Oddly enough, but we tend to think of Ancient Rus agrarian power, traded mainly salt, hemp, wax, fur goods, linen. Meanwhile our ancestors were taken abroad and iron, and iron, famous for its quality all over Europe. He was put in stripes and in the form of finished products — axes, chisels, bells, anchors. Yes, the anchors, because it is now proved that the Russian masters forged them long before the baptism of Rus. This is evidenced by the many exhibits of local history museums, tells the epic.

Oddly enough, but we tend to think of Ancient Rus agrarian power, traded mainly salt, hemp, wax, fur goods, linen. Meanwhile our ancestors were taken abroad and iron, and iron, famous for its quality all over Europe. He was put in stripes and in the form of finished products — axes, chisels, bells, anchors. Yes, the anchors, because it is now proved that the Russian masters forged them long before the baptism of Rus. This is evidenced by the many exhibits of local history museums, tells the epic.

At a later time anchor craftsmen were famous Yaroslavl, Kazan, Vologda, Gorodets, Voronezh, Sankt-Peterburg, city of the Urals. For example, it is known that about a hundred “big deroga anchors” for the Koch marine fleet, built on the orders of Boris Godunov for the navigation of the Arctic ocean, forge in the workshops of Yaroslavl and Vologda.

On the Volga anchor manufacture have long flourished in the Nizhny Novgorod region, mainly in Gorodets. There did anchors weighing from thirty pounds to eighty pounds. Annual production reached the impressive figure of twenty thousand pounds.

When Peter unfolded the domestic shipbuilding, in which Russia received 895 ships, resulted in the rapid development of anchor business. Put the anchor in particular, were to forge the first Russian breeders Demidov, Butanta, Naryshkin, borina and Aristov. Later in Novgorod and Tambov provinces created the “state-owned iron factories”, and near lake Ladoga began survey work on defining the iron ORE business.

Anchors for the frigates Petrovsky fleet, which was built in 1702 on the rivers Svir and Pasha, was forged in Olonets (Lodeynoye pole), and the heavy anchors for large ships of the Russian fleet were manufactured in Izhora, where in 1719 by decree of Peter was established the Admiralty factories.

About the technology of the manufacture of anchors in Russia in the early XVIII century we learn of the “Regulation on the administration of the Admiralty and the shipyard,” published by Peter on 5 April 1722. “Anchor should do the appropriate proportion of good iron and look firmly to the bars firmly, and tight kind of iron have been connected before will be put to the horn”. When heated in the furnace were instructed carefully to ensure that the metal is “neither overheating nor cold to vinati, so tightly svilosa everywhere and riprovare b was not.”

From the anchor masters were required not just to “manage the work with diligence and good craftsmanship,” as from other Smiths, and “the great diligence and extreme art.” Anchor wizard was recalled particularly that he should be held accountable, if the vehicle accident happens because of the broken anchor: “Inasmuch as the whole integrity of the ship is, what it needs to give the answer, if that rasmotrenie done.”

In Russia since Peter each battleship was equipped with five anchors. The largest and the heaviest, typically right deadlift, is called plachta. The second largest, left deadlift — digicam, third — Buhta. He was kept fixed in its stowed position for the second bow for digiKam, on the left cheek of the ship. The fourth anchor was called svarta. It was a spare anchor, and kept him in the hold behind the main mast. The shank of this anchor had primitively to BIMS, and the feet buried in the stone ballast. Stock svarta that it does not interfere with loading into the hold, were placed on the bottom flooring of the flat. Fifth by weight of the anchor is called the toe; it is attached in its stowed position, and coves, but on the right cheek ship behind Plichta.

The shape of the horns and the legs of the Ural anchor.

In the middle of the last century, most trusted anchors in the world were those that forged in the Urals (see Fig.) for Botkin, Serebrianska and Nizhneturinskaya plants.

Forging of the anchor here was subjected to several tests. Finishes tested by heating to a dark cherry color, when through all the disadvantages of forging. Then the anchor tried to strike were dropped on an iron plate from a height of 12 feet. If he passed this test, he was hung and beat seven pound hammers. Thus a pure ringing sound testified that the forging is tight and there are no cavities and cracks. If the anchor has withstood the test, it beat the mark.

