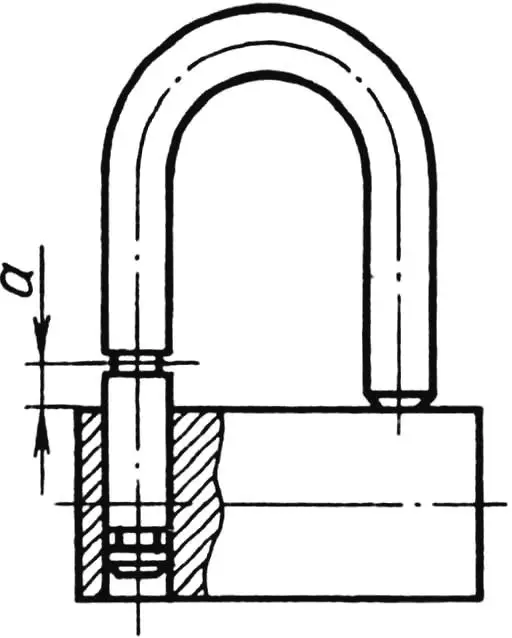

Externally, this padlock is no different from thousands of its counterparts guarding storerooms and dachas, sheds and utility rooms, shops and warehouses. Except for one stunning detail: it opens… with a screwdriver.

Can one trust such an unserious device that even a mischievous boy could unlock?

“You can,” asserts its creator, engineer I. Yankin. “Opening my lock is beyond even a professional burglar, although the key is indeed a small and thin screwdriver, like a knitting needle. The secret is not in the key, but in the lock!”

There is no reason to doubt this assertion, as I. Yankin’s construction of such “cunning” locks is an old hobby, and he has extensive experience in creating them. The author has graciously agreed to share one of his developments — a lock with smooth code setting, accessible for self-manufacturing — with the readers of the Home Craftsmen Club.

Some will say: why make a lock yourself when it’s easier to buy a ready-made, factory one? But even to the best of them, intruders pick keys, and even the secret of combination locks, with fixed intermediate positions of the mechanism, is deciphered by sound and touch. And in winter, a common problem: the mechanisms of factory locks freeze so much that they need to be warmed up.

But wouldn’t everyone want to have a locking device free of these shortcomings, and moreover, the most “cunning” one, not yielding to any lockpick?

I have developed a whole series of such hanging combination locks for various purposes. Their highlight is a constructively guaranteed protection not only from code selection, but also from wrenching the shackle of these locks with a crowbar.

Below is a description of the construction of such a lock and the technological features of manufacturing its parts and fixtures. I am not afraid to reveal them, because the conditional secrecy of the device with the given dimensions and construction scheme can have over four thousand code combinations.

