Important the installation of the exhaust muffler to reduce noise, which, of course, will make a vacation more enjoyable.

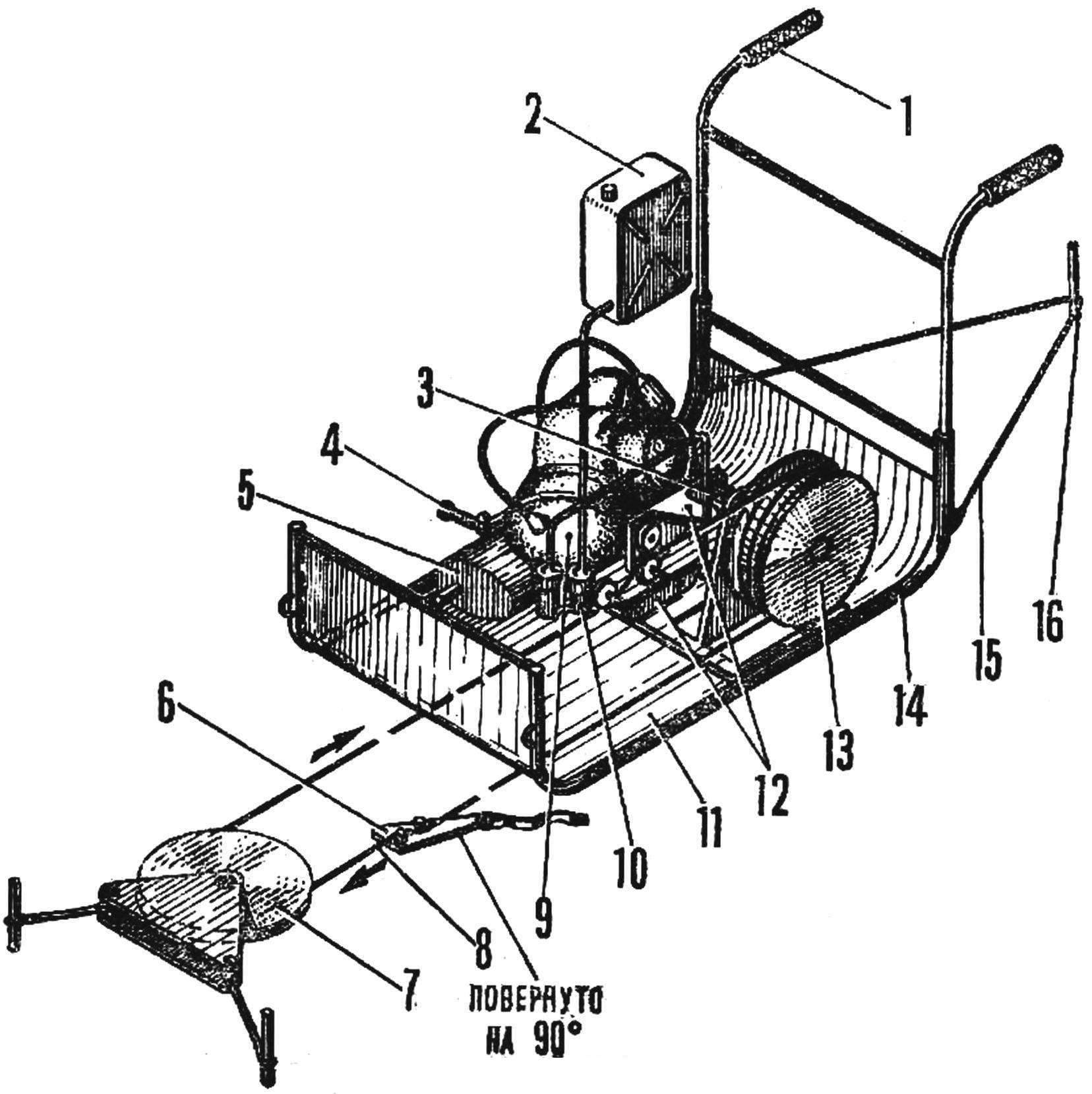

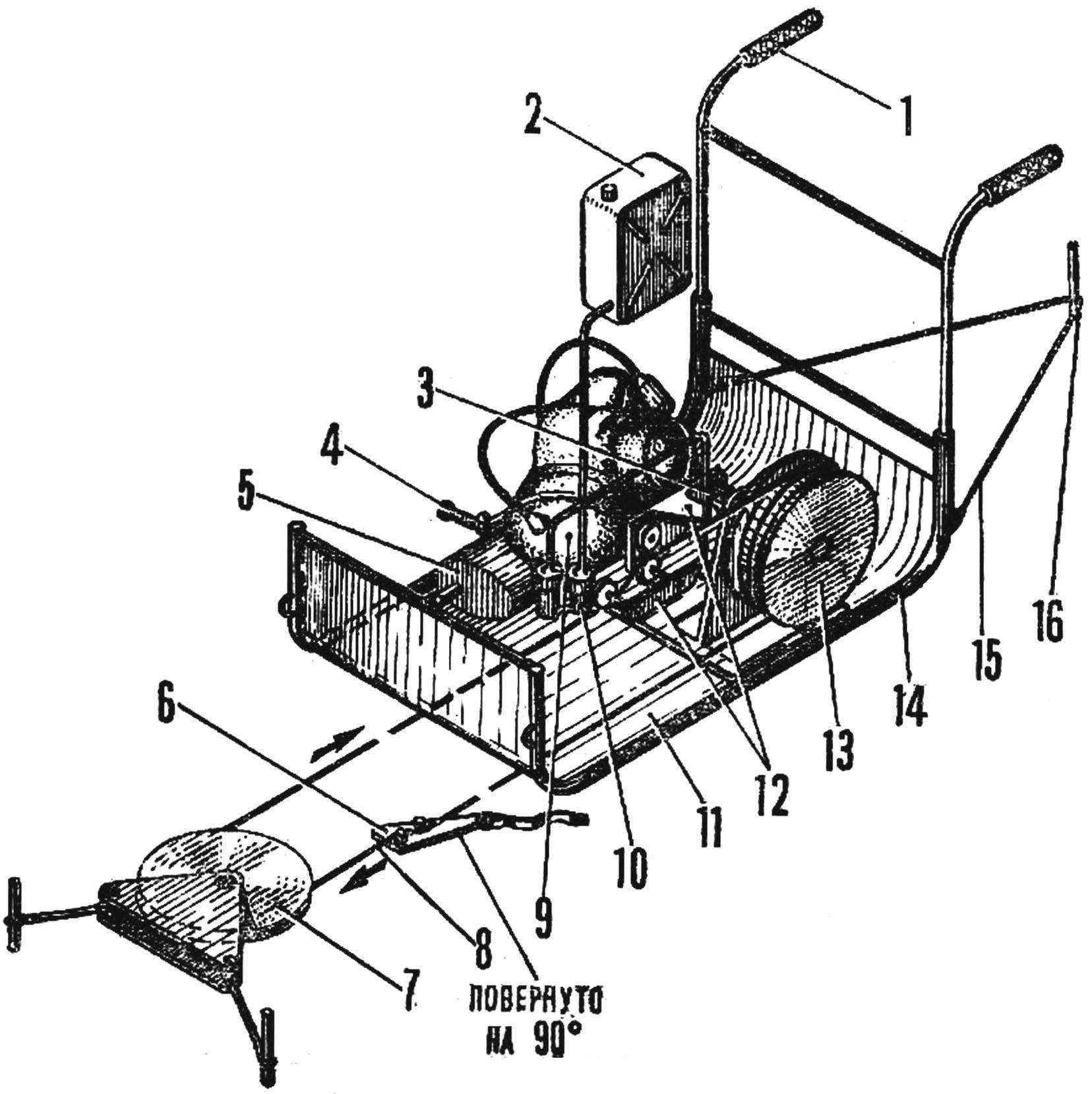

The construction of various variants of the lifts shown to ensure weight within 60 kg, including here and working fuel reserve — 10 l-Lift at the same time allows you to climb the mountain of 10-15 skiers.

Now consider the design of drags — special devices with which the skier grasps three and thus can climb up the hill. The clips are permanently fixed to a moving rope or cable mounted.

Simple hinged clip lever type operate on the principle of jamming or bending the moving wire rope (Fig. 3). Can be they and with eccentric mechanism (Fig. 4). A lever consist of a metal triangular plate somewhat elongated shape and a pair of bushings on the bolts. Bushing set at a certain distance from each other, usually equal to 1.25 diameter of cable that can be securely clamped between them. The corners of the plate are rounded, and the long end thereof on a ring fastened belt.

Fig. 3. The yoke lever type:

1 — towing cable, 2 — plate yoke, D16T, 3 — bushing, brass, 4 — bolt М6х25, 5 — belt 6 — ring belt.

Fig. 4. Yoke eccentric type:

1 — strip, PCB, 4 PCs, 2 — rivet Ø3 mm steel, 4-piece, 3 — arm, steel, 2 PCs, 4— pull cable, 5 — ring, steel, 6 —rivet Ø6 mm, steel, 2 PCs.

The eccentric yoke more complex designs, but it is easier to grab the rope when “landing” on the lift. It consists of two metal arms with pads of the PCB and the metal of the earring between them. The inner ends of the arms have a shallow notch, rounded and delivered to the earring eccentrics, whose role is played by steel rivets. In the manufacture of such yoke must be remembered that the distance between the ends of the clips are selected strictly definitely depending on the diameter of the cable.

