Modern engineering makes high demands on the materials, and they, in turn, to the machining tools. Not by chance all the exhibitions NTTM necessarily demonstrates the new development of young innovators dedicated to solving these problems taking into account the specifics and requirements of each specific production, and often cross-sectoral in nature.

Modern engineering makes high demands on the materials, and they, in turn, to the machining tools. Not by chance all the exhibitions NTTM necessarily demonstrates the new development of young innovators dedicated to solving these problems taking into account the specifics and requirements of each specific production, and often cross-sectoral in nature.

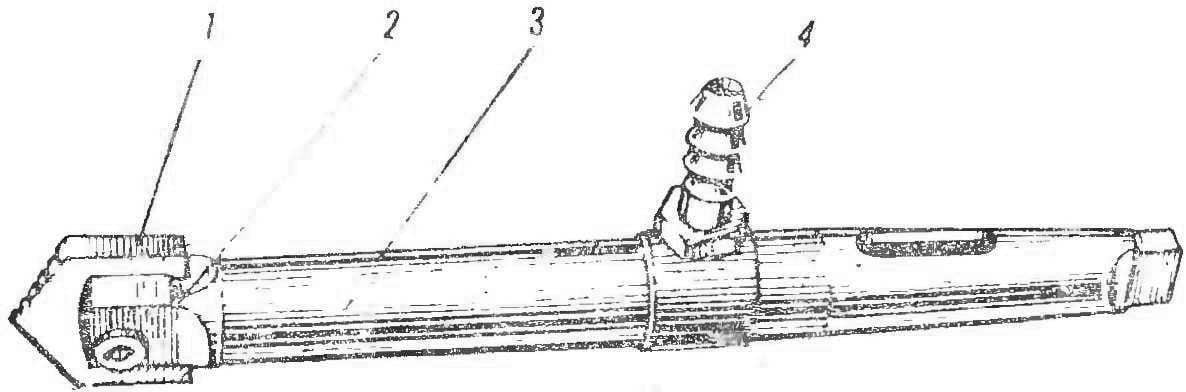

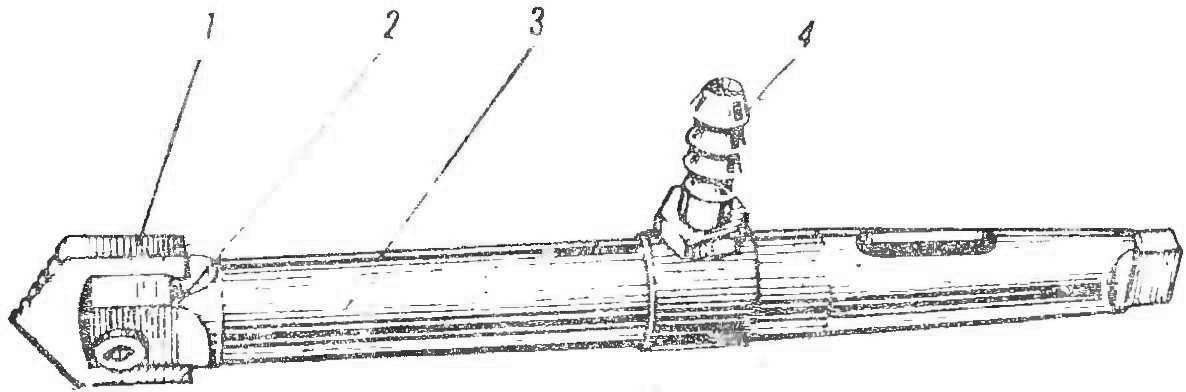

A group of participants NTTM all-Union scientific research tool Institute offers one such solution — a new drill for horizontal holes. It can be used for drilling in structural materials and in alloy steels, non-ferrous metals, even light alloys. A distinctive feature of the tool is the availability on the holder, which holds the high speed carbide plate, special fitting and the channel for supplying the coolant (coolant). With this design, and application of the aqueous emulsion cutting speed reaches 15— 25 m/min for steel and 30 m/min for cast iron.

“Gidrosfera”:

1 — carbide insert, 2 — head drill, 3 — holder, 4 — fitting the coolant.

The new drill can be used on lathes, turret lathe and CNC machining centers.