spot welding was used only in the manufacture of windshield frames.

Thus, the body is structurally simple and quite light. This is explained by the fact that it is not load-bearing. The main load falls on the frame. All components and assemblies of the Neiva are mounted on it.

1, 12 — power unit mounting brackets, 2, 9 — side members, 3 — rear suspension brackets, 4, 5, 6, 7, 8, 13 — cross members, 10, 11 — front axle brackets, 14 — body mounting brackets.

The frame is made up of two rectangular cross-section spars, welded from angles 40X60 and 40X80 mm and six crossbars from channels and angles. Brackets for the power unit, front axle, springs and shock absorbers of the rear suspension, as well as body mounts are welded to the side members.

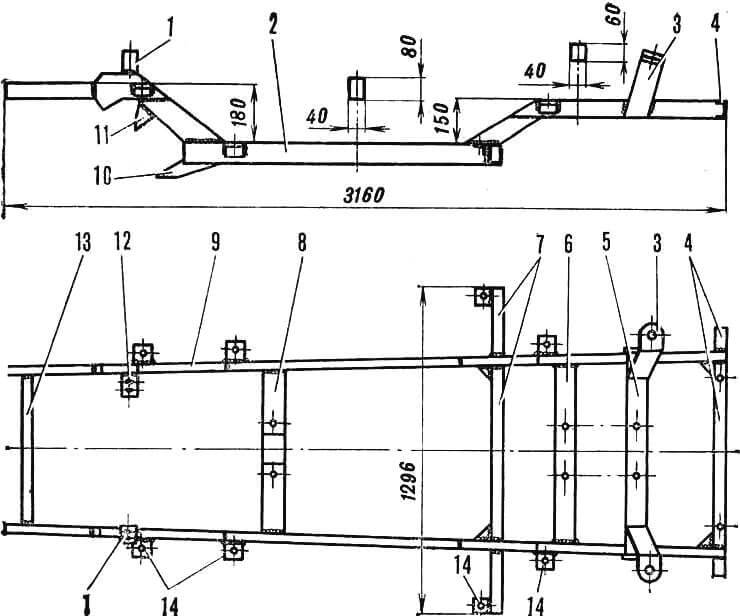

Now about the rear axle engagement mechanism. It is mounted on the end of the gearbox and is controlled by a handle located in the cab next to the parking brake lever.

1 – drive gear, 2 – driven shaft gear, 3 – housing, 4 – cover, 5 – output flange, 6 – bearings No. 205, 7 – shaft, 8 – shaft shank with splines 6X21X25 mm, 9 – fork, 10 – lever, 11 – rod.

The mechanism is based on a gear coupling with involute splines 2.5X18X50 mm. Its drive gear is mounted on the shank of the drive gear of the main transmission of the front axle, and the driven gear, made integral with the shaft and splined shank, is placed in its own housing in bearings. A driveshaft is connected to the output flange for transmitting torque to the rear axle. It is turned on when the lever with the help of a fork connects the gears of the gear coupling.

