Oddly enough, but thirty years ago, humanity knew about what was happening in the depths of the sea, only slightly more than our ancient ancestors. The seabed and for us today — a mysterious, unknown planet, which is known only in General terms, the topography of the atmosphere (the water) Yes, part of living beings.

Oddly enough, but thirty years ago, humanity knew about what was happening in the depths of the sea, only slightly more than our ancient ancestors. The seabed and for us today — a mysterious, unknown planet, which is known only in General terms, the topography of the atmosphere (the water) Yes, part of living beings.

The reason for the ignorance about the physical and biological parameters of blue continent, that the ocean is quite reluctantly tells his secrets: man is only in recent decades began to actively penetrate into the hydro-space.

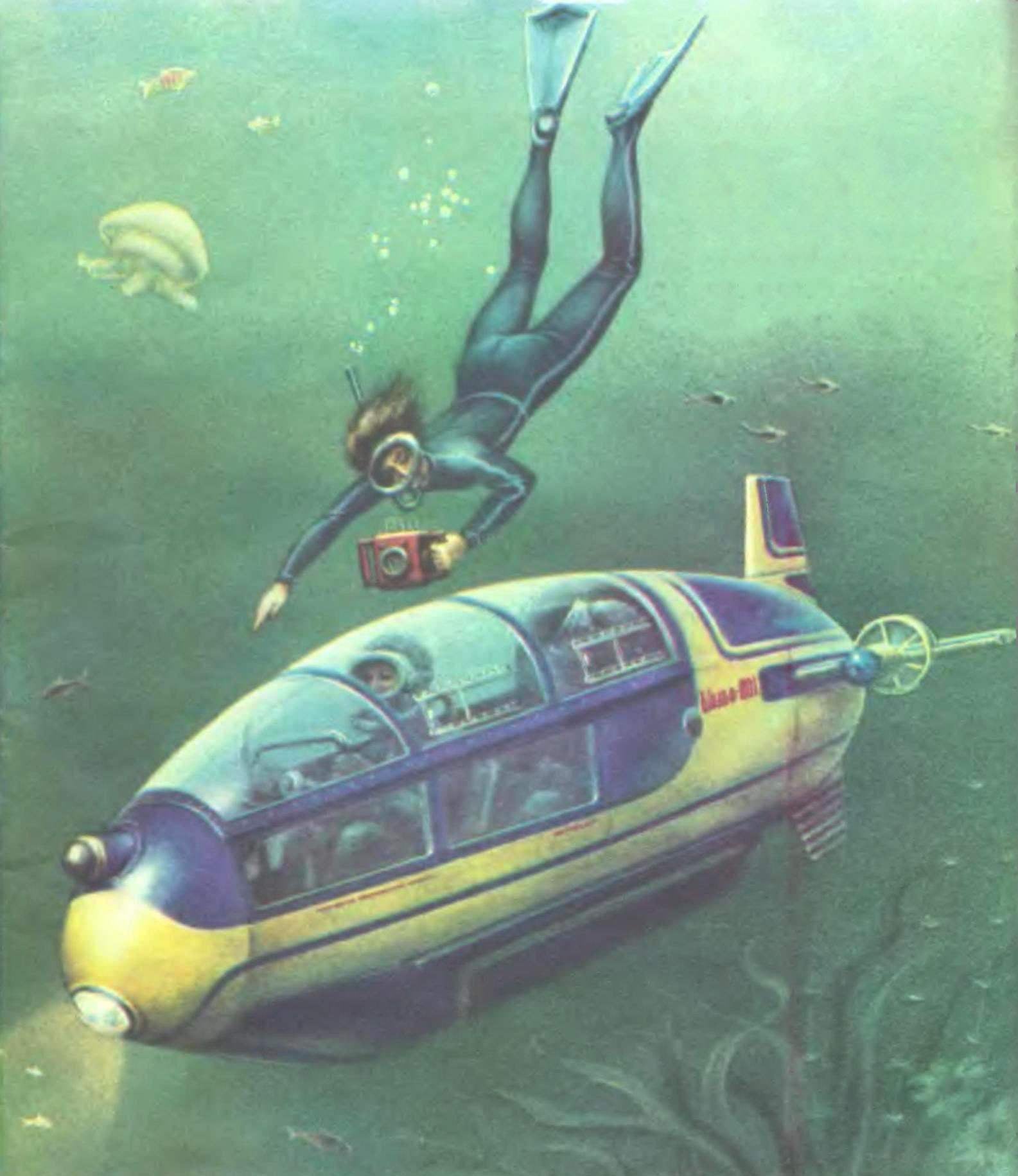

Many years to create underwater vehicles engaged in student design Bureau “Ocean” of the Moscow aviation Institute. The latest development of the student group — double submarine “wet” type “Shelf-001”. It was successfully demonstrated at the held this year the Central exhibition NTTM-78, dedicated to the XVIII Congress of the Komsomol and the 60th anniversary of the Lenin Komsomol, and was awarded a silver medal and two bronze medals ENEA USSR. This twin-engine underwater “plane” and interested readers of our magazine. On the activities of SKB “Ocean” the editorial Board asked its Director V. N. Nepokojchitskij.

We all work and study at the Moscow aviation Institute. We are a collective of student design Bureau “Ocean”. “Why “the Ocean” — ask a^ you probably mean the ocean air, the ocean, that is to say, the fifth?” — “No, — answer — usual ocean”. All designed and built by us, designed for its development. Did the probes and towing, underwater gliders and propellers, simulating a fish fin…

But most of all we are attracted to underwater vehicles. Their full name “submarine carriers legkomolyabb”.

In recent years, have created several variants of such devices and thoroughly tested them. Almost all of them were demonstrated on VDNH USSR and were awarded gold, silver and bronze awards. Some have visited the international exhibitions in Bulgaria, Cuba, USA and Italy.

