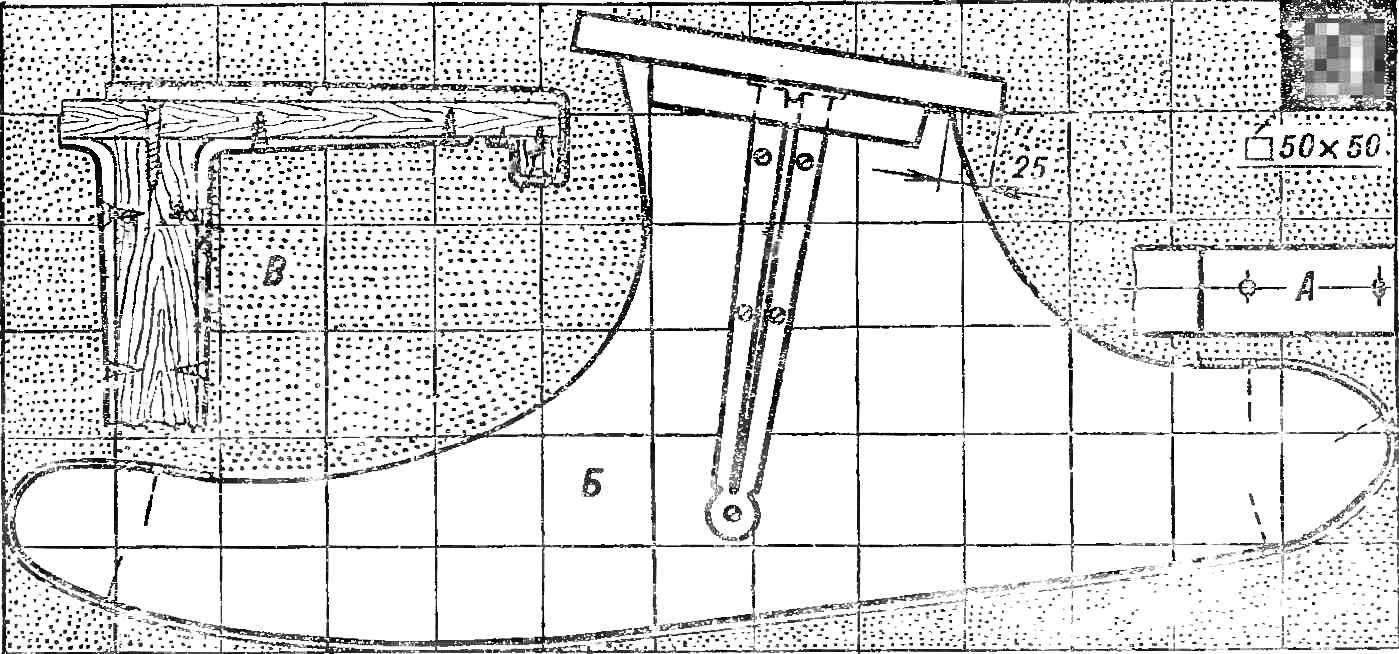

The basis of design — fir or pine Board dimensions mm. 40Х300Х650 Even better to take a few boards with a thickness of 80 to 35 mm, pripojovat them to each other and glue put it on both sides of the plywood (thickness 4 — 6 mm) cheeks. The workpiece slideway (Fig. 2) apply a grid with a side of a square equal to 50 mm, and gently move it to the contour of the Shoe. Vygruznoy saw cut out detail and clean edges.

The basis of design — fir or pine Board dimensions mm. 40Х300Х650 Even better to take a few boards with a thickness of 80 to 35 mm, pripojovat them to each other and glue put it on both sides of the plywood (thickness 4 — 6 mm) cheeks. The workpiece slideway (Fig. 2) apply a grid with a side of a square equal to 50 mm, and gently move it to the contour of the Shoe. Vygruznoy saw cut out detail and clean edges.

