The chassis of the trailer is a hollow shaft resting on the lugs of the longitudinal tubes of the frame and secured them with clamps.

On the shaft located on the wheel hubs with bearings No. 206 and spacer bushings, dvuhventsovye the sprocket drive of the working body, the body which is the similar design as the hub of the left wheel, the drive sprocket, the pedal lifting Polimeni.

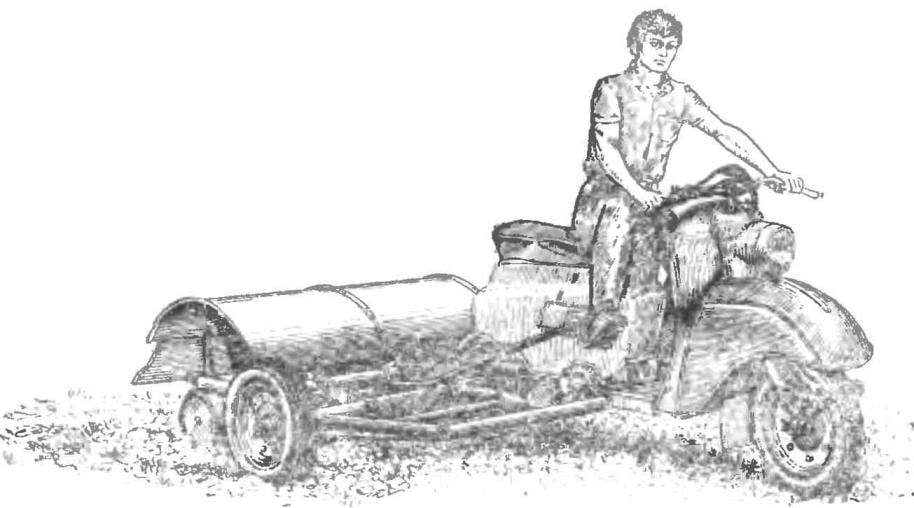

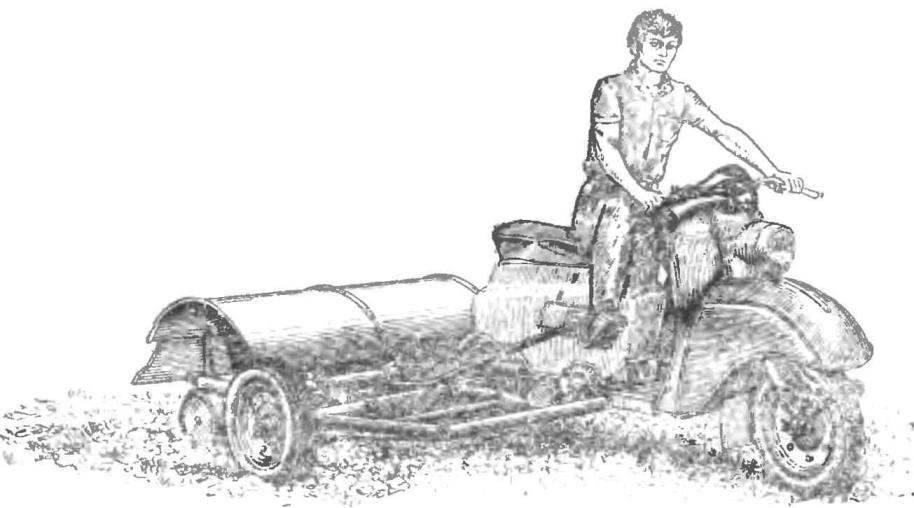

Fig. 1. Scheme arable units:

1 — Vespa, 2 — pedal lift Polimeni, 3 — spring, balancing polimeno, 4 — polymeta. 5 — cover. 6 — wheel-limiter, 7 — chain transmission from Polimeni-to-wheel, 8 — dvuhventsovye star, 9 — engine, 10 — trailer frame, 11 — frame Polimeni, 12 — chain transmission from the engine to polytree.

R and S. 2. The frame of the trailer:

1 — front cross pipe. 2 — rear cross tube. 3 — longitudinal pipe. 4 — eyes. 5 is a horizontal scarf. 6 is a vertical scarf.

The last frame is welded of tubes and steel plates and is hinged to the trailer at three points. On itself it is polimeno — block with bushings welded to the curved and pointed teeth.

Polimeno collected as follows (Fig. 4). On the tubular shaft wear sleeve 19 with the teeth 20, hub 21 with the sprocket, the bearings are No. 210 and polucarpus 22, which are sandwiched between thrust 23 with a yoke 24. Pre-assembled unit by tightening the screws 27, the left of which is provided with a sprocket 28 (processing of dense soils the number of teeth can be reduced from 8 to 7 or even 6).