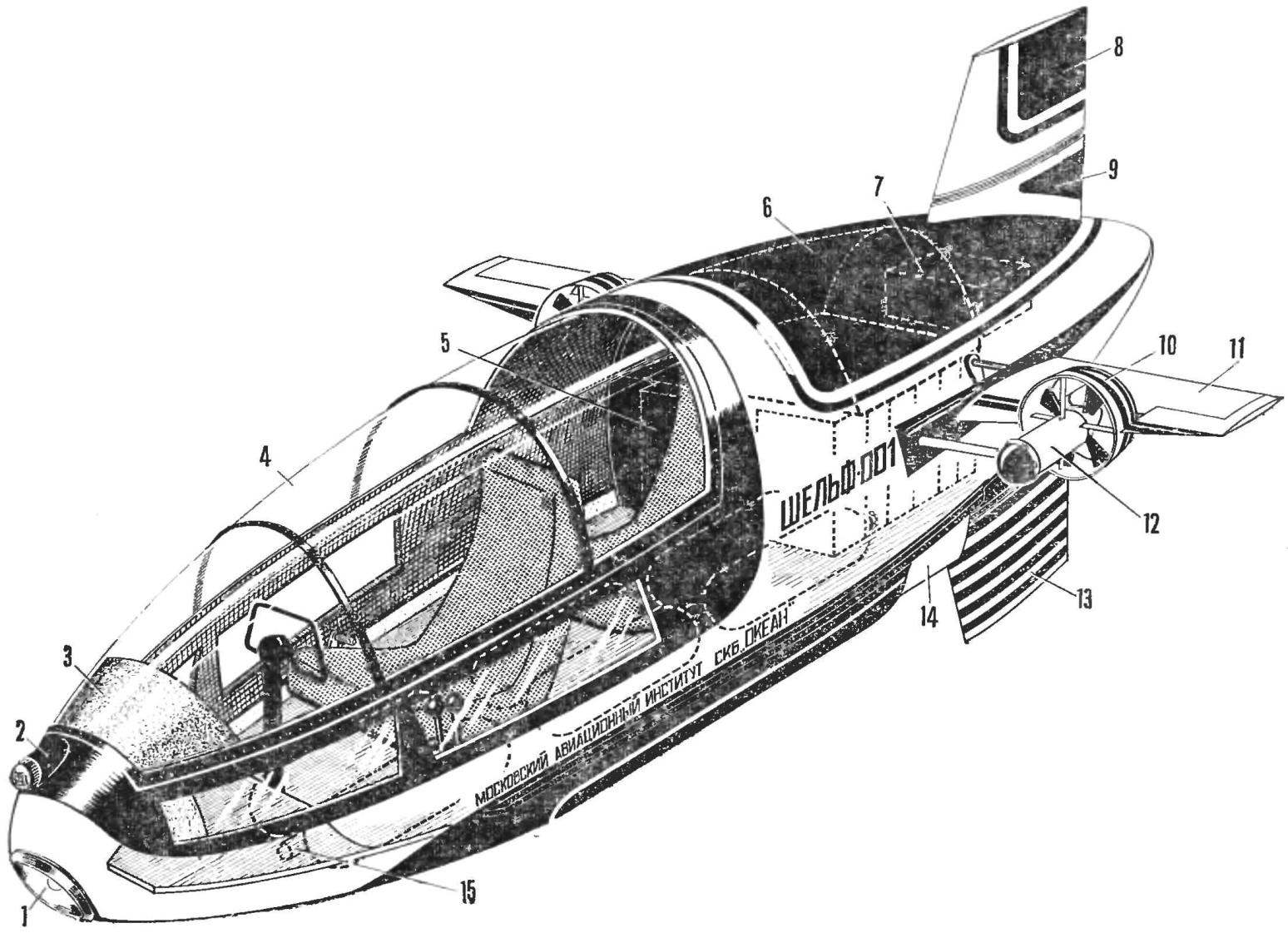

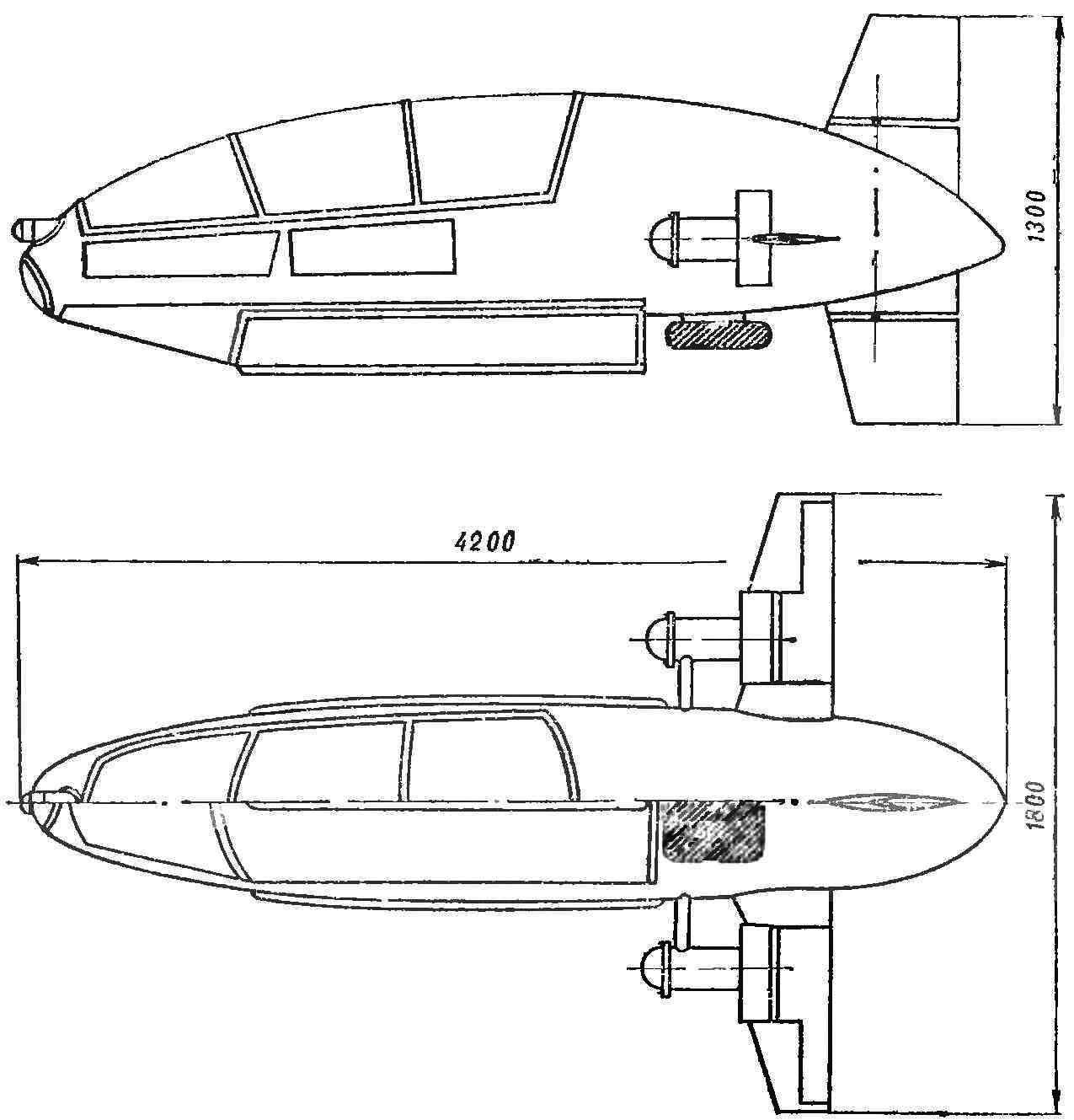

Fig. 1. The layout of the double submarine “Offshore-001”:

1 — headlight, 2 — sonar, 3 — dashboard, 4 — cowl, 5 — battery, 6 — ballast tank, 7 — control unit, electrical