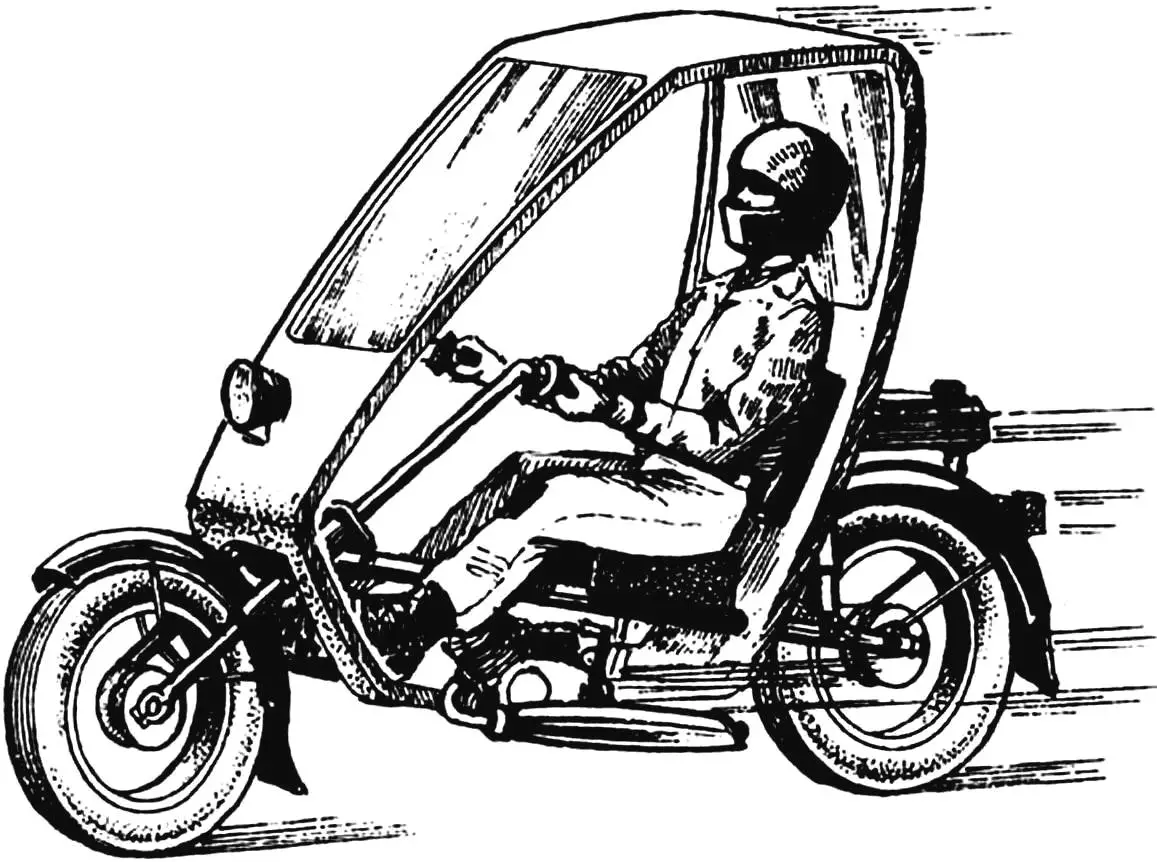

There’s no point in comparing a scooter and a passenger car — they are completely different machines. Nevertheless, motorcycle designers constantly strive to bring the comfort of four-wheeled vehicles to their two-wheeled counterparts. In recent years, lightweight scooters equipped with fairings resembling a small car body without doors have become more common in urban environments. This hybrid transport is significantly more comfortable than a traditional bike — especially for our country’s climate, rich in spontaneous precipitation “in the form of rain and wet snow.”

We present a scooter design developed by engineer I. Mnevnik using components from the Karpaty moped and the Minsk motorcycle. His machine is an elongated and low-profile mokik, well-suited for equipping with a lightweight fairing.

There’s probably no need for a detailed description of the vehicle itself — such DIY builds have been featured more than once in Modelist-Konstruktor. Let’s just highlight the main design features.

