Large and small roads girded our Land, but there are still many unexplored and remote places, fraught with untold natural riches. And today explores the most remote and remote areas: geologists looking for oil and gas in the desert, coal in a snowy tundra; workers build pipelines and Railways, overcoming the mountains and the Sands, swamps and rivers. All these people need such all-terrain vehicles, which would be able to easily and quickly overcome any obstacles in its path and carrying heavy loads. Add to this the climatic conditions in which ATVs are used: temperatures down to -60° or the heat of the desert, high humidity, corrosive…

Large and small roads girded our Land, but there are still many unexplored and remote places, fraught with untold natural riches. And today explores the most remote and remote areas: geologists looking for oil and gas in the desert, coal in a snowy tundra; workers build pipelines and Railways, overcoming the mountains and the Sands, swamps and rivers. All these people need such all-terrain vehicles, which would be able to easily and quickly overcome any obstacles in its path and carrying heavy loads. Add to this the climatic conditions in which ATVs are used: temperatures down to -60° or the heat of the desert, high humidity, corrosive…

Existing ATV is able to basically only work under certain conditions, and only a few prototypes can be used on nearly any terrain. But, in addition to the ability to overcome obstacles, the Rover should have enough speed, easy control, comfort and required lifting capacity.

The main condition for the creation of vehicles and special wheeled off — axis to be driven, each wheel is leading, work. Only in this way the maximum use of the grip.

However, applying only the drive wheels to improve cross is not enough. Known difficulties is the use of traditional schemes of machines: maneuverability is limited by the minimum turning radius, the ability to overcome obstacles — suspension and the diameter of the wheels of the car, etc. So the designers of all countries are seeking unusual types of propulsion and innovative ways to improve the all-terrain qualities of the machines.

MULTIWHEEL

For use on dry soils, in the desert or snowy areas, the increase in permeability is achieved by increasing the number of wheels of the vehicle. Specific ground pressure can be further lowered by the use of wide-arched tire or pneumococcal low pressure.

Among multi-axle vehicles it is necessary to allocate first of all four-axle cars (wheel arrangement 8X8). Specific ground pressure of these vehicles is an average of 0.7—0.8 kg/cm2, which is close to the tracked vehicles. They are able to overcome the moats and ditches with a width of several meters and vertical obstacles up to one meter. Structurally they are more other vehicles are approaching the standard cars, so to develop their production much easier.

At major construction sites of our Country can meet the most common Soviet heavy all-terrain vehicle MAZ-537 with a drive on all eight wheels (Fig. 1). When working with semi-trailer and its load capacity reaches 50 tons In this vehicle mounted twelve-cylinder engine capacity of 525 HP and hydromechanical transmission. The maximum speed of the machine with a full load of 55 km/h.

Fig. 1. Eight-wheel all-terrain vehicle MAZ-537

Abroad issued all-terrain vehicles “8X8” from one light-twin to heavy, with capacity more than 10t, special design. The American company has developed a series of medium-sized cars “8X8” multi-purpose with capacity 4-5 t They embody a number of new trends in the development of vehicles of this class: multi-fuel engine running on the lowest grades of fuel, lightweight aluminum body, mechanical or hydro-mechanical transmission system of regulation of air pressure in the tires, brake sealing. All machines have the buoyancy and move through the water at a speed of 5 km/h due to the rotation of the wheels, and the installation of a conventional boat motor speed increases to 10 km/h.

Interesting design universal four-axle all-terrain vehicle “Tatra-813” created in Czechoslovakia. It is equipped with a powerful air-cooled engine, Central frame tube and independent suspension on all wheels.

Another solution to the problem of reducing the pressure at the soil — instead of the usual wheels pnevmokoccom, which is a barrel-shaped “Pneumatics” with low internal air pressure. They have a diameter of 1 m with a width of 1-1,5 m. These rollers are easy to adjust to the uneven roads and absorb all the shocks, so they equipped all-terrain vehicles (see box) do not require suspension. Usually pneumococci are combined in pairs in the front and rear of the truck. The torque is transmitted through a system of gears. Such machines can easily move through the swamps, sand, snow and even on the railway track. The tab displays the all-terrain vehicle “Hurricane” with capacity of 8 tons, built in our country.

