Thousands of boats and boats, Amateur-built project of OKB “M-K”, travel through the water spaces of rivers, lakes and even seas of our vast country. It’s hugely popular “Muscovite”, “Volzhanka”, “Arrows”, “Mermaid”, “Typhoon” and “Ruslan”. The experienced eye specialist immediately identify them by their characteristic profile and landing on the water, allowing almost the entire speed range to go without a wave. But in recent years an increasing number of “hybrids” of boats and boats, born in OKB “M-K”. This is the result of a creative initiative, attempts on their own to adapt projects to local conditions, the search for new materials and technologies ensuring high quality products.

Thousands of boats and boats, Amateur-built project of OKB “M-K”, travel through the water spaces of rivers, lakes and even seas of our vast country. It’s hugely popular “Muscovite”, “Volzhanka”, “Arrows”, “Mermaid”, “Typhoon” and “Ruslan”. The experienced eye specialist immediately identify them by their characteristic profile and landing on the water, allowing almost the entire speed range to go without a wave. But in recent years an increasing number of “hybrids” of boats and boats, born in OKB “M-K”. This is the result of a creative initiative, attempts on their own to adapt projects to local conditions, the search for new materials and technologies ensuring high quality products.

One of the interesting novelties — boat “Lada” design of our reader V. Kokoreva from Kuibyshev. It was created based on the already tested and well-proven motor boats with the ski in the plane of the keel and hull type “marine knife” American designer Peter Payne. As you know, Paine has designed a fast vessel with an elongated and pointed nose (why it got its name) that can overcome the opposing waves, smoothly cutting them. Approximately the same shape have modern supersonic aircraft: the pointed nose makes it easier to overcome the sound barrier.

The design of the boats “Lada” strongly pointed nose portion into a keel ski (440 mm transom frame) and in combination with sloping side branches samotnych framework forms the body of this modern form, well able glissirovat at different loads and various conditions of water surface. So, with a minimum load (one driver) the motor boat “Lada” can glissirovat on one ski, represents a flat plate; as the load increases, the work included the beveled sections of the bottom. While planing, the quality of the housing decline is much slower than a conventional boat hull “deep V”.

Of course, the work of V. I. Kokorev has the advantages that can assess every fan of motor-boating.