system, 8 — rudder 9 — Kiel, 10 — hydrodynamic ring, 11 — elevon, 12 — way electric motor, 13 — rudder (bottom), 14 we dropped the emergency ballast, 15 — differentia system.

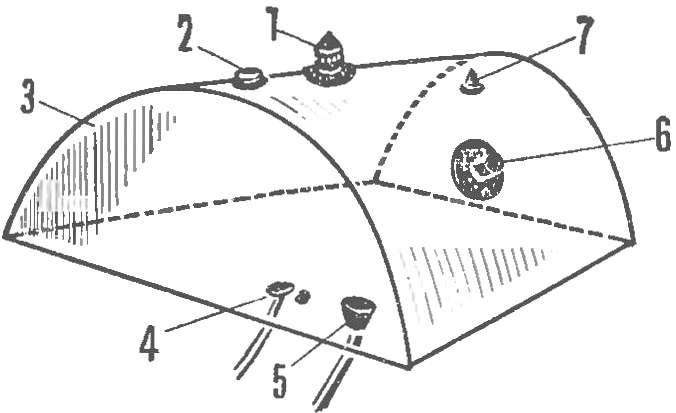

Fig. 2. Ballast tanks:

1 — pneumatic valve air release, 2 — safety valve 3 — shell 4 — purge fitting, 5 — valve water inlet, 6 — automatic compensation of outside pressure, 7 — gauge buoyancy control boats.

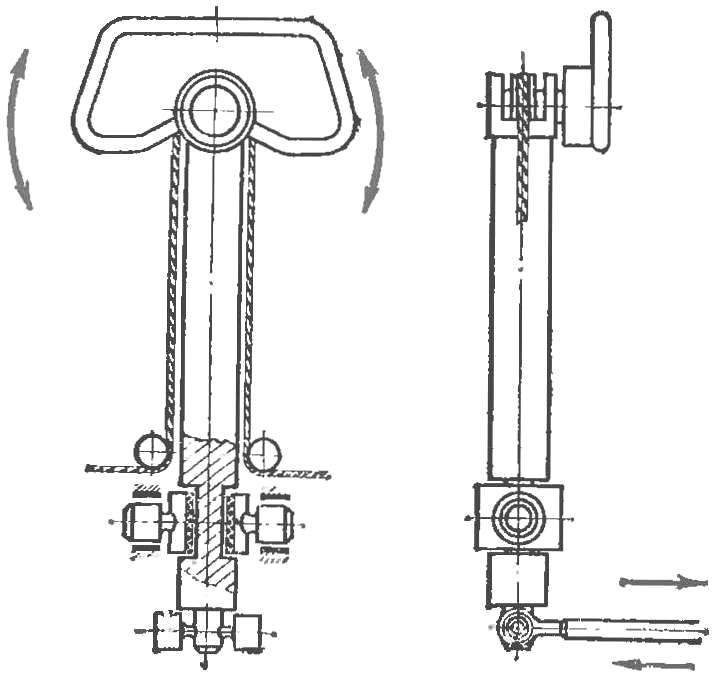

Fig. 3. Schematic diagram of the steering column.