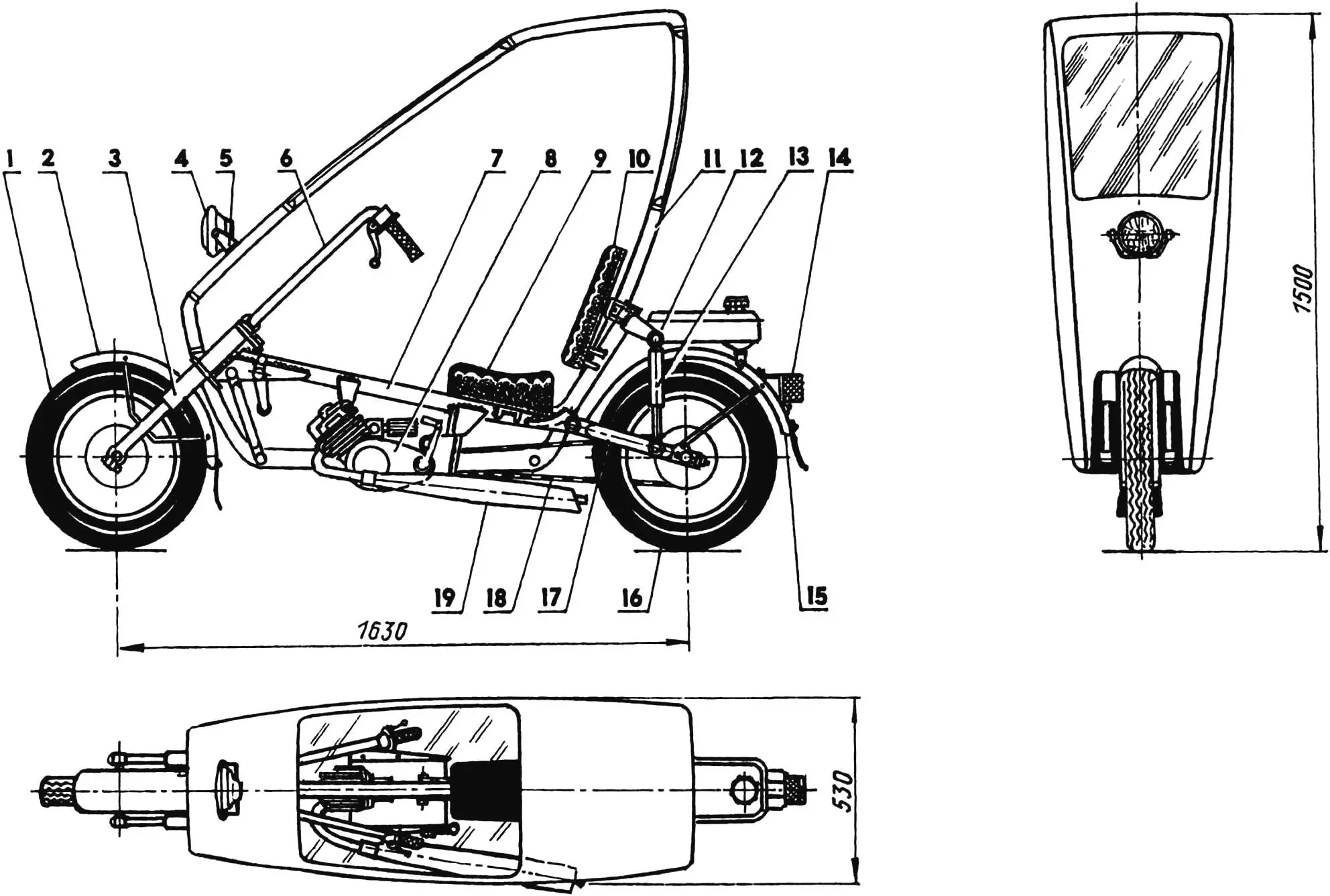

1 — front wheel (from Karpaty moped); 2 — front mudguard (Karpaty); 3 — front fork (from Minsk motorcycle, modified); 4 — headlight (Minsk); 5 — headlight bracket (duralumin, 50×5 strip); 6 — handlebar (steel, 22×1.5 mm pipe); 7 — frame; 8 — V-50 engine (Karpaty); 9 — seat; 10 — backrest; 11 — fairing; 12 — fuel tank (from Riga-11 moped or a plastic canister); 13 — rear shock absorber (Minsk, 2 pcs.); 14 — rear light (Karpaty); 15 — rear mudguard (Karpaty); 16 — rear wheel (Karpaty); 17 — rear swingarm; 18 — bushing-roller chain; 19 — muffler (Karpaty)

