Cars produced in this plant, is huge: the mighty diggers-excavators and the largest rolling mills, tasaciones press and powerful lifts for mines, and other destructive giant size technique. Only certain parts of these steel giants sometimes reach a weight of several tens tons! Of their manufacture, Assembly and adjustment work there’s thousands of workers of different professions, hundreds of technicians and engineers.

Cars produced in this plant, is huge: the mighty diggers-excavators and the largest rolling mills, tasaciones press and powerful lifts for mines, and other destructive giant size technique. Only certain parts of these steel giants sometimes reach a weight of several tens tons! Of their manufacture, Assembly and adjustment work there’s thousands of workers of different professions, hundreds of technicians and engineers.

Novokramatorsk machine-building — enterprise growing. Every year appears new, unprecedented technology, increase the scale of production. This means that the continuously growing demand for workers, young, strong hands, creatively thinking people. And of course, the question arises about the professional orientation, which must guide the young residents of Kramatorsk, today’s schoolchildren to help plant, be interested in their specialty of mechanical engineer.

A special role in this important matter fell to the club of young technicians, which is created at the factory. Doing it in circles, participating in various mass cases Cute, students are introduced to the equipment produced by the plant, with the types and types of these machines, with the specifics leading to factory occupations and professions. The staff club of young technicians strive not only to occupy the leisure of children, but — and this is important to help the school and the family in the Communist education of children, preparing them for socially useful work. They are trying to instill in the students a love for their plant, by its working traditions, to help you choose, on the basis of the inclinations of boys, the future — you need to plant specialty.

PROFESSION — MECHANICAL ENGINEER

Gamma circles in the club is extremely wide, every teenager can find here a dealing. However, if you look closely at the work of this institution, it is easy to see that it is even there are two eye directions.

First and leading, because it is there we deaem here the emphasis — is to promote the engineering professions and professions related to the automation and mechanization of production processes, as well as remote control and electronics: the guys are building working models of machines and mechanisms produced by the plant, design the equipment and technical devices, taking a kind of “industrial relay” from their fathers and older brothers — factory workers.

The second activity Cute — military-Patriotic education of schoolchildren. It is achieved by intensive development of military-technical sports: by air, ship, rocket modeling, radio sport.

To coordinate the activities of the circles, and approval of plans for their joint work, development initiatives and Amateur guys created the self-governing body — Board of the club.

Miniature, infantile actuated hands, in exactly the same giant factory prototype.

All the work in the circles constructed so that, in any of them the student was engaged, he is constantly faced with the basics of the major engineering professions. Whichever model no is made, it needs to perform turning, locksmith and milling work, to be able to read blueprints.

Of course, basic employment skills kids get in school. Here, in the clubs, they improve their skills.