The beginning of a series of underwater vehicles put developed in 1964 (though not in our SKB — it did not yet exist) underwater glider MAI-2. Its engine he had, and followed in tow behind the trawler, the “pilot” was able to observe the trawl and to determine the effectiveness of its work.

A natural extension of this area was underwater mini boat MAI-3, built by us… after 8 years.

It was almost inherent in all such devices the controls cited it in motion by electric motors and could transport two people. Test boats on the Black sea and in the Pacific ocean showed its good performance, to at the same time revealed some drawbacks. In particular, the location of the driver and passenger next to each other made it possible to reduce the midsection of the boat, creating significant resistance to movement that affected the speed and range of stroke, and the control system left something to be desired.

And all of this drew us to search for new technical solutions. From project to project weaknesses become less and less…

Today we face a very serious task — to work out the media for its transfer to the industry. We believe that SKB can handle it: our last work was preceded by five pilot vehicles and a large range of studies in the process of debugging.

Judging by the number of people willing to work in SKB “Ocean”, it is one of the most popular at the Institute. Come to us from almost all faculties and “green” freshmen, and people more experienced than the students. Unfortunately, it can take not every territorial capabilities SKB more than modest. Preference is given to those who bring the idea. The idea of some fantastic machine, device, process. These are connected to experienced employees, teachers, provide an opportunity to work hard on for your project. Of course, everyone works and the main themes of “Ocean”.

A ripe idea, even if it is not feasible within the framework of our Institute, is not lost. On regular scientific and technical seminars, students make presentations, presenting to the court classmates vyneseny projects. And heated debate, sometimes escalating there, to a large extent contribute to identification of optimal solutions.

But to start working with young designers often have with the basics. Log in focuses on the structure of our SLE.

Thus, “Shelf”, for example, developed five design teams were headed by veterans of SLE (undergraduates or graduate students), and helped them to beginning students. This system works on the one hand, contributes to the continuity of senior experience, and with another — helps the “leaders” to cultivate future leaders of the production.

In the end, the members of the SLE become designers with a completely real perception of the entire process of creating the complex unit — from conceptual sketches to working drawings and from billets to their own hand-made parts and components.

Students who graduated and passed the school SKV, cordially greeted at the enterprises of our country. They are, as a rule, immediately, without a period of adaptation, are included in the production business. Many of our “employees” in recognition of their design and research experience, distribute after receiving their diploma at the Department of the Institute.

Thorough, painstaking and competent study of the components and assemblies greatly contributes to the fact that scientific-technical and research activity of students-designers of SLE is a part of the learning process. Most of our developments is a “mosaic” of several course projects. Interest in the actual results makes students to get deeper into the matter: it is useful and long SLE, and for the improvement of future specialists. Specifically, it is only on “the Shelf” was protected by 18 course projects.

In addition to designing and manufacturing complex assemblies, students spend most of the experimental and research work and feel they created the technique. And it increases the responsibility in the design and analysis of underwater vehicles. Besides testing aquamobile contributed to the acquisition of children profession of leskovdol.

Now in detail tell about “Shelf-001”. This is an experimental underwater carrier for two divers.

It allows you to increase the range of divers and researchers from 400-800 m up to 20 km, and the physical effort currently divers to travel to the district research guide for useful work.

Anticipated applications of our system: the transportation of passengers, operational communication between underwater objects examination of a large size or the extent of underwater plantations, research work at depths up to 50 m, film and photography.

If you hold a purely external analogy, the “Shelf” can compare with the underwater twin-engined “plane” of small size with all inherent in such a scheme controls. The total power capacity of about two kilowatts. Each motor rotates a four-bladed screw and develops a thrust of 25 kg. the energy source is a rechargeable battery, the capacity of which allows engines to operate for at least five hours.

