Development and manufacture of printed circuit boards for a single instance of a homemade device with a higher density of mounting becomes sometimes a problem even for the experienced radio Amateur. I have also found the opportunity to do without any preliminary layout of printed wiring conductors, and even without soldering electric and electronic circuits. I replace all of that… wrap.

Development and manufacture of printed circuit boards for a single instance of a homemade device with a higher density of mounting becomes sometimes a problem even for the experienced radio Amateur. I have also found the opportunity to do without any preliminary layout of printed wiring conductors, and even without soldering electric and electronic circuits. I replace all of that… wrap.

Wire wrap soldering iron is not required. One who becomes an adherent of this method of Assembly schemes can undertake the design of electrical and radio equipment from anywhere, such as in a commuter train or even on the beach.

In addition, the installation becomes as dense, more reliable due to repeatability of cheating, which (unlike soldering) is not bad. It’s all the same and no hidden defects. IC, switches, connectors and many other components of the apparatus are made if specially for wrapping, the windings of which, cutting flat metal parts insights form the spring to compress, secure and durable the contacts and circuit connections. The wire wrapping even with little skill are more productive than other types of mounting using solder.

IC, intended for wire wrapping, stick to any rigid base (sheet plastic, metal, glass, plywood, dried clay, the hardened plaster and other surfaces) up conclusions. Mutual location — like on a wiring diagram or close to it. Necessary drilling technology and mounting holes in base no. The distance between the integrated circuit — the minimum possible. And to make it easier and freer to perform the installation and to prevent short circuits, the conclusions of each chip slightly bends to its longitudinal centerline.

Of course, in this installation the marking on the integrated circuit becomes unavailable for viewing. And to avoid confusion, on the back of each MS should be applied explanatory inscriptions indicating its type and the number of the wiring diagram, and a designation of the first output.

