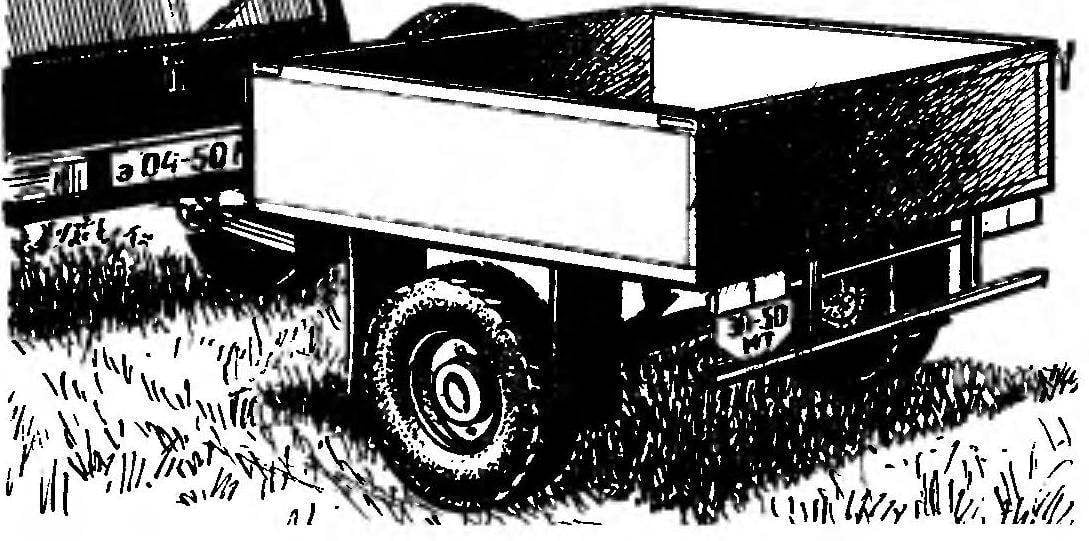

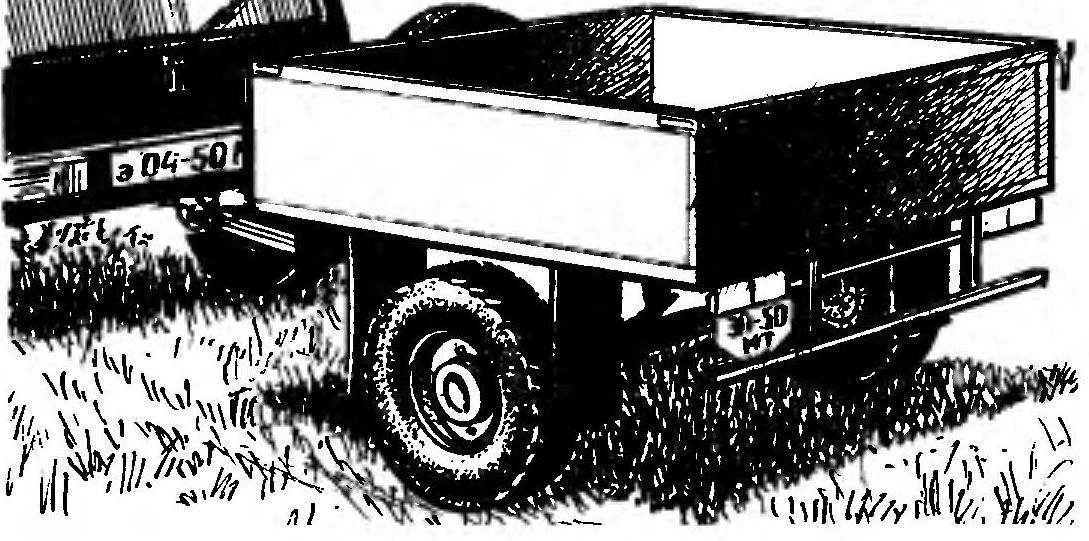

Trailer weight trailer — 250 kg. in Accordance with the requirements of GAI of the total weight of the trailer not equipped with brakes with a load, shall be not more than half the curb weight of the pulling vehicle, i.e. not more than 750 kg. Thus, the capacity precita permitted by the traffic police is 500 kg, the actual is two times more: up to 1000 kg. in addition, hinged tailgate and smooth the floor of the truck provide easy loading and unloading. Currently the trailer is registered and has been used successfully. Have spoken to me of rural craftsmen asking for drawings, so I decided to write to the journal “modelist-Konstruktor”. I hope that many of his readers would undertake the construction of the trailer.

Based on the chassis taken back axle with springs and hubs from the scrap charged to a mobile compressor PR-10. Gauge adapted to gauge the traction of the car. For this thick-walled pipe axis an outer diameter of 80 mm and a shorter cut on a lathe with the removal of chamfers for welding.

Subsequently, the axis is welded by arc welding. The number of spring leaves is reduced on each side by two. Wheels and tires — UAZ — size 8,40×15″. The eyelets of the leaf springs to the frame welded from steel channel and steel pipes of rectangular section 25×50 mm. To grease bolts of fastening of springs have an inner channel and a round head with cut face. The rotation of the bolt eliminates welded to the lug plate with the size 15×25 mm from two-millimeter steel.

The trailer hitch is made of bent steel angle channel. The floor of the truck — sheet steel 2 mm thick. body Pillar, upper frame side and front sides are welded from steel “corners” 32×3. The plane of the sides of the steel sheets having a thickness of 1.2 mm. the Eaves of the rear wall 16 mm diameter machined from steel timber. The direction indicators, dimensions, brake lights from the car KAMAZ. Provides bracket for mounting the license plate sign with the left during the side of the trailer, also its coverage. The protection of the signalling lamps is provided by the welded construction of pipe cross-section 25×25 mm. Grassadonia flaps cut from the conveyor belt; attaching them to rømø welded plate 30×270 mm steel 2 mm thick. the pads are Attached to the plates with bolts.