Interesting compromise normal multiwheel cars with Rover on pneumococci — vosmoy transport “Flextrack-Nodwell 600ТТ”, created in Canada. He pneumococci 32 are combined in two four-axle trucks. All wheel drive. The length of the vehicle is more than 14 m, with a capacity of about 30 MT (Fig. 2).

Fig. 2. Rover on pneumococci

The special construction of the wheel mover applied on the American all-terrain vehicle “Rhino” (see box). It has a hemispherical aluminum alloy wheels with radial ribs-grouser (front diameter 1.8 m, the rear half less). On the highway the wheels are rolling on the greatest diameter, and as the immersion of such a wheel in soft ground contact surface increases, hence, decreasing the pressure on the ground. The machine has a buoyancy and moves through the water using jet propulsion and due to the rotation of the wheels.

This original design has not found wide practical application, but spawned numerous projects of future transport with hemispherical and spherical wheels. In one of the foreign projects (see box) it is proposed multiwheel conveyor with a spherical, elastically connected with wheels for movement on the moon. Machine just copy the profile path and more like a mechanical caterpillar, consisting of a wheel-balls.

CONVEYORS-GIANTS

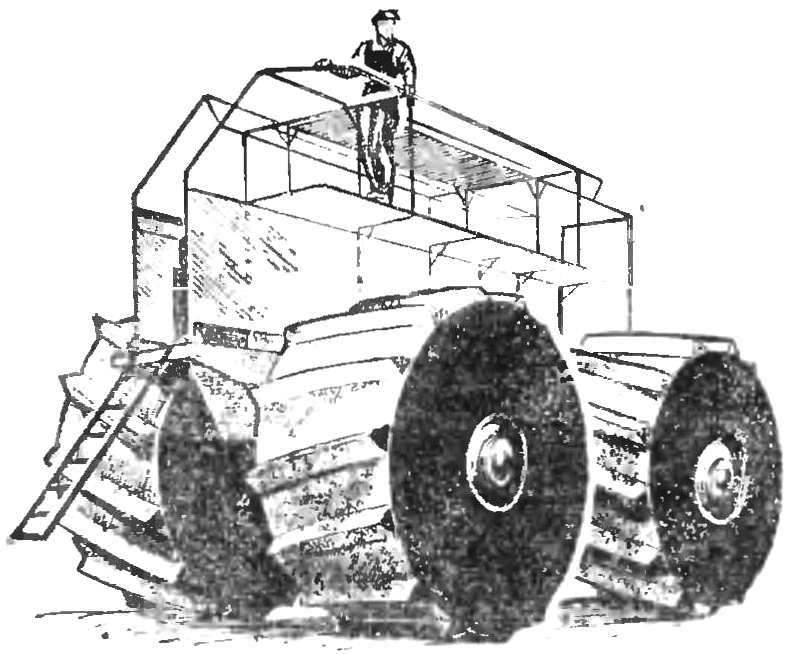

The majority of ATV ground clearance, i.e. the distance from lowest point of chassis to ground is a minimum of 350-500 mm. For comparison, the lumen of a conventional car does not exceed 150-200 mm. of Course, very tempting it would be to create a vehicle with a large clearance. This is possible primarily due to the increase of the diameter of the wheels. It is known that the two wheels with a diameter of 1.6 m equivalent on the traction and coupling indicators ten wheels with a diameter of 1 m. in addition, the large and wide wheels with low-pressure tires provide a large contact area with the ground and thus a small specific pressure.

Original design, with four huge wheels-reels of lightweight metal built by specialists of the Kiev branch of the Institute of communication. The Rover is mounted on a conventional tractor and intended for laying communication lines in a swampy Area. Car-truck terrain MAZ-532 is also equipped with four large diameter wheels, but with pneumatic tyres.

