It happens that a stud or tap gets cut off or broken, remaining in the hole. An unpleasant situation, but not hopeless. A proven technique will help: the hole needs to be drilled out to a larger diameter that allows extracting the fragment, cutting a thread in it, and screwing in a bushing for a new stud or bolt.

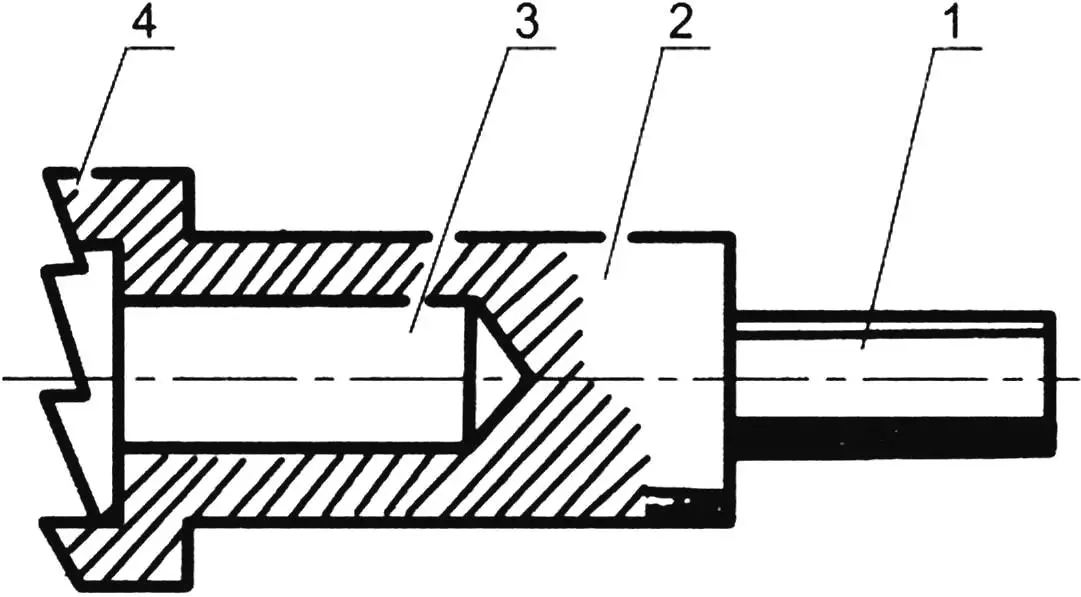

Drill-mill:

1 – shank for chuck; 2 – body; 3 – blind hole for fragment diameter; 4 – head for bushing diameter

A special drill will be required for drilling out. It is a kind of end mill. Its working surface has an axial blind hole, the diameter of which is 0.2-0.5 mm larger than that of the fragment being extracted, as well as teeth cut using a hacksaw and file. The manufactured drill is subjected to heat treatment: heating in a torch flame and rapid cooling.

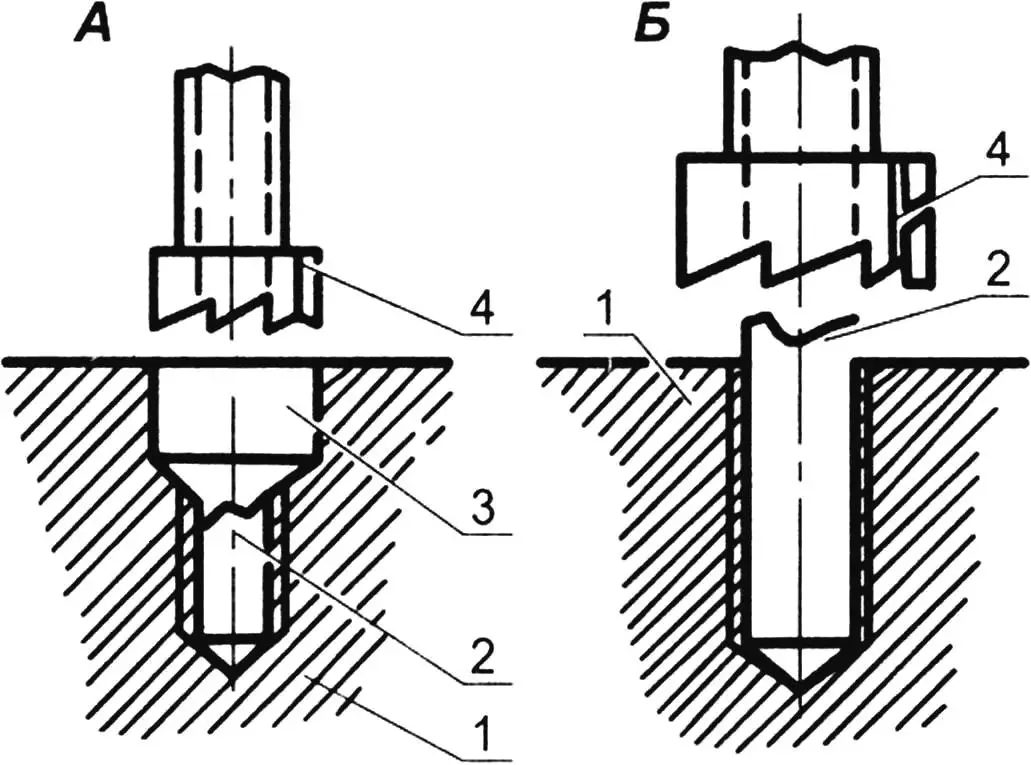

1 – part; 2 – fragment; 3 – hole for bushing; 4 – drill-mill

If a broken stud or tap remains in the body of the part, the hole is first drilled out with an ordinary drill for the future plug, and then milled to the required depth. If the fragment protrudes above the surface – it will itself serve as a guide for the drill, and preliminary drilling is not required.

Hole sizes for bushing

| Fragment thread | Thread to be cut |

|---|---|

| M6 | M10 |

| M8 | M12 |

| M12 | M16 |

After removing the fragment, you need to cut a thread for the bushing, screw it in with paint or “epoxy”, and screw a new stud or bolt into its through threaded hole.

«Modelist-Konstruktor» № 4’2025, Semen OSTRY