Design

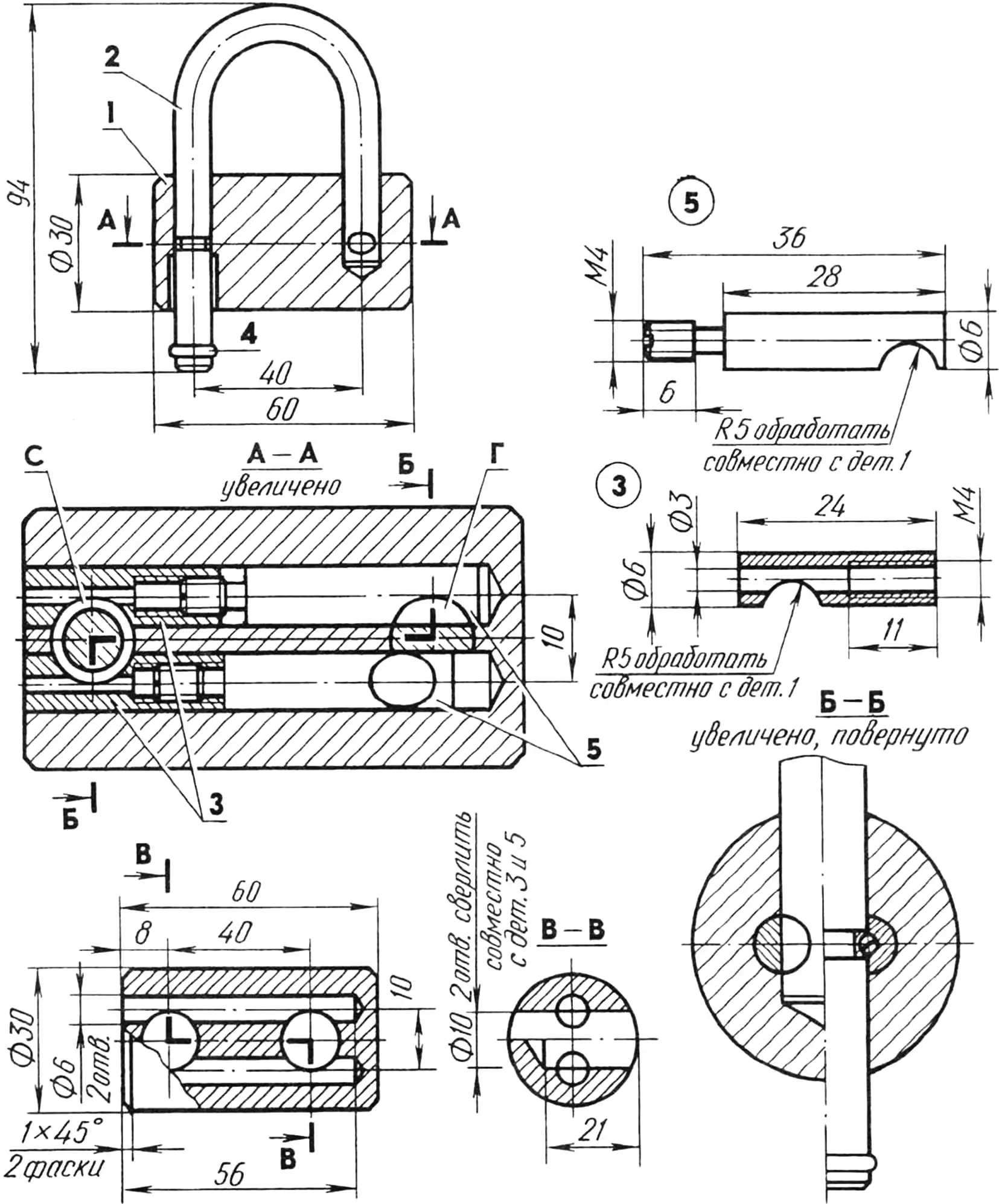

The lock has a body, a shackle, two bushings, a retaining ring, and two pins. The bushings are fixed in the body by an extendable shackle entering the semicircular grooves of the bushings. In the latter, pins rotate on threads, moving through holes in the body and acting as locking elements. On the cylindrical surface of the pins, there are also semicircular grooves that, at a certain position in the bushings, coincide with the blind hole in the body for the lock shackle — this corresponds to the “open” position: the shackle freely inserts into the lock body until it stops. If we now insert the screwdriver-key, it enters the pin slot; when rotated, the pin with its cylindrical part will enter the shackle groove and lock it. The code for opening will be the location of the groove on the pin and the number of key turns. To increase the lock’s secrecy, a second pin with its own code serves.

1 — body (duralumin, bronze, brass): 2 — shackle (steel 40Х, rod Ø 10); 3 — bushings (bronze); 4 — retaining ring (steel, wire Ø 2.5); 5 — pin (steel 40Х, 2 pcs.).

The mechanical strength of such a unit against break-in is undoubtedly much higher than in most constructions where the shackle is fixed by a bolt of small cross-section — the weakest part. It will not be possible to pick the lock code “by touch” either, since at the moment of opening, the key is in the shackle groove and does not allow one to feel — has it been freed from the locking elements?

The through hole for the long end of the shackle is countersunk from below to the diameter of the retaining ring, which prevents it from exiting the body, which would lead to a violation of the lock assembly.

Manufacturing

The proposed lock, as already noted, is not only particularly strong, but also a delicate mechanism. However, since we are not oriented toward factory manufacturing, we will omit tolerances and fits on the drawings: the required accuracy can be achieved through joint processing and fitting of parts, quite accessible to the most modest workshop of a home craftsman.

First, from a round steel rod with a diameter of 10 mm, we will cut a blank 162 mm long for the shackle. On it, we will make a chamfer and two grooves, then bend the shackle (with any lever with an eye or a nut welded at the end).

We will turn two bushings (from bronze) and two pins (from steel), as well as a blank for the lock body (from duralumin, bronze, brass). In the blank, we will drill two holes with a diameter of 6 mm for the bushings, clamping it in the lathe chuck with an eccentricity of 5 mm. Then, inserting the bushings flush, at a distance of 8 mm from the end, we will drill a through hole “C” with a diameter of 10 mm — for the long end of the shackle. Marking the bushings “right” and “left,” we will extract them from the body.

Next, we will insert the long end of the shackle into the prepared hole for it in the body, allowing the short end to rest against the body; we will mark this place (as the center of the blind hole “G”) and, measuring the distance “a,” bring it to 6 mm by grinding the short end of the shackle.

Now we will screw the pins into the bushings first until they stop, then unscrew them to an arbitrary distance (but less than 4 mm) and insert the bushings into the corresponding holes of the body according to the marks “left” and “right.” We will fix them by inserting the long end of the shackle into the through hole, after which we will drill in the body, parallel to it, the previously marked blind hole “G” with a diameter of 10 mm to a depth of 21 mm. For control, we will insert the short end of the shackle into it and, if necessary, finish it.

Again, we will disassemble everything to parts — we need to cut slots on the ends of the threaded parts of the pins (for the screwdriver-key) with a hacksaw blade (with ground set). For ease of use, the initial position of the slots should be the same. We will assemble the lock again, but without inserting the short end of the shackle into the body; we will align the groove on its long end with the holes in the bushings. With a screwdriver with a stem diameter of 3 mm through the holes in the bushings, we will check the freedom of axial movement of the pins; if necessary, we will grind the pins.