Teeth for uniformity of stroke Polimeni should be positioned on a circle so that they entered the land right and left in pairs. Then the screws 27 and finally tighten sleeve attached to the shaft, which drilled seven holes for bolts 25, and one bolt the torque limit 26.

Polimeno placed in brackets 16 of the frame, put the chain 29, 33 and 34, the tension of which is adjusted by screws in the intermediate shaft 31 and the rods 23. On the right end of the frame 16 installing the bracket 17 with the wheel, the limiter 18, which specifies the depth of tillage. Put the pedal 35 and equilibrated polimeno spring.

The collected mechanisms are checked, lubricated and weight manually rotated. You can start the engine and start processing the infield. It is necessary to move the circles, and the constancy of the speed of the working body to adjust the “gas”, otherwise arable land will turn out wavy. Dry soil at a uniform depth of plowing get by installing another two-wheel-limiter 18 on the ends of the tubes of the frame 16.

On the turns when hitting an obstacle or when the motor is overloaded polimeno raise the pedal. If engine power is not enough, the extreme cutters are removed. Moving from site to site, the chain 34 is removed, and the screw 11 is moved to star 7.

It may happen that for increasing patency of the wheel Assembly will need to blokirovat.

R and S. 3. Frame Polimeni:

1 — power tube, 2 — support tubes 3, 4 are angles of attachment to the frame of the trailer 5 — ears body mounting an intermediate shaft, 6 — loop for casing, 7 — sleeve for installation of wheels-limiters, 8 — mounting bracket shaft Polimeni

R and S. 4. The layout and design of the arable units:

1 — the frame of the scooter. 2 — the frame of the trailer, 3 — shaft of the trailer (St45), 4 — puck, 5— clamp (Ст35), 6 — spacer tube, 7 — dvuhventsovye asterisk (St45), 8. 10 — spacer sleeve (STZ), 9 — hub (STZ), 11 — screw. 12 is the drive sprocket (St45). 13 — the wheel bolts, 14 — the wheel. 15 — drive circuit step 15,875 mm), 16 — frame Polimeni, 17 — bracket 18 — wheel-limiter. 19— of the tubular shaft. 20 — sleeve with prongs (St45), 21 — hub with an asterisk (St45). 22 — polucarpus bearings (STZ), 23 — thrust (Ст35), 24 — rocker (STZ). 25 — bolts M10. 20 — bolt torque limit M8, 27 — screw (STZ). 28 — sprocket (St45), 29 — a transmission chain (pitch 15.875 mm), 30 — zzattack (St45), 31 — intermediate shaft (St45). 32 — the case of the intermediate shaft (STZ). 33 — way circuit (step 15,875 mm). 34 — the transmission chain (pitch 19,05 mm). 35 pedal lift Polimeni.

To make a tractor from a scooter — it’s hardly a surprise: the home motor transport has long become a common basis of such structures. But, after working in the garden or in the garden, again easy to turn the tractor in a scooter is, without a doubt, design the find of our readers, A. Gordin.

Indeed, is it really necessary to produce the motors in your household!

Do I need a separate self-propelled SEL’khozagregat!

Isn’t it better to have a universal drive to different working bodies that facilitate the work on the plot!

We invite craftsmen who built such structures, to share their experiences: sprinkle photos, drawings, descriptions you have created a universal means of small mechanization. Waiting for such materials and from heads of circles of selhozmashinostroeniya and young technicians — participants of competition of magazine “Small-scale mechanization” — for the best design of auxiliary machinery, fixtures and hand tools to work on the plot and a student opinionsthe (conditions published in the “M-K” № 8, 1984).

A. GORDIN, p. Lobva, Sverdlovsk region.

Recommend to read MOPED AT ANY AGE Conceiving the design of the moped, I set a goal to make it easy to operate for the driver any age. This moped I have and get: easy to control on the road and on the dirt road, with... OLD FRIEND "Soap", "the Hunchback", "Fafik" — not once nicknamed little brisk Zaporozhets 965-th model. Many of us that he began his "auto" biography. Not all, however, know how motley was the...  In different areas of our country the soil was treated in different ways. Soil and climatic characteristics, natural, imprint and on the design of small tools, which are developed by the owners of household plots. Some building microfracture and tillers, designed for the use of the plow, others motorize.

In different areas of our country the soil was treated in different ways. Soil and climatic characteristics, natural, imprint and on the design of small tools, which are developed by the owners of household plots. Some building microfracture and tillers, designed for the use of the plow, others motorize.