The scooter frame is a backbone type, bent from a 34×2.5 mm steel pipe. The front fork is from a Minsk motorcycle, slightly shortened. The handlebar is homemade, bent from 22×1.5 mm steel pipe. The rear swingarm is also homemade (though a standard one from a moped or Minsk would work), with shock absorbers from Minsk. The fuel tank is from a Riga-11 moped. If such a tank can’t be found (Riga-11 has long been discontinued), a suitable plastic motor oil canister can be used — just fit a standard motorcycle fuel tap.

The engine is a V-50 type (commonly installed on most Soviet mopeds), with a foot-operated gear shifter and kick starter.

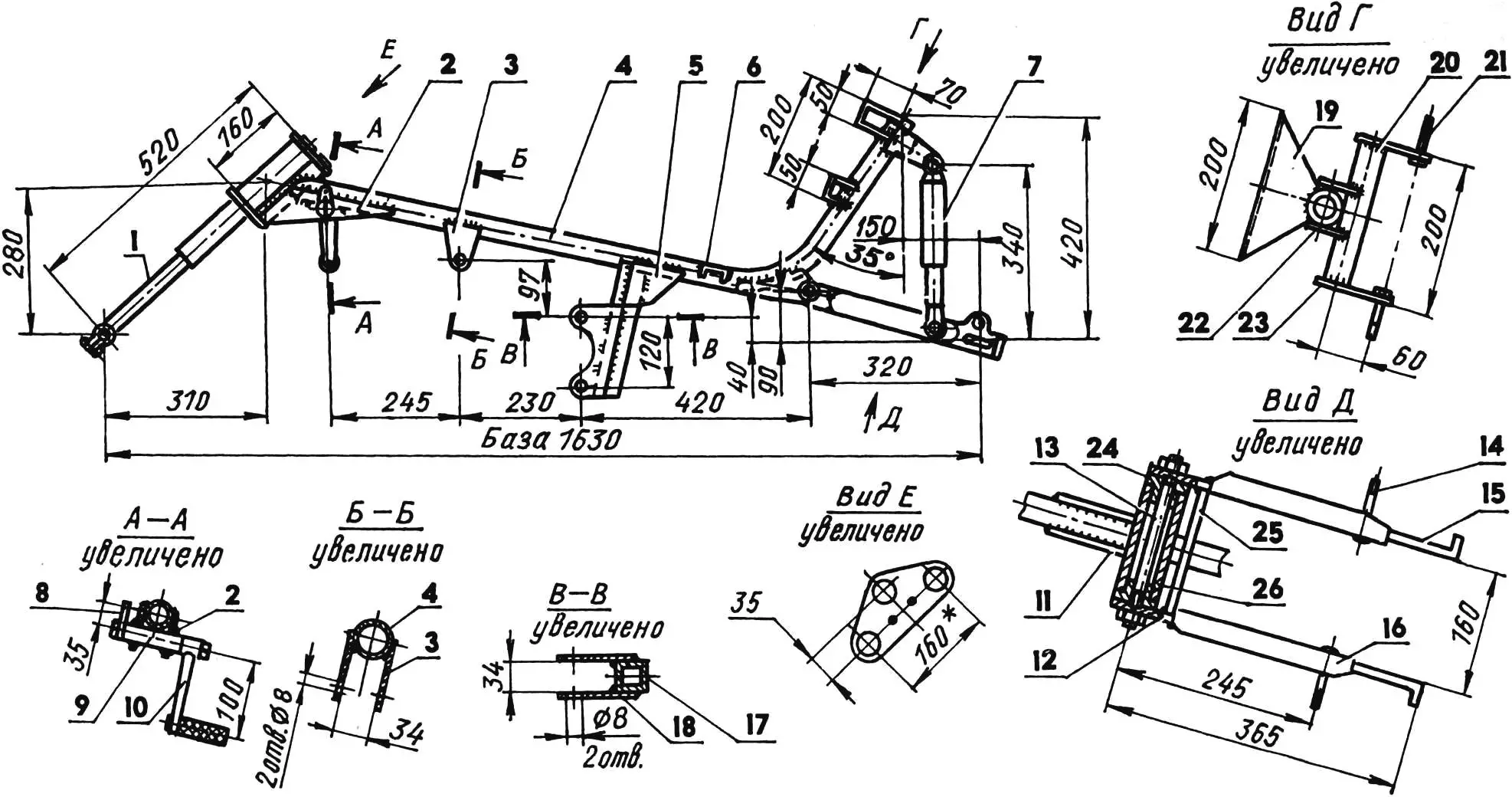

1 — front fork (from Minsk motorcycle, modified); 2 — frame reinforcement (steel, s2 sheet, 2 pcs.); 3 — front engine brackets (steel, s3 sheet); 4 — frame backbone beam (steel, 34×2.5 pipe); 5 — rear engine mount reinforcement (steel, s2 sheet, 2 pcs.); 6 — seat bracket (steel, 50x25x2.5 U-channel, L100, 2 pcs.); 7 — rear shock absorber (Minsk, 2 pcs.); 8 — brake lever (steel, s3 sheet); 9 — brake bushing (steel, 16×2 pipe); 10 — brake pedal arm (crank from child’s bicycle); 11 — gusset (steel, s3 sheet, 2 pcs.); 12 — plate (steel, 40×3 strip, 2 pcs.); 13 — rear fork hinge axle (steel, M12 stud with nuts and washers); 14 — lower rear shock bracket (steel, M10 bolt, 2 pcs.); 15 — rear wheel bracket (steel, 40×3 strip, 2 pcs.); 16 — swingarm beam (steel, 24×2.5 pipe, 2 pcs.); 17 — rear engine mount base (steel, 34×34 pipe); 18 — rear engine bracket (steel, s3 sheet, 2 pcs.); 19 — upper backrest mount (steel, s2 sheet); 20 — crossbar (steel, 30×2.5 pipe); 21 — upper rear shock bracket (steel, M10 bolt, 2 pcs.); 22 — gusset (steel, s2.5 sheet, 2 pcs.); 23 — bracket (steel, s3 sheet, 2 pcs.); 24 — bushing (bronze or nylon, 2 pcs.); 25 — cross tie (steel, 40×5 strip); 26 — swingarm hinge housing (steel, 36×2.5 pipe).

In views G and D the shocks are omitted for clarity

The seat and backrest are homemade and identical in structure. Each consists of a plywood base (12 mm thick), a cushion made of porous rubber (two 20 mm layers), foam rubber (one or two 40 mm layers), and a faux leather cover. The seat and backrest are attached to the frame using brackets bent from 2 mm steel sheet. The front brake is cable-actuated (Bowden-type housing), while the rear brake is foot-operated via a homemade pedal mounted on the right side of the frame; also cable-connected to the rear wheel brake mechanism.