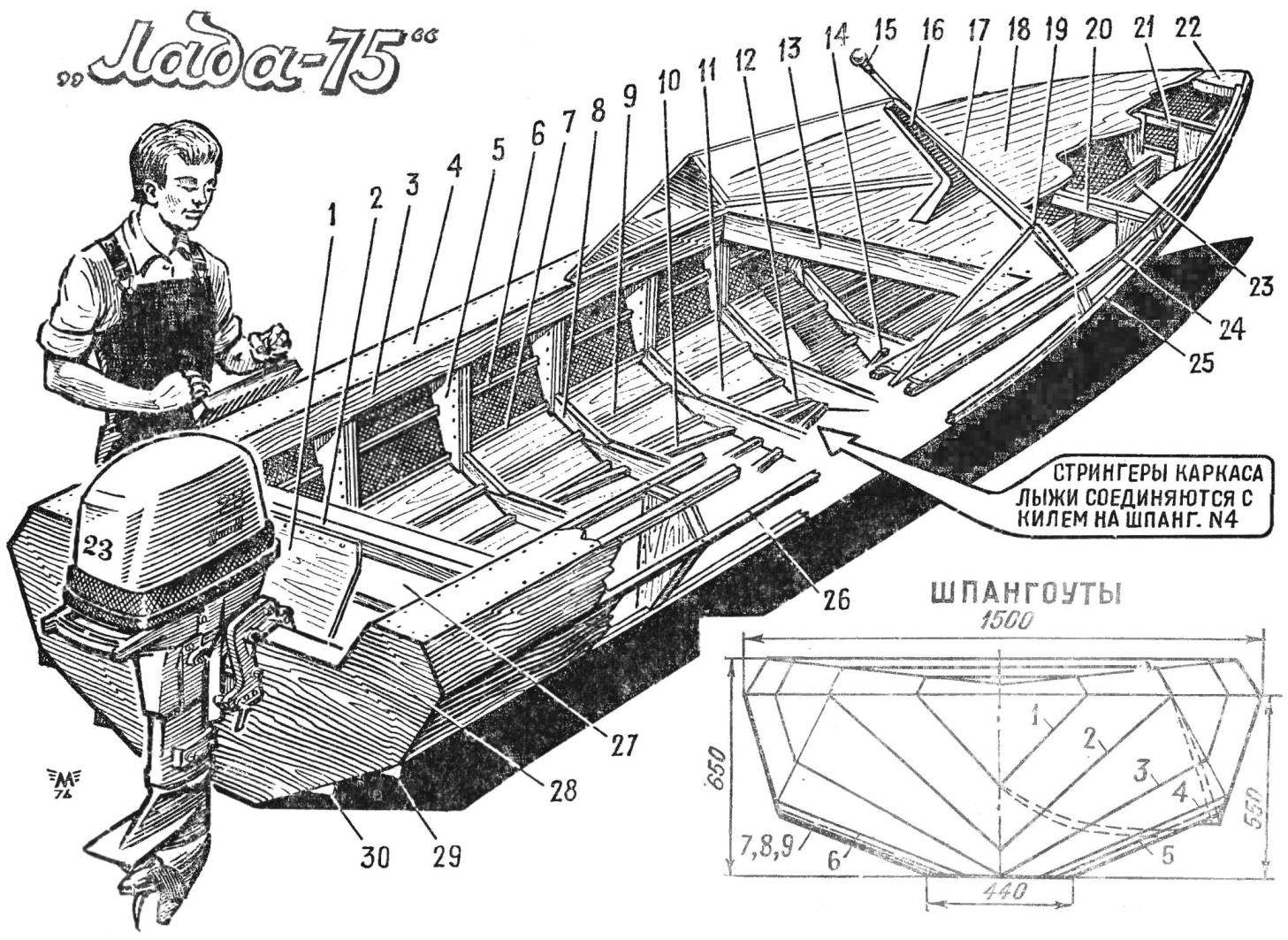

Fig. 1. General view of boats:

1 — sub box, 2-beams frame No. 8, 3 — rail, 4 gunnel, 5 — side gusset plate of the frame № 6, 6 — side stringer, 7 — zygomatic stringer, 8 — partimers bulkhead No. 5, 9 — bottom-stringer the 10 — stringer of the frame to the skis 11— plating bottom (plywood 4 mm thick), 12 — connection of the keel to the stringers of the frame to the skis 13 — extended beams of the frame № 4, 14 — the back end of the “blade” stem, 15 — masthead light, 16 — pillar of the windscreen, 17 — windscreen, 18 — deck (plywood with a thickness of 3 mm), 19 — lateral front windscreen, 20 — BIMS bulkhead No. 2, 21 — the frame No. 1, 22 — bow-boss, 23 “blade” stem, 24 — side stringer 25 — bilge stringer, a 26 — corner side stringer 27 back seat, 28 — the covering of transom (plywood thickness 10 mm), 29 — zygomatic longitudinal redan, 30 — bottom longitudinal redan. On the theoretical samotnom terms “blade” stem not shown.

According to the purpose of “Lada-75” — crew boat high seaworthiness, designed for single outboard engine with a capacity of not less than 25— 30 HP Combination of hull type “deep V” with a wide shaped ski along the keel and bow, made in the form of “blades” should ensure a good germination rate for wave and soft motion on waves up to 0.75 m without noticeable speed reduction.

