The car was built in the days when I realized that the promised “reformers” two cars in exchange for vouchers, not only to me but also most Russians have never get. While we had to work more, and life became worse. On the salary they were paid very irregularly, could not buy a car. But it was necessary to survive. The hope remained only on the earth-mother — only she could help. But the suburban area was far outside the city, and get to it there is nothing.

The car was built in the days when I realized that the promised “reformers” two cars in exchange for vouchers, not only to me but also most Russians have never get. While we had to work more, and life became worse. On the salary they were paid very irregularly, could not buy a car. But it was necessary to survive. The hope remained only on the earth-mother — only she could help. But the suburban area was far outside the city, and get to it there is nothing.

Decided to do at least some vehicle. He began to pick up the units and mechanisms from a variety of techniques, the benefit of working in Vtorchermet and all that was needed, bought at the price of iron scrap at that time he was still not in the price.

Preparing the materials and components found Amateur designers of transport equipment, which advised me to build a car, and a tractor (or rather, self-propelled chassis which is jokingly called “tractorable”), To such technology, they say, the requirements are not so stringent, and registration with the authorities is easier than in road inspection.

Thinking through the design of the vehicle, tried to use existing units and mechanisms without excessive alterations, although without them it is also not cost — because most of them were from different cars and tractors, and even completely unknown from any equipment.

