The knives or Strug indispensable when machining curved surfaces. To make them simply — it will only have an old file with a length of about 200 mm. In the first file you need to termoobrabotki. Soshlifovat previously a small area, gradually heat the file evenly along its length until, while in ground place appears red-brown film of oxides, after which the file is cooled in water or air. This heat treatment will reduce the brittleness of steel, while maintaining the hardness necessary for cutting edge on plow.

The knives or Strug indispensable when machining curved surfaces. To make them simply — it will only have an old file with a length of about 200 mm. In the first file you need to termoobrabotki. Soshlifovat previously a small area, gradually heat the file evenly along its length until, while in ground place appears red-brown film of oxides, after which the file is cooled in water or air. This heat treatment will reduce the brittleness of steel, while maintaining the hardness necessary for cutting edge on plow.

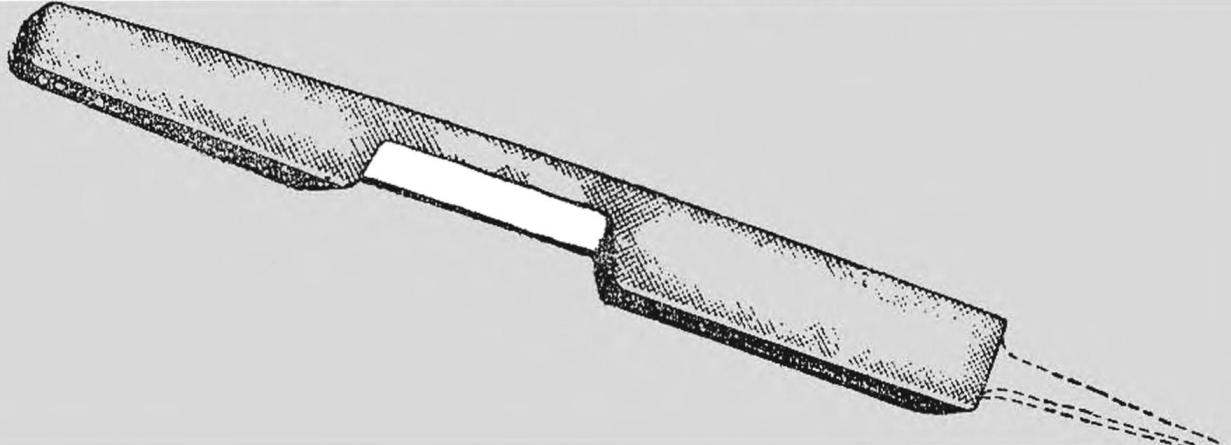

In the middle of a file is the sample length of about 50 mm, the width of the file in this place should be about 15 mm.

To obtain a cutting edge grind the inner side of the groove at an angle of about 30°. When handling do not overheat the metal, it can lose hardness and wear resistance. The characteristic symptom of overheating — the appearance of the blade tint.

Remove the shank of a file. It can be done with a hacksaw, as the steel was released during heat treatment. Remains dull tool the sharp edges and bring the blade on the whetstone and grindstone and plow ready to work.