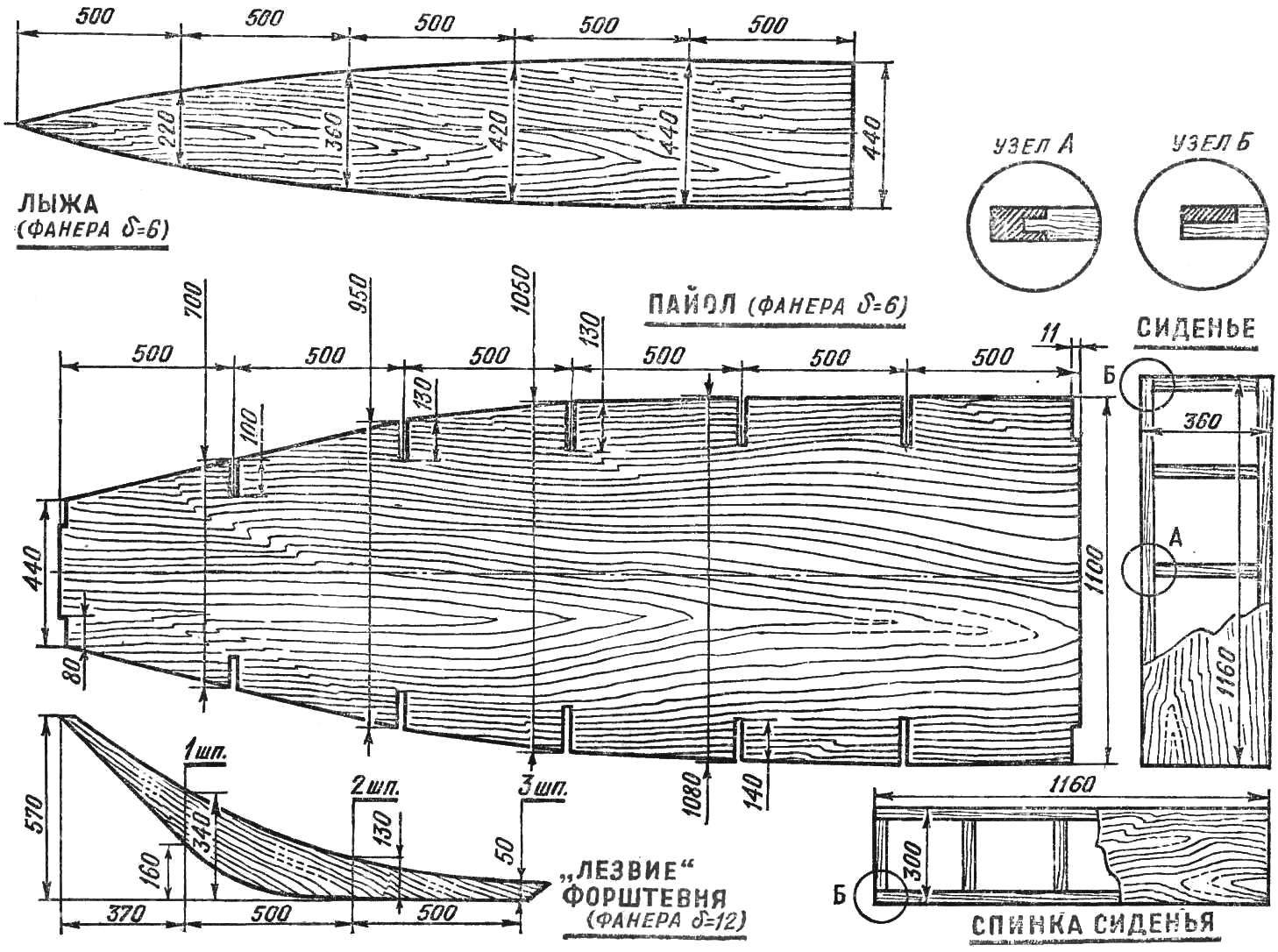

Wedge shaped planing area (ski) has a length of 2.5 m and a width at the transom of 0.44 m, which allows the boat with one driver glissirovat, hardly touching the water sides (with minimal resistance), and tow a water-skier weighing up to 80 kg.