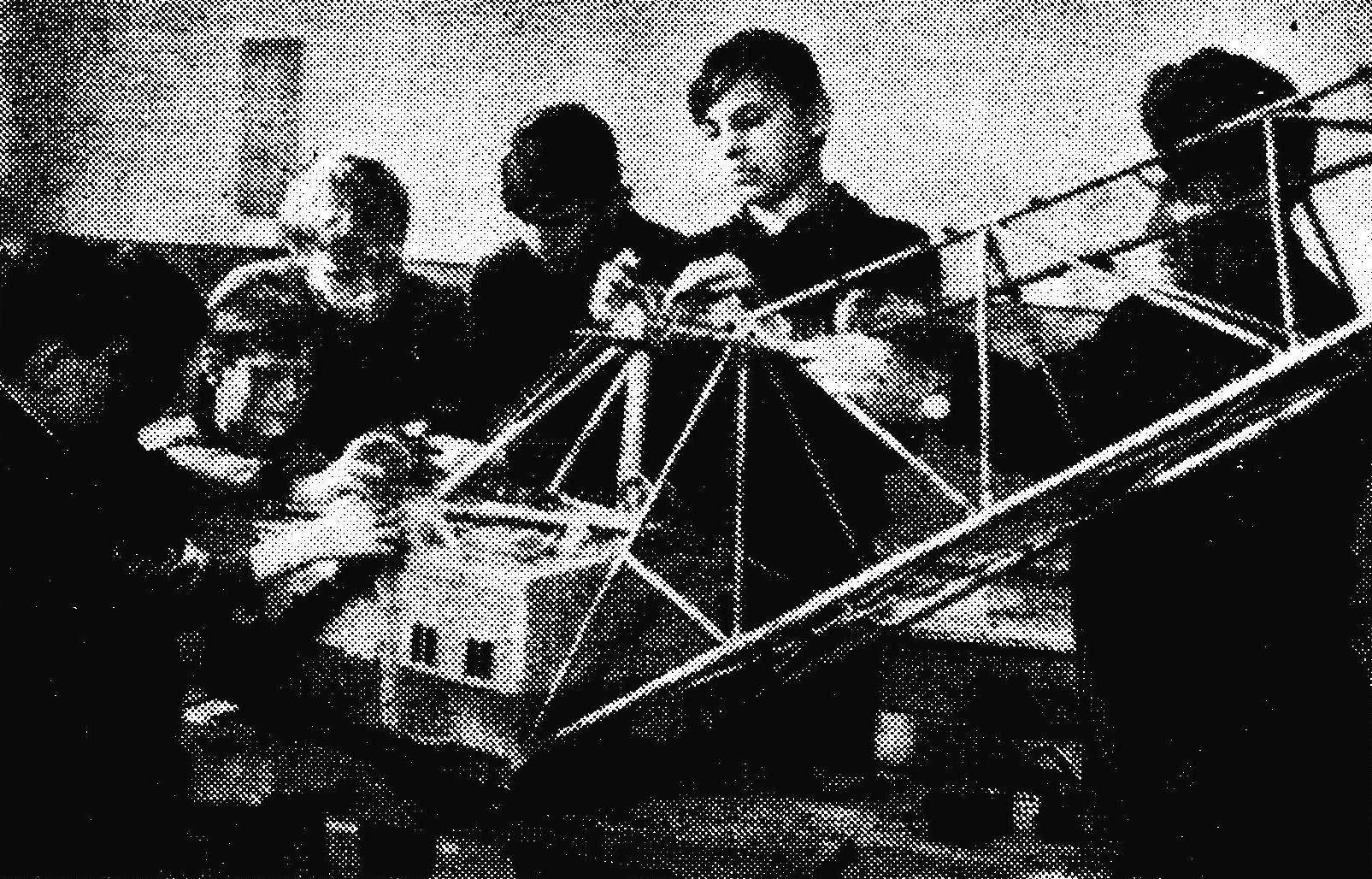

It is noteworthy that in the circles that Cut guys for real production drawings independently develop drawings of their models at scale. To modify and simplify the design of some nodes with respect to the models they carry out the necessary experiments.

It is especially difficult and time-consuming construction of a new kinematics and power units. They have to be customized to the available, often random motors, gears and other parts. This removable characteristics of the different engines, is calculated the gear ratio of the gears, and then I must design the tables, dictionaries, technical literature. Heads of clubs give young people maximum independence themselves only to direct their work towards minimizing the trial and error to determine error, seeking with them the causes of failures, which are inevitable in the creative process.

— It often happens that, in spite of the proper constructive solution of the kinematics in accordance with the prior art, on the model, some parts move too slowly, says club Director V. P. Martyshev. — It happened, for example, in the modeling press and the regenerative furnace. It turned out that for demonstration models for the purpose of greater clarity — all the process needed to be accelerated. Further, in the manufacture of the demonstration models we this circumstance will certainly take into account, ahead of time have amended the calculations.

After performing sketches and working drawings of young technicians usually begin to manufacture of parts and Assembly of components. In Cute NKMZ both of these processes, we tried to parallel that with a little ahead of the “production” drawing and graphic works. The result is a big gain in time. At these stages of the creative process the members will learn a lot for yourself: practice and master the most efficient methods of processing metal, get acquainted with the system of fits and tolerances, measurement methods, etc. And then follows a most interesting Assembly, commissioning, testing and validation of the model.

Thus, in the manufacture of existing models the guys are all the main stages of the creative process of design: reading and making drawings, experimentation before manufacturing a prototype and test its performance. During this period, they learn the purpose of each node of the model and the prototype, the principle of interaction between the parts, gain the skills management model and the concept of the management of the machine itself.

All this combined, first, promotes the development of technical thinking of a teenager, and secondly, a serious to familiarize him with the technology of processing of materials: metals, wood, plastics with their many physical and chemical properties. In the circles Kuta, in particular, great attention is given to familiarize the children with the methods of production and application of synthetic materials. They have perfectly mastered the technology of manufacturing of details of the models are made of fiberglass and synthetic resins, castings, nylon and polystyrene plastics. When machining drilling young technicians successfully used the jigs, turning work — templates and shaped cutters.