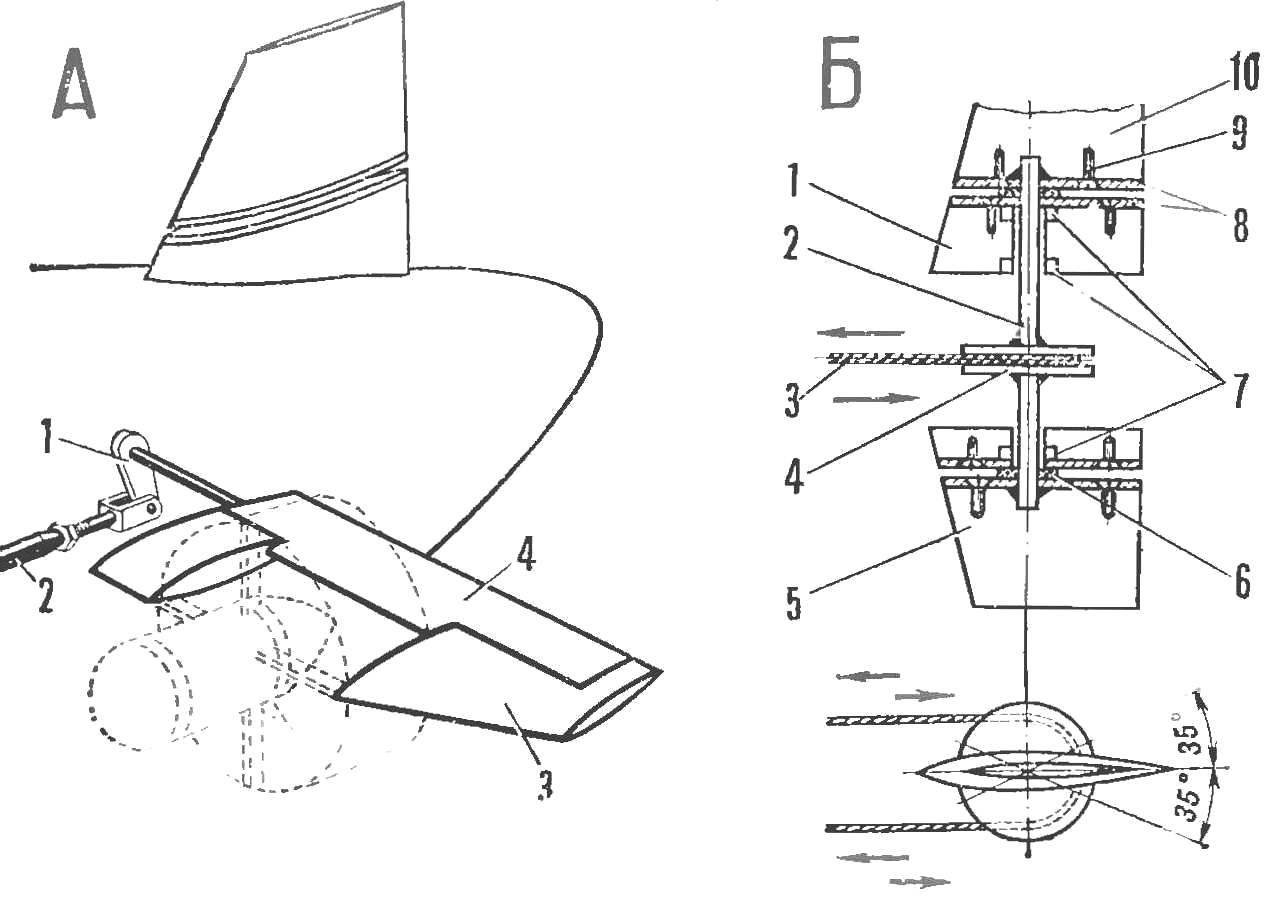

Aquamobile controlled (by rate, list and trim) only one wheel. The Executive authorities are turning the rudders vertical direction (upper and lower) and the elevons, which are the rudders of depth with simultaneous coordinated their deflection, and Aileron — with mutually opposite.

Drive all control surfaces — the traction-rope. The elevons are connected to the wheel rods, and the rudder — ropes. Steering column can be rejected at 15° to 18° from the neutral position, causing a corresponding deflection of the elevons (rudder depth) at 30° and 35°. The rotation of the steering wheel ±60° from neutral causes a corresponding deflection of the rudder at ±35°.