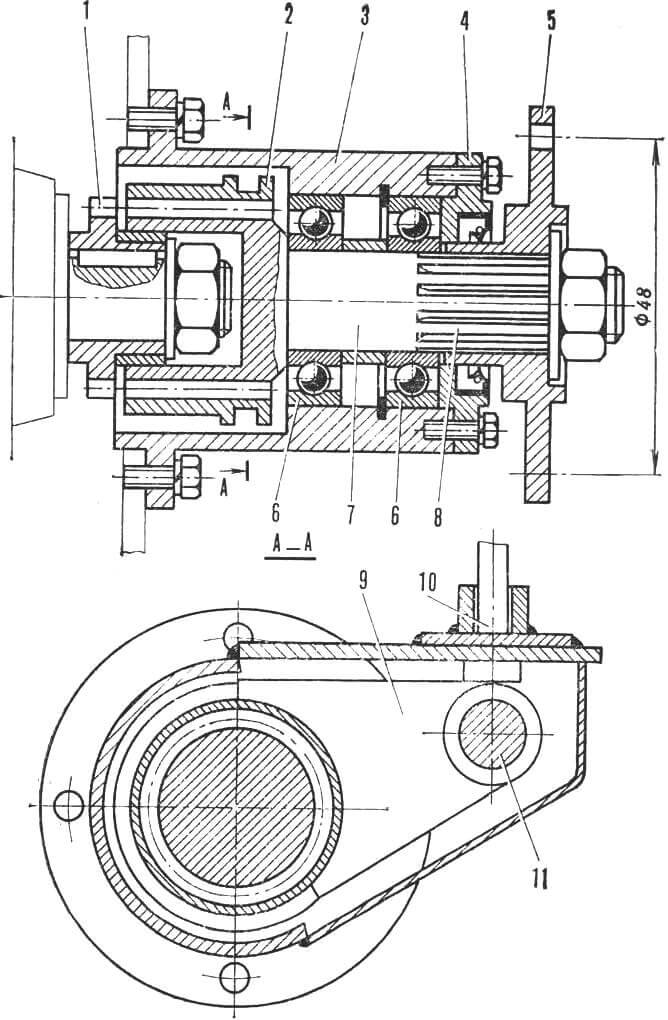

Front axle from ZAZ-966 with modification. To obtain the desired direction of rotation of the front wheels, wheel reducers are introduced into the transmission, mounted directly on the gearbox housing.

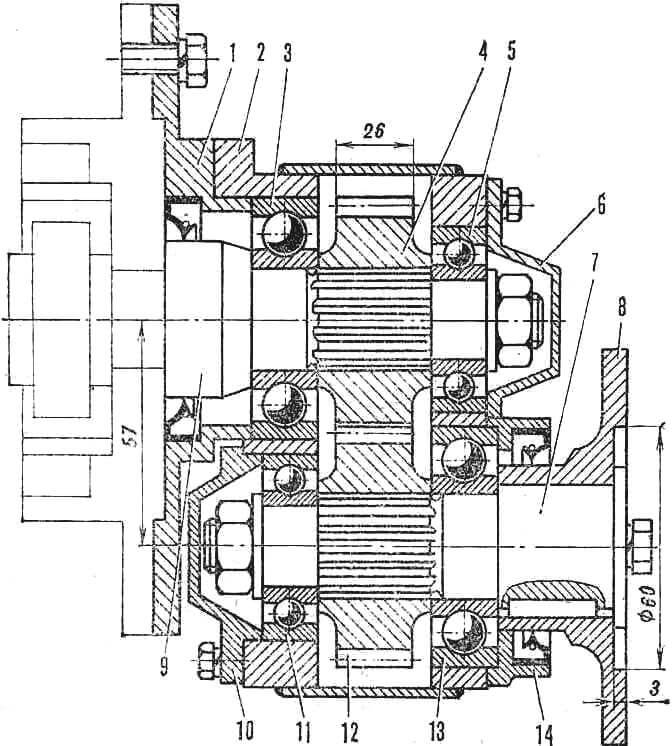

1 – flange, 2 – housing, 3, 13 – bearings No. 305, 4, 12 – upper and lower gears (Z = 19, m = 3, splines 6X21X25 mm), 5, 11 – bearings No. 204, 6, 10 – end caps, 7 – driven shaft, 8 – flange, 9 – drive shaft, 14 – cover.

Wheel gearboxes, in addition, increase the ground clearance of the all-terrain vehicle and, accordingly, cross-country ability. Each of them is single-stage, with external gears. The upper gears are mounted on the splines of the drive shafts, mounted in ball bearings and receiving torque from the axle shafts of the main gear. The shafts are covered with covers on opposite sides.

And the lower gears are mounted on the splines of the driven shafts, which have flanges at the outer ends for connecting to the axle shafts of the front wheels. The shafts rotate in housings with bearings and are closed at the ends with covers with seals. The flange hubs pass through these seals. Gears and gear shafts are made of 40X steel and heat treated to HRc 48… 52.