Similar machines built by two American firms. One of the all-terrain vehicles (Fig. 3) is provided with four hollow metallic wheels with a diameter of 2.7 m and a width of 1.5 m, which simultaneously serve and floats. On the outer surface of the wheel cylinders are high ribs, lugs. They are required for traction and movement on the water, where they play the role of the blades of the water wheel. The machine speed on land up to 20 km/h on water 10 km/h.

Fig. 3. Hollow wheels are on the water floats

Two-axle all-terrain vehicle “snow-Buggy” has eight unsprung wheel with a diameter of 3 m is installed On the machine diesel rated at 400 HP & genset to power the electric motors built into the wheels. Turn this cumbersome machine, slowing down the wheel with one side or the other. Due to the low tyre pressure require no additional amortization of the chassis and at the same time ensures high throughput. With weight of 20 tons, the speed of the vehicle on the road is 13 km/h.

The world’s largest all-terrain vehicle called “big wil” (“the Big wheel”), created in Canada. He intended for the carriage of geological parties and oil production stations in the most rugged places. The Rover is mounted on a oil rig, and the housing has a living room of 40 people. Four huge wheels with a Diameter of 15 meters and four gas turbine engines with a total capacity of 12 thousand HP let him free to overcome almost any obstacle — a small river, swamp, undergrowth, each wheel has an independent suspension with a stroke of 2.7 m.

Total weight of machine-giant 540 T. When one of the first tests of this metal mastodon stuck in a deep crevice, by any existing lifting means to rescue him failed.

HINGED AND ARTICULATED

To move around selenoproteins terrain with high vertical obstacles and steep hills the ATV with a classical layout is almost unusable. For this purpose different types of cars with “broken” frame and a special articulated vehicles.

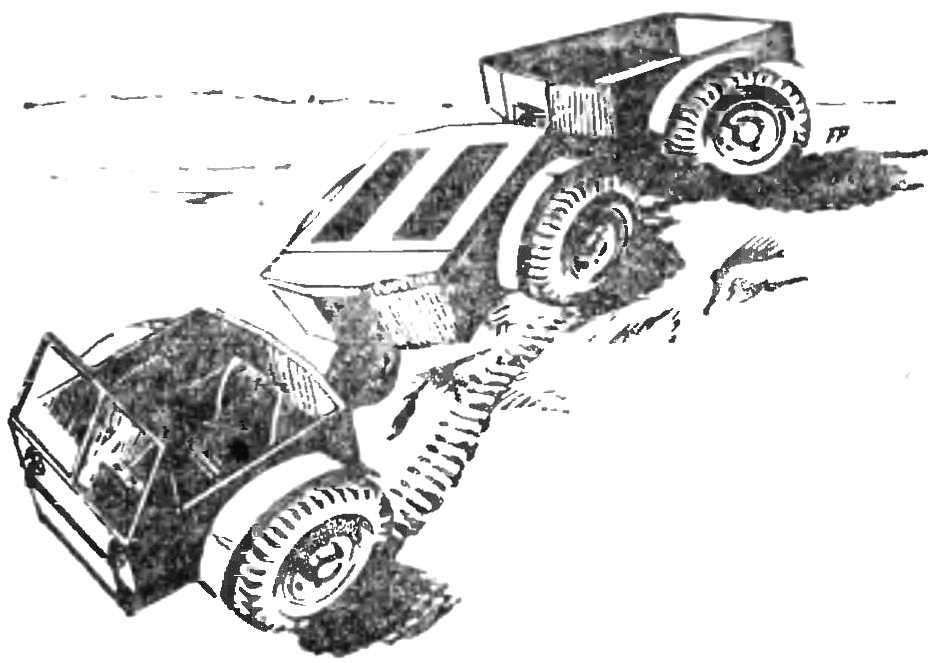

A distinctive feature of them is that they consist of several pivotally interconnected parts, which can move freely relative to each other in one or several planes (Fig. 4). Like a caterpillar, crawls such transport through an obstacle, repeating all its contours.