Yaw control is carried out of the upper and lower swing keels. Both are cantilever mounted to two shafts, connected between the friction clutch. In the groove formed by the two halves of the clutch is missing the control cable. Both shafts planted in Teflon bearings. Each keel is attached with four bolts to a plate welded to the end of fat. The fixed part of the keel is laminated from fiberglass and is installed directly on the frame aft of the carrier. Stabilizers connected to the frame in exactly the same way as the fixed part of the keel. Similarly, the rudders and elevons are made. Connect them with wheel — rigid rods.

By the way, this scheme aquamobile — elevons and rudder — first appeared only on the “Shelf”. We tried to manage our boats and jet rudders placed directly behind the nozzle of the water jets, and rotation propeller systems. But all these schemes were either too bulky, or required costs so scarce on Board of electricity, or does not provide sufficient maneuverability. The problem of choice of control system for medium long remained open because the views of the members of the CSC on this matter are divided. But one day after a “hard” dispute someone timidly suggested: “why not take advantage of the scheme “flying wing”?” The main developers Alexey Pomazkin and Viktor Mayorov initially skeptical of this idea. Apparently, too much dominated them the idea of control aquamobile with rotary engines, but after working it for Kuhlmann found that it provides less resistance to movement and good maneuverability, but the design of the embodiment is even more simple.

Fig. 4. The Executive authorities control boat:

A — the depth and roll: 1 — rocking chair, 2 — rod, 3 — regulator, 4 — elevon. B — direction: 1 Kil, 2 — steering shaft 3 — control cable 4 — clutch, 5 — lower rudder, 6 — fluoroplastic washer, 7 — bearings, 8 — dural plate, 9 — bolts rudder, 10 — upper rudder.

Fig. 5. General view of aquamobile.

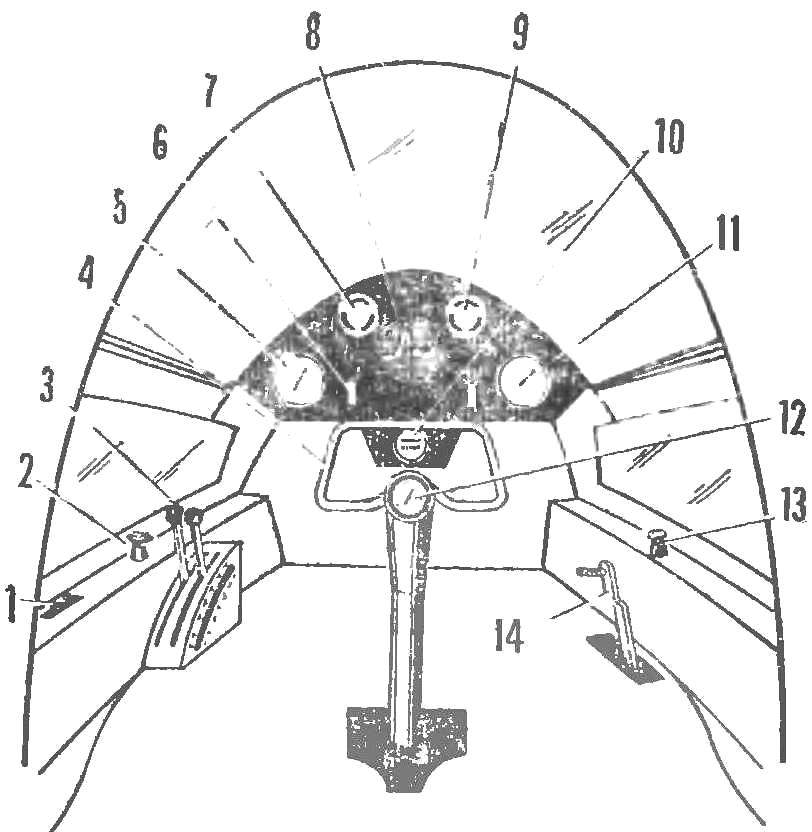

Fig. 6. Equipment cabin aquamobile:

1 — control knob filling ballast tanks, 2 — tap feed ballast tanks with high pressure air, 3 — control knobs speed engines, 4 — rudder, 5, 11 — tachometer, 6 — switch on-Board power supply, 7, 9 — high pressure gauges, 8 — sonar 10 — magnetic compass, 12 — gauge, 13 — tap and recharge the life support system of high pressure air, a 14 — arm resetting the emergency ballast.