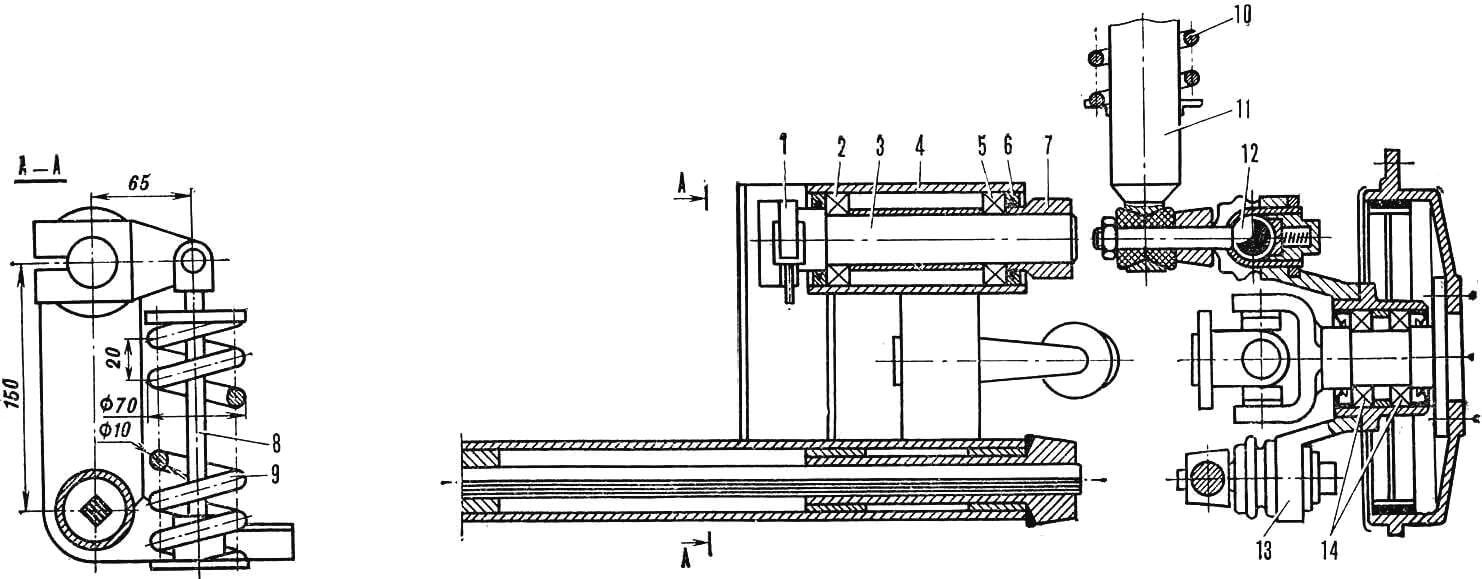

1 – lower arm, 2, 5 – bearings No. 206, 3 – roller, 4 – pipe, 6 – end cap with seal, 7 – upper suspension arm, 8 – rod, 9 – spring, 10 – additional spring, 11 – front shock absorber, 12 – upper ball joint pin, 13 – steering knuckle, 14 – roller bearings No. 2007107.

The front axle suspension is a lever-torsion bar type from the Zaporozhets car. Due to the front engine location on the Neiva, the middle part of the upper torsion bar is cut out. Instead, two cylindrical springs are used as an elastic element, transmitting force through rods to the upper arms, which are mounted on the rollers. The latter rotate in ball bearings No. 206, placed in pipes and closed with end caps with seals. Upper forged suspension arms are placed on the outer ends of the rollers.

The steering knuckle is a structure that combines the ball pin sockets and the wheel turning lever. The upper pin of the steering knuckle ball joint, taken from a ZAZ-968 car, serves as a support for the front shock absorber with an additional spring. The design of the front wheels is the same as the rear wheels (from ZAZ-966).