Subsequent actions are directly aimed at creating the secret code of the lock. We will screw one of the pins until it stops, then unscrew it until its groove aligns with the hole in the body, counting the number of half-turns. We will record the resulting number — this will be the code of this pin, corresponding to the “open” position. We will make marks on the end of the body (bushing) and the screwdriver-key for unlocking the lock.

For verification, we will repeat the actions with the screwdriver-key blindly, counting to ourselves the code number of its half-turns for this pin, and, if necessary, turn the screwdriver until the marks align.

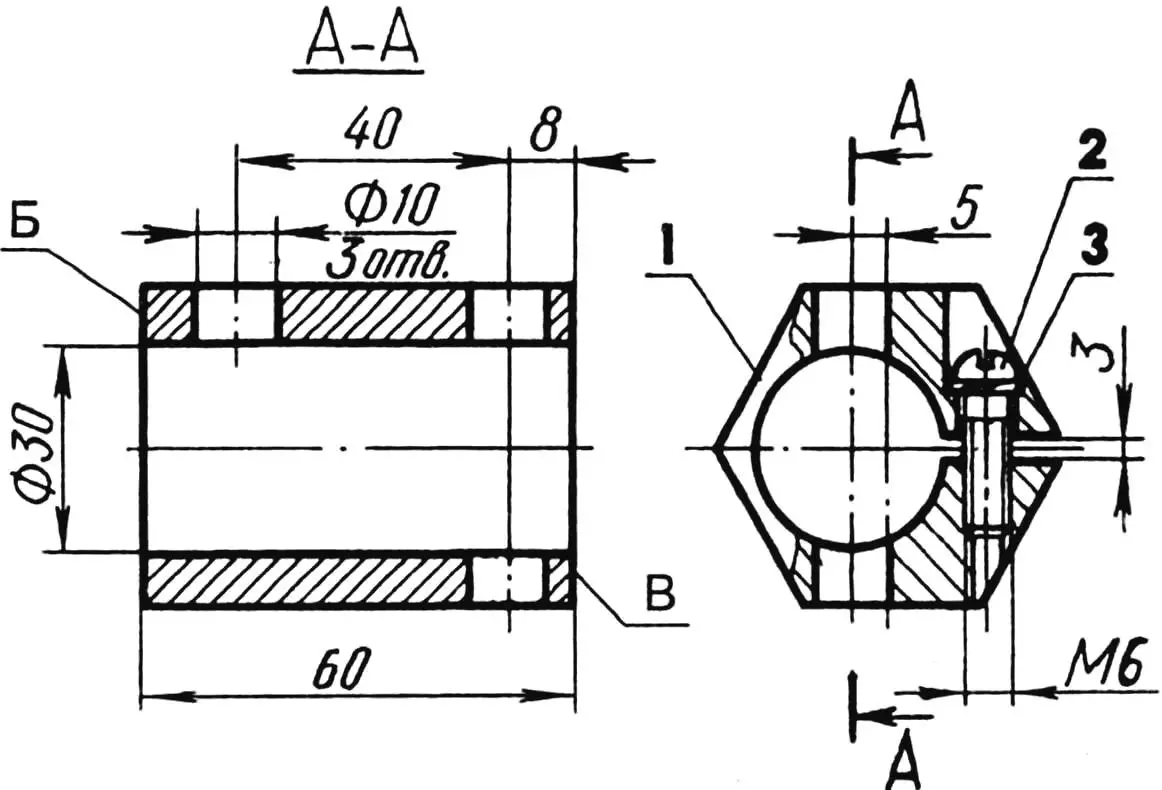

1 — body (steel, hexagon 46…65); 2 — screw M6 (2 pcs.); 3 — spring washer (2 pcs.).

We will fully repeat the same operations for creating and checking the code for the second pin. After this, we will remove the shackle from the body and countersink the through hole from below to a diameter of 12 mm to a depth of 10 mm.

We will make semicircular grooves on the short end of the shackle. To prevent an intruder’s hacksaw from overcoming the shackle, we will harden it, and if possible, oxidize the shackle and body against corrosion.

Now we can finally assemble the lock and install a wire retaining ring in the groove on the long end of the shackle, turning it to a free passage in the prepared hole.

When manufacturing several such locks, it is advisable to use a universal jig-mandrel that eliminates marking. In this case, we will clamp the lock body blank in the jig using tightening screws M6 and install it in the lathe chuck with end “B.” From the side of end “V” on the lathe, we will drill a hole with a diameter of 6 mm to a depth of 56 mm; then we will turn the jig in the machine chuck by 180° — and repeat the operation. Installing the bushings with pins in the resulting holes, we will drill, without removing the blank from the jig, two holes with a diameter of 10 mm: one through, the other to a depth of 21 mm. As for assembly-adjustment and finishing operations, they are the same as in single manufacturing.

I. YANKIN, engineer, Baikonur, Kazakhstan