This is difficult and I passed, but in the end solved this problem. My experience is already used by a few people that it allows to judge that the solution we have found quite successful. So I want to share them via the journal “modelist-Konstruktor” with other homebrew.

No, I did not invent any new wheel. I just made two wheels from the car of the raised passableness, the GAZ-66. Immediately I say. Do not be afraid of their number — eight pieces for four tires. They can be purchased pretty easily and inexpensively. Drivers “sixty-sixth” at the first opportunity try to get rid of the regular wheels because of the great complexity in their dismantling-Assembly and replace with more comfortable, with the retaining split ring. And they’re probably right: after all, you want to turn is to roll as many as 14 screws on the disk.

The regular wheel of the GAZ-66 consists of a disc, the rim and detachable side. Disk welded to the rim; together they constitute a single component — the wheel. Outer wall is attached to the wheel disc fourteen special bolts M16, pressed into the sockets of the disk and the cone (centre) nuts.

Since the used wheel was designed for trucks, to provide the necessary strength and rigidity it had a large thick steel stamped parts, and hence the mass excess for the air suspension.

In order to facilitate the wheel, secured it on the table of milling machine clamps and AA – (end) cutter diameter of 50 mm (you can use a mill and 70 mm) were chosen in the rim of the window. Not to wrestle with the geometry of the window was placed between the bolt holes. Thus they also turned fourteen. Anyone have a milling machine, the wheel can be alleviated and drilling many holes. Although such work is very time consuming, but it may be even the best option — after all, a lightweight wheel will retain greater stiffness.

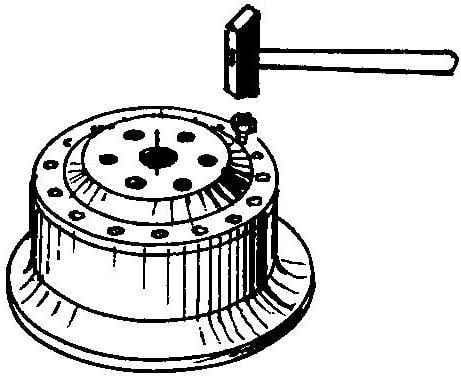

Wheel with detachable side of the car of the raised passableness, the GAZ-66:

1 — rim; 2 — detachable side; 3 — drive; 4 — M16 bolts (14 pieces); 5 — cone (centre) and nuts M16 (14 PCs)

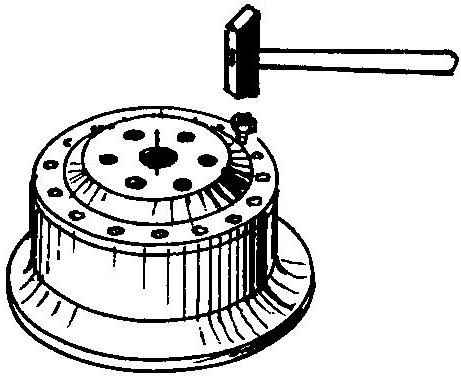

Flotation tire for pneumatic assemblies:

1 — the main rim with disc; 2 — detachable rim; 3 — bolt M16 (7 pieces); 4 — conical (centering) the nut (7 pieces)

Next the wheel for the same purpose was optcial on the lathe (the machine must be such that it can be processed of the workpiece with a radius of 300 mm and more).

First, cut the rim side of the rim (it is made of 6 mm steel, so cut off the ring was pretty heavy).

Then eased the wheel disc. He stamped from steel sheet of thickness 10 mm for a wheel suspension is unnecessary. Therefore, the cross section of the disk is reduced and made variable: the rim is 4 mm in the middle (the tapered part) is 5 mm, the inner part is 6 mm Angle of rotation of the toolholder of the machine the turning of the cone was 45 degrees.

In the end, the wheel (immediately felt) was almost twice easier.

The same technology has processed and the second wheel of the GAZ-66, but he still cut the cone part of the disc together with the inner as superfluous, leaving only the flange part is received, thus, the detachable wheel rim. Holes made the cone on the respective lower surfaces of the nuts.

Some bolts, broken hammer, slightly deformed — they had to correct and re-run the thread. The bolt is also facilitated by drilling them in the axial hole diameter of 8 mm. in addition, for the wheel Assembly only used seven of the fourteen bolts, hammering in them into the drive wheels via a socket.

And one more thing. To install the stake–8A on the hub axle air suspension inner part of its disk must match it. But this correspondence is possible only under the condition that the hub used car GAZ-66. From this position there are at least three exits. The first is to modify and adapt the regular drive wheels. The second is to provide a drive an additional mounting ring with identical holes for fastening to the drive and for fastening to the hub. Third — cut the internal part of the disc, and in its place weld another, the corresponding hub.

Vivianne bolts from the holes in the wheel disc

Making basic rim and outer rim with disc of wheel GAZ-66 (shaded parts removed)

Wheel for pneumatic disassembled. This option is more wasteful than described in the text. For its production will require not two, but three wheels from the GAZ-66

Tire for wheels used from tractor truck and eased her according to the technology described in the “Modeller-designer” (No. 12’2000). Chose this tire because it has the same bore diameter as the rim made the wheels — 18″(457 mm) and large width. However, the seat ring of the tire still had a little work with a angle grinder and lubricate — then it easily went into place.

The result was a wide wheel with demountable rim (as the car “Zaporozhets” or motorized), with wide-Pneumatics.

By mass, it is not heavier “classic” self-made wheel for pneumatic-tired machines, but its design, of course, incomparable with the past — it looks like the product of factory manufacture.

V. BARANOV, Novosibirsk, Russia

Recommend to read GRINDING THE SEEDS? PLEASE! Becoming a farmer, I was faced with the necessity of grinding of beet seeds and alfalfa. Asked how to cope with this problem experienced large farms, and that is, on the image made a... TRICYCLE WITH ROLL The history of car industry it is known that the first car was three-wheeled crew K. Benz. In the future, with increasing speed, was replaced by four-wheeled machine, the more stable...

Whatever you say, the main and most available in the production of multigrade engine homemade all-terrain transport vehicles remains pneumatic— wheel with low tire pressure. But for a lot of Amateur designers making wheels of pneumatic-tired machines presents certain difficulties. Sometimes hard even to determine their design. Traditional rims — two rims with cradles between them, seated on the disc or the hub via the spokes, in the manufacture of complex, and their design, as they say, leaves much to be desired.

Whatever you say, the main and most available in the production of multigrade engine homemade all-terrain transport vehicles remains pneumatic— wheel with low tire pressure. But for a lot of Amateur designers making wheels of pneumatic-tired machines presents certain difficulties. Sometimes hard even to determine their design. Traditional rims — two rims with cradles between them, seated on the disc or the hub via the spokes, in the manufacture of complex, and their design, as they say, leaves much to be desired.