No welding or modern technological methods of joining metal surfaces with a laser or super glue — not supplanted the old, but not aging method: solder. And it is promising new products, many originate from the participants NTTM, young innovators.

No welding or modern technological methods of joining metal surfaces with a laser or super glue — not supplanted the old, but not aging method: solder. And it is promising new products, many originate from the participants NTTM, young innovators.

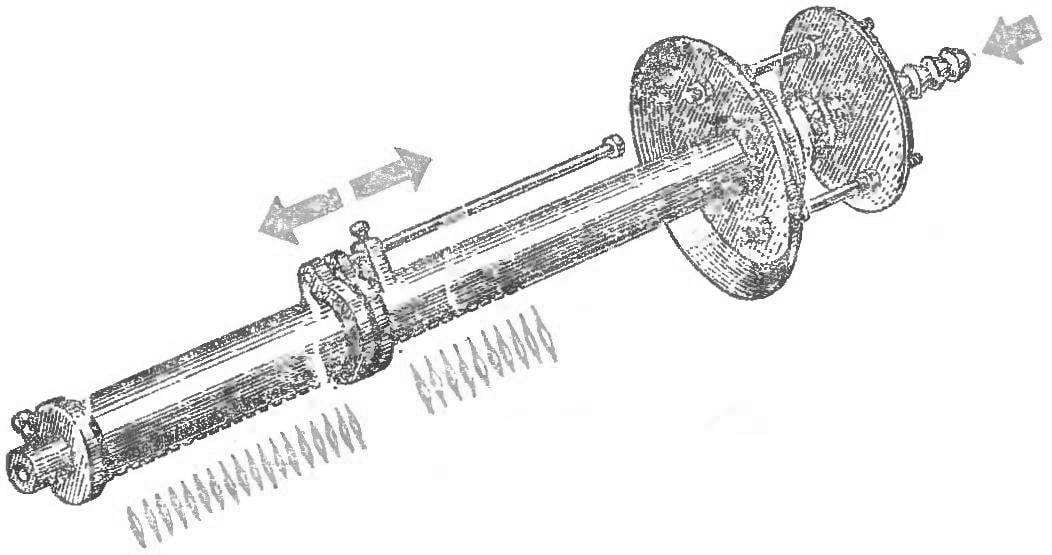

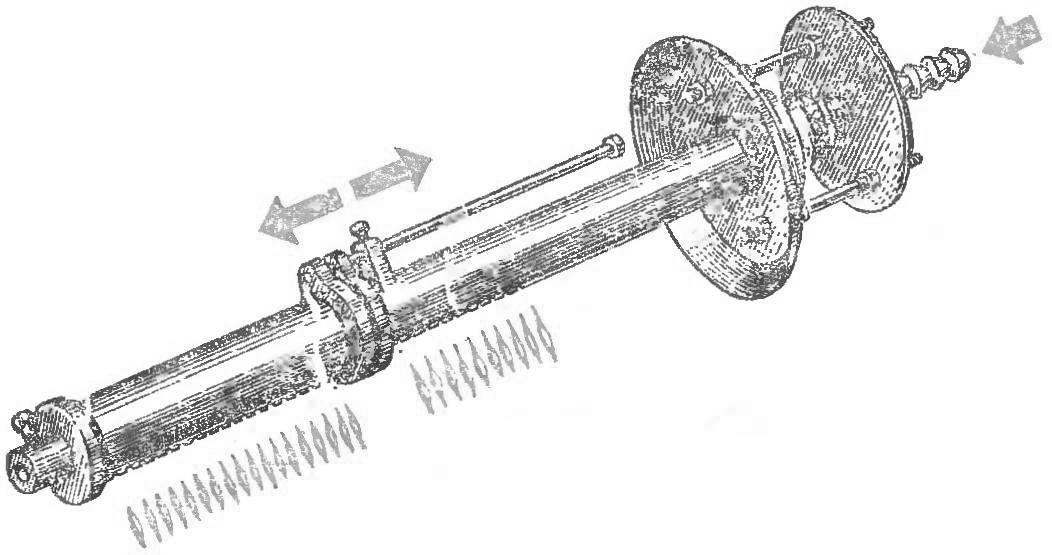

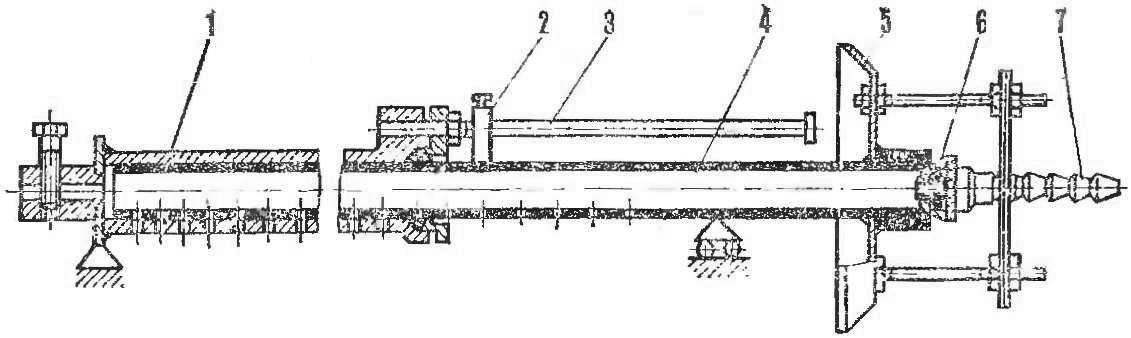

One of the innovations born in Vitebsk machine-tool plant named after S. M. Kirov. Here, we developed an original telescopic burner, which allows you to solder fusible solder, a light details: small workpiece — the burner is reduced, it is required to connect the long “soldering” is extended to a desired size.

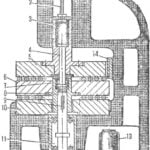

The “secret” in that the burner tube is made of a composite. Its outer tube is made with plugged end and is mounted on the rod, and one through the slider with the inner tube connected to the shield and a gas fitting with a regulating screw. Bar with fixed slider is used to set the size of the fire area, and also prevents accidental rotation of the pipes relative to each other — that is, provides a coincidence of the holes of the outer and inner tube. Gas through the nozzle and the regulating nut is served in the cavity of the tubes, extended perforated sections sets the size of fire area — brazed the entire length of the workpiece. This eliminates the warping of the product, ensures uniform heating, improves the quality of the connection, it becomes possible mechanized soldering process parts with a length up to 470 mm.

Gas soldering iron:

1 — outer tube, 2 — slider, 3 — rod, 4 — internal tube, 5 — shield 6 — regulating nut, 7 — fitting to the pipeline.