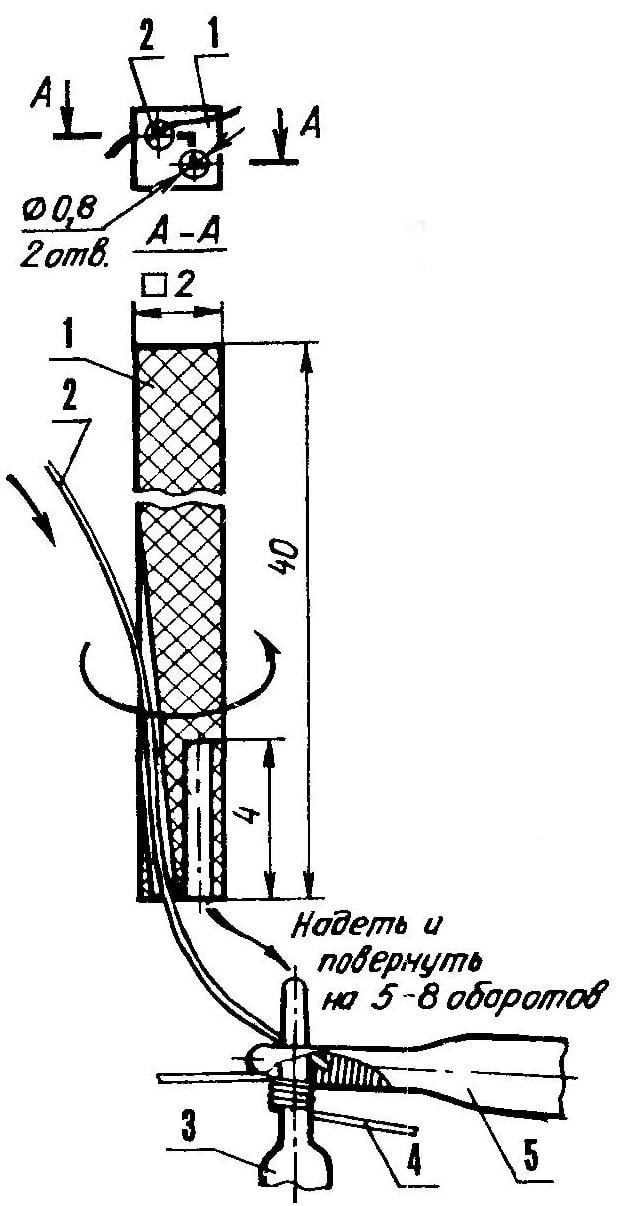

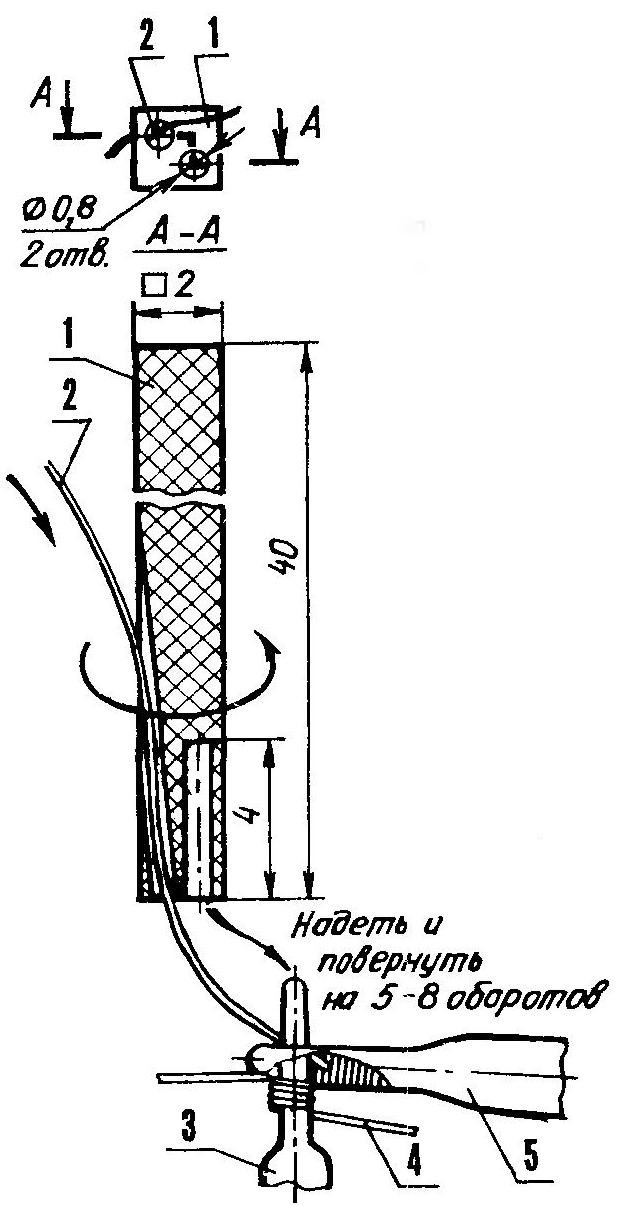

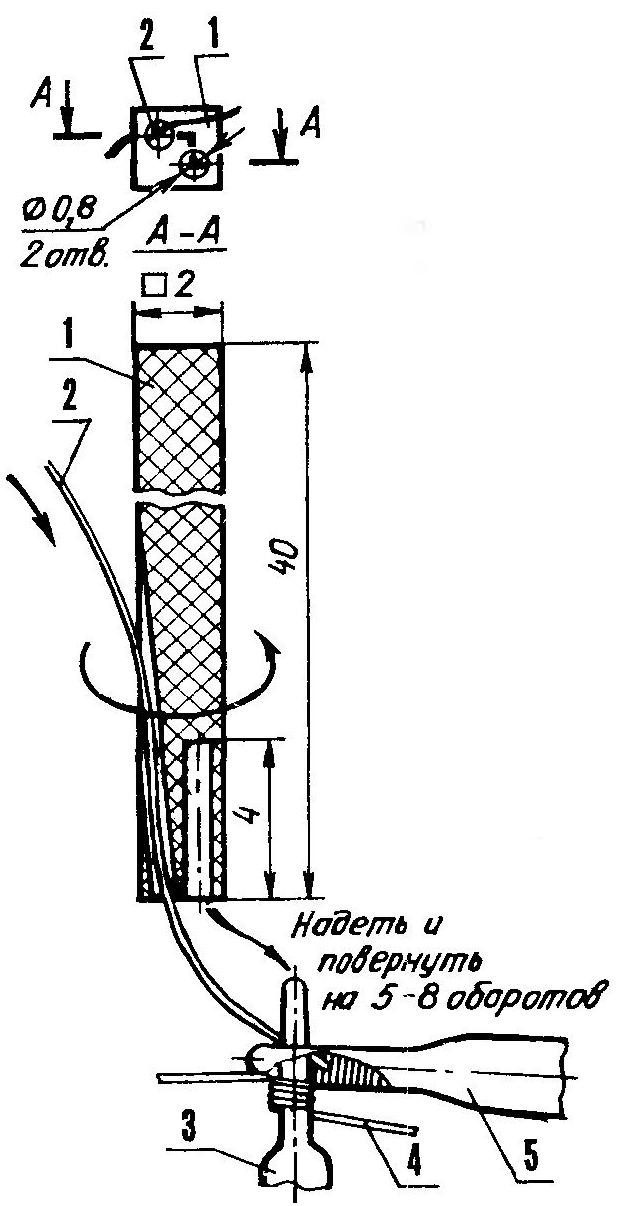

Cheaters is a plastic or metal rod of square section with a side of 2 mm. At the end of it (two diagonally located corners), there are two holes diameter 0.8 mm. One of them is inclined facing side face and serves as a channel for mounting the wires. The other hole was deaf, drilled parallel to the axis of kruscica to a depth of 4 mm. it is inserted Into the output circuits or radio.

Work with this tool is simple. In the channel of the cheaters from the side walls of the insert tinned solid copper wire 0.2 mm in diameter. make it a mounting end protrudes from the end face of the tool by 5-7 mm. Then bring to a mounted withdrawal, introduced it in a blind hole of the end face of the cheaters and hold with tweezers mounting end of the wire, turn the cheaters for five to eight turns. The result is tinned copper wire freely extends through the conduit and the circumferential flat on the pins of the chip. The connection is mechanically strong and has proven to be electrically reliable.

The wire wrapping is easy and reliable:

1 — cheaters; 2 installation wire, 3 — output IC (or other “plaskovitsky” radio); 4 — mounted wire-wrap electric circuit; 5 — forceps

Then cheaters is transferred to the next closest output of a chip and perform a wire wrap on it. When transferring cheaters wire extends freely through the canal, emerging from the side wall. Consistently moving from a single chip to another, perform all connections.

After making the last wrap of the same chain, wire bite, and proceed to install the next. However, the mounting of the circuit may be implemented as a single wire, but multiple segments. Then some of the leads of the chips will contain two or more markups. It is inevitable in electrical assemblies and when connecting multiple short links, and also in cases when it is required to eliminate the gaps discovered in the Assembly of complex circuits. Mount one or several circuits, proceed to the optimisation of the laying of the connecting sections. Tweezers mounting the arch wire so as to prevent accidental contact links. If it is determined that the connection is incorrect, he was immediately dismantled.