Fig. 4. Multi-wheeled all-terrain vehicle

Fig. 5. Articulated all-terrain vehicle

In the early 50-ies in Switzerland has created a three-axis machine “Metric”, consisting of two sections pivotally connected with each other. The justification for this was that the average axis (Fig. 5). She was hanged four of the balancer, the ends of which are attached to the front and rear wheels. On the front section installed power unit and cabin, rear intended for the carriage of goods. Through a system of hydraulic cylinders the two sections can be moved at an angle of 30° relative to each other. Any of the wheels is able to rise above the ground, which gives the machine the ability to move askew, yell, keeping the horizontal position. When driving on the highway the average axle is lifted, and the vehicle moves only on the front and rear wheels. The transfer of torque to the wheels is through valuable transfer of a prisoner inside the rocker. Management and throughput is entirely dependent on the experience and skill of the driver.

In the United States built a few articulated wheeled vehicles that have a power unit installed on the front section so that it can detach and move independently. Rear section, driven system, propeller shaft, used to transport people and goods. The connecting hinge between the two sections has three degrees of freedom and allows them to take almost any position relative to each other, which greatly increases the maneuverability and flexibility of the machine.

Floating two-piece Rover of “the Devil”, built in the USA, each of the four wheels is mounted on the end of a long rocker and has an individual chain drive. The levers can rotate around the fixing point to the frame 360 degrees, and wheels to occupy a variety of provisions, adapting to the terrain profile. Maximum clearance of the vehicle is 1080 mm. Machine literally can step over obstacles up to 1.5 m and a depth of 2 m, alternately shifting their “legs”are balance weights. She walks freely on the hillside, keeping the horizontal position. To facilitate the loading and unloading is able to sink to the bottom. The movement on the water provides the propeller. “Devil” is a class of transitional designs from the usual all-terrain vehicles, wheeled, walking.

TRAINS

The capacity of a single, even off-road cars are limited, so the designers work hard on creating road trains of high permeability.