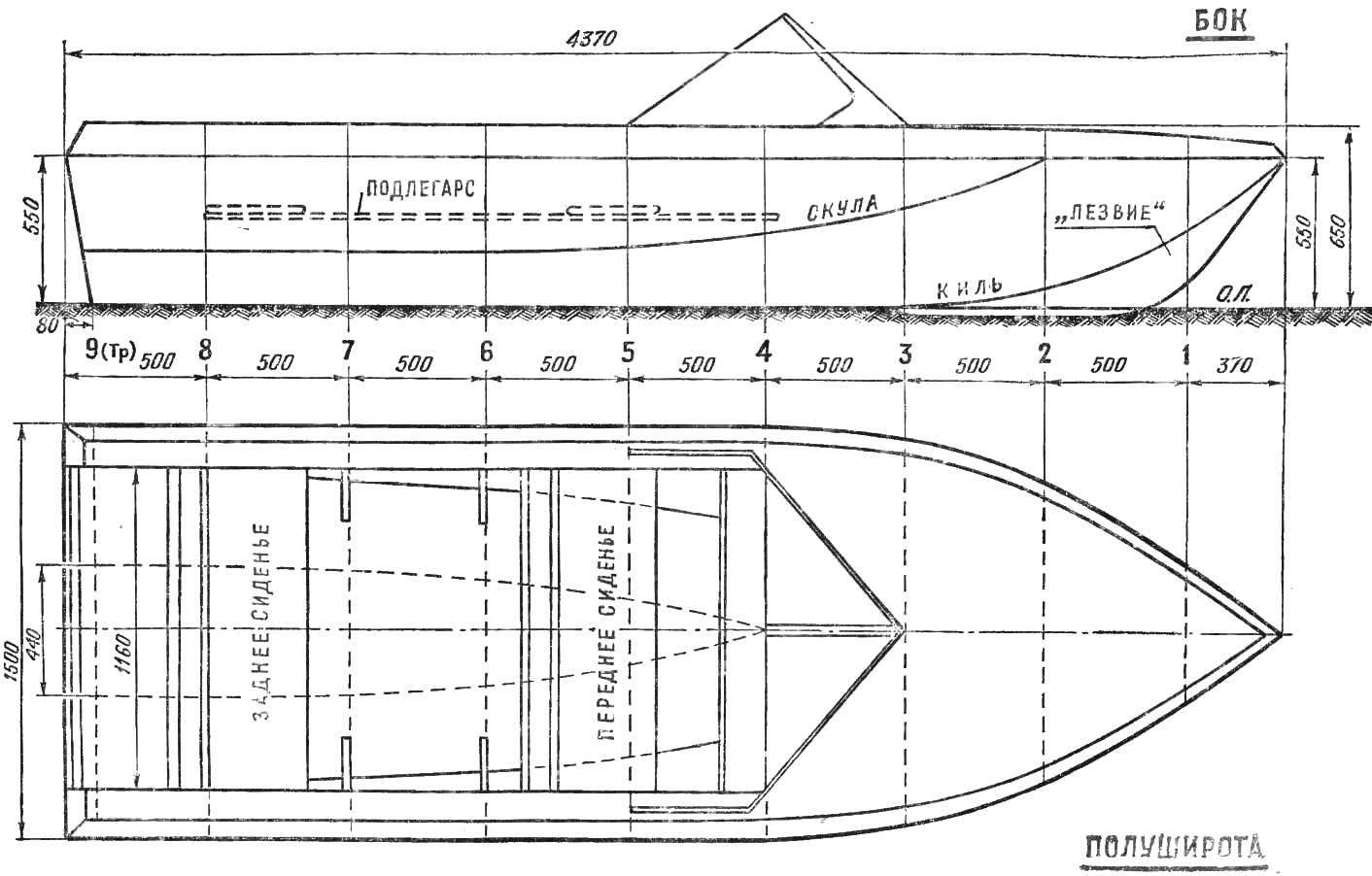

Fig. 2. Projection “side” and “Poloshirt”.

