When installing the radio a lot of time to spend on processing wires. First of all you need to remove the insulation, clean, tinned with stinging, and then proceed to soldering. Except for this the soldering iron, necessary lies, cutter and blade. And together with the isolation often cuts off part of the wire cores, n then have to start all over again. I propose a simple adaptation to the soldering iron. The eye eliminates unnecessary hassle, save time, improve the quality of construction works.

When installing the radio a lot of time to spend on processing wires. First of all you need to remove the insulation, clean, tinned with stinging, and then proceed to soldering. Except for this the soldering iron, necessary lies, cutter and blade. And together with the isolation often cuts off part of the wire cores, n then have to start all over again. I propose a simple adaptation to the soldering iron. The eye eliminates unnecessary hassle, save time, improve the quality of construction works.

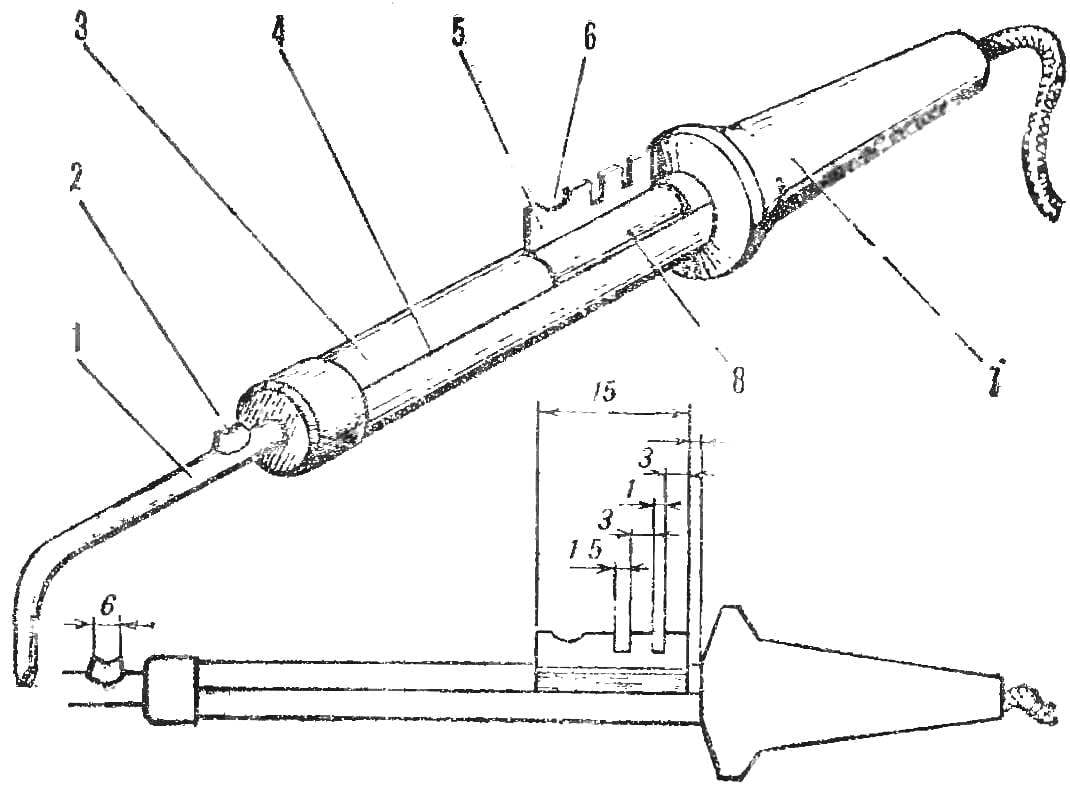

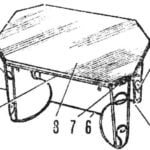

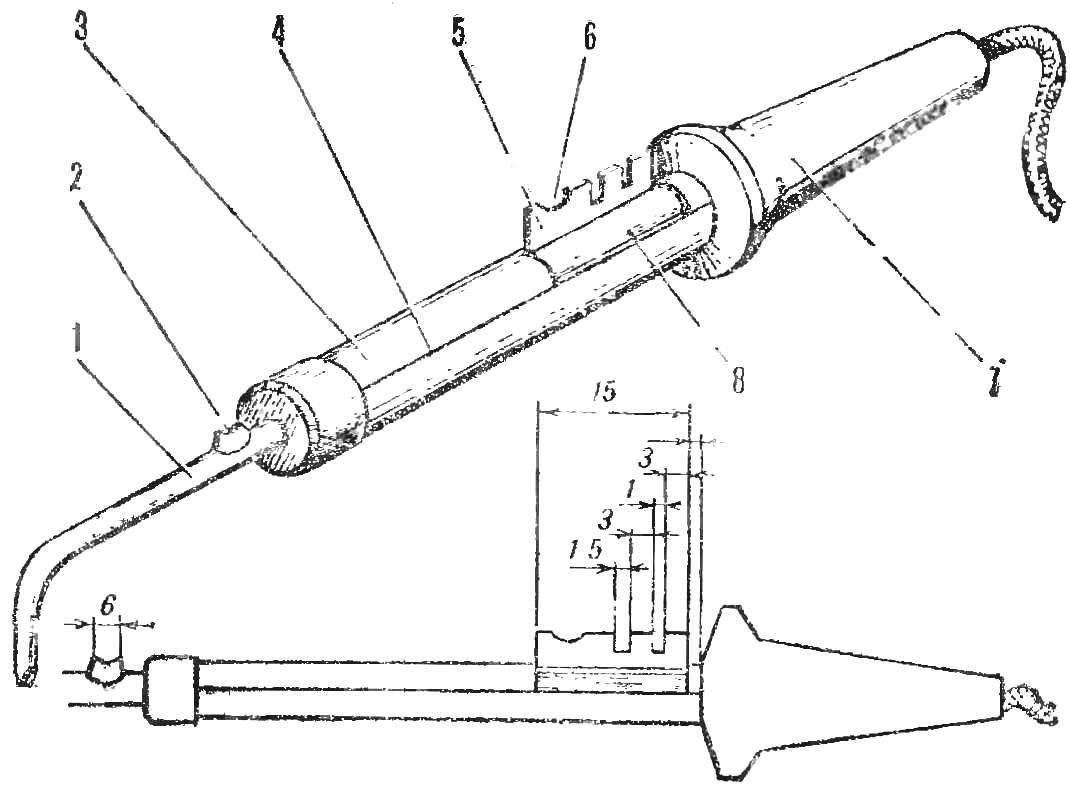

In the body of the soldering iron at a distance of 1 and 16 mm away from the two handles make cutting saw blade blade. Nadeleny section length of 15 mm bent at an angle of 90° and at a distance of 3 and 7 mm from the right edge, make two cut width of 1 and 1.5 mm (see figure). On the opposite edge with a round needle file make a notch with sharpened edges — a kind of mounting the knife. On the tip of the iron with table vise, make a ledge for the firing wires.

Use a soldering iron easier than usual. Mounting wire attached to the ledge of the heated soldering tip and burned around the circumference of the metal core. In the formed wire rod insert corresponding to the slot on the bent portion of the body. Now it only remains to pull the wire, and insulation easy to get away with veins.

Modified electric soldering iron:

1 — sting, 2 — lug firing insulation, 3 — body, 4 — SDV, 5 — bent area, 6 — knife wire stripper, 7 — handle, 8 — a patch of sheet metal.

If the wire is to be clean from oxide or enamel, use a pointed recess.

Formed in the housing of the soldering iron close window cut sheet.

A. MALTSEV, p. Medium, Irkutsk region.