Fig. 1. Cargo trailer to the car “Niva”:

1 — clip (steel, rod diameter 20), 2 — plate reinforcing (steel, thickness 10 mm), 3 — baffle reinforcement (steel, 4x100x125), 4 — pole (steel, channel No. 12), 5 — plate reinforcing (steel, 5x50x90), 6 — front bracket spare wheel (steel pipe 20), 7 — trim body (steel, 32×32 area), 8 — a lining of a body (steel, thickness 1.2 mm), 9 — the bottom surface (steel, thickness 2 mm)The 10 — castle 11 — the loop 12 — bumper (steel, pipe 25×15), 13 — bulkhead (steel, channel No. 16), 14 — eye (steel), 15 — longitudinal connection (steel tube 25×25), 16 — cross connection (steel tube 25×25), 17 — edging of the rear wall (steel, pipe 25×50), 18 —splash plate (steel, 2x150x280), 19 — plate support (steel, 14x140x160), 20 — brace (steel) 21 — axis (from the compressor PR-10).

R and S. 2. Towing device;

1 — baliproperty(steel,труба45хЗ,5),2 — rear mounting bracket (steel, area 75×8), 3 — the clamp (steel, thickness 4 mm), 4 — bracing (steel, area 32×3), 5 — plate mounting (steel, thickness 6 mm), 6 — hook towing (UAZ), 7 — bolt М12х40 (4 PCs.).

Fig. 3. Panel (steel, thickness 4 mm).

The spare wheel is located in front of the trailer and is fixed to the bracket by three nuts M14.

All parts of the trailer painted with automotive paint ML-152 grey.

The procedure for manufacturing the frame of the trailer.

To the base of the two channels are welded three cross — tube section 25×50 mm. And then the eyelets for attaching the springs.

It is necessary to prepare the axle to the hub. To the base of the frame to secure the springs to the axle. In the rear attachment spring provided in detail, compensating for their elongation during movement.

Next, you need to make the drawbar of the trailer and the towing device to the vehicle.

The most appropriate Assembly of the frame with the drawbar to engage the drawbar of the trailer behind the towing hook of the car, then the base of the frame with the leaf springs and axle on wheels to deliver and a horizontal position; insert the pole into the base of the frame and weld arc welding as per drawing.

Assembly and welding of other parts of the body, I think the difficulties will not imagine therefore turn to the description of the towbar.

It consists of a rigid beam bracket, clamp, pads, braces, plates, towbar. Towbar taken from the UAZ.

Design mounted on the vehicle body at four points. The front end of the plate drawn through the four bolts М8х30 to the floor of the trunk and covers the floor crossmember. The rear is fixed to the bumper by two bolts М8х25 and two bolts М10х25.

Curved beam pipe with a diameter of 45 mm with a wall thickness of 3.5 mm. the Clamp and cover plate made of sheet steel with a thickness of 4 mm. the Rear bracket of the corner angle steel 75×8. In it for the tow hitch mounting drilled hole with a diameter of 13 mm. of the bottom Edge of the bracket trimmed on a milling machine. Corner bracing made of angle steel 32×3. Plate is cut from steel with a thickness of 6 mm. In them according to the drawing it is necessary to mark and drill holes with a diameter of 8.6 mm, thread M 10×1,25.

You can now begin installation. The clamp carefully marked and drilled holes in the floor of the trunk, it is necessary to consider that the towing device shall be located strictly along the axis of the car. The clamp and cover plate are tightened with bolts М8х30. Drilled to place the openings in the rear bumper, fastened with bolts M10 bracket. Towing eyes of the vehicle to replace the plates.

Welding is best done by setting the car does not lift or pit. Arc reconciliation to grab the beam to the clamp and the bracket, and the bracing — to-bracket and plates.

Not to spoil the weld parts of the car, the entire structure should be dismantled and scald on a welding table. Left to clean up the seams, paint and install the towbar on the car. Last mounted with four bolts to the towbar.

You need to connect to the onboard network of the car lights.

As a safety device, be sure to install steel cable diameter 8… 10 mm or chain.

A. LINCHENKO, engineer, Psebay, Krasnodar Krai

Recommend to read NOT BARKS, BUT THE GARDEN WILL NOT LET ME Garden, summer cottage or a rural farm house without a fence is not enough. And if in the cottages it often just serves as a border between neighbors, the farmstead a farmstead is also a... DESKTOP TREBUCHET Many of us have been fascinated by the exploits of Ivanhoe, Lancelot, read about the struggle and death of evpatii Kolovrat, admired the stories of John. P. P. Tolkien. These interests... Scroll back to top

Favorite car in the village is undoubtedly the all-wheel drive, all-terrain VAZ 2121 “Niva”. Trailers specifically for this model, having a large capacity and the ability to operate in off-road conditions, our industry, unfortunately, not released. What a pity! Need them villager is huge: it is necessary and the materials to bring, and fertilizer, and to deliver to the market the products of his garden. In short, the trailer to “the Field” is a must! That’s why I designed and built it yourself.

Favorite car in the village is undoubtedly the all-wheel drive, all-terrain VAZ 2121 “Niva”. Trailers specifically for this model, having a large capacity and the ability to operate in off-road conditions, our industry, unfortunately, not released. What a pity! Need them villager is huge: it is necessary and the materials to bring, and fertilizer, and to deliver to the market the products of his garden. In short, the trailer to “the Field” is a must! That’s why I designed and built it yourself.