CONSULTANT — WORKSHOP

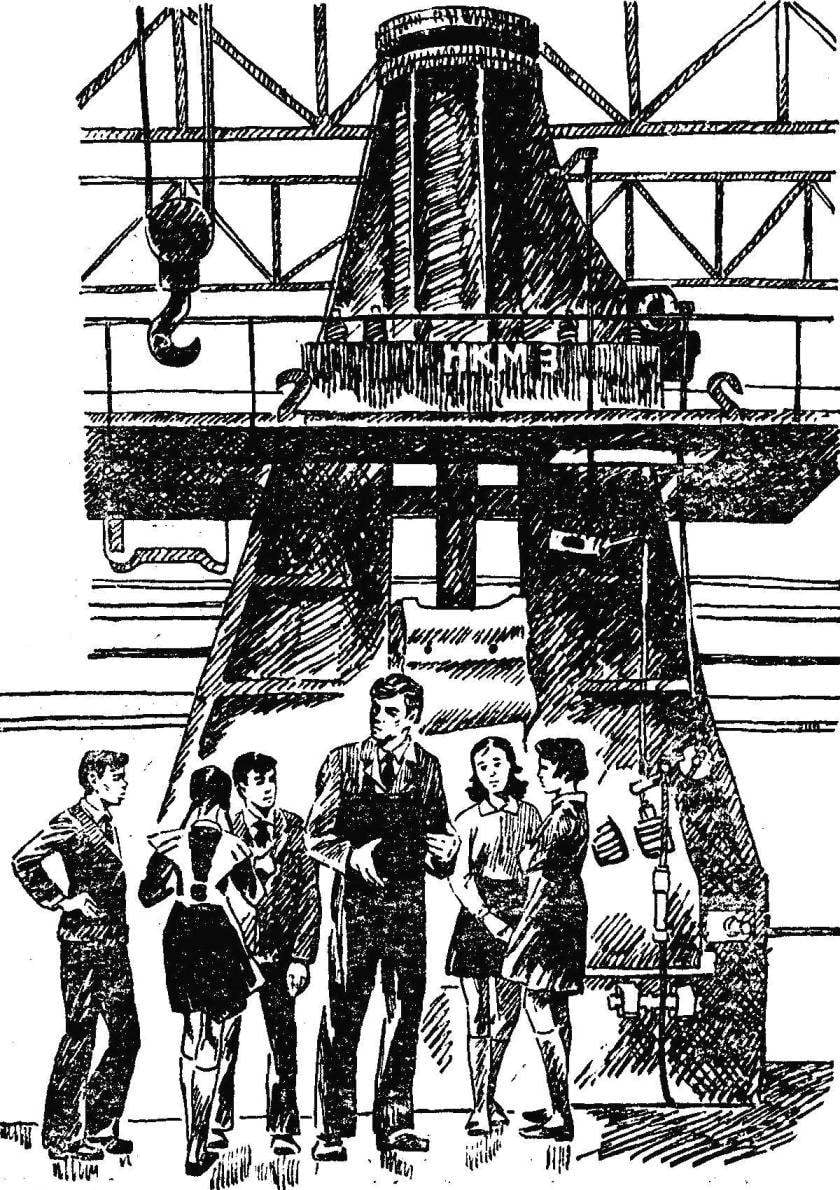

Guys often go to workshops and departments of the plant. There they are getting acquainted with manufacturing process machines that meet the most advanced performance, leading engineers and designers. And get them a lot of valuable information.

For example, in the manufacture of the model manipulator and the press (giant prototypes of their work in a press-forging shop) young technicians consulted at the mechanic shop and the driver-operator that demonstrated all the operations performed by the manipulator, explained the advantages and disadvantages of the machine. After this meeting was born the boys the idea to simulate a remote control, allowing the operator to stand far enough away from the red-hot steel bar.

Occurred a curious case. Somehow during a conversation with the machinist operator (the boys designed then model press) revealed that a very limited stroke of the hammer reduces the capacity of the press. Together conjured over the sketches and proposed to apply in the design of the retractable support columns. With the help of the leader of the group is turners machine shop V. S. Firyulina device modeled in metal. Acted it perfectly. Who knows, maybe this idea will attract even the attention of specialists!

For many years the Novo-Kramatorsk plant produced pulverizing mill, machine, steel jaws which are capable of grinding huge blocks of ore before sending it to the concentrator. But then came a time when these giant constructions with a drum diameter of three to four meters ceased to satisfy the workers. Then the plant created a project of a new car with more power and increased, respectively, the diameter of the drum. However, to identify some properties of the new machine in addition to the drawings made by factory designers, required an experienced model. The authors of the project went to the club of young technicians with a request to make a working model of the future mill.

Under the guidance of the Director of the club V. P. Martyshov build a model of the dragline produced by the plant.

Twenty-two kutuza of the engineering circle, led by engineer N. T. Nechepurenko, undertook the construction of the model of the machine. The Assembly of the factory drawing was sketched, carefully selected material for future products.

Factory designers and engineers together with the kids meticulously studied the work of the nodes in the model, on-the-go improved its design, as a way to test new ideas. In a word, was a real search creative work, where sometimes forget that some people — graduates and others — teenagers, just learning the basics of technical’ skill. In fact, together they created a new type of pulverizing mill, which soon began to produce. It together because the experimental model has allowed many to clarify and correct in the drawings, to bring, that is to say, the idea of the machine prior to actual implementation in industrial product.