How distributed is the anchor of the ship? After all, one ship needs an anchor of the same weight and the other other.

In addition to the various simple formulas are purely empirical nature, which have already been described in the middle of the last century in the Russian Navy used the precise rule derived from comparison of the weight of the anchors with the dimensions of the ships of the Russian, British and French fleets. The length of the ship between perpendiculars was multiplied by the greatest Width with the lining and the obtained result was divided by some number. It was for drehtechnik ships — 40, dvuhmestnij — 41, frigates — 42, corvettes — 45, Brigham 50, tenders and schooners — 55, large transports — 45, medium and small transports — 50.

The resulting quotient was shown the weight of the anchor in pounds. For example, the length trehletnego battleship “Twelve Apostles” — one of the biggest battleships of the Russian fleet — gon-deck was 211 feet 9 inches, with a shell width — 58 feet and 6 inches. The product equal to 12 599,125. This number is divided by 40, showed the weight of the anchor in pounds — 314.

The length of the ship, “Rostislav” Gondek was equal to 197 feet and 4 inches, the width from the valance is 57 feet. Work — 11 246 divided by 40, showed the weight of the anchor — 274 pounds.

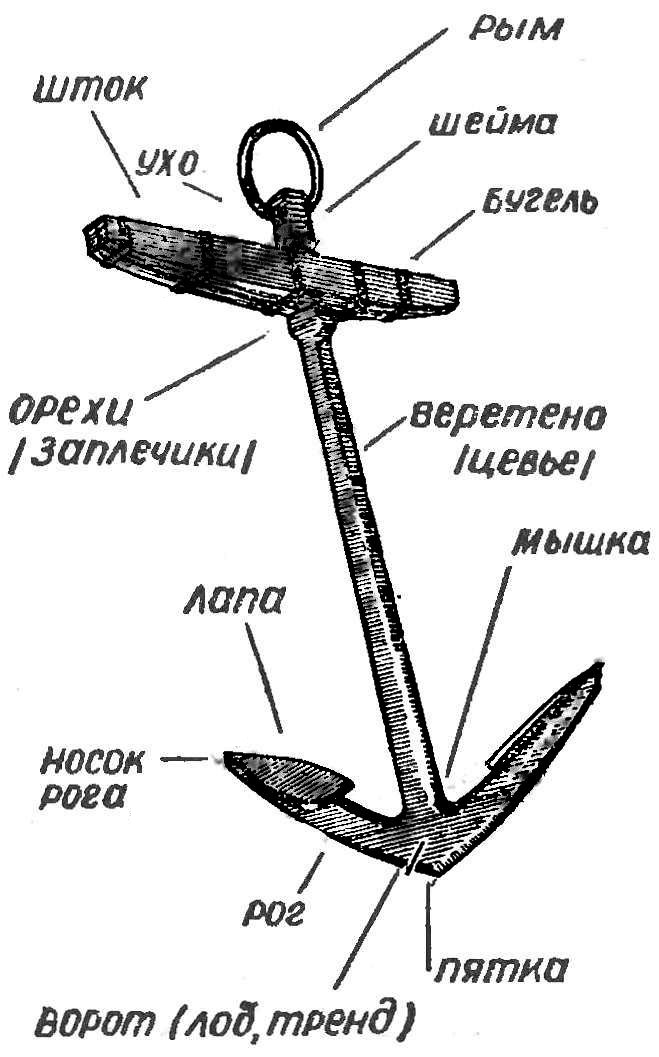

During the reign of Peter was established and the names of the parts of the armature, however, partially lost or distorted in our time. These names are given in the figure below: the spindle (forearm), horn, paw, toe, horn, winch (forehead), the heel, mouse, nuts (shoulder), rod, bracket, sheyma, eye, ear. They have been in use as a blacksmiths, and sailors. But at the end of last century books on seamanship were .such “enhanced” name of the anchor as a “trend” (gate, or forehead). This name, as already mentioned, was in our Maritime language of English (trend — curving, bending). Nevertheless, this term we are stuck.

From the editors: In connection with the publication of the book by L. Skryahina Kastoria anchors” journal ceases publication of material on the subject. Those wishing to trace the evolution of anchors fully we refer to this book (L. Skryagin, “history of the anchor.” M.,”Transport”, 1973).