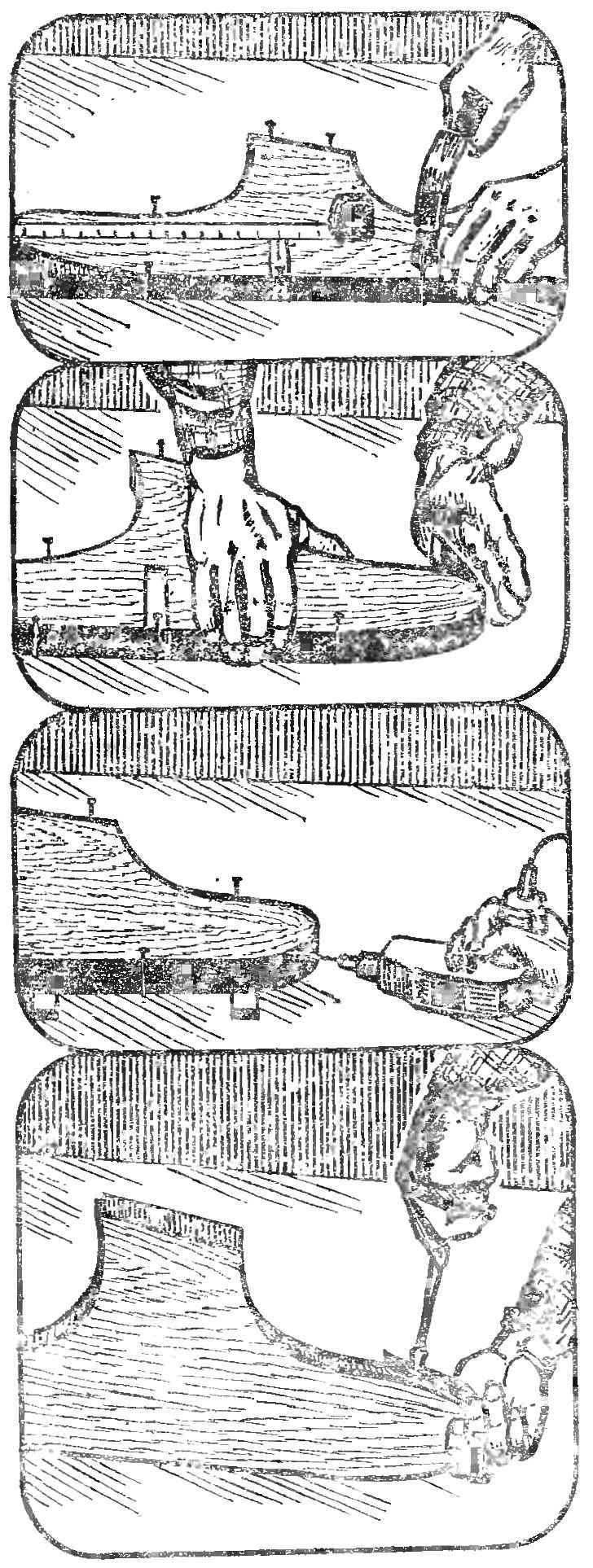

End of skid — steel strip 1,5X40X900 mm. the Centre strip should coincide with the point spaced from the nose of the sled to 325 mm. is sufficient To firmly press the fittings, use the following method (Fig. 3). Fasten the rail to the workbench (this can be done using usual nails, scoring them according to the contour of the workpiece), the fittings should fit snugly to the base. Next, drill in the wrought five holes for the size you have available screws (diameter 4-5 mm) and rassenkunde them. Screws wrap, starting from the middle left and right, bending the strip. The sharp edge of the nosing should be rounded and thoroughly cleaned.