Before you climb the mountain with the help of a tug, learn how to use the clip. Remember that it is unacceptable to do on the belt loop and push there hand or to wind the belt on the brush, it is also impossible to take the rope with your hands even with gloves or mittens; place of “landing” on the lift and off should be equipped with horizontal platforms. Now take the bow in the arm, with bushings down to another attach the strap. Install the yoke on the cable and gently pull the strap until the cable will slip, but if it is harder to pull, the clip will jam the rope and goes with him up. This point is most crucial: if you weaken the tension, the clip can come off. To avoid this, but try to adjust the belt tension by hand. Before you start moving up, step forward, this will soften the jerk, will reduce the load on the engine, and it will be easier to land.

As we neared the rotator lift, it is necessary to release the cable from the yoke. It is enough to slightly loosen the belt tension by myself at first a little forward and then quickly straight them. You can also make an energetic step forward, pushing ski to slightly overtake a moving cable: then the belt will SAG and bow falls. Remember that you cannot leave the belt without releasing the clip from the grip, the cable can sprinit, and then the belt will be wrapped around the cable. At best it will be cut in the swivel block in the worst possible accident with failure of the lift.

Yu. a. ZOTOV, N. SHERSHAKOV

For tourists and skiers in big mountains with difficult terrain and significant elevation usually put a chairlift. At its traction-bearing rope they have special hangers with one or two armchairs. The length of such lifts is limited to 1.5—2 km: experience has shown that the rise in excess of time 10-15 minutes, can during winter lead to trouble — frostbite unprotected skin, especially the face.

For tourists and skiers in big mountains with difficult terrain and significant elevation usually put a chairlift. At its traction-bearing rope they have special hangers with one or two armchairs. The length of such lifts is limited to 1.5—2 km: experience has shown that the rise in excess of time 10-15 minutes, can during winter lead to trouble — frostbite unprotected skin, especially the face.