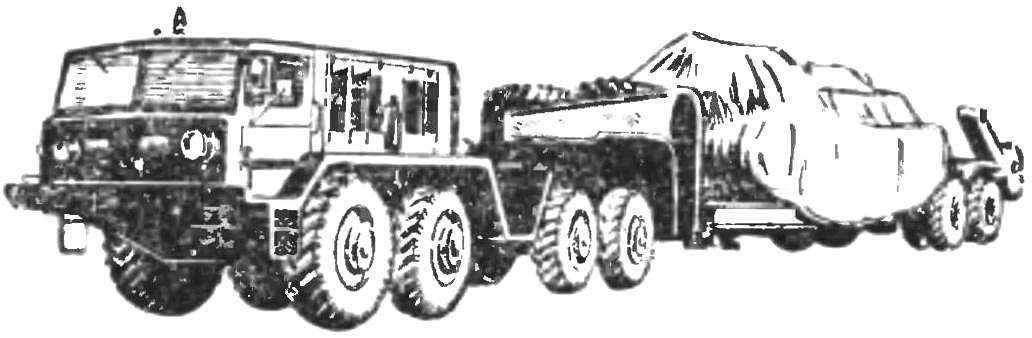

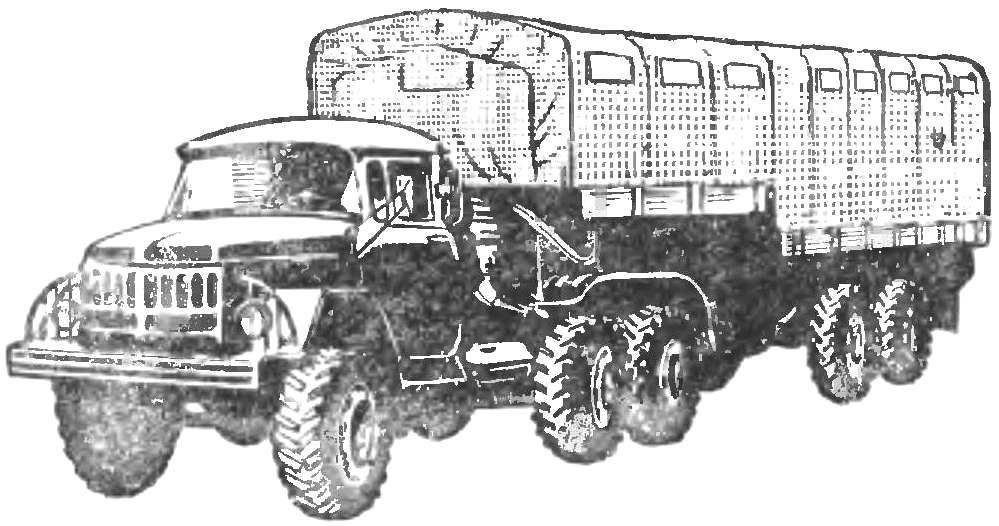

In the Soviet Union on the basis of truck all terrain vehicle ZIL-131 (6X6) truck ZIL-137 (Fig. 6) with two-axle semitrailer with lifting capacity of 10 T. Recently the Mytishchi machine-building plant has developed another semi-active MMP-881 14 tons of cargo to work with the truck tractor KrAZ-255Д.

Fig. 6. Lorry ZIL-137 with active semitrailer

The drive from the towing vehicle to the wheels of these semi automatic, through system of cardan shafts.