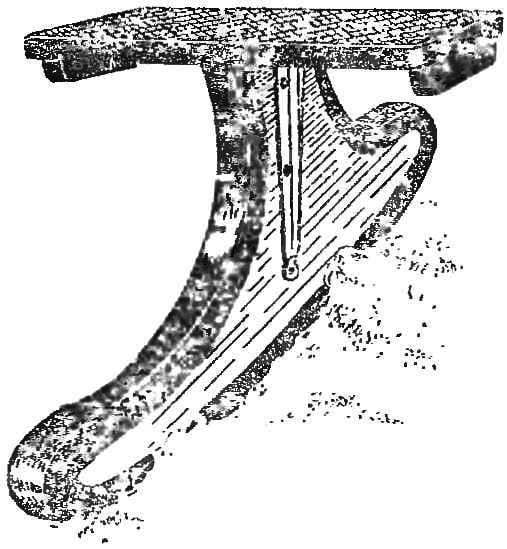

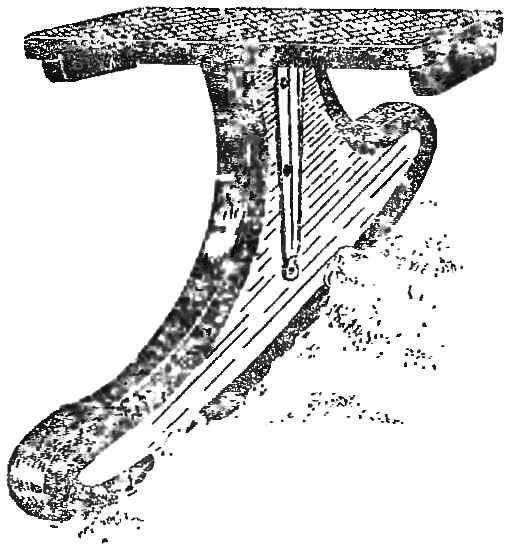

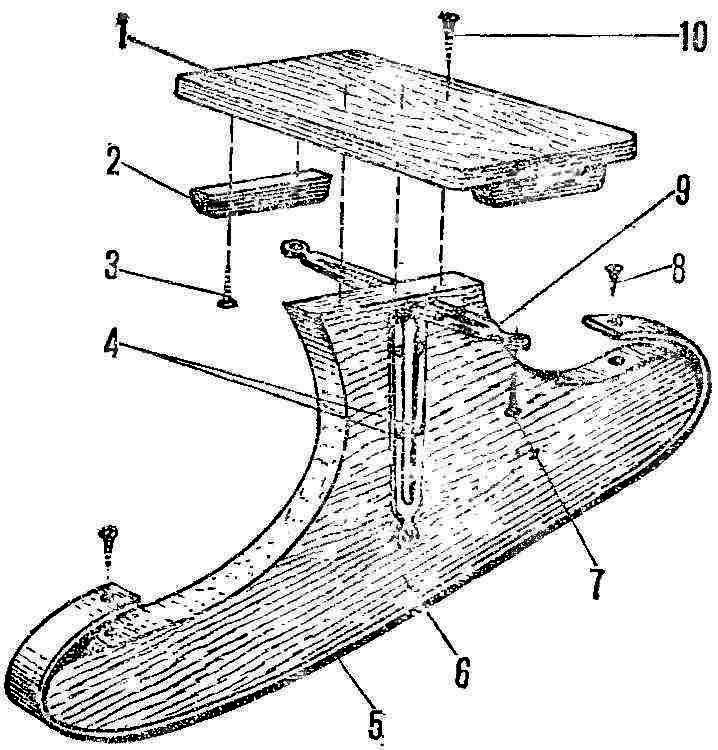

Fig. 1. Device odnopolnyh sleigh:

1 — seat (plywood 15X200X375 mm), 2 — handle, 3, 4, 7, 8, 10 — screws, 5 — weight (steel strip 1,5X40X900 mm), 6 — snake, 9 — console (steel strip S=3 mm 15X200 mm)

Fig. 2. The main elements of the sled.

Fig. 3. The sequence of operations for installation of fittings.

The seat is cut out from a sheet of plywood with a thickness of 15-18 mm, strip the ends. Trim — artificial leather with foam padding — nail furniture nails. The seat tube to the skid with four screws: two directly to the snake and two to the console, curved steel strip. From the bottom to the seat screws are attached handles — two wooden bars 20X20X125 mm.