Required for wire wrap wire is easy to get from multicore Assembly, clean off the insulation and obiodiv copper component. The wire diameter may vary from the picture shown. Importantly, this wire was easy to perform cheat.

Upon completion of the wire wrapping to the conclusions of the ICJ and other elements (whether there are they cheat or not) soldered if it is provided by a circuit diagram hinged “kruglosutochnye” radio. Moreover, soldering can be performed on top of the wrapping.

Installation of the most part, a web of non-contiguous bare wires. However, sometimes it seems that the close location of such conductors threatens to short circuit, but it is not. The air that separates them, is an excellent insulator, and wire in the normal operating conditions of the instrument, never by themselves will not close. So, no need to fill it “epoxy” because he will then become unsuitable for repair.

Impression of the high complexity of laying wires is also not true. On top of that the installation is highly visible and any damage including breakages and short circuits, can be easily detected visually, what can be said about printed circuit boards. Well, when you replace a burned-out chip is adhered to the new free space and perform the necessary connections are all the same wrap. Moreover, in order not to spoil the installation, burnt chip… recommended to leave the instrument, a mouthful of only suitable to her wires, if they interfere with device operation.

Other advantages of cheating include high performance as well as the prospect of automating this installation: based on a modified high-speed cheaters that will fulfill the function of a wire cutter Assembly, working in conjunction with coordinatographs and PC under a single program. This will allow to get rid of time-consuming in the design and manufacture of printed circuit boards, to eliminate environmental pollution that occurs at different stages of the PCB, to reduce the size and cost of the equipment while increasing its reliability.

SOLONIN, Konotop, Ukraine