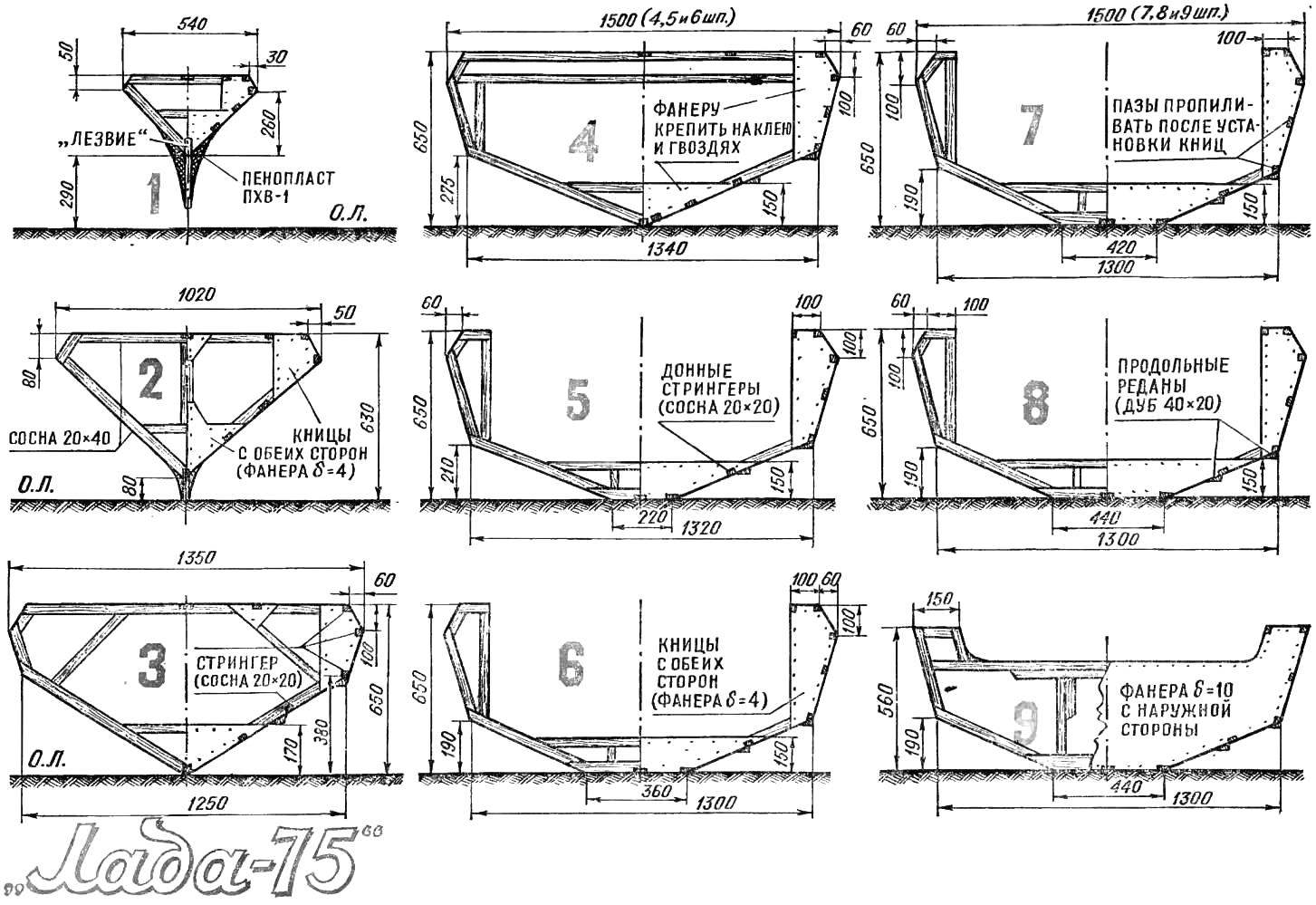

Fig. 3. Working drawings of the frames.

Fig. 4. Working drawings of the skis, the soles, the “blade” stem and seats.

The wooden frame of the boat is going in the usual way from samotnych frames connected by longitudinal cutting elements (stringers). Trim sides and bottom of waterproof plywood of 3 mm thickness, ski — plywood with a thickness of 6 mm or 4 mm followed by pasting the fiberglass in the thickness of 1-1,5 mm.

Samotnie frame is collected from pine sticks 40X20 mm, in accordance with the design drawings shown in figure 1. Scarves made of plywood 4 mm thick should be placed on both sides in epoxy glue and fastened with screws 15X2 interspersed with nails for better attachment of the gussets to the frames. Voids between the bars it is desirable to fill with foam stamps PS-1. Transom Board from bars 40X20 mm sheathed on one side with plywood of 10-12 mm, also on epoxy glue, screws and nails. If so there is no plywood, transom frame, you can sheathe a thin (3-4 mm), but with both sides filling the voids between the bars of foam. The stem serves as a “blade” cut from 12 mm plywood (see constructive drawing). To pair the “blade” hull lines space on both sides is filled with foam and glued a piece of fiberglass, cut to place.

The housing Assembly is conducted in the usual way, up the keel frame on the stocks. After sheathing a plywood boat with fiberglass glued, ASTT (b) to the epoxy or polyester resin: pensiri, deck in the fore part and sides in one layer, the bottom (to the cheekbones) — in two layers. After complete polymerization of the resin the boat nitroglycerine painted enamels.

MAIN TECHNICAL DATA

Length the greatest, m…………………………………………..4,37

Breadth overall, m………………………………………….1,5

Board height, m…………………………………………………..0,65

Passenger capacity………………………………………..up to 4 people.

Weight (wooden version), kg……………………………….120

Power outboard motor, HP………………………..30

The maximum speed with one driver, km/h…..45