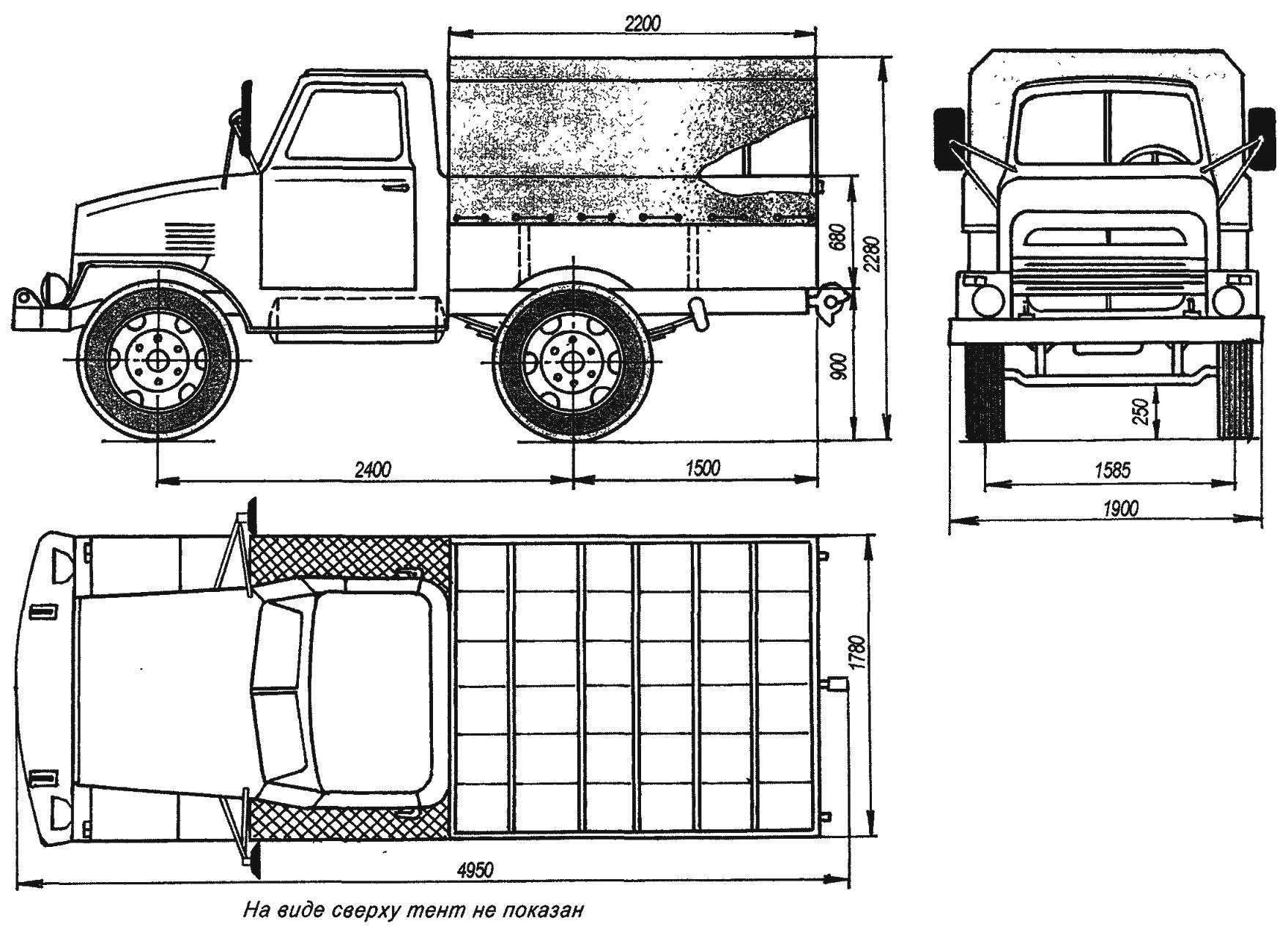

Frame, along with suspension (springs and even shocks), used from the old car GAZ-51 — on the roads, this car no longer run and you can see it is that in museums. But the technology enthusiasts with experience probably know the “home country roads”, as lovingly called the car in the difficult postwar years.

Under the hood is a diesel engine from a tractor T-16

Shortened rear axle of the truck GAZ-51 on tractorable

The frame to shorten it, cut out almost 900 mm side members between the two cross-beams, for removing, no need of one of them. The front and rear frames are joined, the joints of the spars picked up welding and reinforced on both sides of the welded plates from 4 mm steel sheet.

In this “surgical” intervention of the side walls, perhaps weak, but, as shown by further long-term exploitation, not much, and it handled all of the loads, and often with congestion. But not had to redo the attachment points of the rear springs, and drawbar, as if would cut off the rear part of the frame.

Looking ahead, I note that at least resistant brackets podreczniku on the frame and left, but podreczniki to put did not become — there were some springs.