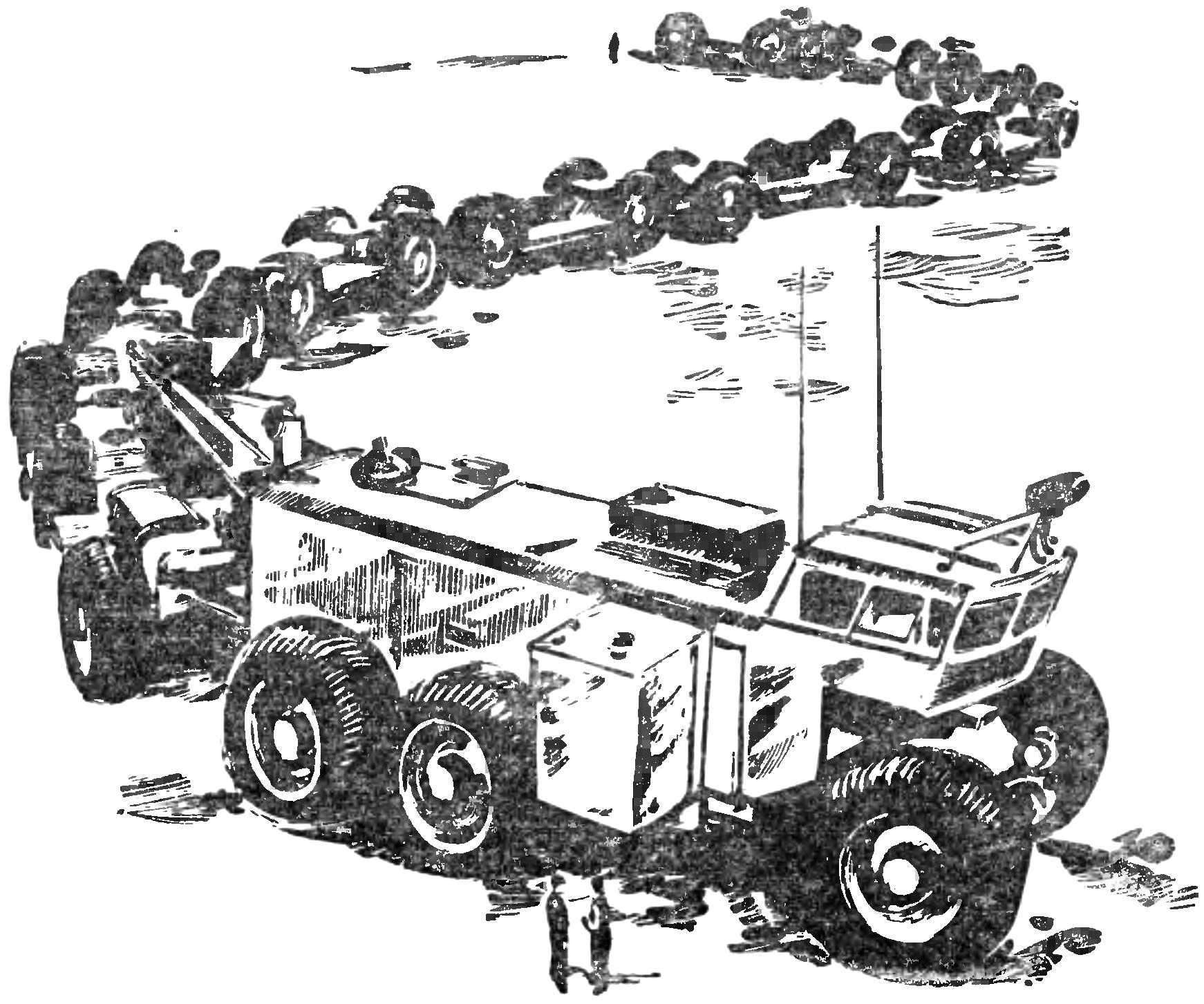

Such designs are developed in other countries. In France, for the movement of sand deserts built active semi-trailer “Titan” with hydraulic drive. In Finland, all-terrain vehicle “Sisu” (4X4) equipped with a special hydraulic pump for the drive motor of the active wheels of the trailer. Hydraulic transmission to the motor-wheels of the trailers is very promising thanks to its convenient layout and great compactness. Disadvantages hindering the development of this system is the high specific pressure (150-200 kg/cm2), the need for precise machining and high quality seals. Therefore, many companies prefer to use a mechanical or electric transmission. For example, the American firm “LeTourneau” is developing a series of multilink trucks with individual electric drive to each wheel. They are designed for operation in conditions of far North. One of these trains consists of five active trailers, another of the ten, reaching a length of about 200 m (Fig. 9). On the tractor installed diesel unit with a capacity of up to 3500 HP, powering all the electric motor-wheel trailer.

CRAWLER

Truck mover has been known for over 100 years, and during that time, he has not changed. Its main advantage over wheel — low specific pressure on the ground, and one of the major drawbacks is the complexity of a turn, especially on rough terrain.

Tracked ATVs are no different in such a wide variety of designs, such as the wheel, but the main directions of their development are the same: an increase in the length and width of the tracks, the creation of articulated and multi-section machines. Depending on the purpose they are manufactured with a lifting capacity of hundred kilograms to tens of tons, with a width of treads up to 1 m and more. For most of them the average specific pressure in the range of 0,15—0,33 kgf/cm2, but there are Champions snowmobiles with a pressure of 0.03 kgf/cm2, which is almost equal to the pressure of the skier on the snow.