Especially remember the guys working on the model of the mill, meetings with the lead project engineer of this mill I. P. Padewski. He not only introduced them to the principles of the structure of the machine itself, but also spoke in detail about the purpose of individual units and parts, their functions, kinematics, was introduced to the design process of these machines, with the order of drafting, technology of production of parts. With special emphasis he did on those occupations that are especially needed for the plant to produce these cars. Such meetings were held frequently. And when the work was completed, specialists of the plant together with the guys tested a model, gave her an excellent rating.

OUTSIDE OF THE CIRCLE

The works of pupils Kuta Novokramatorsk machine-building plant are not confined to the walls of children’s institutions. For example, in response to the call “Young technology — agriculture” guys have designed and fabricated some devices and gadgets which are of practical importance for agricultural production. Among them: crusher feed, a photoelectric device for determining the percentage of starch potatoes, which the students issued the copyright certificate; a device for protection of three-phase motor when one phase is open and a number of other designs. These children were exhibited at the Central exhibition NTTM in Moscow and was awarded the diploma of the USSR exhibition of economic achievements.

The club extends its impact on feeder schools, and they had no less seven, is in the district as a centre for the organization of technical creativity and professional orientation of children in schools and in specially created rooms in student housing units. To coordinate this work, in the neighborhood of the plant when the club established a special Council. Together with the House equipment of the plant, he organized, in particular, the lecture “what to be?”. The main purpose of the lecture is to provide guidance to future graduates on the profession of engineering. For this purpose, along with the Bureau of technical information of the enterprise Board CYTA has developed an extensive series of tours for high school students called “Plant factories”. In a timely and deliberate choice by students of the professions are good and such massive events as the release of the oral magazine “Want to know” the evening of science and technology, meetings with innovators and inventors, drummers of Communist labor. All these things are carried out by Cytoscape with the obligatory participation of children from schools, in the club NKMZ still not working.

Will the mill!

An example is the special issue titled “the handyman” which was prepared by the engineering club. It is curious to note the contents of the program of the oral magazine. Seemingly boring at first glance, the topic “General information about the profession mechanic”, “a Brief historical sketch of the emergence plumbing”, “is There a future for the profession of a locksmith”, expertly-trained and well-illustrated, with the participation of famous masters plumbing — factory workers with demonstration of thematic newsreel made the boys keen interest.

For students in tenth grade, graduates of schools of the neighborhood, the club works as a lecturer “Who to be?”.

The theme of the lecture is extremely diverse. He talks about his hometown, about a factory his glorious revolutionary, combat and labor traditions of the workers ‘ occupations. The guys here regularly meet the Heroes of Socialist Labor — factory workers, honored innovators, and Komsomol activists.

How fruitful can be the similar form and mass work with students, shows at least an example. Just one year the club of young technicians was organized four editions of lectures on the theme “Whom to be?” sixteen issues of the magazine “Horizons”, four of the oral magazine “Want to know” matinees devoted to significant dates of the country, a large number of meetings and conversations with innovators, foremost production, film programme, excursions in Building technology enterprises, the plant itself, in its Museum of revolutionary fame.

The guys from the surrounding schools together with teachers labor are frequent guests in the club of young technicians of NKMZ, come on the tour in its workshops and laboratories, visit the permanent exhibition of children’s technical creativity. Here they talk about the cases of inmates Cut of the plant, about their Affairs for the plant.

It is known that in any city or village children wishing to engage in technology, is always many times more than can accommodate children’s out-of-school institution. Not included in the circle of children make crafts at home and, of course, need particular help from the adults. The parents of these craftsmen are not always able to help them, as not all the questions guys, they are competent enough. And it is here that Teens especially need help from outside.

To do this, the factory Chute organized correspondence club of young technicians — a kind of club in club. A member may be each student with the active mass participation in all club events, tours, evenings, meetings with heroes, veterans of labor, the best workers, participation in the preparation of the oral magazine “know-it-all” lecture “Whom to be?”.

The main task of the correspondence of the club is to acquaint students with various fields of science and technology, to provide them with everything necessary to build models at home, to send technical creativity of children, to develop their professional orientation according to the inclinations of each.

What, you ask, the production effect of all this multi-faceted and extensive career guidance activities of the factory club? And it is significant: nearly 800 former members Cut working for various companies in the country, including more than 120 in workshops and departments of NKMZ. Workers and craftsmen, technicians and engineers.

So living and working, a friendly team of enthusiasts of technical creativity one of many in a series of children’s establishments of trade unions of the factory club of young technicians. Institutions, which today plays a very serious role, a role first, the initial stage in preparing the young generation to productive work, its timely professional orientation.

Yuri STEPANOV