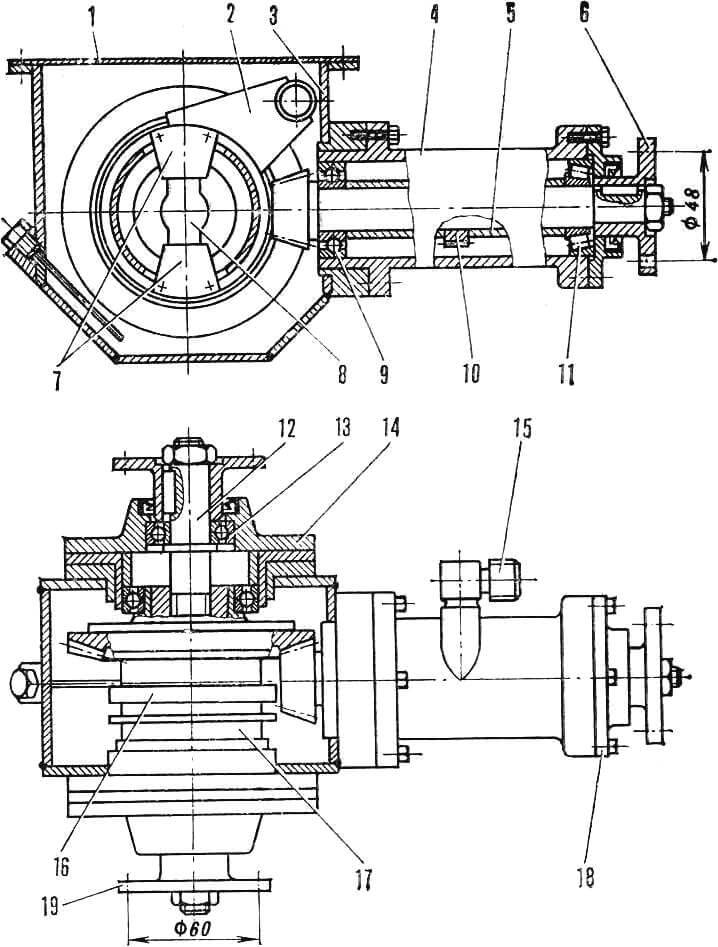

The rear axle gearbox with a gear ratio of 4.63 has a main gear with bevel gears from a ZAZ-965A assembled with a differential.

1 – housing cover, 2 – fork, 3 – housing, 4 – cup, 5 – drive gear shaft, 6 – propeller shaft flange, 7 – plates, 8 – block, 9, 13 – ball bearings No. 206, 10 – speedometer drive gear, 11 – angular contact roller bearing No. 7206, 12 – axle shaft, 14 — differential cover, 15 — speedometer drive, 16 — locking ring, 17 — main gear, 18 — driveshaft cover, 19 — axle shaft flange.

The main gear is placed in a welded housing with a cover. Axle shafts are inserted into the internal grooves of the hubs of the differential side gears, at the outer ends of which flanges are attached for connecting cardan shafts (from Moskvich), which transmit rotation to the rear wheels. The axle shafts rotate in bearings No. 206, pressed into the covers. The drive gear shaft runs in a cup with two bearings, closed by a lid with a sealing collar. At the free end of the shaft shank there is a cardan flange, and in the middle there is a speedometer drive gear.

To increase the vehicle’s cross-country ability, a differential lock has been introduced. It is turned on with a fork through a ring connected to the cracker by two plates.

The rear suspension of the car is independent, spring-lever, from the ZAZ-966 car.

Now briefly about the technical characteristics of the Neiva. Car carrying capacity: four people plus 100 kgf of cargo or 2 people and 240 kgf of cargo. In addition, it can tow a trailer weighing 300 kgf.

The weight of the car without payload, oil, gasoline, spare wheel and a set of tools is 570 kgf, equipped – 620 kgf. It is distributed on the wheels as follows: 57% on the front, 43% on the rear.

With such weight data, the Neiva reaches a speed of 80 km/h on a horizontal section of an asphalt highway. The control fuel consumption is 7.5 liters per 100 km.

A. FOMIN, Alapaevsk, Sverdlovsk region.