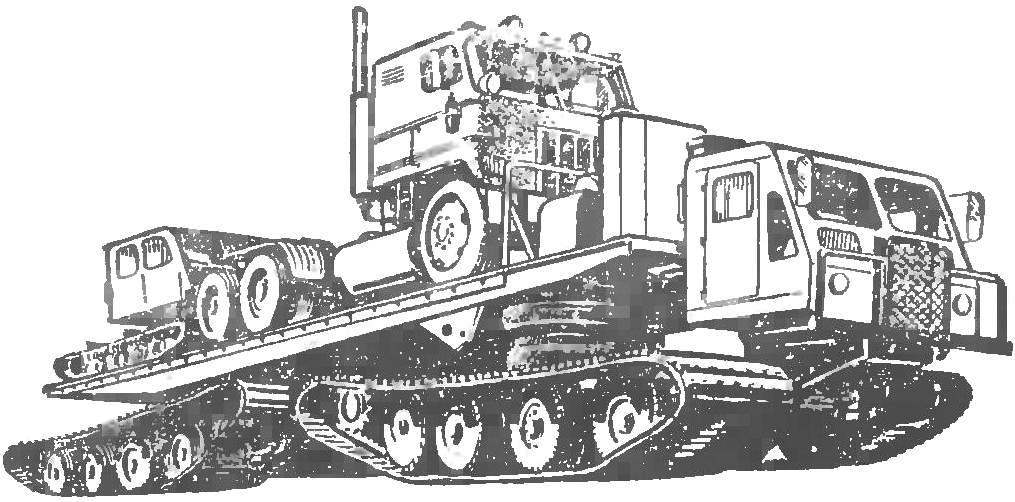

Fig. 7. Articulated tracked all-terrain vehicle

Created and two-piece off-road vehicles, front and rear sections which are connected with a special hinge. Such, for example, the Swedish “Bolinder-Munktell” and the American “Polcat”. In the Soviet all-terrain vehicle US-0157М with capacity of 8 t, a pilot batch of which is a recent released by the Ural automobile plant, has four tracks, grouped into two trucks, each with its own drive and control system. In the next five years these machines will work in the most remote parts of Siberia, serving geologists, oil and gas producers. The same principle has built a strong canadian all-terrain vehicles firms “Flextrack-Nodwell” (Fig. 7) and “Formost”.

NEW IDEAS

Of great interest are a search designs using fundamentally new ways of movement on the ground.

Thus, the American all-terrain vehicle “Arall” — a combination of wheeled and tracked machines, which has two tracks with 13 pnevmokokkami instead of trucks. All rinks in the leading. When driving on difficult terrain, rotate and tracks and rollers, and on the highway — only the bottom rollers caterpillar. The speed of the car overland 40 km/h on water 10 km/h.

The principle of the Archimedean screw used in a so-called worm or screw the ATVs. Screws-rotors or worms which would be screwed into the ground and allow the car translational motion. During rotation of the rotors in different directions moves forward or backward when rotating in one direction — sideways. The rotation is carried out, like tracked vehicles, the braking of the rotors of one of the parties. Hollow propellers of this type also provide buoyancy and movement in the water. This all-terrain vehicle of GPI-72 design in the Gorky Polytechnic Institute on the Basis of the truck GAZ-66. Similar samples of known machines built in the U.S. and Holland. Four all-terrain vehicle “Dorothy” sequential reels created in Japan.

An interesting principle of using an air cushion to improve cross transports. Injected under the bottom of the air lifts the vehicle over the ground, and the specific pressure on the soil is greatly reduced. One such sample was created in England based on a light all-terrain vehicle “land Rover”. It is equipped with two fans, and even with minimal lifting air cushion, specific ground pressure is reduced to 0,0243 kg/cm2.

Fig. 8. All-terrain vehicle with a “triangular” mover

Fig. 9. Giant multi-link road train

Unusual all-terrain vehicle built by an American company “Lockheed” (Fig. 8). In place of every one of the wheels had the original form of the mover of the three pneumococcal that if the vertices of the triangle attached to the radial arms at an angle of 120°. When driving on rough terrain, when hitting an obstacle the brackets with the rollers rotate around its axis, and on a level road axle brackets are locked and the car rides only on the lower pairs of rollers.

Recently, a lot is said and written about walking — walkers. Live their “prototypes” in nature without significant difficulties can take place where not under force to pass either one of the most advanced vehicles. But the complexity of such arrangements and manage push their practical application in the distant future Although a few experimental machines, as well as transitional samples have already been created.