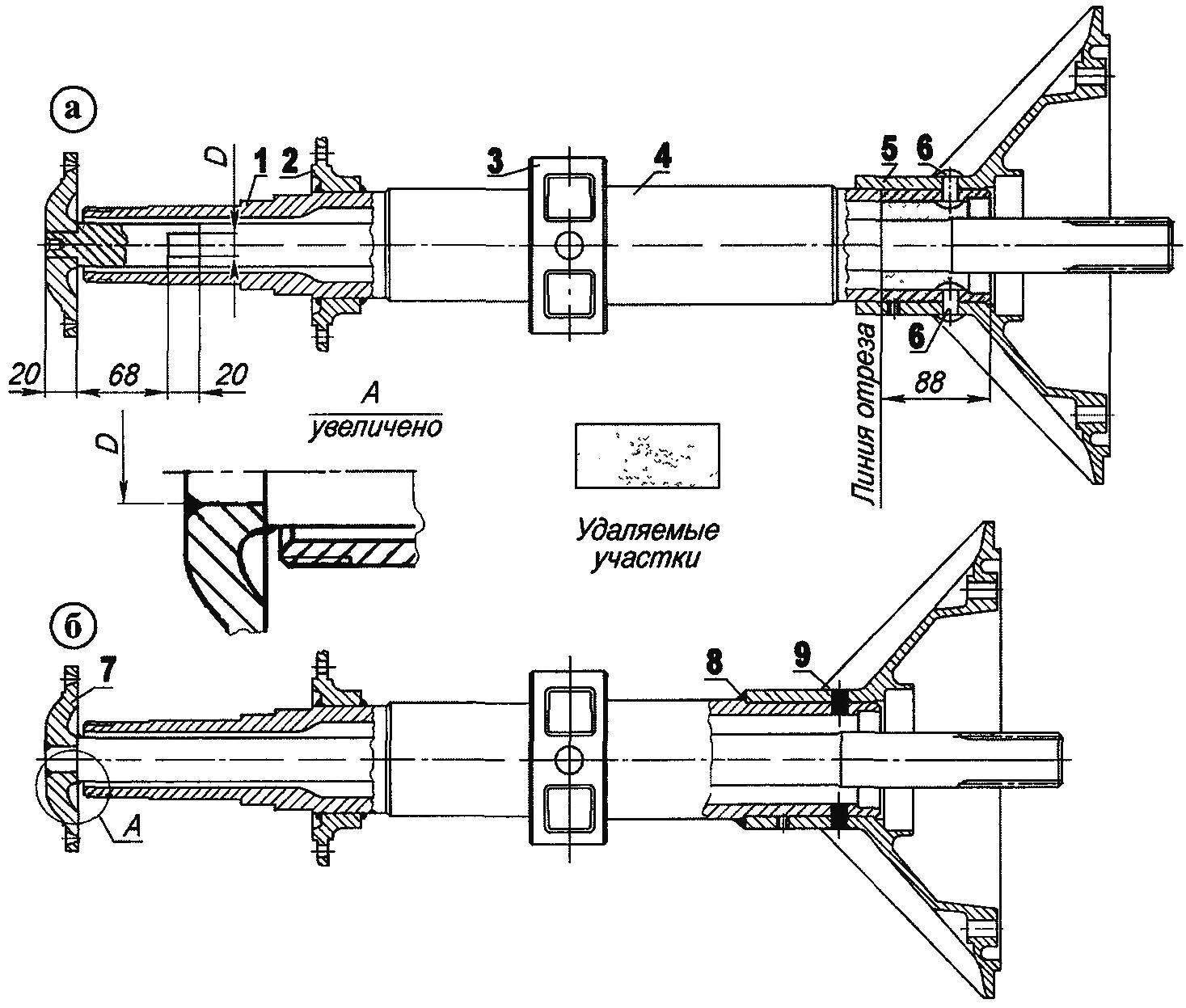

Rear axle sause (or shortened — as you like) so that the rear track match the front. To do this, dismantle the beam and separated Carter, the main transmission into two parts on the connector. “Stockings” (tubular palubicki) separated from the case main gear, knocking out rivets. Each “stocking” was shortened to 88 mm from the side of the crankcase, and bored through the end in strict accordance with the cut off, re-inserted into the standard hole in the crankcase, obariv in a circle and making the joint “welded rivet” in the old holes. It would be possible to connect the “stockings” with Carter again the rivets, drilled new holes in “stockings”. But for me the weld was easier, so as to disassemble the connection in the future is not expected. With such a modification had to be moved in the direction of the wheels and spring lodgements platform for mounting the springs to the beam with step-ladders.

Half shafts (drive shafts) rear wheels also had to be shortened accordingly. But this operation is made with side flanges, as at other ends of the cut slots. Flanges cut, to withstand a depth of 20 mm; axle shortened according to the thickness of the cut flange. In the flanges complied with Central hole: first drill a small, to ensure alignment; then wasted to the diameter D is slightly smaller than the diameter of the axle shaft, making the outer side of the flange is quite deep and wide chamfers.

The end of the axle shaft is also bored through to a diameter D at a length of 20 mm (thickness of flange) by a large chamfer at the end put on the Flange axis and the two parts are reliably welded to each other circumferential seams in the chamfers end, and the influx from the back side of the flange, after checking the concentricity of the flange.

The front axle is also from GAZ-51, it remained unchanged.

Cab — team, of units of different machines. So, the windshield (front windscreen) glass is used all from the same GAZ-51, door — GAZ-52. The grille and bumper is from a ZIL-130, fenders, hood, frame and cab roof — all homemade.

The body is also homemade, floor and sides are welded from 2 mm sheet steel for the frame made of rolled steel of various sizes: rectangular pipes, angles, channels Rear wall of the body is pulled down (or opening — as you like). Over the body gave a spatial frame of wooden bars and on the frame put a removable awning made of bits of old truck with a rising rear canopy.

“Tractorable”

Alteration (shortening) of the semi-axes and “stockings” of the rear axle of the truck GAZ-51 to narrow the track of the rear wheels “tractorable” (and the left part of the bridge to rework, b — after the alteration; continuous numbering):

1 — driveshaft with a flange at one end and slots on the other; 2 — a flange of fastening of a wheel; 3 — the bed springs, 4 — left (in the direction of machine) beam (“stocking”) rear axle; 5 — left side of rear axle; 6 — studs; 7 — flange separated from the axle shaft; 8 — a new welded seam; 9 — elektroskripka

Engine — diesel, with a capacity of 16 liters from the tractor T-16. It gives you the right to classify the machine as a tractor or self-propelled chassis.

Gas tank capacity of 60 liters made of old Belovskogo receiver (the accumulator in the pneumatic brake system) and placed on the left side of the frame under the cab as a regular place under the front part of the body cut off. For this reason, the spare wheel had to be placed in the body at the front side in a vertical position. The consumption of diesel fuel — about 9 litres per 100 km on a country road.

The clutch, as the engine from the tractor T-16, and the box changes gear (transmission) is from the GAZ-51. For coupling of the clutch and the transaxle made the adapter plate, and driveshaft shortened. In the journal “modelist-Konstruktor” this method of docking was described repeatedly, so there will not. Reducer no, he’s at such slow speed diesel (about 2600 rpm) and is not needed.

Electrical equipment (generator) tractor — MT-16.

System voltage — 12 V.

Steering as well as brake system, is from the GAZ-51 is used unchanged, except for the fact that they shortened the tube going to the rear brakes.

The cabin is equipped with seat GAZ-52, and panel with all instruments — from the GAZ-51.

The speed of the car at registration is limited to 60 km/h But the roads and not to develop, and on public roads have to leave only in the city, where is known to exceed that speed and not permitted. Capacity is also restricted to two tons.

V. ANDREEV, Ryazan