Bridges connect to the attachment points on the spars in the same way as for the scooter — bolts with nuts and split lock washers. After checking the frame on symmetry, absence of distortions and compliance dimensions of the drawing are welded attachment points of the body and the tubular crossmember. Two of them from the pipe with a diameter of 20 mm is designed for mounting of seats and cabins, two curved tube diameter 30 mm — motor mount of the engine and one in the rear of the frame — bearing main gear (reverse gear). As can be seen from the drawings, the reverse gear is mounted vertically, with an asterisk (it is, incidentally, a cargo scooter) up the lever of switching reverse in this case is the front of the fly.

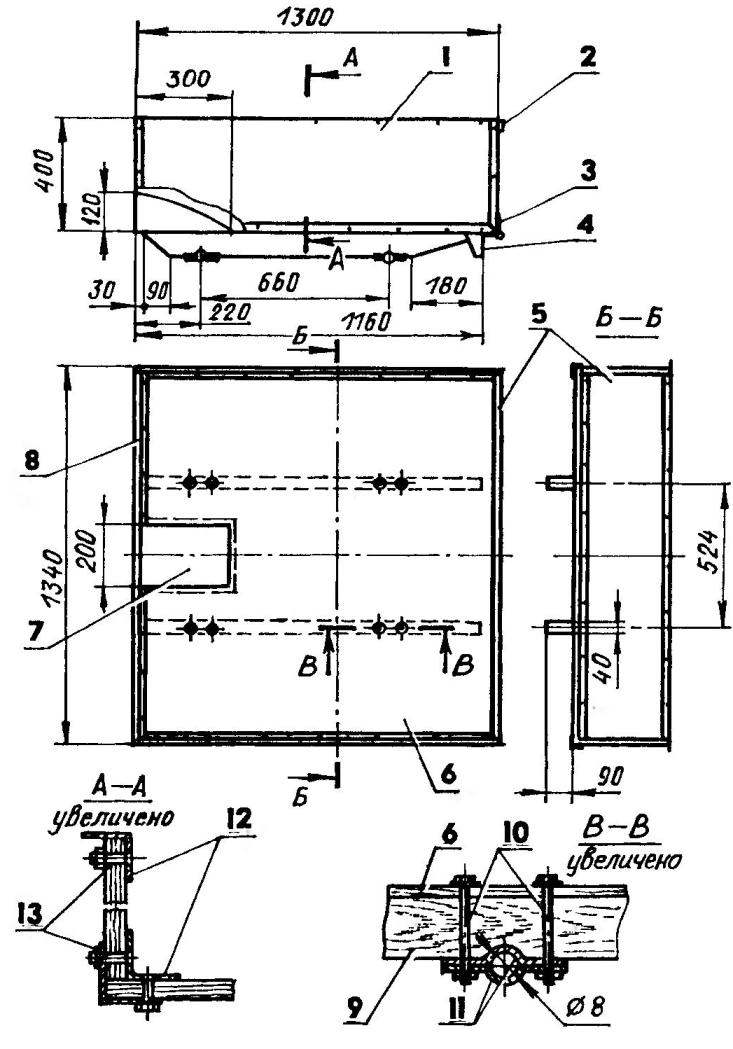

The body of malogruzovaja:

1 — side panel (plywood, s12); 2 — lock-latch tailgate; 3 — loop drop side; 4 — unit rear lights (steel, sheet s2); 5 — panel folding Board (plywood of 12); 6 — base plate (plywood 12); 7 — a lining of a niche (steel, sheet s2); 8 — side piping (aluminum, angle 30x30x3); 9 — the base body (pine, whetstone 90×40); 10 — mounting bolts M8 nuts and washers; 11 — poluchaut (steel strip 40×3); 12 — connecting the body components (aluminum, angle 30x30x3); 13 — M5 bolts with nuts

The engine is mounted on the frame for the bottom and front nodes, that is enough. The exhaust pipe normally, from TG-200M, a homemade silencer, which is a hollow cylinder, inside of which is twisted into a tight roll of fine steel mesh.

The bed of the truck is assembled from plywood panels with a thickness of 12 mm. Prepared for the Assembly of the workpiece twice impregnated with hot linseed oil and covered with two coats of oil paint. The body is assembled with dural corners 30x30x3 mm and M5 bolts with countersunk heads and nuts. Moreover, the joints of panels angles located both outside the body and inside — it is possible to obtain a very rigid construction. Edging boards are also of duralumin angles. The base body consists of two pine sticks section 90×40 mm, attached to the bottom bottom M6 bolts with nuts. Before installing the bars of the base twice impregnated with varnish and covered with oil paint. In PE the front part of the body provided a niche for the cylinder of the engine — it is welded from steel sheet 2 mm thick and are secured to the body with M5 bolts with nuts.

Cabin malogruzovaja collected by the technology is very advantageous for Amateur construction. For the beginning of thin steel tubes welded lightweight frame cabins and frames of doors. On the frame also welded fixed frame windshield and rear window. By the way, for malogruzovaja as frontal successfully approached the rear door glass of the car “Moskvich-2141”, part of the same door was used for the formation of the frontal panel of the cab.

Next, the plywood was cut the frames and secured with soft wire on a pipe frame, after which the space between the frames filled with blocks of construction foam. The actually shaping of the cab and doors was carried out integral. The surface of the cab aligned with a long sharp knife, a homemade plane, a piece of iron which is at an angle of 45 degrees to its axis, and coarse sandpaper.

After treatment of external surfaces, the thickness of the foam filling increased to 20 mm. in order To control the thickness of the shell was used “beacons” — an ordinary match, cut to a length of 20 mm and colored with marker. (“Beacons” are introduced from the outside into the foam flush with the surface of the cab, and the processing of the internal surfaces of the material is consistently chosen as long as the cutter is not hooked for the next “beacon.”)

The thus prepared surface of the cabin were covered with fiberglass with one layer inside and three outside. After polymerization of the binder with fine teeth handsaw carved doors, and then processed doorways and the ends of the doors. Inside the cabin are covered with artificial leather.

Seat, driver and passenger improvised: they are tubular frames, covered with rubber rings cut from the wheel camera truck with foam and artificial leather.

Managing malogruzovaja — car type. Brake system hydraulic, motorized FDD. A throttle and clutch cable. The pedal unit (gas-brake-clutch) mounted on a hinged nodes, welded to the frame rails. Handle gear shift located between the seats under the right hand of the driver; the box drive — with a hard thrust and the intermediate lever. On the right hand is the handle of switching reverse (reverse).

Wiring the car is the same as “Ant”. This scooter lights, turn indicators, speedometer, ignition switch and warning lights.

I. KHOROSHEV,engineer