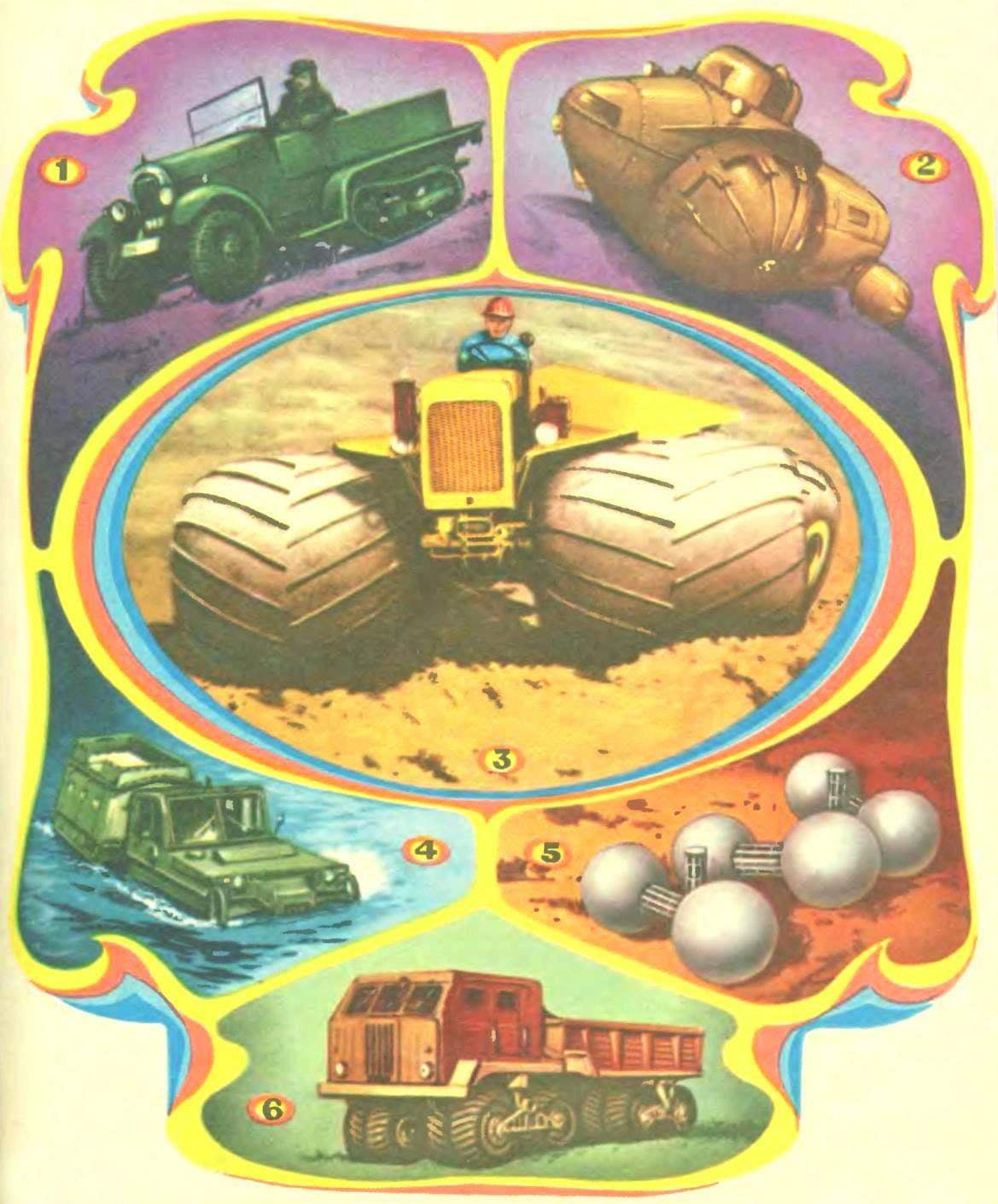

1. One of the first off — half-track car (France).

2. ATV “Rhino” on the hemispherical wheels of aluminum alloy. On the hard surface of the mover rolls on the largest diameter; in soft ground “connects” the rest of the hemispheres.

3. Wide, up to 1.5 m, pneumococci provide high permeability and replaced with a soft suspension.

4. The articulated all-terrain vehicle”amphibian” trailer-not afraid amphibious marshy soils and water obstacles.

5 Sarkad — transport with spherical wheels and a flexible connection units — designed to be driven on the moon.

6. Pneumococci Rover “Hurricane” (USSR), coupled between the front and rear of the trolley, are easily overcome and the Sands, swamps and deep snow. All wheelsets — leading.

A few years ago, the Soviet Professor G. Cates proposed a draft of a wheeled-walking mechanism, based on carrying his front wheel forward through the obstacle on the air with the subsequent transfer to them of the entire weight of the car and pulling the rear wheels — a complete mechanical simulation of the movements occurring in living beings. Maybe that’s so all-terrain vehicles is the future?

So, many designs, many ideas, a lot of controversy. And it is unlikely their solution will be unique. One thing is clear: the Rover of the future will be a synthesis of the best qualities of its predecessors. And perhaps his word could say here and a large army of modelers, testing in miniature that can then be incorporated in real structures.

E. KOCHNEV, engineer