One of the important controls aquamobile — ballast tank. Changing the buoyancy of the apparatus, the tank allows it to float and sink. However, this can be done without ballast, by horizontal rudders, but this is possible only in movement. To dive you must open the upper and lower valves: at the same time through the bottom in the tank penetrates seawater, and through the upper air escaping. Changes in buoyancy can be observed in mounted inside the cockpit of a dial gauge.

Also important is the maintenance in the ballast tanks pressure equal to the outboard. The fact that the thin shell of the tank may not oppose any significant external loads and greater depths can be deformed. To avoid this, the boat provides automatic compensation; for the ascent of the compressed air is gradually vented through the relief valve. The ascent is due to the creation of excess pressure of air (purge) in the ballast tank.

The idea of pressurization of the ballast tanks did not appear immediately. Our first boat — in particular, MAI-3 MAI-7 — automatic payment had not, and external pressure, we tried to contrast that with enough hard shell ballast tanks. But the weight was considerable, and the problem of resistance to great depths (at fifty meters external pressure of 5 ATM!) remained open,

“Microbrigade” Andrew Teteriatnik there was a proposal to make the tank thin-walled, anodized aluminium sheet and outer pressure to neutralize the excess air pressure in the ballast tanks. The calculations showed that the weight of the new system is smaller than the old, and the reliability it was almost one hundred percent.

Most of the systems on aquamobile for greater reliability zadublirovanny. So, in addition to basic, it includes a system of emergency ascent, which can be used in the event of malfunctions in the ballast tank. With the full flooding of the tank it allows the unit to acquire positive buoyancy.

In the life support system includes eight seven-liter cylinders with compressed air (operating pressure in each — 200 ATM), shut-off valve for shutoff of the air supplied to a breathing machine, breathing machine itself. The latter consists of two reducer units, lowering the air pressure to the so-called docking (to 5-6 ATMs), and the actual breathing machine that supplies air to divers under pressure of the environment.

When they began to talk about the “Shelf” as the prototype of the future of the industrial design, was a problem of the reliability of aquamobile. The team of Igor Galkin, and with it all our staff had to think twice over the duplication of many systems. For example, guys have provided ballast as a purely mechanical way, and with the help of Pneumatics; the cockpit canopy became possible or just open or use the emergency reset. And as with almost all units and mechanisms responsible for neutralization of emergencies.

Case “Shelf” — the combined structure. Frame bow riveted from aluminum (alloy AMG-6) profiles and covered with sheet duralumin with a thickness of 0.6 mm and a feed of welded tubes (stainless steel) and lined with fiberglass with a thickness of 3.5 mm. Cabin, occupying the front of the boat, closed with a light lantern. Seat the pilot and passenger are located in her tandem. The aft carrier is reserved for battery, ballast tank, control unit electric system and the attachment points of the vertical and horizontal tail.

If you compare all we have built submersibles, we can see that the “Shelf-001” differ from its predecessors a good hydrodynamic shape ensures low drag and excellent maneuverability. It is the merit of our designer and Builder Vyacheslav Gasiunas. It may give the impression that his work was easier all: well, I think, that there, took it and painted to be beautiful! but this is not so. The fact that Glory was forced to compare the incomparable and to reconcile the irreconcilable: each of the design “microbrigade” demanded the compliance of the overall layout their devices, sometimes even to the detriment of others. To unite all contradictions, to conclude all systems of the boat in the perfect interfere with the housing to link the pilot and passenger positions so that the crew were safe and comfortable to work — that was the task of our designers. And they did that.

This year aquamobile is thoroughly tested on the Black sea. Specified incorporated in the project specifications, tested system — particularly those that are responsible for life support, simulated emergency…

We believe it will take not so much time, and in the coastal depths of the continental shelf media, like ours, will be as common as cars on land. The project of mass aquamobile tailored to the requirements of serial production has already been established in our SKB and now work for the industry.