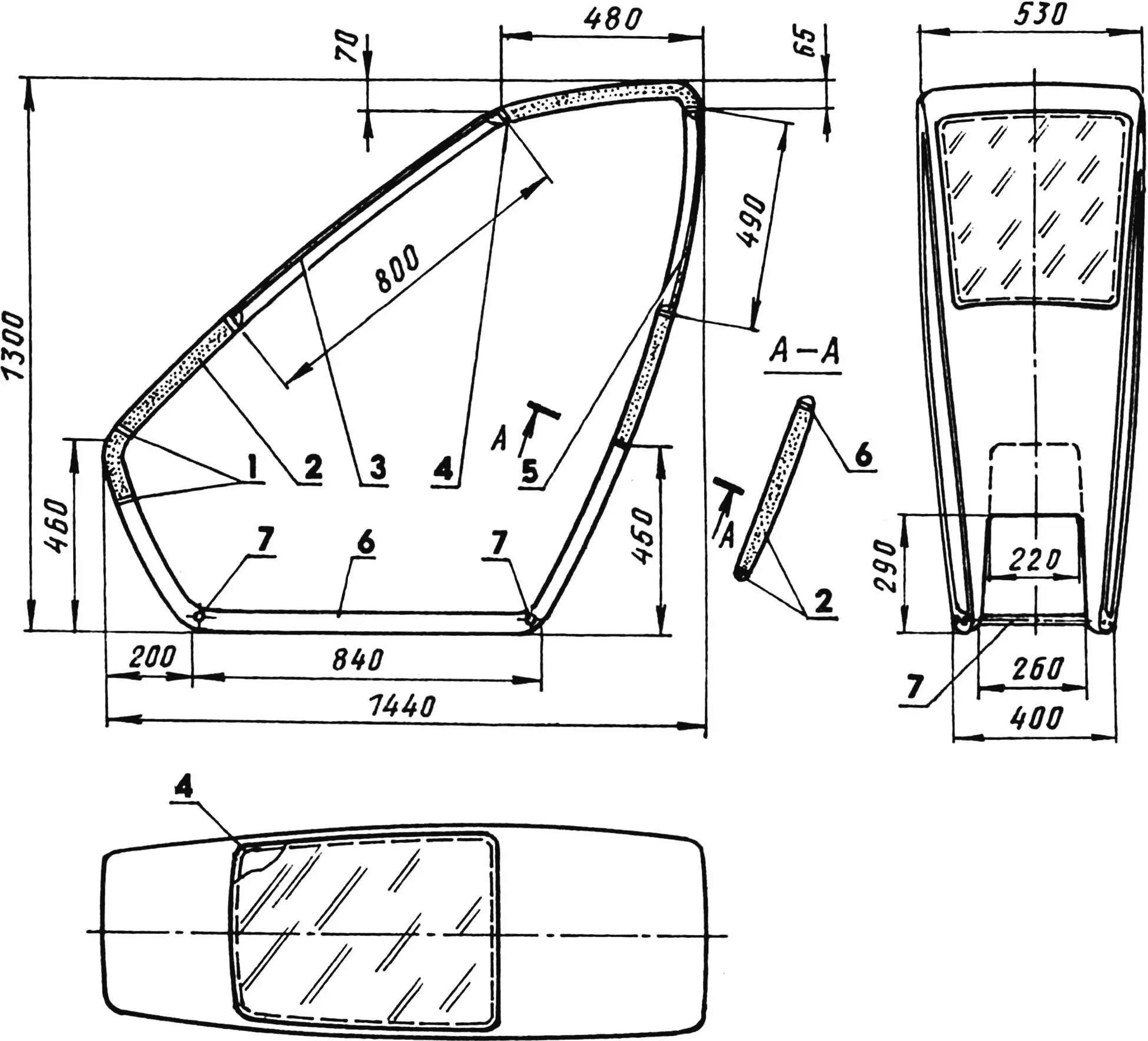

The fairing is lightweight, consisting of a plywood frame, foam filler, and a fiberglass shell bonded with epoxy resin.

1 — crossbeams (plywood s12); 2 — filler (construction foam); 3,5 — glazing (acrylic glass s4); 4 — window trim (plywood s6); 6 — fairing frame (two layers of s6 plywood); 7 — tie rods (M12 studs with nuts and washers)

The base of the frame is two structures glued from 6 mm plywood. Each is laminated from two layers with overlapping joints, giving a final thickness of 12 mm. The prepared frames are joined with 12 mm plywood crossbeams using mortise joints. At the bottom, the frames are fastened with M12 steel studs and nuts. The front and rear window openings are trimmed with 6 mm plywood, onto which 4 mm acrylic glazing is mounted.

The assembled frame is checked for warping or asymmetry. Then, the front, rear, and roof sections are filled with blocks of construction foam glued with epoxy. After curing, excess foam is trimmed with a sharp knife and sanded to shape using coarse sandpaper on a plywood block. Foam blocks are also glued to the side surfaces and rounded to complete the fairing shape. The fairing is then covered with 2–5 layers of fiberglass cloth with epoxy resin.

The prepared fairing is sanded, leveled with auto putty if needed, re-sanded, and painted with automotive enamel — ideally in two tones: dark for the lower half, light for the top. The interior is painted gray.

Finally, the glazing is installed, and the fairing is mounted on the scooter.

Controlling a scooter with a fairing is no different than riding a regular moped.

I. MNEVNIK